Engine Block Core Shift . If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. The term core shift relates to the deviation of a foundry core during the casting process. If they are in the center of the cast bulkhead in the. Even on a new block, this is important because core shift can cause one side of a cylinder. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. That is to say, the core moves from its. Finally, sand cleanout, especially from relatively small passages such. The easiest way to check for core shift is to look at the cam and lifter bores. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block.

from www.freeasestudyguides.com

Finally, sand cleanout, especially from relatively small passages such. The easiest way to check for core shift is to look at the cam and lifter bores. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. Even on a new block, this is important because core shift can cause one side of a cylinder. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. That is to say, the core moves from its. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. The term core shift relates to the deviation of a foundry core during the casting process.

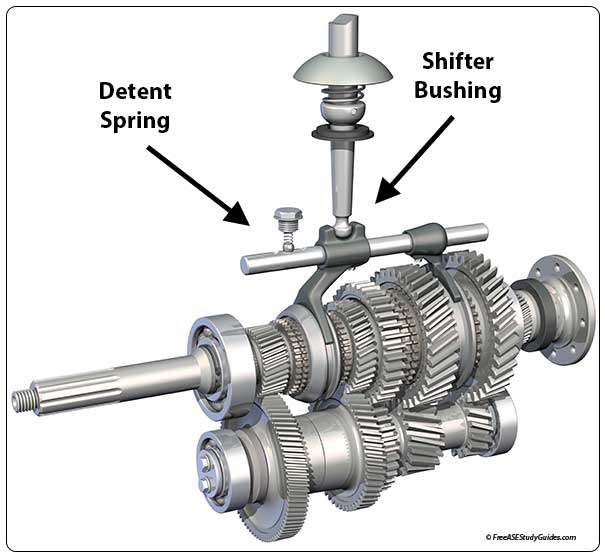

Shift Linkage and Shift Rails

Engine Block Core Shift Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. Finally, sand cleanout, especially from relatively small passages such. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. Even on a new block, this is important because core shift can cause one side of a cylinder. The easiest way to check for core shift is to look at the cam and lifter bores. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. If they are in the center of the cast bulkhead in the. The term core shift relates to the deviation of a foundry core during the casting process. That is to say, the core moves from its. Sonic testing can tell you the thickness of the cylinder walls quickly and easily.

From www.club4ag.com

OST068 Smok'n Engine Block Core Shift If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. If they are in the center of the cast bulkhead in the. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Sonic testing can tell you the. Engine Block Core Shift.

From www.2040-parts.com

Buy 1966 Chevy 283 Chevy II Nova Bare Block Core 3862194 in Phoenix Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. Even on a new block, this is important because core shift can cause one side of a cylinder. Finally, sand cleanout, especially from relatively. Engine Block Core Shift.

From www.freeasestudyguides.com

Shift Linkage and Shift Rails Engine Block Core Shift That is to say, the core moves from its. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. Sonic testing can tell you the thickness of the cylinder walls quickly and easily.. Engine Block Core Shift.

From www.dragzine.com

World Products Explains Core Shift And How They Cured It Engine Block Core Shift Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. Finally, sand cleanout, especially from relatively small passages such. The easiest way to check for core shift is to look at the cam and lifter bores. If they are in the center of the cast bulkhead in the. The term core shift relates to the. Engine Block Core Shift.

From www.motortrend.com

How It Works Edelbrock’s HIP Cylinder Head Casting Tech Engine Block Core Shift Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. The term core shift relates to the deviation of a foundry core during the casting process. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. If you're. Engine Block Core Shift.

From club4ag.com

OST069 Transformation Engine Block Core Shift Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. That is to say, the core moves from its. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove. Engine Block Core Shift.

From www.mopardiy.com

How to Build Mopar Engines for Performance The Block Guide Mopar DiY Engine Block Core Shift That is to say, the core moves from its. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Even on a new block, this is important because core shift can cause one side of a cylinder. The term core shift relates to the deviation of a foundry. Engine Block Core Shift.

From www.popularrestorations.com

Tour of an Engine Rebuild Shop (Part 3 Machining the Block) Engine Block Core Shift The term core shift relates to the deviation of a foundry core during the casting process. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Even on a new block, this is important because core shift can cause one side of a cylinder. Sonic testing can tell. Engine Block Core Shift.

From mooregoodink.com

What is core shift and why is it detrimental? Moore Good Ink Engine Block Core Shift When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. The easiest way to check for core shift is to look at the cam and lifter bores. If they are in the center of the cast bulkhead in the. Core shift or core. Engine Block Core Shift.

From mooregoodink.com

What is core shift and why is it detrimental? Moore Good Ink Engine Block Core Shift The term core shift relates to the deviation of a foundry core during the casting process. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. The easiest way to check for core shift is to look at the cam and lifter bores. Even on a new block, this is important because core shift can cause. Engine Block Core Shift.

From www.zr1specialist.com

Injector Housing Core Shift Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. Even on a new block, this is important because core shift can cause one side of a cylinder. Finally, sand cleanout, especially from relatively. Engine Block Core Shift.

From mooregoodink.com

What is core shift and why is it detrimental? Moore Good Ink Engine Block Core Shift Even on a new block, this is important because core shift can cause one side of a cylinder. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. When you cast a block, they have to put cores in the mold to take up the space where the bore for. Engine Block Core Shift.

From v8buick.com

Understanding Core Shift in the 455 block why sonic checking is so Engine Block Core Shift Even on a new block, this is important because core shift can cause one side of a cylinder. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Finally, sand cleanout, especially from relatively small passages such. The term core shift relates to the deviation of a foundry core during. Engine Block Core Shift.

From schematicguides.z21.web.core.windows.net

Manually Shifting An Automatic Transmission Engine Block Core Shift That is to say, the core moves from its. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. The term core shift relates to the deviation of a foundry core during the casting process. If they are in the center of the. Engine Block Core Shift.

From www.enginelabs.com

World Products Explains Core Shift And How They Cured It Engine Block Core Shift The easiest way to check for core shift is to look at the cam and lifter bores. Finally, sand cleanout, especially from relatively small passages such. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. If you're using an old 400 block,. Engine Block Core Shift.

From www.diyauto.com

Understanding Core Shift in the 455 block why sonic checking is so Engine Block Core Shift That is to say, the core moves from its. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any. Engine Block Core Shift.

From www.diyauto.com

Understanding Core Shift in the 455 block why sonic checking is so Engine Block Core Shift That is to say, the core moves from its. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. The term. Engine Block Core Shift.

From www.youtube.com

Castings Core Shift & Breakage YouTube Engine Block Core Shift Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting. Engine Block Core Shift.

From www.enginelabs.com

World Products Explains Core Shift And How They Cured It Engine Block Core Shift Finally, sand cleanout, especially from relatively small passages such. The easiest way to check for core shift is to look at the cam and lifter bores. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings. Engine Block Core Shift.

From www.hotrod.com

This 426Cube 318 Poly Can Outgun Hemis! Hot Rod Network Engine Block Core Shift If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. The term core shift relates to the deviation of a foundry core during the casting process. The easiest way to check for core shift is to look at the cam and lifter bores. To remove any potential stress risers, use. Engine Block Core Shift.

From mooregoodink.com

What is core shift and why is it detrimental? Moore Good Ink Engine Block Core Shift Sonic testing can tell you the thickness of the cylinder walls quickly and easily. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. The easiest way to check for core shift is to look at the cam and lifter bores. The term. Engine Block Core Shift.

From www.zhycasting.com

Present situation of casting technology and equipment for engine block Engine Block Core Shift Finally, sand cleanout, especially from relatively small passages such. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. The term core shift relates to the deviation of a foundry core during the casting process. When you cast a block, they have to put cores in the mold. Engine Block Core Shift.

From www.racingjunk.com

Choosing the Right Cylinder Blocks Part I RacingJunk News Engine Block Core Shift If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Even on a new block, this is important because core shift can cause one side of a cylinder. If they are in the center of the cast bulkhead in the. To remove any potential stress risers, use a die grinder. Engine Block Core Shift.

From ls1tech.com

5.7 Ls1 block with crack sleeved LS1TECH Engine Block Core Shift The term core shift relates to the deviation of a foundry core during the casting process. The easiest way to check for core shift is to look at the cam and lifter bores. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. Even on a new block, this is important because core shift can cause. Engine Block Core Shift.

From bangshift.com

SEMA New Product Blueprint Engines New 302 Block Is The Engine Block Core Shift If they are in the center of the cast bulkhead in the. The term core shift relates to the deviation of a foundry core during the casting process. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. The easiest way to check. Engine Block Core Shift.

From www.viczcar.com

Questions About Core Shift In L28 Blocks. Engine Auszcar Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. The term core shift relates to the deviation of a foundry core during the casting process. Finally, sand cleanout, especially from relatively small passages such. If you're using an old 400 block, the main thing is to check. Engine Block Core Shift.

From www.zhycasting.com

Casting process plan of engine block ZHY Casting Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. That is to say, the core moves from its. Even on a new block, this is important because. Engine Block Core Shift.

From www.diyauto.com

Understanding Core Shift in the 455 block why sonic checking is so Engine Block Core Shift The easiest way to check for core shift is to look at the cam and lifter bores. If they are in the center of the cast bulkhead in the. When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. Finally, sand cleanout, especially. Engine Block Core Shift.

From core-shifters.com

Shifter base for Tremec TKO aftermarket 5 speed Core Shifters Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. That is to say, the core moves from its. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. When you cast a block, they have to put cores in the mold to take. Engine Block Core Shift.

From www.v8buick.com

Understanding Core Shift in the 455 block why sonic checking is so Engine Block Core Shift If they are in the center of the cast bulkhead in the. That is to say, the core moves from its. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Finally, sand cleanout, especially from relatively small passages such. Even on a new block, this is important. Engine Block Core Shift.

From www.youtube.com

Core Shift Analysis Autodesk Moldflow Insight YouTube Engine Block Core Shift To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. That is to say, the core moves from its. When you cast a block, they have to put cores in the mold to. Engine Block Core Shift.

From www.enginelabs.com

World Products Explains Core Shift And How They Cured It Engine Block Core Shift That is to say, the core moves from its. If they are in the center of the cast bulkhead in the. Sonic testing can tell you the thickness of the cylinder walls quickly and easily. If you're using an old 400 block, the main thing is to check the block and make sure it doesn't. Even on a new block,. Engine Block Core Shift.

From forums.autodesk.com

Core Shift Analysis Core contact detection Autodesk Community Engine Block Core Shift When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. That is to say, the core moves from its. The easiest way to check for core shift is to look at the cam and lifter bores. Even on a new block, this is. Engine Block Core Shift.

From ls1tech.com

LSX block question LS1TECH Camaro and Firebird Forum Discussion Engine Block Core Shift Sonic testing can tell you the thickness of the cylinder walls quickly and easily. The easiest way to check for core shift is to look at the cam and lifter bores. If they are in the center of the cast bulkhead in the. Core shift or core float—the movement of cores within the mold—sometimes causes problems as well. The term. Engine Block Core Shift.

From www.whichcar.com.au

Engine block preparation Tech Torque Engine Block Core Shift When you cast a block, they have to put cores in the mold to take up the space where the bore for instance is going to be. Finally, sand cleanout, especially from relatively small passages such. To remove any potential stress risers, use a die grinder and appropriate cutting bit to remove any casting flashings in the block. The term. Engine Block Core Shift.