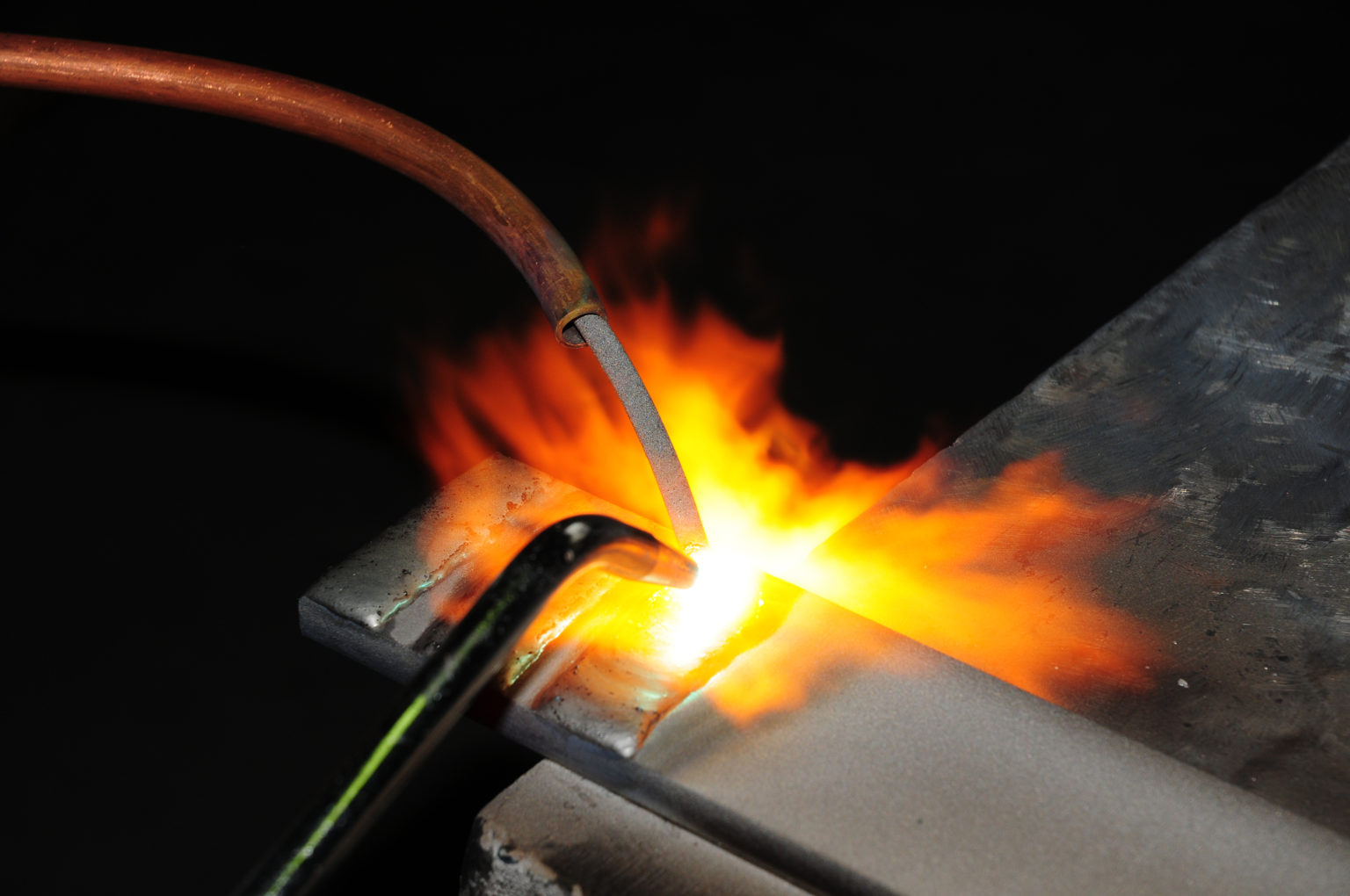

Wire Rope End Welding . Here are a few pictures describing the method: A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Ropes with diameters up to 40mm can be fused and tapered. Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Although it seems like a good and clean method, it restricts the individual strands from. We offer fused and tapered wire rope. Only rotation resistant wire rope can be welded. The separation zone of the rope is heated by electricity and at reaching the right. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. Looking for the best rope end preparation? Interested in how it’s done? Pouring molten or epoxy material. A fused and tapered end is now is available to choose as an option. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter.

from www.technogenia.com

Pouring molten or epoxy material. Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. A fused and tapered end is now is available to choose as an option. Here are a few pictures describing the method: Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. Although it seems like a good and clean method, it restricts the individual strands from. The separation zone of the rope is heated by electricity and at reaching the right. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Looking for the best rope end preparation? Ropes with diameters up to 40mm can be fused and tapered.

Welding Ropes Technogenia

Wire Rope End Welding Pouring molten or epoxy material. Interested in how it’s done? Ropes with diameters up to 40mm can be fused and tapered. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. We offer fused and tapered wire rope. Pouring molten or epoxy material. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Only rotation resistant wire rope can be welded. Looking for the best rope end preparation? Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Although it seems like a good and clean method, it restricts the individual strands from. A fused and tapered end is now is available to choose as an option. Here are a few pictures describing the method: A socket can be attached to the end of a wire rope cable using a variety of different methods, including: The separation zone of the rope is heated by electricity and at reaching the right.

From www.kingsing.com

Automatic Wire Rope Welding and Cutting Machine Wire Rope End Welding A socket can be attached to the end of a wire rope cable using a variety of different methods, including: We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Only rotation resistant wire rope can be welded. Pouring molten or epoxy material. Ropes with diameters up to 40mm can. Wire Rope End Welding.

From www.lamhongs.com.sg

Services Lam Hong Group Wire Rope End Welding Although it seems like a good and clean method, it restricts the individual strands from. Ropes with diameters up to 40mm can be fused and tapered. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Only rotation resistant wire rope can be welded. Pouring molten or epoxy material. We can carry this. Wire Rope End Welding.

From www.unirope.com

Wire Rope End Attachments Archives Unirope Ltd. Wire Rope End Welding Ropes with diameters up to 40mm can be fused and tapered. Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Interested in how it’s done? Looking for the best rope end preparation? Although it seems like a good and clean method, it restricts the individual. Wire Rope End Welding.

From wireropenews.com

End Termination for Crane Ropes BridonBekaert Ropes Group Wire Rope End Welding Interested in how it’s done? We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Although it seems like a good and clean method, it restricts the individual strands from. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Pouring molten or. Wire Rope End Welding.

From www.unirope.com

Wire Rope End Attachments Archives Unirope Ltd. Wire Rope End Welding Here are a few pictures describing the method: Only rotation resistant wire rope can be welded. Interested in how it’s done? We offer fused and tapered wire rope. A fused and tapered end is now is available to choose as an option. A socket can be attached to the end of a wire rope cable using a variety of different. Wire Rope End Welding.

From zjqqdgss.en.made-in-china.com

10mm Elevator Flexible Galvanized Stainless Steel Wire Rope End Wire Rope End Welding A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Interested in how it’s done? Pouring molten or epoxy material. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Wire seizing is soft wire used to keep the individual. Wire Rope End Welding.

From www.unirope.com

Wire Rope End Attachments Archives Unirope Ltd. Wire Rope End Welding Ropes with diameters up to 40mm can be fused and tapered. A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Although it seems like a good and clean method, it restricts the individual strands from. Strecker offers a comprehensive range of wire rope and cable welding machines from the. Wire Rope End Welding.

From www.mainco.co.uk

Assemblies, Slings & Rigging Mainco Wire Ropes Ltd Wire Rope End Welding Although it seems like a good and clean method, it restricts the individual strands from. Interested in how it’s done? Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Here are a few pictures describing the method: We can carry this process out for you on both galvanised and stainless steel wire. Wire Rope End Welding.

From www.lift-sling.com

Wire Rope Cutting & Welding Machine China Lifting Slings, bing Wire Rope End Welding We offer fused and tapered wire rope. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. Here are a few pictures describing the method: Although it seems like a good and clean method, it restricts the individual strands from. A socket can be attached to the end of a. Wire Rope End Welding.

From yieto.com

Stainless steel wire rope ER 308,309,310 Stainless steel welding wire Wire Rope End Welding A fused and tapered end is now is available to choose as an option. Interested in how it’s done? Here are a few pictures describing the method: We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Looking for the best rope end preparation? The separation zone of the rope. Wire Rope End Welding.

From volleymetal.en.made-in-china.com

Cable Collapsible Corrugated Wire Rope Reels Welding Iron Drum China Wire Rope End Welding We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Interested in how it’s done? The separation zone of the rope is heated by electricity and at reaching the right.. Wire Rope End Welding.

From www.unirope.com

Wire Rope End Attachments Archives Unirope Ltd. Wire Rope End Welding Ropes with diameters up to 40mm can be fused and tapered. Pouring molten or epoxy material. Interested in how it’s done? Although it seems like a good and clean method, it restricts the individual strands from. The separation zone of the rope is heated by electricity and at reaching the right. A socket can be attached to the end of. Wire Rope End Welding.

From www.stainless-steelsheetcoil.com

Factory Wholesales SUS 304 304 316 316L 1mm 2mm Stainless Steel Welding Wire Rope End Welding Interested in how it’s done? Ropes with diameters up to 40mm can be fused and tapered. Looking for the best rope end preparation? Although it seems like a good and clean method, it restricts the individual strands from. Here are a few pictures describing the method: Wire seizing is soft wire used to keep the individual wire rope component ends. Wire Rope End Welding.

From www.youtube.com

Fantastic wire rope splice methods. Incredible automatic steel wire Wire Rope End Welding A fused and tapered end is now is available to choose as an option. Only rotation resistant wire rope can be welded. Here are a few pictures describing the method: Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Socketing is the process of attaching. Wire Rope End Welding.

From machiningandwelding.com

Machining & Welding Wire Rope Terminations Cable Ends Wire rope Wire Rope End Welding Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Here are a few pictures describing the method: Wire seizing is soft wire used to keep the individual wire rope. Wire Rope End Welding.

From www.rvtalk.net

How To Swage Wire Rope Without Tool Wire Rope End Welding We offer fused and tapered wire rope. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Only rotation resistant wire rope can be welded. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. A socket can be attached. Wire Rope End Welding.

From www.youtube.com

YOU NEVER SEEN THESE WIRE ROPE IDEAS BEFORE YouTube Wire Rope End Welding A fused and tapered end is now is available to choose as an option. The separation zone of the rope is heated by electricity and at reaching the right. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Here are a few pictures describing the method: Interested in how it’s done? Strecker. Wire Rope End Welding.

From joiqyrfof.blob.core.windows.net

Rigging Wire Rope Slings at Russell Kleinman blog Wire Rope End Welding Looking for the best rope end preparation? We offer fused and tapered wire rope. A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Only rotation resistant wire rope can be welded. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm. Wire Rope End Welding.

From skanat.com

End fitting of ropes НПО «СОЮЗКАНАТ» Wire Rope End Welding Ropes with diameters up to 40mm can be fused and tapered. We offer fused and tapered wire rope. Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. A socket can be attached to the end of a wire rope cable using a variety of different. Wire Rope End Welding.

From www.coordinatedcompanies.com

Wire Rope Terminations Coordinated A CERTEX Company Wire Rope End Welding Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Here are a few pictures describing the method: The separation zone of the rope is heated by electricity and at reaching the right. Although it seems like a good and clean method, it restricts the individual. Wire Rope End Welding.

From www.wire-ropesling.com

6x36WS / 8x36WS Steel Wire Rope Sling With Equal Lay Construction Wire Rope End Welding Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Looking for the best rope end preparation? Pouring molten or epoxy material. Only rotation resistant wire rope can be welded. A fused and tapered end is now is available to choose as an option. We offer fused and tapered wire rope. Ropes with. Wire Rope End Welding.

From studylib.net

Wire rope end treatments. Sharrow Lifting Products Wire Rope End Welding Socketing is the process of attaching a termination fitting to the end of a wire rope cable. The separation zone of the rope is heated by electricity and at reaching the right. Interested in how it’s done? Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire. Wire Rope End Welding.

From www.mazzellacompanies.com

Wire Rope End Terminations Sockets, Wire Rope Clips, and Splices Wire Rope End Welding We offer fused and tapered wire rope. Looking for the best rope end preparation? Pouring molten or epoxy material. Interested in how it’s done? Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Socketing is the process of attaching a termination fitting to the end. Wire Rope End Welding.

From www.blackdownoffroad.co.uk

13mm X 28metre Steel Wire Rope with Thimble and plain end. Wire Rope End Welding We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. We offer fused and tapered wire rope. Looking for the best rope end preparation? Although it seems like a good and clean method, it restricts the individual strands from. A fused and tapered end is now is available to choose. Wire Rope End Welding.

From www.rigginginternationalgroup.com

Rope Access Welding Services Rigging International Group Wire Rope End Welding Looking for the best rope end preparation? Interested in how it’s done? Socketing is the process of attaching a termination fitting to the end of a wire rope cable. A socket can be attached to the end of a wire rope cable using a variety of different methods, including: The separation zone of the rope is heated by electricity and. Wire Rope End Welding.

From www.youtube.com

How to keep steel wire cable ends together. No fraying. YouTube Wire Rope End Welding Interested in how it’s done? We offer fused and tapered wire rope. Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. A socket can be. Wire Rope End Welding.

From ropeaccesswelding.blogspot.com

Rope Access Welding AHRM Rope Access Coded Welding services Perth WA Wire Rope End Welding Pouring molten or epoxy material. Only rotation resistant wire rope can be welded. A socket can be attached to the end of a wire rope cable using a variety of different methods, including: Socketing is the process of attaching a termination fitting to the end of a wire rope cable. A fused and tapered end is now is available to. Wire Rope End Welding.

From www.alamy.com

Wire rope connection Stock Photo, Royalty Free Image 123097067 Alamy Wire Rope End Welding Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Ropes with diameters up to 40mm can be fused and tapered. The separation zone of the rope is heated by electricity and at reaching the right. Looking for the best rope end preparation? Strecker offers a. Wire Rope End Welding.

From www.hescocrane.com

Wire Rope Seizing & End Terminations — HESCO Crane Inspection Crane Wire Rope End Welding Interested in how it’s done? A socket can be attached to the end of a wire rope cable using a variety of different methods, including: We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Here are a few pictures describing the method: Pouring molten or epoxy material. Socketing is. Wire Rope End Welding.

From www.mazzellacompanies.com

Wire Rope End Terminations Sockets, Wire Rope Clips, and Splices Wire Rope End Welding Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Looking for the best rope end preparation? Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. Here are a few pictures describing the method: Pouring molten or epoxy material. Ropes with diameters. Wire Rope End Welding.

From www.latchandbatchelor.co.uk

Rope EndConnections Latch and Batchelor Wire Rope End Welding Here are a few pictures describing the method: We offer fused and tapered wire rope. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. Pouring molten or epoxy material. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter.. Wire Rope End Welding.

From www.technogenia.com

Welding Ropes Technogenia Wire Rope End Welding Interested in how it’s done? Ropes with diameters up to 40mm can be fused and tapered. Looking for the best rope end preparation? A socket can be attached to the end of a wire rope cable using a variety of different methods, including: We can carry this process out for you on both galvanised and stainless steel wire ropes upto. Wire Rope End Welding.

From www.iqsdirectory.com

Wire Rope Sling What Is It? How Is It Made? Types Of Wire Rope End Welding Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Only rotation resistant wire rope can be welded. We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. The separation zone of the rope is heated. Wire Rope End Welding.

From www.thedriller.com

A Driller’s Primer on Wire Rope Connections, Rigging 20200527 The Wire Rope End Welding We can carry this process out for you on both galvanised and stainless steel wire ropes upto 28mm in diameter. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. Strecker offers a comprehensive range of wire rope and cable welding machines from the se, pa, ms and mk series. The separation zone. Wire Rope End Welding.

From www.youtube.com

Wire Rope Assemblies Rope Services Direct YouTube Wire Rope End Welding Here are a few pictures describing the method: Wire seizing is soft wire used to keep the individual wire rope component ends bound together while cutting, preparing, and handling a wire rope. Socketing is the process of attaching a termination fitting to the end of a wire rope cable. The separation zone of the rope is heated by electricity and. Wire Rope End Welding.