Plug Gage Tolerance Chart . Indicating gaging is typically mastered at maximum material condition. The go member would be specified as.4990” plus. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance selection, the 10% gage rule. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Master gages tolerance is split 50/50 gage maker's. Classes of threads are differentiated by the amount of tolerance and allowance specified.

from freyabaxter.z13.web.core.windows.net

On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Indicating gaging is typically mastered at maximum material condition. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Master gages tolerance is split 50/50 gage maker's. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance selection, the 10% gage rule. The go member would be specified as.4990” plus.

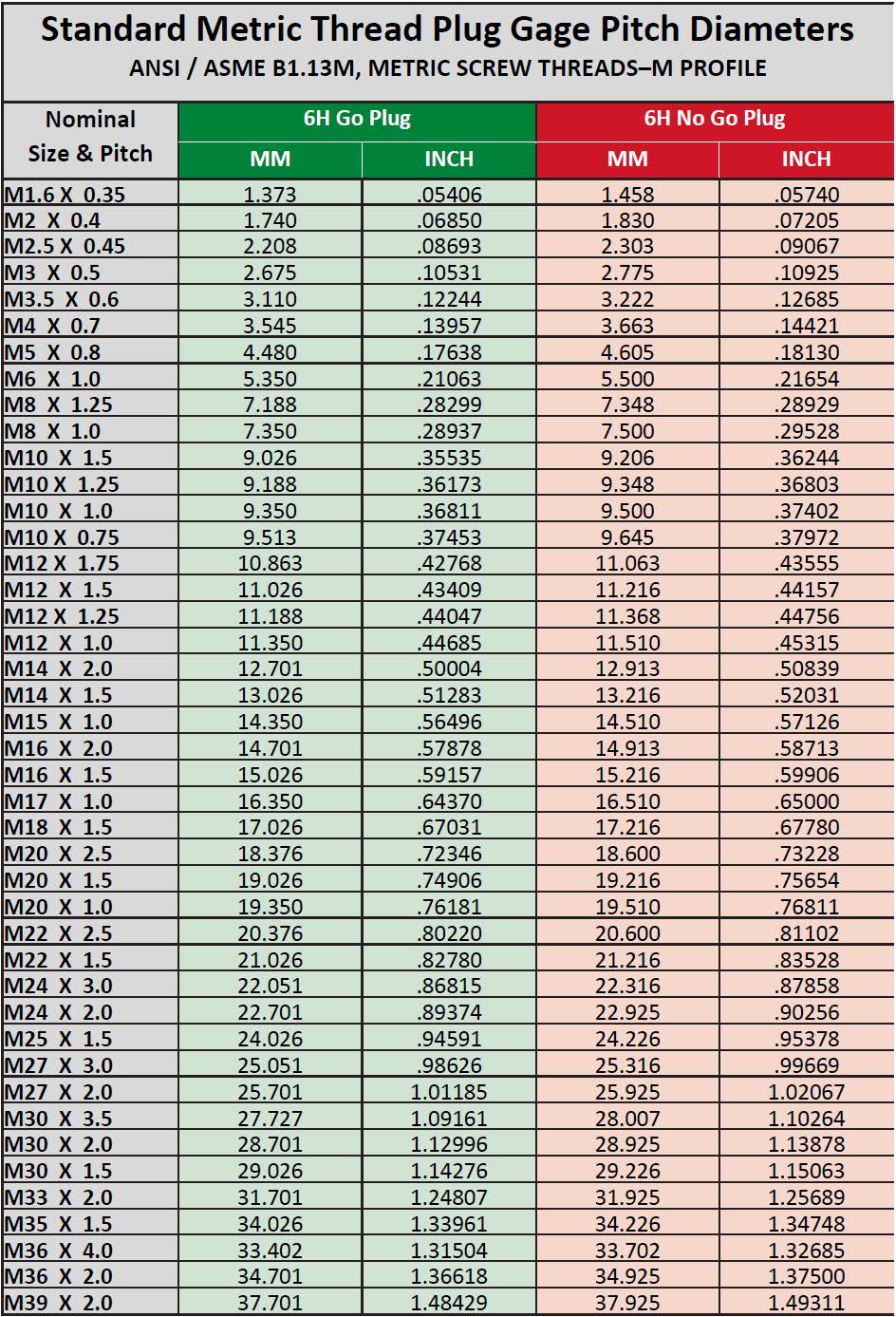

6h Thread Tolerance Chart

Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Indicating gaging is typically mastered at maximum material condition. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Master gages tolerance is split 50/50 gage maker's. Gage tolerance selection, the 10% gage rule. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The go member would be specified as.4990” plus.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Plug Gage Tolerance Chart The go member would be specified as.4990” plus. Indicating gaging is typically mastered at maximum material condition. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Master gages tolerance is split 50/50 gage maker's. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Classes of threads are differentiated. Plug Gage Tolerance Chart.

From www.engineersedge.com

International Tolerance (IT) Grades Table Chart Engineers Edge Plug Gage Tolerance Chart To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Indicating gaging is typically mastered at maximum material condition.. Plug Gage Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Plug Gage Tolerance Chart The go member would be specified as.4990” plus. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Indicating gaging is typically mastered at maximum material. Plug Gage Tolerance Chart.

From mungfali.com

Plain Plug Gauge Tolerance Chart Plug Gage Tolerance Chart Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Gage tolerance selection, the 10% gage rule. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Master gages tolerance is split 50/50 gage maker's. Indicating. Plug Gage Tolerance Chart.

From tillescenter.org

Vermont Gage 361149040 5/824 UNEF 3A NoGo Ring Gage tillescenter Test Plug Gage Tolerance Chart The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance selection, the 10% gage rule. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Indicating. Plug Gage Tolerance Chart.

From grmetrology.com

Plug Gage Calibration GR Metrology Plug Gage Tolerance Chart The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. The go member would be specified as.4990” plus. Classes of threads are differentiated by the amount of tolerance and allowance specified. Gage tolerance selection, the 10% gage rule. To calculate gage tolerances, the general rule of thumb is to. Plug Gage Tolerance Chart.

From www.tanfel.com

Industrial Metrology GO and NOGO Thread Plug Gauges Thread Gages Plug Gage Tolerance Chart Gage tolerance selection, the 10% gage rule. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. The go member would be specified as.4990” plus. Master gages tolerance is split 50/50 gage maker's. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. To calculate gage. Plug Gage Tolerance Chart.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Tolerance Chart On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Indicating gaging is typically mastered at maximum material condition. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Diameter tolerance chart reference. Plug Gage Tolerance Chart.

From cncpartschina03.blogspot.com

cnc turning parts Metric thread gages standard pitch diameter chart Plug Gage Tolerance Chart Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Master gages tolerance is split 50/50 gage maker's. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Indicating gaging is typically mastered at maximum material condition. Classes of threads are differentiated by the amount. Plug Gage Tolerance Chart.

From klazojxgt.blob.core.windows.net

What Is The Tolerance Of Thread Plug Gauge at Juan Gish blog Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. The go member would be specified as.4990” plus. Master gages tolerance is split 50/50 gage maker's. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Gage tolerance selection, the 10% gage rule. To calculate gage tolerances, the general rule of thumb is to use 10% of. Plug Gage Tolerance Chart.

From nabgauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Plug Gage Tolerance Chart Master gages tolerance is split 50/50 gage maker's. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. The go member would be. Plug Gage Tolerance Chart.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Tolerance Chart Gage tolerance selection, the 10% gage rule. Master gages tolerance is split 50/50 gage maker's. Classes of threads are differentiated by the amount of tolerance and allowance specified. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended. Plug Gage Tolerance Chart.

From www.scribd.com

10. Gage Tolerances PDF Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Gage tolerance selection, the 10% gage rule. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. To calculate gage tolerances, the general rule of thumb is to use 10% of. Plug Gage Tolerance Chart.

From www.judgetool.com

Thread Plug Gages STI (HELICOIL) Titanium Nitride Coated (Inch Plug Gage Tolerance Chart Gage tolerance selection, the 10% gage rule. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. The go member would be specified as.4990” plus. Cylindrical plug gage go member is to the plus side,. Plug Gage Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Plug Gage Tolerance Chart To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance. Plug Gage Tolerance Chart.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. The go member would be specified as.4990” plus. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Classes of threads are differentiated by the amount of tolerance and allowance. Plug Gage Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Plug Gage Tolerance Chart The go member would be specified as.4990” plus. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Indicating gaging is typically mastered at maximum material condition. Gage tolerance selection, the 10% gage rule. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Master gages tolerance is split. Plug Gage Tolerance Chart.

From willrich.com

Thread Gage Design and Thread Gages Designations Willich Plug Gage Tolerance Chart On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Indicating gaging is typically mastered at maximum material condition. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Master gages tolerance is split 50/50 gage maker's. The go member would be specified as.4990” plus. The chart of product tolerances. Plug Gage Tolerance Chart.

From dxodlrnxu.blob.core.windows.net

Plug Gauge Tolerance Chart Pdf at Carolyn Fredrick blog Plug Gage Tolerance Chart Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. Classes of threads are differentiated by the amount of tolerance and allowance specified. Gage tolerance selection, the 10% gage rule. The go member would be specified as.4990” plus. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. The. Plug Gage Tolerance Chart.

From mungfali.com

Plain Plug Gauge Tolerance Chart Plug Gage Tolerance Chart Master gages tolerance is split 50/50 gage maker's. Gage tolerance selection, the 10% gage rule. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. The go member would be specified as.4990”. Plug Gage Tolerance Chart.

From basicstomechanicalengineering.blogspot.com

Mechanical Engineering Basics International Tolerance Grade Plug Gage Tolerance Chart Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. Master gages tolerance is split 50/50 gage maker's. On the industry standard gagemaker. Plug Gage Tolerance Chart.

From www.colegiosantainescampestre.edu.co

Pipe Thread Plug Gages NPT NPTF ANPT Judge Tool Gage, 57 OFF Plug Gage Tolerance Chart Master gages tolerance is split 50/50 gage maker's. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Gage tolerance selection, the 10%. Plug Gage Tolerance Chart.

From www.teachtoearn.in

Gagemakers Tolerance Chart Willich Precision Instruments, 40 OFF Plug Gage Tolerance Chart Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Indicating gaging is typically mastered at maximum material condition. Classes of threads are differentiated by the amount of tolerance and allowance specified. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. The chart of product tolerances for plain. Plug Gage Tolerance Chart.

From bceweb.org

Spline Tolerance Chart A Visual Reference of Charts Chart Master Plug Gage Tolerance Chart On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The go member would be specified as.4990” plus. Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance. Plug Gage Tolerance Chart.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Tolerance Chart To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Master gages tolerance is split 50/50 gage maker's. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. The chart of product. Plug Gage Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Plug Gage Tolerance Chart On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Gage tolerance selection, the 10% gage rule. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Classes of threads are differentiated. Plug Gage Tolerance Chart.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Plug Gage Tolerance Chart Classes of threads are differentiated by the amount of tolerance and allowance specified. Master gages tolerance is split 50/50 gage maker's. Indicating gaging is typically mastered at maximum material condition. Gage tolerance selection, the 10% gage rule. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. To calculate gage tolerances, the general rule of thumb is. Plug Gage Tolerance Chart.

From www.shars.com

5/1618 Go/No Go Double End Thread Plug Gage Plug Gage Tolerance Chart Classes of threads are differentiated by the amount of tolerance and allowance specified. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical. Plug Gage Tolerance Chart.

From www.torq-n-seal.com

Torq N' Seal® High Pressure Tube Plugs Tips and Tricks Plug Gage Tolerance Chart The go member would be specified as.4990” plus. Gage tolerance selection, the 10% gage rule. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator for plain cylindrical i.d. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Indicating gaging is typically mastered at maximum material condition. Classes of threads are differentiated by the amount of. Plug Gage Tolerance Chart.

From freyabaxter.z13.web.core.windows.net

6h Thread Tolerance Chart Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. Gage tolerance selection, the 10% gage rule. The chart of product tolerances for plain plug and ring gages may be used as a guide for recommended gage tolerance. Classes of threads are differentiated by the amount of tolerance and allowance specified. Diameter tolerance chart reference (ansi/asme b89.1.5) meyer gage tolerance calculator. Plug Gage Tolerance Chart.

From dxodlrnxu.blob.core.windows.net

Plug Gauge Tolerance Chart Pdf at Carolyn Fredrick blog Plug Gage Tolerance Chart Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Gage tolerance selection, the 10% gage rule. Indicating gaging is typically mastered at. Plug Gage Tolerance Chart.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Plug Gage Tolerance Chart Master gages tolerance is split 50/50 gage maker's. To calculate gage tolerances, the general rule of thumb is to use 10% of your part tolerance. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. The go member would be specified as.4990” plus. The chart of product tolerances for plain plug and ring. Plug Gage Tolerance Chart.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Tolerance Chart On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. Indicating gaging is typically mastered at maximum material condition. Gage tolerance selection, the 10% gage rule. Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. The. Plug Gage Tolerance Chart.

From mavink.com

Plug Gauge Tolerance Chart Plug Gage Tolerance Chart Cylindrical plug gage go member is to the plus side, nogo member is to the minus side. Indicating gaging is typically mastered at maximum material condition. The go member would be specified as.4990” plus. Classes of threads are differentiated by the amount of tolerance and allowance specified. Master gages tolerance is split 50/50 gage maker's. Diameter tolerance chart reference (ansi/asme. Plug Gage Tolerance Chart.

From mavink.com

Gage Makers Tolerance Chart Plug Gage Tolerance Chart Indicating gaging is typically mastered at maximum material condition. On the industry standard gagemaker chart,.0001” is classified as a class z tolerance. The go member would be specified as.4990” plus. Classes of threads are differentiated by the amount of tolerance and allowance specified. Gage tolerance selection, the 10% gage rule. To calculate gage tolerances, the general rule of thumb is. Plug Gage Tolerance Chart.