Gear Position System . in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. The diagram below shows a simple gear system. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. position, velocity, and acceleration in gear systems: The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter.

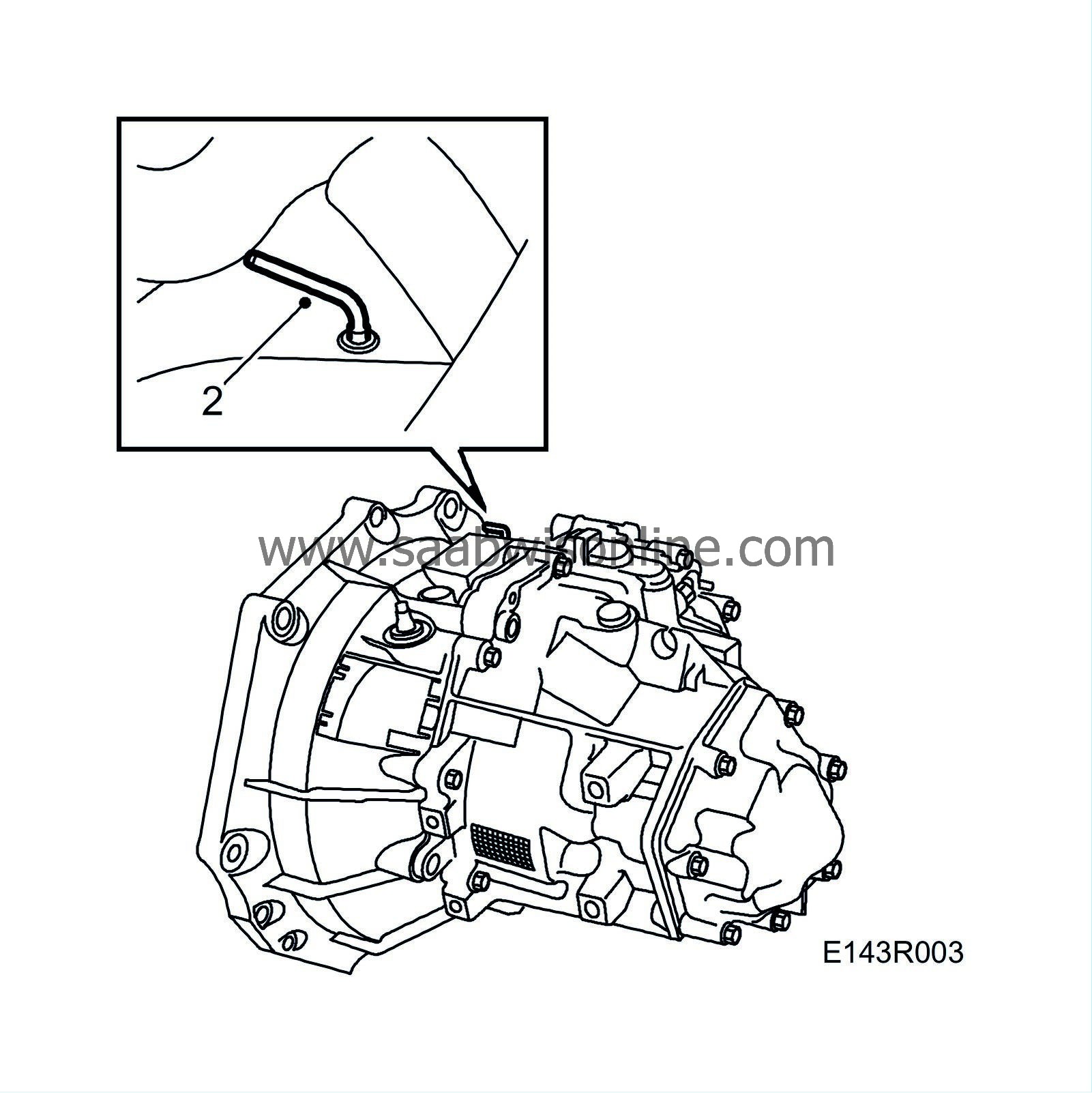

from saabwisonline.com

position, velocity, and acceleration in gear systems: gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. The diagram below shows a simple gear system. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts.

Checking and adjusting the gear position 95 2003 SAAB

Gear Position System realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The diagram below shows a simple gear system. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. position, velocity, and acceleration in gear systems: position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears.

From petersengineering.blogspot.com

an Engineer Boeing 767200/300 Main Landing Gear Gear Position System position, velocity, and acceleration in gear systems: realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The most basic case of a gear train is the transmission of rotation and. Gear Position System.

From saabwisonline.com

Checking and adjusting the gear position 95 2003 SAAB Gear Position System position, velocity, and acceleration in gear systems: The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. realizing precise and fast position control of the gear is. Gear Position System.

From mogcentral.com.au

Gearbox Gear Position Switch Mog Central Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a. Gear Position System.

From www.alamy.com

System of gear Stock Photo Alamy Gear Position System gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. realizing precise and fast position control of the gear is a challenging issue because of its. Gear Position System.

From www.eaton.com

Landing gear systems Eaton Gear Position System gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The diagram below shows a simple gear system. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. The most basic case of a gear train is the transmission of. Gear Position System.

From www.chegg.com

Solved In the gear system shown in Figure, the motor applies Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. position, velocity, and. Gear Position System.

From www.hondacarindia.com

Honda Jazz Owners Manual & other information Honda Car India Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. position, velocity, and. Gear Position System.

From inchbyinch.de

INCH Technical English pictorial derailleur gear system Gear Position System position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. realizing. Gear Position System.

From www.alamy.com

The driver hand is putting the gear lever to change the automatic gear Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. gear shifting force. Gear Position System.

From www.dreamstime.com

Change the Automatic Gear Position with the Driver Hand. Stock Image Gear Position System The diagram below shows a simple gear system. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The most basic case of a gear train is the transmission. Gear Position System.

From learndriving.tips

Why Are Gears Used in Cars » Learn Driving Tips Gear Position System gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. position, velocity, and acceleration in gear systems: The diagram below shows a simple gear system. gear shifting force refers to the. Gear Position System.

From www.researchgate.net

Gear installation position diagram. Download Scientific Diagram Gear Position System position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. . Gear Position System.

From www.youtube.com

BICYCLE BASICS Low vs High Gear Which Gear is Easier and Which is Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position, velocity, and acceleration in gear systems: realizing precise and fast position control of the gear is a. Gear Position System.

From www.dreamstime.com

Gear System Stock Photo Image 26319410 Gear Position System gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. The diagram below shows a simple gear system. in order to solve the problem of measuring various parameters and accuracy of. Gear Position System.

From www.tec-science.com

Transmission ratios of gears (Willis equation) tecscience Gear Position System gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The diagram below shows a simple gear system. The most basic case of a gear train is the transmission of. Gear Position System.

From www.howacarworks.com

How manual gearboxes work How a Car Works Gear Position System in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts.. Gear Position System.

From www.2carpros.com

Gear Position Sensor Where Does the Gear Position Sensor Go? Gear Position System realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. The diagram below shows a simple gear system. gearing systems are mechanisms that use gears to transmit motion,. Gear Position System.

From www.design-engineering.com

Picking the Right Linear Positioning Device Design Engineering Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new.. Gear Position System.

From resource.download.wjec.co.uk.s3.amazonaws.com

Design and Technology Gear Position System gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. The diagram below shows a simple gear system. realizing precise and fast position control of the gear is a. Gear Position System.

From flatshift.co.uk

Geartronics Sequential gearbox electronic systems Professional Gear Position System position, velocity, and acceleration in gear systems: gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. The diagram below shows a simple gear system. . Gear Position System.

From www.researchgate.net

circuit diagram for gear position and clutch engage/disengage mechanism Gear Position System The diagram below shows a simple gear system. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. position, velocity, and acceleration in gear systems: position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. gear shifting force refers to the. Gear Position System.

From www.geartronics.co.uk

Geartronics Sequential gearbox electronic systems Professional Gear Position System position, velocity, and acceleration in gear systems: gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. The diagram below shows a simple gear system. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. The most basic case of. Gear Position System.

From www.slideshare.net

Aircraft landing gear system Gear Position System The diagram below shows a simple gear system. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. gearing systems are mechanisms that use gears to transmit motion, force,. Gear Position System.

From 3d-mds-academy.com

Gear Fundamentals 3DMDS Academy Gear Position System in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position, velocity, and acceleration in gear systems: position sensors are used to ensure that a. Gear Position System.

From differenttypesofengineering.blogspot.com

Introduction to Steering Gear Different Types of Engineering Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears,. Gear Position System.

From www.tiger-explorer.com

How to change the Gear Position Sensor "How To" Technical Articles Gear Position System gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. . Gear Position System.

From blog.manchesterebikes.co.uk

eBike gear system options Manchester eBike Blog Gear Position System realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. position, velocity,. Gear Position System.

From www.century-of-flight.net

Retractable Landing Gear Explained Aviation History Century of Flight Gear Position System gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. The diagram below shows a simple gear system. in order to solve the problem of measuring various parameters and. Gear Position System.

From shipfever.com

Understanding Steering Gear System in Ships With Clarity ShipFever Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. The diagram below shows a simple gear system. in order to solve the problem of measuring various parameters and. Gear Position System.

From www.yourmechanic.com

How to Figure Out the Gear Ratio of Your Car YourMechanic Advice Gear Position System in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position, velocity, and acceleration in gear systems: The diagram below shows a simple gear system. . Gear Position System.

From www.chegg.com

Position analysis of a landing gear; the coordinates Gear Position System The diagram below shows a simple gear system. realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. position, velocity, and acceleration in gear systems: The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gearing systems are mechanisms that. Gear Position System.

From navyaviation.tpub.com

Figure 672.Landing gear position indicating system (A) typical; (B Gear Position System The most basic case of a gear train is the transmission of rotation and power between two parallel shafts. gear shifting force refers to the resistance that the control lever knob needs to overcome when engaging a certain gear. position, velocity, and acceleration in gear systems: realizing precise and fast position control of the gear is a. Gear Position System.

From www.aircraftsystemstech.com

Aircraft Systems Aircraft Landing Gear System Maintenance Gear Position System gearing systems are mechanisms that use gears to transmit motion, force, or power from one shaft to another. The diagram below shows a simple gear system. position, velocity, and acceleration in gear systems: position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. in order to solve the problem. Gear Position System.

From www.aircraftsystemstech.com

Aircraft Landing Gear Retraction Gear Position System position, velocity, and acceleration in gear systems: realizing precise and fast position control of the gear is a challenging issue because of its nonlinearity, parameter. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. The most basic case of a gear train is the transmission of rotation and power. Gear Position System.

From www.bodine-electric.com

Gearmotors > Bodine Electric Company Gear Position System in order to solve the problem of measuring various parameters and accuracy of internal and external straight cylindrical gears, a new. position sensors are used to ensure that a gear fork operates smoothly and safely when switching gears. The diagram below shows a simple gear system. realizing precise and fast position control of the gear is a. Gear Position System.