Puddling Process Definition . Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize.

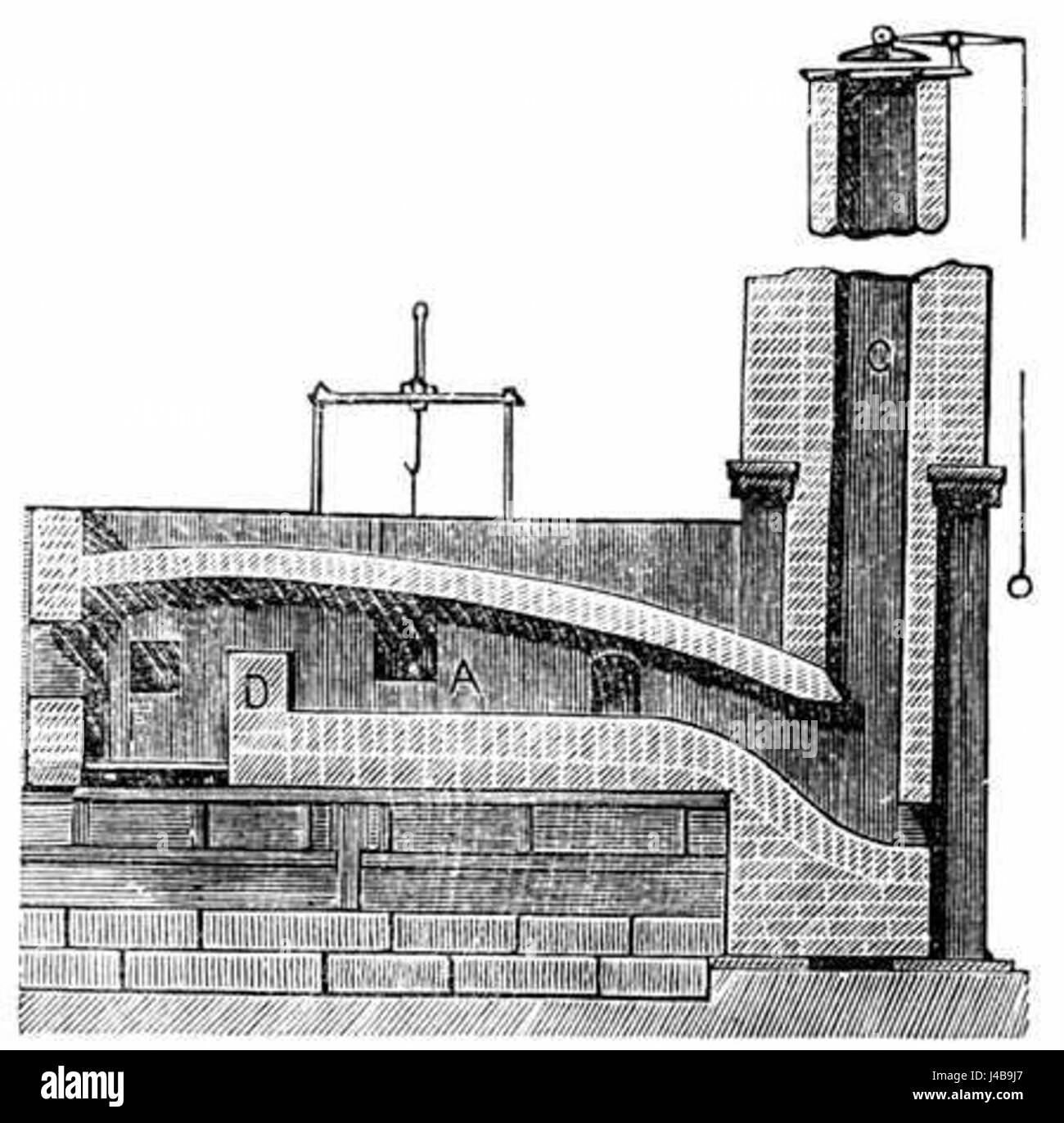

from www.alamy.com

The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of.

Puddling furnace hires stock photography and images Alamy

Puddling Process Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to.

From www.youtube.com

Puddling Furnace in Hindi Wrought iron in Hindi Gear Institute Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Cort’s ‘puddling process’, which built upon earlier work by the. Puddling Process Definition.

From www.alamy.com

Puddling works hires stock photography and images Alamy Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the. Puddling Process Definition.

From tangerfiv.com

Puddlers, Shinglers & Rollers the Story of Smeedbaar Iron Culturenl Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling process, method of converting pig iron into wrought iron by subjecting. Puddling Process Definition.

From www.slideshare.net

Puddling Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling was the process of choice for producing wrought iron. Puddling Process Definition.

From sandaidhzoie.blogspot.com

10+ make process flow SandaidhZoie Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process is a smelting technology in which pig iron is puddling on. Puddling Process Definition.

From www.youtube.com

Production Of Wrought Iron In Puddling Furnace YouTube Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat. Puddling Process Definition.

From www.youtube.com

Puddling process is used in the manufacture of a. Wrought iron b. P Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled. Puddling Process Definition.

From www.slideserve.com

PPT Puddling Furnace PowerPoint Presentation, free download ID1459870 Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling process, method of converting pig iron into wrought iron. Puddling Process Definition.

From www.theengineeringprojects.com

Blockchain Mining Definition, Process, Pooling & Miners The Puddling Process Definition Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting pig iron. Puddling Process Definition.

From www.youtube.com

Puddling Furnace Civil Fitter Blub Studio Welder Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. The puddling process is a method of converting pig iron into wrought iron. Puddling Process Definition.

From slideplayer.com

The Urbanization Game Industrialization in England, or any other small Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling was the process of choice for producing wrought iron and. Puddling Process Definition.

From www.alamy.com

Puddling furnace hires stock photography and images Alamy Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting. Puddling Process Definition.

From www.slideshare.net

12 1 Puddling Process Definition Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter. Puddling Process Definition.

From tractorkarvan.com

How to do Puddling in Paddy Field and their Benefits Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat. Puddling Process Definition.

From www.alamy.de

Puddling furnace Fotos und Bildmaterial in hoher Auflösung Alamy Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process, method of converting pig iron into wrought iron by subjecting it. Puddling Process Definition.

From www.youtube.com

Puddling Meaning YouTube Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling was the process of choice for producing wrought iron. Puddling Process Definition.

From www.britannica.com

Iron processing Definition, History, Steps, Uses, & Facts Britannica Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities. Puddling Process Definition.

From iq.opengenus.org

Global Average Pooling Puddling Process Definition Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling was the process of choice for producing wrought iron. Puddling Process Definition.

From www.youtube.com

Puddling Definition Need Advantages YouTube Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process, method of converting pig iron into wrought iron by subjecting it. Puddling Process Definition.

From etc.usf.edu

Puddling Furnace ClipArt ETC Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the. Puddling Process Definition.

From tmcgeedesign.com

0 Result Images of 4 Types Of Erosion Explained PNG Image Collection Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. Puddling was the process of choice for producing wrought iron and steel. Puddling Process Definition.

From www.researchgate.net

Schematic diagram of the puddling implement Download Scientific Diagram Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling was the process of choice for producing wrought iron. Puddling Process Definition.

From stock.adobe.com

Henry Cort's puddling furnace, 1766 Stock Photo Adobe Stock Puddling Process Definition Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Puddling process, method of converting pig iron into. Puddling Process Definition.

From www.researchgate.net

Two common types of pooling method. Download Scientific Diagram Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled. Puddling Process Definition.

From www.highcountryhistory.org.au

Puddling gold High Country History Hub Puddling Process Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting. Puddling Process Definition.

From slideplayer.com

Industrial Revolution Urbanization Simulation ppt download Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace. Puddling Process Definition.

From www.vrogue.co

Example Of Convolutional Neural Network Cnn Architecture Download Vrogue Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. Puddling was the process of choice for producing. Puddling Process Definition.

From www.slideserve.com

PPT Puddling Furnace PowerPoint Presentation, free download ID1459870 Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled. Puddling Process Definition.

From tractorkarvan.com

How to do Puddling in Paddy Field and their Benefits Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method of converting pig iron into wrought iron by heating. Puddling Process Definition.

From www.slideserve.com

PPT Industrial PowerPoint Presentation, free download ID2292151 Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process is a smelting technology in which pig iron is puddling on. Puddling Process Definition.

From ergo.slv.vic.gov.au

Puddling Ergo Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled new forms of bridges and other structures to be made. The puddling process is a method used to convert pig iron into wrought iron by. Puddling Process Definition.

From workingtheflame.com

Interesting Facts About Sheet Metal (History, Science, & Industry Puddling Process Definition The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling was the process of choice for producing wrought iron and steel for. Puddling Process Definition.

From www.slideserve.com

PPT Puddling Furnace PowerPoint Presentation, free download ID1459870 Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. The puddling process is a method used to convert pig iron into wrought iron by removing impurities. Puddling Process Definition.

From www.youtube.com

Industrial Revolution. Episode 6 Puddling Process (1784) Henry Cort Puddling Process Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the. Puddling process is a smelting technology in which pig iron is puddling on the bottom of the furnace built with iron oxide to. The puddling process is a method of converting pig iron into wrought iron by heating. Puddling Process Definition.

From www.slideshare.net

Puddling furnace PPT Puddling Process Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method of converting pig iron into wrought iron by heating it in a reverberatory furnace and stirring it to oxidize. Cort’s ‘puddling process’, which built upon earlier work by the ironmaster peter onions transformed engineering and enabled. Puddling Process Definition.