Discontinuities In Welding . A discontinuity is a flaw in the weld, but. The number or extent of the. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). We've compiled a list of the most common weld discontinuities and how to correct them. Discussed several of the most common welding. A discontinuity is an interruption of the physical structure of the weldment. A defect is a discontinuity that causes the weldment to be unable to meet. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the.

from bnurwinanto.blogspot.com

A discontinuity is an interruption of the physical structure of the weldment. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. The number or extent of the. A discontinuity is a flaw in the weld, but. We've compiled a list of the most common weld discontinuities and how to correct them. A defect is a discontinuity that causes the weldment to be unable to meet. Discussed several of the most common welding.

QUALITY CONTROL AND SHE ENGINEERING Visual inspection and Weld

Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. We've compiled a list of the most common weld discontinuities and how to correct them. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A discontinuity is a flaw in the weld, but. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). Discussed several of the most common welding. A discontinuity is an interruption of the physical structure of the weldment. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. The number or extent of the. A defect is a discontinuity that causes the weldment to be unable to meet.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Discontinuities In Welding Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity is a flaw in the weld, but. A defect is a discontinuity that causes the weldment to be unable to meet. A discontinuity is an interruption of the physical structure of the weldment. Discussed several of the most common welding. Interruptions or flaws in the. Discontinuities In Welding.

From www.shutterstock.com

2,389 Weld defect Images, Stock Photos & Vectors Shutterstock Discontinuities In Welding A discontinuity is a flaw in the weld, but. A discontinuity is an interruption of the physical structure of the weldment. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). The number or extent of the. We've compiled a list of the most common weld discontinuities and how to correct them. A defect is a discontinuity. Discontinuities In Welding.

From weldingofwelders.com

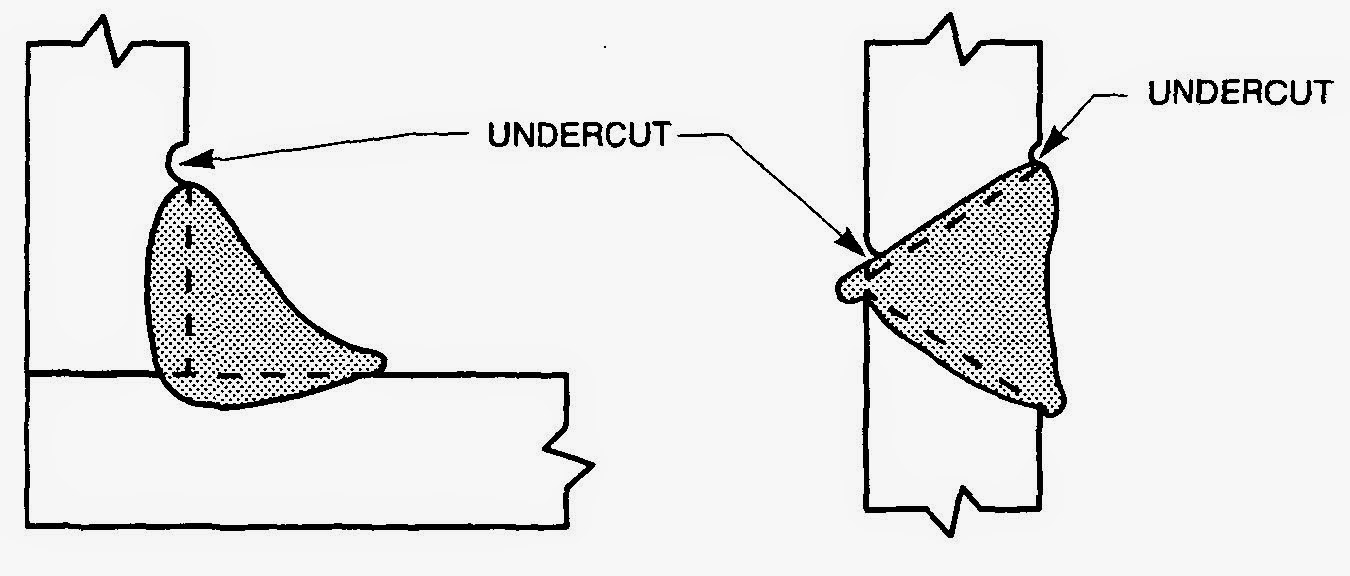

Undercut in Welding Welding of Welders Discontinuities In Welding Discussed several of the most common welding. We've compiled a list of the most common weld discontinuities and how to correct them. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect).. Discontinuities In Welding.

From www.onestopndt.com

Understanding Weld Discontinuities Discontinuities In Welding Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A defect is a discontinuity that causes the weldment to be unable to meet. Discussed several of the most common welding. We've compiled a list of the most common weld discontinuities and how to correct them. A weld discontinuity is an interruption of the. Discontinuities In Welding.

From weldingpros.net

Welding defects, Discontinuities, and How To Prevent them Discontinuities In Welding The number or extent of the. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A discontinuity is a flaw in the weld, but. We've compiled a list of the most common weld discontinuities and how to correct them. A weld discontinuity is an interruption of the typical structure of a material, while. Discontinuities In Welding.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Discontinuities In Welding A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. We've compiled a list of the most common weld discontinuities and how to correct them. A discontinuity is a flaw in the weld, but. The number or extent of the. A defect is a discontinuity. Discontinuities In Welding.

From www.slideshare.net

Presentation on common weld dicontinuities Discontinuities In Welding A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A discontinuity is a flaw in the weld, but. The number or extent of the. A discontinuity is an interruption of the physical structure of the weldment. Discussed several of the most common welding. Key. Discontinuities In Welding.

From www.youtube.com

Weld Joint Defects/ discontinuities.. YouTube Discontinuities In Welding The number or extent of the. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Discussed several of the most common welding. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). We've compiled a list of the most common weld. Discontinuities In Welding.

From sentin.ai

The 10 Common Weld Defects You Should Know. sentin Discontinuities In Welding We've compiled a list of the most common weld discontinuities and how to correct them. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). Discussed several of the most common welding. A discontinuity is an interruption of the physical structure of the weldment. A defect is a discontinuity that causes the weldment to be unable to. Discontinuities In Welding.

From slidetodoc.com

WELD DEFECTS WELD DISCONTINUITIES DISTORTION AND ITS CONTROLS Discontinuities In Welding Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. We've compiled a list of the most common weld discontinuities and how to correct them. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity is an interruption of the physical structure of the weldment. A defect is a. Discontinuities In Welding.

From www.youtube.com

Weld Defects & Discontinuities [QA/QC] YouTube Discontinuities In Welding A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Discussed several of the most common welding. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. The number or extent of the. A defect is a discontinuity that. Discontinuities In Welding.

From www.weldingis.com

10 Welding Defects and Discontinuities Causes & Remedies Discontinuities In Welding The number or extent of the. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity is an interruption of the physical structure of the weldment. A defect is a discontinuity that causes the weldment to be unable to meet. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called. Discontinuities In Welding.

From bnurwinanto.blogspot.com

QUALITY CONTROL AND SHE ENGINEERING Visual inspection and Weld Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A defect is a discontinuity that causes the weldment to be unable to meet. We've compiled a list of. Discontinuities In Welding.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Discontinuities In Welding The number or extent of the. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A discontinuity is a flaw in the weld, but. We've compiled a list of the most common weld discontinuities and how to correct them. Discussed several of the most. Discontinuities In Welding.

From www.artofit.org

Welding discontinuities causes and fixes Artofit Discontinuities In Welding A defect is a discontinuity that causes the weldment to be unable to meet. The number or extent of the. A discontinuity is a flaw in the weld, but. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity. Discontinuities In Welding.

From mungfali.com

Weld Discontinuities Chart Discontinuities In Welding A defect is a discontinuity that causes the weldment to be unable to meet. A discontinuity is a flaw in the weld, but. We've compiled a list of the most common weld discontinuities and how to correct them. Discussed several of the most common welding. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A weld. Discontinuities In Welding.

From lincolnelectricasiapacific.ac-page.com

Welding 101 Lincoln Electric Discontinuities In Welding A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A discontinuity is a flaw in the weld, but. A discontinuity is an interruption of the physical structure of the weldment. The number or extent of the. Key terms to remember when welding and evaluating. Discontinuities In Welding.

From theweldings.com

Welding Defects StepbyStep causes and preventions Weld World Discontinuities In Welding Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Discussed several of the most common welding. A discontinuity is an interruption of the physical structure of the weldment.. Discontinuities In Welding.

From www.weldingis.com

10 Welding Defects and Discontinuities Causes & Remedies Discontinuities In Welding We've compiled a list of the most common weld discontinuities and how to correct them. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A discontinuity is a flaw in the. Discontinuities In Welding.

From slidetodoc.com

WELD DEFECTS WELD DISCONTINUITIES DISTORTION AND ITS CONTROLS Discontinuities In Welding Discussed several of the most common welding. A defect is a discontinuity that causes the weldment to be unable to meet. The number or extent of the. A discontinuity is a flaw in the weld, but. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts. Discontinuities In Welding.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Discontinuities In Welding A defect is a discontinuity that causes the weldment to be unable to meet. Discussed several of the most common welding. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity is a flaw in the weld, but. We've compiled a list of the most common weld discontinuities and how to correct them. A discontinuity. Discontinuities In Welding.

From knightsinspection.com

NDT DISCONTINUITIES Knights Inspection Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. Discussed several of the most common welding. A defect is a discontinuity that causes the weldment to be unable to meet. We've compiled a list of the most common weld discontinuities and how to correct them. A discontinuity is a flaw in the weld, but. The number or. Discontinuities In Welding.

From www.weldingandndt.com

Welding Defects Classification, Causes and Remedies Welding and NDT Discontinuities In Welding Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A defect is a discontinuity that causes the weldment to be unable to meet. Discussed several of the most common welding. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. We've. Discontinuities In Welding.

From www.slideserve.com

PPT Visual Guide to Weld Defects & Discontinuities PowerPoint Discontinuities In Welding A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A defect is a discontinuity that causes the weldment to be unable to meet. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). The number or extent of the. A discontinuity. Discontinuities In Welding.

From www.scribd.com

Discontinuities Soldering Welding Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. We've compiled a list of the most common weld discontinuities and how to correct them. The number or extent of the. A weld discontinuity is an interruption of the typical structure of. Discontinuities In Welding.

From www.theengineerspost.com

16 Common Types of Welding Defects [Causes, Remedies] PDF Discontinuities In Welding Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A discontinuity is a flaw in the weld, but. A defect is a discontinuity that causes the weldment to be unable to meet. We've compiled a list of the most common weld discontinuities and how to correct them. A discontinuity is an interruption of the physical structure. Discontinuities In Welding.

From www.slideserve.com

PPT Visual Guide to Weld Defects & Discontinuities PowerPoint Discontinuities In Welding A discontinuity is a flaw in the weld, but. The number or extent of the. A discontinuity is an interruption of the physical structure of the weldment. A defect is a discontinuity that causes the weldment to be unable to meet. We've compiled a list of the most common weld discontinuities and how to correct them. Discussed several of the. Discontinuities In Welding.

From www.onestopndt.com

Understanding Weld Discontinuities Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. Discussed several of the most common welding. The number or extent of the. A defect is a discontinuity that causes the weldment to be unable to meet. A discontinuity is a flaw in the weld, but. Key terms to remember when welding and evaluating welds (indication, discontinuity, and. Discontinuities In Welding.

From knoxfr.com

Welding Defects And What They Are? How To Avoid Them! Knox Incorporated Discontinuities In Welding We've compiled a list of the most common weld discontinuities and how to correct them. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. A defect is a discontinuity that causes the weldment to be unable to meet. Key terms to remember when welding. Discontinuities In Welding.

From weldinganswers.com

10 Types of Welding Discontinuities Explained WELDING ANSWERS Discontinuities In Welding Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A defect is a discontinuity that causes the weldment to be unable to meet. We've compiled a list of the most common weld discontinuities and how to correct them. The number or extent of the. A discontinuity is a flaw in the weld, but.. Discontinuities In Welding.

From blog.thepipingmart.com

What are Welding Defects? ThePipingMart Blog Discontinuities In Welding A defect is a discontinuity that causes the weldment to be unable to meet. Discussed several of the most common welding. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. The number or extent of the. Key terms to remember when welding and evaluating. Discontinuities In Welding.

From www.scribd.com

Welding Discontinuities Porosity Undercut Fusion PDF Discontinuities In Welding A defect is a discontinuity that causes the weldment to be unable to meet. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). We've compiled a list of the most common weld discontinuities and how to correct them. The number. Discontinuities In Welding.

From slidetodoc.com

WELD DEFECTS WELD DISCONTINUITIES DISTORTION AND ITS CONTROLS Discontinuities In Welding We've compiled a list of the most common weld discontinuities and how to correct them. A discontinuity is an interruption of the physical structure of the weldment. A weld discontinuity is an interruption of the typical structure of a material, while a weld defect is a type of discontinuity that impacts the. Interruptions or flaws in the physical, mechanical or. Discontinuities In Welding.

From slidetodoc.com

WELD DEFECTS WELD DISCONTINUITIES DISTORTION AND ITS CONTROLS Discontinuities In Welding A discontinuity is an interruption of the physical structure of the weldment. A discontinuity is a flaw in the weld, but. The number or extent of the. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. Discussed several of the. Discontinuities In Welding.

From weldingintro.com

12 Most Common Welding Discontinuities & Defects Discontinuities In Welding A discontinuity is a flaw in the weld, but. Key terms to remember when welding and evaluating welds (indication, discontinuity, and defect). A defect is a discontinuity that causes the weldment to be unable to meet. The number or extent of the. Interruptions or flaws in the physical, mechanical or metallurgical properties of a weld are called discontinuities. A discontinuity. Discontinuities In Welding.