Double-Sided Foam Tape Meaning . It can also be used for sealing, depending on the requirements of the product. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. This is known as the wetting process.

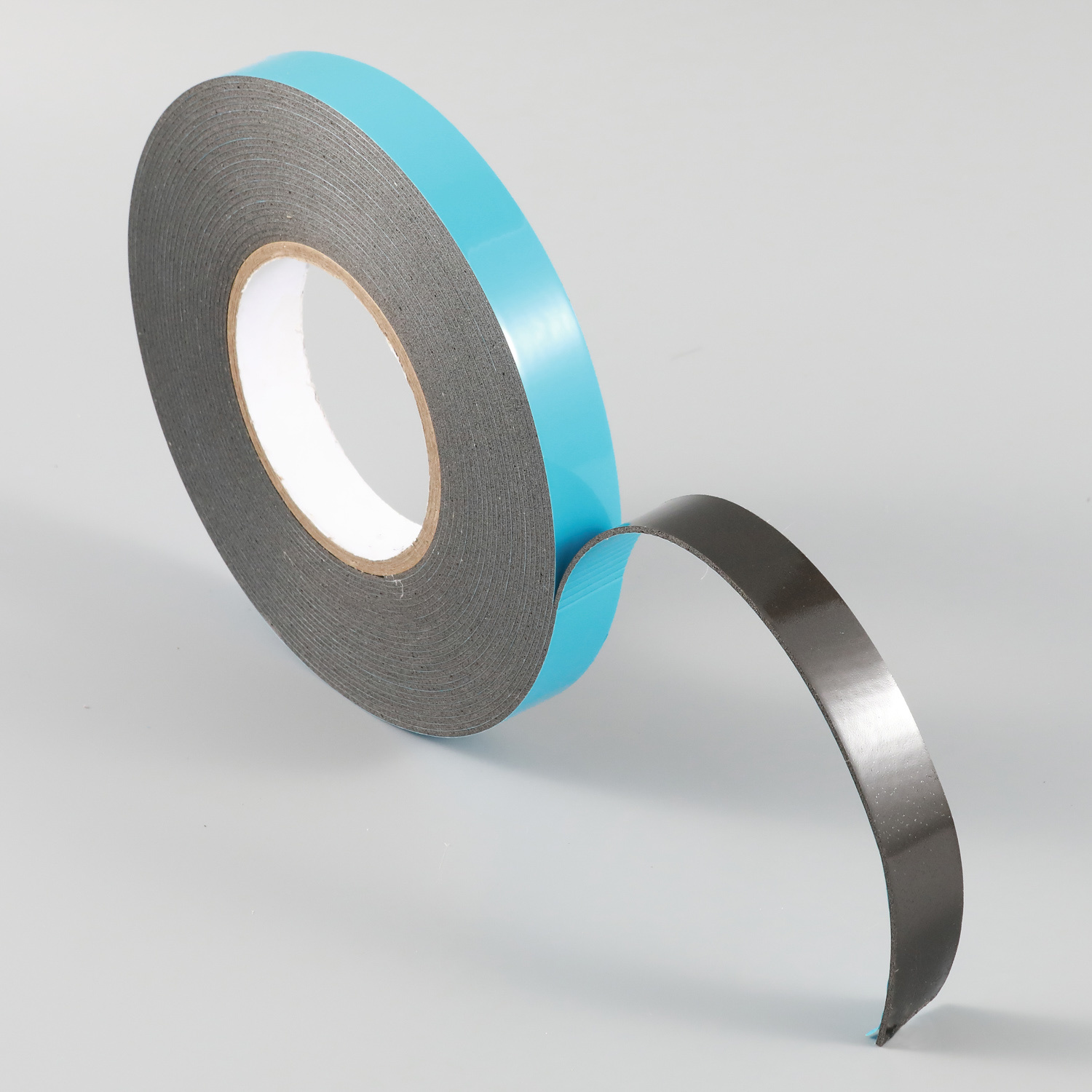

from www.tapestown.com

It can also be used for sealing, depending on the requirements of the product. This is known as the wetting process. The bonding process can be broken down into three main steps: No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly.

Double sided foam tapes

Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? No air, and no sound, end up leaking out. The bonding process can be broken down into three main steps: When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. It can also be used for sealing, depending on the requirements of the product. This is known as the wetting process.

From nationalstationery.co.za

DOUBLE SIDED FOAM TAPE 18mm x 1m x 1mm National Stationery Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. This is known as the wetting process. The bonding process can be broken down into three main steps: Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it. Double-Sided Foam Tape Meaning.

From safetybox.co.uk

Double Sided Foam Tapes Foamed Double Side Tapes Double-Sided Foam Tape Meaning When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve. Double-Sided Foam Tape Meaning.

From www.flickr.com

Doublesided foam tapes are used for temporary or permanen… Flickr Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. The bonding process can be broken down into three main steps: Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape is. Double-Sided Foam Tape Meaning.

From www.amazon.ae

Double Sided 3M Adhesive Tape, 1 inch Width x 9 FT Length, 3M VHB Heavy Double-Sided Foam Tape Meaning It can also be used for sealing, depending on the requirements of the product. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? This is known as the wetting process. When double sided tape is applied to a. Double-Sided Foam Tape Meaning.

From thestationeryshop.com.sg

Double Sided Foam Tape The Stationery Shop Equipping Offices In Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. This is known as the wetting process. The bonding process can be broken down into three main steps: When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Double sided tape is designed. Double-Sided Foam Tape Meaning.

From muralsrd.com

DOUBLESIDED FOAM TAPE Double-Sided Foam Tape Meaning Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly. Double-Sided Foam Tape Meaning.

From www.sunwintra.com

3M ORIGINAL 18MM X 1.5M PE FOAM DOUBLE SIDED TAPE Double-Sided Foam Tape Meaning This is known as the wetting process. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. The bonding process can be. Double-Sided Foam Tape Meaning.

From ctaltd.co.uk

Double sided foam tape 5508 CTA Ltd Double-Sided Foam Tape Meaning This is known as the wetting process. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. No. Double-Sided Foam Tape Meaning.

From www.grainger.com

3M™ VHB™ RP+040GF, Acrylic, DoubleSided Foam Tape 799Z02RP+040GF Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. It can also be used for sealing, depending on. Double-Sided Foam Tape Meaning.

From www.goldimageprinting.com

Double Sided Foam Tape Double Sided Mounting Tape GIP Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. The bonding process can be broken down into three main steps: This is known as the wetting process. It can also be used for sealing, depending on the requirements of the product. No air, and no. Double-Sided Foam Tape Meaning.

From nationalstationery.co.za

DOUBLE SIDED FOAM TAPE 24mm x 1m x 3mm National Stationery Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. It can also be used for sealing, depending on the requirements of the product. This is known as the wetting process. Using double sided foam tape instead of screws or bolts to help hold. Double-Sided Foam Tape Meaning.

From omark.com.sg

Strong Double Sided Foam Tape Manufacturer Omark Worldwide Double-Sided Foam Tape Meaning It can also be used for sealing, depending on the requirements of the product. The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape. Double-Sided Foam Tape Meaning.

From www.grainger.com

3M™ VHB™ GPH160GF, Acrylic, DoubleSided Foam Tape 793ZD4GPH160GF Double-Sided Foam Tape Meaning Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. This is known as the wetting process. It can also be used for sealing, depending on the requirements of the product. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. The bonding process can be broken down into three main steps:. Double-Sided Foam Tape Meaning.

From www.tapestown.com

Double sided foam tapes Double-Sided Foam Tape Meaning Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? The bonding process can be broken down into three main steps: When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. No. Double-Sided Foam Tape Meaning.

From store.gsstationery.com

Double Sided Tape Eva Foam 12mm X 10m Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. It can also be used for sealing, depending on the requirements of the product. The bonding process can be broken down into three main steps: This is known as the wetting process. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound. Double-Sided Foam Tape Meaning.

From www.actionhardware.com.sg

Double Sided Foam Tape Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? This is known as the wetting process. The bonding process can be broken down into three main steps: It can also be used for sealing, depending on the requirements of the. Double-Sided Foam Tape Meaning.

From www.yousantape.com

PVC Foam double sided Tape Adhesive Tape,Double Sided Tape,High Double-Sided Foam Tape Meaning This is known as the wetting process. No air, and no sound, end up leaking out. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Double sided tape is designed to bond to a wide range of surfaces, but how exactly. Double-Sided Foam Tape Meaning.

From www.hndmd.com

Double sided foam tape (Heavy duty) (1 inch) CAAT14 HNDMD Double-Sided Foam Tape Meaning The bonding process can be broken down into three main steps: No air, and no sound, end up leaking out. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Using double sided foam tape instead of screws or bolts to help. Double-Sided Foam Tape Meaning.

From www.lazada.com.ph

'nExcel Double Sided Foam Tape 24mm Lazada PH Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. No air, and no sound, end up leaking out. When double sided tape is. Double-Sided Foam Tape Meaning.

From omark.com.sg

Double Sided EVA Foam Tape Omark Worldwide (s) Pte. Ltd. Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. This is known as the wetting process. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. No air, and no sound, end up leaking out. It can also. Double-Sided Foam Tape Meaning.

From dcatape.com

PE DoubleSided Foam Tape for Mounting DCA Tape Double-Sided Foam Tape Meaning The bonding process can be broken down into three main steps: It can also be used for sealing, depending on the requirements of the product. This is known as the wetting process. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? Using double sided foam tape instead of screws. Double-Sided Foam Tape Meaning.

From www.kingswoodos.co.uk

Double Sided FOAM Tape 25mm x 25 meter Kingswood Office Supplies Double-Sided Foam Tape Meaning No air, and no sound, end up leaking out. It can also be used for sealing, depending on the requirements of the product. The bonding process can be broken down into three main steps: Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? This is known as the wetting. Double-Sided Foam Tape Meaning.

From www.richengsz.com

3m 1600T Waterproof Strong Adhesion Double Sided Pe Foam Adhesive Tape Double-Sided Foam Tape Meaning This is known as the wetting process. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? The bonding process can be broken down into three main steps: When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Using double sided foam tape. Double-Sided Foam Tape Meaning.

From www.lazada.com.ph

Deli Strong Double Sided Foam Tape Mounting Tape For Multiple Bonding Double-Sided Foam Tape Meaning The bonding process can be broken down into three main steps: No air, and no sound, end up leaking out. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. It can also be used for sealing, depending on the requirements of the product. Double sided tape is designed to bond to a. Double-Sided Foam Tape Meaning.

From supplies.com.ph

Double Sided Tape (Croco) Green Foam Tape 3/4 18mm 1M Supplies 24/7 Double-Sided Foam Tape Meaning Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? It can also be used for sealing, depending on the requirements of the product. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Using double sided foam tape instead of screws or bolts to help hold insulation in. Double-Sided Foam Tape Meaning.

From presbond.com

Double Sided Foam Tape — PresBond Double-Sided Foam Tape Meaning The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or. Double-Sided Foam Tape Meaning.

From www.orient-treasure.com

3M Double Sided Foam Tape 18mm Orient Treasure Trading Sdn Bhd Double-Sided Foam Tape Meaning Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? It can also be used for sealing, depending on the requirements of the product. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Foam tapes. Double-Sided Foam Tape Meaning.

From shopee.ph

3M Foam Double Sided Tape 5 Meter Length Heavy Duty White EVA Foam Tape Double-Sided Foam Tape Meaning The bonding process can be broken down into three main steps: This is known as the wetting process. No air, and no sound, end up leaking out. Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Double sided tape is designed to bond to a. Double-Sided Foam Tape Meaning.

From www.grainger.com

3M DoubleSided Foam Tape 3/4 in x 5 yd, 1.1 mm Tape Thick, Indoor and Double-Sided Foam Tape Meaning When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. No air, and no sound, end up leaking out. The bonding process can be broken down into three main steps: Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? Using double sided. Double-Sided Foam Tape Meaning.

From www.grainger.com

3M™ VHB™ GPH160GF, Acrylic, DoubleSided Foam Tape 793ZC9GPH160GF Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. This is known as the. Double-Sided Foam Tape Meaning.

From www.alibaba.com

Doublesided Foam Mounting Tape Black Coated Acrylic Adhesive Pe Double Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. This is known as the wetting process. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it. Double-Sided Foam Tape Meaning.

From www.llstationery.com

Apollo Double Sided Pe Foam Tape L & L Sationery Double-Sided Foam Tape Meaning Using double sided foam tape instead of screws or bolts to help hold insulation in place will enclose sound booths or auditoriums more thoroughly. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? It can also be used for sealing, depending on the requirements of the product. When double. Double-Sided Foam Tape Meaning.

From www.mscdirect.com

Norton 1 x 108 x .043 In. Blue Liner DoubleSided Foam Tape Double-Sided Foam Tape Meaning It can also be used for sealing, depending on the requirements of the product. When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. The bonding process can be broken down into three main steps: Foam tapes can be created using polyethylene, acrylic, pvc or polyurethane. Double sided tape is designed to bond. Double-Sided Foam Tape Meaning.

From www.amazon.in

ETI Double Side Foam Tape 24mm X 5Meter Set of 3, White Amazon.in Double-Sided Foam Tape Meaning When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. This is known as the wetting process. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? No air, and no sound, end up leaking out. Foam tapes can be created using polyethylene,. Double-Sided Foam Tape Meaning.

From multipack.ee

Doublesided Acrylic Foam tape 19mmx33m, thicness 1mm, transparent Double-Sided Foam Tape Meaning This is known as the wetting process. No air, and no sound, end up leaking out. Double sided tape is designed to bond to a wide range of surfaces, but how exactly does it achieve this? When double sided tape is applied to a surface, the adhesive spreads out and wets the surface. Foam tapes can be created using polyethylene,. Double-Sided Foam Tape Meaning.