Plastic Profile Extrusion . The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as.

from www.mbbrfiltermedia.com

This process does not include forming sheet or film products. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Profile extrusion is the process of creating continuous shapes of plastic through extrusion.

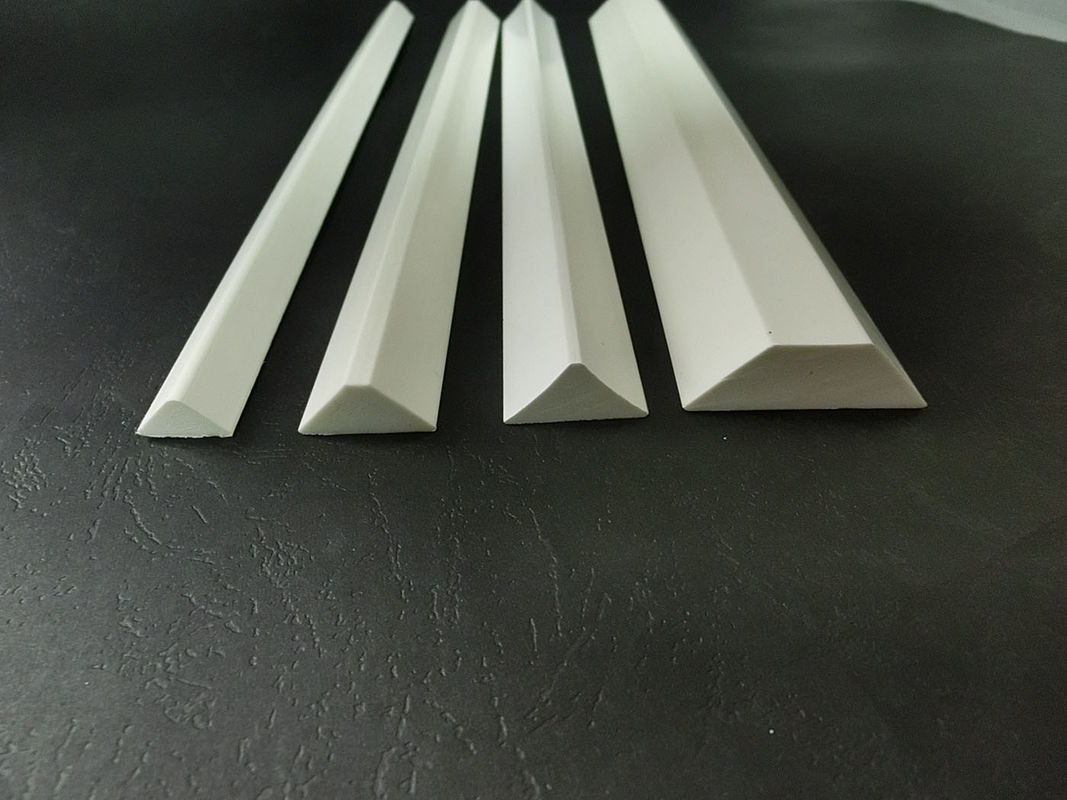

Plastic Extrusion Profiles Waterproof

Plastic Profile Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This process does not include forming sheet or film products. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs.

From rt-plastic-extrusion.en.made-in-china.com

PVC/ABS/PC Polycarbonate Plastic Extrusion Extruded Profiles China Plastic Profile Extrusion Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. This process does not. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow. Plastic Profile Extrusion.

From www.eaton.com

Plastics Custom Profile Extrusion Eaton Plastic Profile Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. This process. Plastic Profile Extrusion.

From

Plastic Profile Extrusion This process does not include forming sheet or film products. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. The plastic products produced by profile extrusion can be solid (like vinyl siding) or. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. This process does not include forming sheet or film products. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers. Plastic Profile Extrusion.

From

Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Profile extrusion is the process. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. The plastic products produced by profile extrusion can be. Plastic Profile Extrusion.

From

Plastic Profile Extrusion The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Plastic extrusions are sometimes referred to as plastic sections or profiles and. Plastic Profile Extrusion.

From

Plastic Profile Extrusion The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion. Plastic Profile Extrusion.

From zauderer.com

Plastic Extrusion Profiles Zauderer Associates Plastic Profile Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic. Plastic Profile Extrusion.

From www.dwplastics.co.uk

Plastic Extrusions for Construction Building Products DW Plastics Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. This process does not include forming sheet or film products. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. It offers design engineering, tooling, fabrication and 3d printing services for custom. Plastic Profile Extrusion.

From

Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. This process does not include forming sheet or film products. Plastic. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. This process does not include forming sheet or film products. Plastic extrusion is a process where granular pieces of plastics go through. Plastic Profile Extrusion.

From

Plastic Profile Extrusion The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Explore the world of plastic extrusion — its definition, purpose,. Plastic Profile Extrusion.

From www.northlandplastics.com

Polyethylene Extrusions Custom HDPE, LDPE & MDPE Profiles Plastic Profile Extrusion Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. This process does not include forming sheet or film products. Plastic extrusion is a process. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow. Plastic Profile Extrusion.

From

Plastic Profile Extrusion This process does not include forming sheet or film products. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a.. Plastic Profile Extrusion.

From www.youtube.com

U/PVC & F/PVC PROFILES COEXTRUSION LINE YouTube Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Plastic extrusions are sometimes referred to as plastic sections or. Plastic Profile Extrusion.

From www.jwellextruderglobal.com

Special Plastic Profile Extrusion Line Manufacturer Jwell Machinery Plastic Profile Extrusion The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. This process does not include forming sheet or film products. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder. Plastic Profile Extrusion.

From

Plastic Profile Extrusion This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier. Plastic Profile Extrusion.

From

Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic extrusions are sometimes referred to as plastic sections or. Plastic Profile Extrusion.

From www.northlandplastics.com

Plastic Profile Extrusion Capability Northland Wisconsin Plastic Profile Extrusion Profile extrusion is the process of creating continuous shapes of plastic through extrusion. This process does not include forming sheet or film products. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Plastic extrusions are sometimes referred to as. Plastic Profile Extrusion.

From www.mbbrfiltermedia.com

Plastic Extrusion Profiles Waterproof Plastic Profile Extrusion The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Plastic extrusion is a process where granular pieces of plastics. Plastic Profile Extrusion.

From www.dwplastics.co.uk

Plastic Extrusion Profiles D W Plastics Plastic Profile Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier of plastic profile. Plastic Profile Extrusion.

From lakelandplastics.com

Plastic Extrusion Custom Plastic Extrusion Profiles Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs.. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusions are sometimes referred. Plastic Profile Extrusion.

From www.merchantcircle.com

The Basic Principles Of Plastic Extruded Profiles Keller Plastics in Plastic Profile Extrusion Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a.. Plastic Profile Extrusion.

From www.everplast.com.tw

PVC PROFILE EXTRUSION LINE Everplast Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Profile extrusion is the process of creating continuous. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. This process does not include forming sheet or film products. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Profile extrusion is the process of. Plastic Profile Extrusion.

From

Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. The plastic products produced by profile extrusion can be solid (like vinyl siding) or hollow (like drinking straws). Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various. Plastic Profile Extrusion.

From

Plastic Profile Extrusion It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. This process does not include forming sheet or film products. Explore the world of plastic extrusion — its definition, purpose, working, advantages, disadvantages, and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up. Plastic Profile Extrusion.

From

Plastic Profile Extrusion This process does not include forming sheet or film products. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up. Plastic Profile Extrusion.

From www.indiamart.com

Manufacturer of PVC Extrusion Profile & Plastic Extrusion Profile by Plastic Profile Extrusion Lakeland plastics is a manufacturer and supplier of plastic profile extrusion products for various industries and applications. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. It offers design engineering, tooling, fabrication and 3d. Plastic Profile Extrusion.

From

Plastic Profile Extrusion Plastic extrusions are sometimes referred to as plastic sections or profiles and are produced using a piece of equipment known as. It offers design engineering, tooling, fabrication and 3d printing services for custom plastic extrusion needs. Profile extrusion is the process of creating continuous shapes of plastic through extrusion. This process does not include forming sheet or film products. Plastic. Plastic Profile Extrusion.