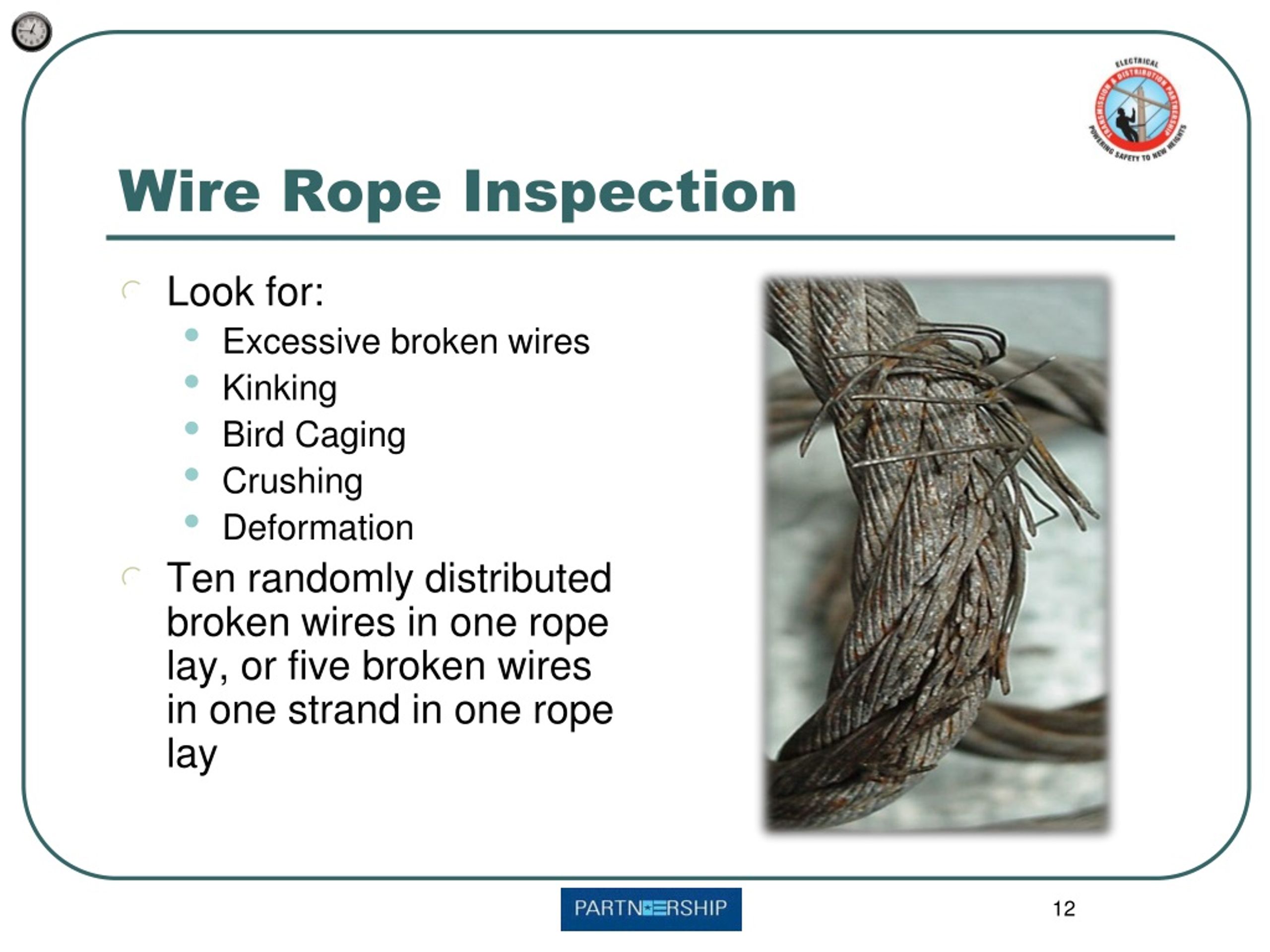

Visual Inspection Of Wire Rope Slings . If necessary, remove dirt and grime so wires. The person inspecting the sling should check for major. Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: Wire ropes receive two types of inspections: A visual inspection should be performed whenever a wire rope sling is used. This inspection should look for any signs of damage, such as broken wires,. A daily visual inspection the person handling the sling must do this each day and should. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. Wire rope slings must be visually inspected before use. A prior to use visual inspec tion, and additional. A daily visual inspection the person handling the sling must do this each day. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible.

from www.slideserve.com

Slings with excessive broken wires, severe corrosion, localized wear, damage to end. The person inspecting the sling should check for major. Wire rope slings must be visually inspected before use. A prior to use visual inspec tion, and additional. A daily visual inspection the person handling the sling must do this each day. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. If necessary, remove dirt and grime so wires. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. This inspection should look for any signs of damage, such as broken wires,. A daily visual inspection the person handling the sling must do this each day and should.

PPT Wire Rope Inspection PowerPoint Presentation, free download ID

Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. Wire ropes receive two types of inspections: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. A visual inspection should be performed whenever a wire rope sling is used. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. Wire rope slings must be visually inspected before use. The person inspecting the sling should check for major. A daily visual inspection the person handling the sling must do this each day. A prior to use visual inspec tion, and additional. If necessary, remove dirt and grime so wires. This inspection should look for any signs of damage, such as broken wires,. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. A daily visual inspection the person handling the sling must do this each day and should. Both astm b.30.9 regulations require that wire rope slings receive two types of inspections:

From www.slideserve.com

PPT Wire Rope Inspection PowerPoint Presentation, free download ID Visual Inspection Of Wire Rope Slings To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. Wire ropes receive two types of inspections: Wire rope slings must be visually inspected before use. A daily visual inspection the person handling the sling. Visual Inspection Of Wire Rope Slings.

From klatzozkz.blob.core.windows.net

Inspection Criteria For Wire Rope Slings at Kathleen German blog Visual Inspection Of Wire Rope Slings The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. This inspection should look for any signs of damage, such as broken wires,. A prior to use visual inspec tion, and additional. A daily visual inspection the person handling the sling must do. Visual Inspection Of Wire Rope Slings.

From vdocuments.mx

NWWRInspectionofSlings NW Wire Rope Visual Inspection Of Wire Rope Slings A prior to use visual inspec tion, and additional. If necessary, remove dirt and grime so wires. This inspection should look for any signs of damage, such as broken wires,. Wire rope slings must be visually inspected before use. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work. Visual Inspection Of Wire Rope Slings.

From www.linkedin.com

Steel Wire Rope Inspections Visual and Rope Testing Methods Visual Inspection Of Wire Rope Slings A prior to use visual inspec tion, and additional. Wire ropes receive two types of inspections: A daily visual inspection the person handling the sling must do this each day. The person inspecting the sling should check for major. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling. Visual Inspection Of Wire Rope Slings.

From www.youtube.com

WIRE ROPE/SLING INSPECTION & EXAMINATION YouTube Visual Inspection Of Wire Rope Slings A visual inspection should be performed whenever a wire rope sling is used. Wire ropes receive two types of inspections: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. To. Visual Inspection Of Wire Rope Slings.

From wiretest.ru

Tool Set for Visual Inspection of Steel Wire Ropes wiretest.ru Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. If necessary, remove dirt and grime so wires. A visual inspection should be performed whenever a wire rope sling is used. The person inspecting the sling should check for major. Wire ropes receive two types of inspections: Wire rope slings must be visually inspected. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings If necessary, remove dirt and grime so wires. Wire ropes receive two types of inspections: Wire rope slings must be visually inspected before use. The person inspecting the sling should check for major. A prior to use visual inspec tion, and additional. A daily visual inspection the person handling the sling must do this each day. The purpose of a. Visual Inspection Of Wire Rope Slings.

From topslings.com.my

Visual Inspection & Certification Wire Rope, Slings & Lifting Visual Inspection Of Wire Rope Slings Slings with excessive broken wires, severe corrosion, localized wear, damage to end. A visual inspection should be performed whenever a wire rope sling is used. A daily visual inspection the person handling the sling must do this each day. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work. Visual Inspection Of Wire Rope Slings.

From www.katradis.com

Wire Rope Inspection & Maintenance A full guide Katradis Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. If necessary, remove dirt and grime so wires. The person inspecting the sling should check for major. This inspection should look for any signs of damage, such as broken wires,. To detect possible damage, you should perform a visual inspection of the entire sling. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. A visual inspection should be performed whenever a wire rope sling is used. A prior to use visual inspec tion, and additional. This inspection should look for any signs of damage, such as. Visual Inspection Of Wire Rope Slings.

From store.iti.com

Wire Rope Inspection Guidelines (25/pack) ITI Bookstore Visual Inspection Of Wire Rope Slings To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. This inspection should look for any signs of damage, such. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. Wire rope slings must be visually inspected before use. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. This inspection should look for any signs of. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect a Synthetic Sling to OSHA and ASME Standards Visual Inspection Of Wire Rope Slings Slings with excessive broken wires, severe corrosion, localized wear, damage to end. If necessary, remove dirt and grime so wires. Wire ropes receive two types of inspections: This inspection should look for any signs of damage, such as broken wires,. Wire rope slings must be visually inspected before use. A visual inspection should be performed whenever a wire rope sling. Visual Inspection Of Wire Rope Slings.

From www.indiamart.com

Wire Rope Sling Inspection Certification Service in Vadodara Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day. The person inspecting the sling should check for major. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. Wire rope slings must be visually inspected before use. If necessary, remove dirt and. Visual Inspection Of Wire Rope Slings.

From www.alatas.com

Annual Wire Rope Inspections Alatas Visual Inspection Of Wire Rope Slings The person inspecting the sling should check for major. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. A daily visual inspection the person handling the sling must do this. Visual Inspection Of Wire Rope Slings.

From www.youtube.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards L Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. A prior to use visual inspec tion, and additional. If necessary, remove dirt and grime so wires.. Visual Inspection Of Wire Rope Slings.

From resources.herculesslr.com

Wire Rope Sling Inspection Hercules SLR Visual Inspection Of Wire Rope Slings Slings with excessive broken wires, severe corrosion, localized wear, damage to end. The person inspecting the sling should check for major. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. Wire ropes receive two types of inspections: This inspection should look for any signs of damage,. Visual Inspection Of Wire Rope Slings.

From www.youtube.com

LiftAll Wire Rope Sling Inspection YouTube Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. Wire ropes receive two types of inspections: If necessary, remove dirt and grime so wires. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Slings with. Visual Inspection Of Wire Rope Slings.

From www.certifiedslings.com

Wire Rope Warnings & Inspection Guide Certified Slings & Supply Visual Inspection Of Wire Rope Slings To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. A daily visual inspection the person handling the sling must do this each day. A prior to use visual inspec tion, and additional. This inspection should look for any signs of damage, such as broken wires,. The. Visual Inspection Of Wire Rope Slings.

From almonaliza.com

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing, 59 OFF Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day. Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: The person inspecting the sling should check for major. A daily visual inspection the person handling the sling must do this each day and should. A prior to use visual inspec tion,. Visual Inspection Of Wire Rope Slings.

From www.kwrs.com

Wire Rope Slings Wire Rope Sling Inspection Kennedy Wire Rope and Sling Visual Inspection Of Wire Rope Slings A visual inspection should be performed whenever a wire rope sling is used. The person inspecting the sling should check for major. Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: If necessary, remove dirt and grime so wires. Wire ropes receive two types of inspections: A daily visual inspection the person handling the sling. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day. A daily visual inspection the person handling the sling must do this each day and should. If necessary, remove dirt and grime so wires. A prior to use visual inspec tion, and additional. A visual inspection should be performed whenever a wire rope sling is used.. Visual Inspection Of Wire Rope Slings.

From www.techknowserv.com

Wire Rope Testing A Review of Different Nondestructive Testing Methods Visual Inspection Of Wire Rope Slings Slings with excessive broken wires, severe corrosion, localized wear, damage to end. A visual inspection should be performed whenever a wire rope sling is used. A daily visual inspection the person handling the sling must do this each day. The person inspecting the sling should check for major. To detect possible damage, you should perform a visual inspection of the. Visual Inspection Of Wire Rope Slings.

From topslings.com.my

Visual Inspection & Certification Wire Rope, Slings & Lifting Visual Inspection Of Wire Rope Slings Wire rope slings must be visually inspected before use. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. A daily visual inspection the person handling the sling must do this each day and should. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be. Visual Inspection Of Wire Rope Slings.

From www.liftshift.co.za

Steel Wire Rope Slings Visual Inspection Of Wire Rope Slings Slings with excessive broken wires, severe corrosion, localized wear, damage to end. The person inspecting the sling should check for major. A prior to use visual inspec tion, and additional. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Both astm b.30.9. Visual Inspection Of Wire Rope Slings.

From www.youtube.com

LiftAll Wire Rope Sling How to Inspect for Damage YouTube Visual Inspection Of Wire Rope Slings Wire ropes receive two types of inspections: Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: The person inspecting the sling should check for major. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. A daily visual. Visual Inspection Of Wire Rope Slings.

From inspectiongc.com

Wire Rope Inspection Inspection GC Visual Inspection Of Wire Rope Slings A daily visual inspection the person handling the sling must do this each day and should. If necessary, remove dirt and grime so wires. Wire rope slings must be visually inspected before use. A daily visual inspection the person handling the sling must do this each day. The purpose of a sling inspection is to determine if a wire rope. Visual Inspection Of Wire Rope Slings.

From smathanshse.blogspot.com

HSE Insider Steel Wire Rope Sling Inspection Part 1 Visual Inspection Of Wire Rope Slings This inspection should look for any signs of damage, such as broken wires,. A daily visual inspection the person handling the sling must do this each day. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. To detect possible damage, you should. Visual Inspection Of Wire Rope Slings.

From klatzozkz.blob.core.windows.net

Inspection Criteria For Wire Rope Slings at Kathleen German blog Visual Inspection Of Wire Rope Slings A visual inspection should be performed whenever a wire rope sling is used. A daily visual inspection the person handling the sling must do this each day and should. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Wire rope slings must. Visual Inspection Of Wire Rope Slings.

From klatzozkz.blob.core.windows.net

Inspection Criteria For Wire Rope Slings at Kathleen German blog Visual Inspection Of Wire Rope Slings A prior to use visual inspec tion, and additional. A visual inspection should be performed whenever a wire rope sling is used. Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: The person inspecting the sling should check for major. The purpose of a sling inspection is to determine if a wire rope sling retains. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

Wire Rope Sling Inspection and Removal Criteria Mazzella Visual Inspection Of Wire Rope Slings This inspection should look for any signs of damage, such as broken wires,. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. Slings with excessive broken wires, severe corrosion, localized wear, damage to end. A visual inspection should be performed whenever a wire rope sling is. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings Both astm b.30.9 regulations require that wire rope slings receive two types of inspections: If necessary, remove dirt and grime so wires. A prior to use visual inspec tion, and additional. The person inspecting the sling should check for major. A daily visual inspection the person handling the sling must do this each day and should. A visual inspection should. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Visual Inspection Of Wire Rope Slings A prior to use visual inspec tion, and additional. Wire rope slings must be visually inspected before use. A visual inspection should be performed whenever a wire rope sling is used. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. The person inspecting the sling should. Visual Inspection Of Wire Rope Slings.

From www.mazzellacompanies.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards Visual Inspection Of Wire Rope Slings Wire rope slings must be visually inspected before use. The person inspecting the sling should check for major. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. To detect possible damage, you should perform a visual inspection of the entire sling by. Visual Inspection Of Wire Rope Slings.

From www.hhilifting.com

Wire Rope Slings Guide for Accurate Inspection, Replacement and Visual Inspection Of Wire Rope Slings The person inspecting the sling should check for major. This inspection should look for any signs of damage, such as broken wires,. To detect possible damage, you should perform a visual inspection of the entire sling by making all parts of the sling readily visible. A daily visual inspection the person handling the sling must do this each day. Slings. Visual Inspection Of Wire Rope Slings.