Dish Forming Formula . Dished head formulae equations and calculator: Pressure vessel design and calculators. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Fabrication of a dish e. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Formula for calculating the blank diameter of a dish end. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Asme pressure vessel section i: A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal.

from www.semanticscholar.org

Asme pressure vessel section i: A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Formula for calculating the blank diameter of a dish end. Pressure vessel design and calculators. Dished head formulae equations and calculator: Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Fabrication of a dish e. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the.

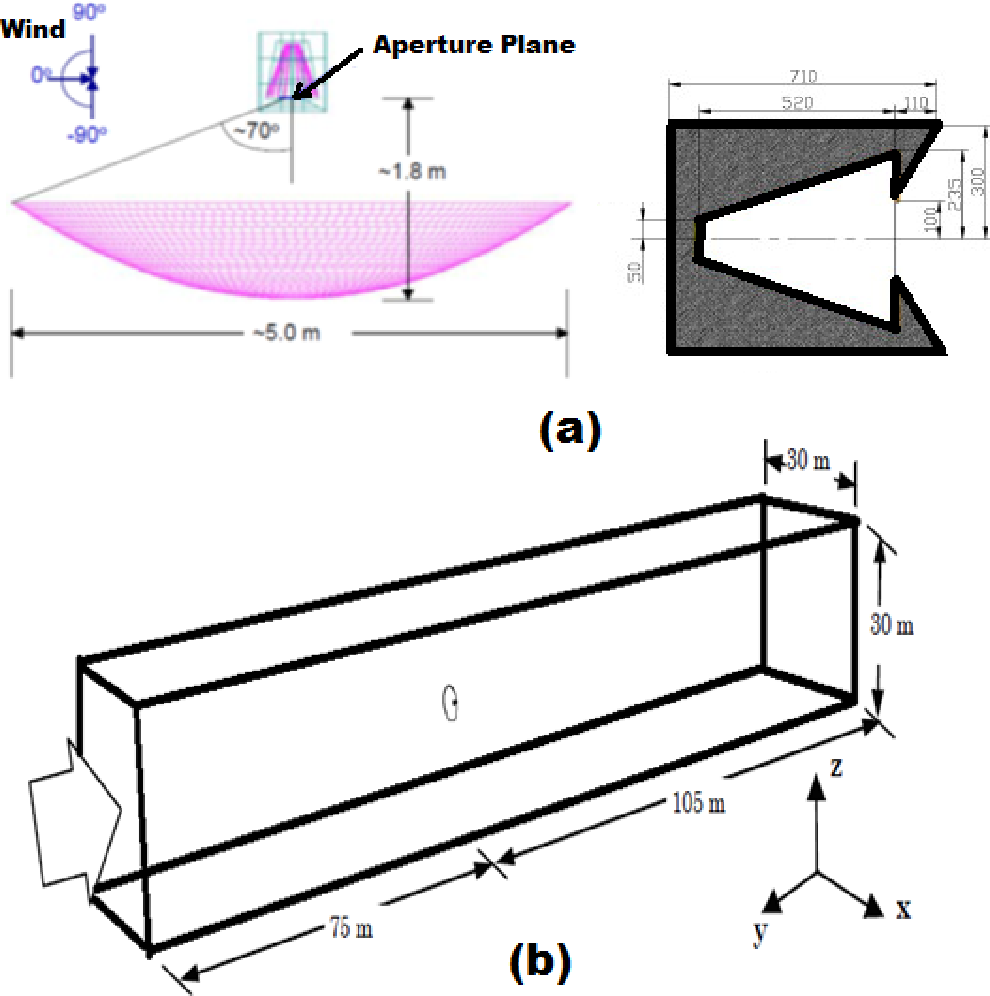

Figure 1 from Impact of Dish Structure on the Convective Heat Loss From

Dish Forming Formula Fabrication of a dish e. Dished head formulae equations and calculator: Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Pressure vessel design and calculators. Formula for calculating the blank diameter of a dish end. Fabrication of a dish e. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Asme pressure vessel section i:

From www.youtube.com

Dishend template full explained in Hindi Torispherical and 21 deep Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Formula for calculating the blank diameter of a dish end. Pressure vessel design and calculators. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1. Dish Forming Formula.

From www.youtube.com

Hemispherical dish end fabrication terms YouTube Dish Forming Formula Formula for calculating the blank diameter of a dish end. Dished head formulae equations and calculator: Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Pressure vessel design and calculators. Fabrication of a dish e. A dishing and flanging line can form heads of. Dish Forming Formula.

From www.nash-eng.com

Forming Division Nash Engineering Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Pressure vessel design and calculators. Formula for calculating the blank diameter of. Dish Forming Formula.

From www.scribd.com

DISH END Dish Forming Formula Formula for calculating the blank diameter of a dish end. Asme pressure vessel section i: Fabrication of a dish e. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via. Dish Forming Formula.

From www.faccin.com

Dished Heads Dish End Forming Machines Faccin Dish Forming Formula A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Dished head formulae equations and calculator: The following are equations and a calculator to determine the wall. Dish Forming Formula.

From www.slideshare.net

Question bank Dish Forming Formula Asme pressure vessel section i: Pressure vessel design and calculators. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Dished head formulae equations and. Dish Forming Formula.

From www.thefabricator.com

Dished end manufacturing for beginners Dish Forming Formula Dished head formulae equations and calculator: Asme pressure vessel section i: Formula for calculating the blank diameter of a dish end. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Define the dish shape is that the curvatures of the two radii are equal at. Dish Forming Formula.

From www.thefabricator.com

Dished end manufacturing for beginners Dish Forming Formula A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Fabrication of a dish e. Asme pressure vessel section i: Pressure vessel design and calculators. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Dished head. Dish Forming Formula.

From www.slideshare.net

Presentation on SECVIII Dish Forming Formula Formula for calculating the blank diameter of a dish end. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Fabrication of a dish e. Dished head formulae equations and calculator: Asme pressure vessel section i: A dishing and flanging line can form heads of any shape,. Dish Forming Formula.

From www.slawinski.co.uk

Dishing torispherical head, ellipsoidal head, spherical dished bottom Dish Forming Formula Asme pressure vessel section i: Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Formula for calculating the blank diameter of a dish end. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater. Dish Forming Formula.

From www.youtube.com

HOW TO DRAW A TORISPHERICAL DISH IN 2D DETAIL EXPLANATION TUTORIAL 3 Dish Forming Formula The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Dished head formulae equations and calculator: Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Fabrication of a dish e.. Dish Forming Formula.

From www.semanticscholar.org

Figure 1 from Impact of Dish Structure on the Convective Heat Loss From Dish Forming Formula Dished head formulae equations and calculator: Fabrication of a dish e. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Pressure vessel design and calculators. Formula for calculating the blank diameter of a dish end. Asme pressure vessel section i: Define the dish shape. Dish Forming Formula.

From www.youtube.com

Tutorial Dish End/Dish Head Design & Fabrication Process/Torispherical Dish Forming Formula A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Fabrication of a dish e. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Dished head formulae equations and calculator: Define the dish shape is. Dish Forming Formula.

From www.thefabricator.com

Dished end manufacturing for beginners Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Dished head formulae equations and calculator: Fabrication of a dish e. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or.. Dish Forming Formula.

From akshayrothe.blogspot.com

TYPES OF DISHED ENDS 21 Ellipsoidal Dished Ends.(Elliptical Dished Dish Forming Formula Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. The following are equations and a calculator to determine the wall thinkness and working pressure of an. Dish Forming Formula.

From www.slideshare.net

Ced_ppt Dish Forming Formula The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Dished head formulae equations and calculator: Formula for calculating the blank diameter of a dish end. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via. Dish Forming Formula.

From www.scribd.com

DISH END BLANK DIA CALCULATION.docx Sphere Volume Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Pressure vessel design and calculators. Formula for calculating the blank diameter. Dish Forming Formula.

From www.slideshare.net

A.s.m.e Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Dished head formulae equations and calculator: Formula for calculating the blank diameter of a dish end. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions. Dish Forming Formula.

From fayazam.blogspot.com

Engineering Calculations Surface Area and Blank Diameter Calculations Dish Forming Formula Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Formula for calculating the blank diameter of a dish end. Fabrication of a dish e. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. The following. Dish Forming Formula.

From www.slideshare.net

Ced_ppt Dish Forming Formula The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Formula for calculating the blank diameter of a dish end. Fabrication of a dish e. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the. Dish Forming Formula.

From www.youtube.com

Forming of Dish Heads Methods of Forming Whizz Engineers YouTube Dish Forming Formula Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. The following are equations and a calculator to determine the wall thinkness. Dish Forming Formula.

From www.youtube.com

Flow Forming / Metal Spinning / Shear Forming using ABAQUS CAE YouTube Dish Forming Formula Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Pressure vessel design and calculators. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. A dishing and flanging line can form. Dish Forming Formula.

From www.youtube.com

Dish Head I what is Knuckle Radius 17 & Crown Radius 90 and Dish Forming Formula Pressure vessel design and calculators. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Fabrication of a dish e. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Formula for calculating the blank diameter. Dish Forming Formula.

From tdec.co.za

Products The Dished End Company Dish Forming Formula Asme pressure vessel section i: Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Formula for calculating the blank diameter of a dish end. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Pressure vessel. Dish Forming Formula.

From www.youtube.com

Tolerence for Fabrication of Vessel Part 2 (Dish End) YouTube Dish Forming Formula Asme pressure vessel section i: Fabrication of a dish e. Dished head formulae equations and calculator: Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Formula for calculating the blank diameter of a dish end. Pressure vessel design and calculators. A dishing and flanging line can. Dish Forming Formula.

From www.youtube.com

How to make Ellipsoidal dished in Autocad. YouTube Dish Forming Formula Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. A dishing and flanging line can form heads of any shape, be it. Dish Forming Formula.

From www.thefabricator.com

Dished end manufacturing for beginners Dish Forming Formula Pressure vessel design and calculators. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Formula for calculating the blank diameter of a. Dish Forming Formula.

From phoenix-engineering.co.th

Dish Head Forming Phoenix Engineering & Construction Co., Ltd. Dish Forming Formula Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Formula for calculating the blank diameter of a dish end. Dished head formulae equations and calculator: Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the. Dish Forming Formula.

From risenmetal.net

Steel Torispherical Head Dish End Tank Head Dish Forming Formula Asme pressure vessel section i: Formula for calculating the blank diameter of a dish end. Dished heads can be manufactured using a combination of processes, spinning & flanging, where the spherical radius is made via the spinning process and the. Pressure vessel design and calculators. Fabrication of a dish e. Define the dish shape is that the curvatures of the. Dish Forming Formula.

From www.youtube.com

CALCULATION OF BLANK FOR ELLIPSOIDAL DISHED HEAD , HEIGHT, KNUCKLE Dish Forming Formula The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. Asme pressure vessel section i: Dished heads can be manufactured using a combination. Dish Forming Formula.

From www.slideshare.net

Ced_ppt Dish Forming Formula Pressure vessel design and calculators. Define the dish shape is that the curvatures of the two radii are equal at the plane where regions 1 and 2 join. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. A dishing and flanging line can form heads. Dish Forming Formula.

From www.youtube.com

Elliptical Dish End fabrication Terms 21 type YouTube Dish Forming Formula Pressure vessel design and calculators. Formula for calculating the blank diameter of a dish end. Dished head formulae equations and calculator: Fabrication of a dish e. Asme pressure vessel section i: The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Define the dish shape is. Dish Forming Formula.

From www.youtube.com

How to get Elliptical head 21 Development size I Ellipsoidal dish head Dish Forming Formula Asme pressure vessel section i: Pressure vessel design and calculators. A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Fabrication of a dish e. Dished. Dish Forming Formula.

From www.youtube.com

Torispherical Dish End fabrication terms YouTube Dish Forming Formula Dished head formulae equations and calculator: The following are equations and a calculator to determine the wall thinkness and working pressure of an ellipsoidal head with t/l greater than or. Fabrication of a dish e. Formula for calculating the blank diameter of a dish end. A dishing and flanging line can form heads of any shape, be it flat, conical,. Dish Forming Formula.

From www.youtube.com

Dished End Types What is Crown Radius,Knuckle Radius, SF How to Dish Forming Formula Asme pressure vessel section i: A dishing and flanging line can form heads of any shape, be it flat, conical, standard, torispherical, semielliptical, or ellipsoidal. Formula for calculating the blank diameter of a dish end. Fabrication of a dish e. Pressure vessel design and calculators. Dished head formulae equations and calculator: Dished heads can be manufactured using a combination of. Dish Forming Formula.