End Milling Diagram . This feature is produced by a dish angle produced on the cutter. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. The profile refers to the shape of the cutting end of the tool. Square, corner radius, and ball. It is typically one of three options: The sharp edge of the end mill tooth. Face milling and end milling are two similar milling processes with distinct tooling and applications. Cutting edges are only on a top. Diagram of the end milling process. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Side milling, curved surface milling. In this guide, we will look at some critical processes in the end milling process. From definition, classification, advantages to. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. Learn more about face milling vs.

from www.mechical.com

In this guide, we will look at some critical processes in the end milling process. Square, corner radius, and ball. Diagram of the end milling process. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. From definition, classification, advantages to. The profile refers to the shape of the cutting end of the tool. All the details on these. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces.

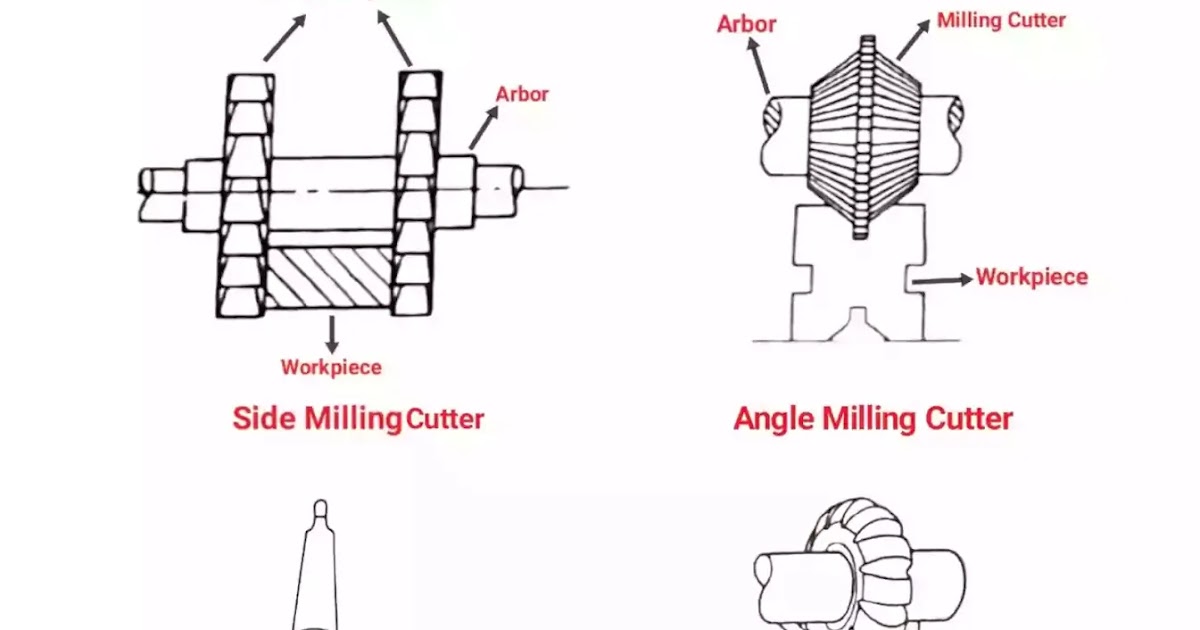

Types of Milling Cutters and Their Uses,Cutting Principle,Feed

End Milling Diagram Diagram of the end milling process. It is typically one of three options: All the details on these. Cutting edges are only on a top. In this guide, we will look at some critical processes in the end milling process. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. Square, corner radius, and ball. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. This feature is produced by a dish angle produced on the cutter. The sharp edge of the end mill tooth. The profile refers to the shape of the cutting end of the tool. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Side milling, curved surface milling. Diagram of the end milling process. Face milling and end milling are two similar milling processes with distinct tooling and applications.

From www.cncmasters.com

The 8 Most Important Parts of a Milling Machine CNC Masters End Milling Diagram All the details on these. Face milling and end milling are two similar milling processes with distinct tooling and applications. It is typically one of three options: Learn more about face milling vs. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. The profile refers. End Milling Diagram.

From www.researchgate.net

Cutting forces for ballend milling process a schematic diagram of End Milling Diagram The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. Face milling and end milling are two similar. End Milling Diagram.

From www.3qmachining.com

What Is Face Milling Cutter 3Q Machining End Milling Diagram The sharp edge of the end mill tooth. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. From definition, classification, advantages to. Side milling, curved surface milling. All the details on these. Cutting edges are only on a top. The size measured as a straight line across the center of. End Milling Diagram.

From www.autodesk.com

Top 8 Milling Tools for CNC Cutting Fusion 360 Blog End Milling Diagram Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Side milling, curved surface milling. It is typically one of three options: In this guide, we will look at some critical processes in the end. End Milling Diagram.

From jordonhefner.blogspot.com

roughing end mill cutter diagram Jordon Hefner End Milling Diagram The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Cutting edges are only on a top. This feature is produced by a dish angle produced on the cutter. Face milling and end milling are two similar milling processes with distinct tooling and applications. The size measured as a straight line. End Milling Diagram.

From www.researchgate.net

Schematic for calculation of material removal rate during end milling End Milling Diagram Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. The sharp edge of the end mill tooth. This feature is produced by a dish angle produced on the cutter. From definition, classification, advantages to. Cutting edges are only on a top. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other. End Milling Diagram.

From solutionpharmacy.in

Construction, Working of End Runner Mill Solution Parmacy End Milling Diagram Learn more about face milling vs. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Diagram of the end milling process. The profile refers to the shape of the cutting end of the tool. In this guide, we will look at some critical processes in the end milling process. The. End Milling Diagram.

From mavink.com

Milling Machine Labeled Diagram End Milling Diagram Diagram of the end milling process. Square, corner radius, and ball. The profile refers to the shape of the cutting end of the tool. All the details on these. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. From definition, classification, advantages to. In this guide, we will look at. End Milling Diagram.

From www.researchgate.net

Schematic representation of end milling operation Download Scientific End Milling Diagram The profile refers to the shape of the cutting end of the tool. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Side milling, curved surface milling. This feature is produced by a dish angle produced on the cutter. Square, corner radius, and ball. Diagram of the end milling process.. End Milling Diagram.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Milling Diagram Learn more about face milling vs. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. Cutting edges are only on a top. It is typically one of three options: The profile refers to the shape of the cutting end of the. End Milling Diagram.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 PowerPoint Presentation, free End Milling Diagram Square, corner radius, and ball. Diagram of the end milling process. Learn more about face milling vs. Face milling and end milling are two similar milling processes with distinct tooling and applications. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. It is typically one of three options: Side milling, curved surface milling.. End Milling Diagram.

From engineeringlearn.com

Operation of Milling Machine Engineering Learn End Milling Diagram The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. From definition, classification, advantages to. Square, corner radius, and ball. Diagram of the end milling process. Side milling, curved surface milling. It is typically one of three options: This feature is produced by a dish angle produced on the cutter. The. End Milling Diagram.

From dusan.sts.si

Frezanje Tehnologija na End Milling Diagram Square, corner radius, and ball. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. Side milling, curved surface milling. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Face milling and end milling are two similar milling processes. End Milling Diagram.

From mungfali.com

Diagram Of Milling Machine End Milling Diagram Learn more about face milling vs. Square, corner radius, and ball. Side milling, curved surface milling. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. This feature is produced by a dish angle produced on the cutter. In this guide, we will look at some critical processes in the end milling process. All. End Milling Diagram.

From www.researchgate.net

Diagram of side milling process Download Scientific Diagram End Milling Diagram The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. The profile refers to the shape of the cutting end of the tool. Diagram of the end milling process. Square, corner radius, and ball. In this guide, we will look at some critical processes in the. End Milling Diagram.

From www.mechanicalbooster.com

What is Milling Machine Operation, Parts and Types. Mechanical Booster End Milling Diagram All the details on these. Square, corner radius, and ball. In this guide, we will look at some critical processes in the end milling process. Side milling, curved surface milling. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. Learn more. End Milling Diagram.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers End Milling Diagram The sharp edge of the end mill tooth. Side milling, curved surface milling. Cutting edges are only on a top. In this guide, we will look at some critical processes in the end milling process. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. The. End Milling Diagram.

From www.transtutors.com

(Solved) Question 1 By using a labelled diagram describe the function End Milling Diagram The profile refers to the shape of the cutting end of the tool. Side milling, curved surface milling. All the details on these. Cutting edges are only on a top. Learn more about face milling vs. The sharp edge of the end mill tooth. The size measured as a straight line across the center of a theoretical circle formed by. End Milling Diagram.

From www.researchgate.net

Illustration of end milling process. Download Scientific Diagram End Milling Diagram This feature is produced by a dish angle produced on the cutter. The sharp edge of the end mill tooth. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. The size measured as a straight line across the center of a. End Milling Diagram.

From ksp-group.ir

فرز سی ان سی فرز cnc چیست ؟ خاوران صنعت پاسارگاد End Milling Diagram Cutting edges are only on a top. Square, corner radius, and ball. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. From definition, classification, advantages to. In this guide, we will look at some critical processes in the end milling process.. End Milling Diagram.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits End Milling Diagram It is typically one of three options: The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Diagram of the end milling process. From definition, classification, advantages to. The sharp edge of the end mill tooth. Face milling and end milling are two similar milling processes. End Milling Diagram.

From toolnotes.com

Milling Operations ToolNotes End Milling Diagram The profile refers to the shape of the cutting end of the tool. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. Side milling, curved surface milling. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. The size measured as a straight line. End Milling Diagram.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Milling Diagram From definition, classification, advantages to. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Diagram of the end milling process. Learn more about face milling vs. Cutting edges are only on a top. All the details on these. Square, corner radius, and ball. Face milling. End Milling Diagram.

From edwardocooley.blogspot.com

roughing end mill cutter diagram Edwardo Cooley End Milling Diagram The sharp edge of the end mill tooth. Learn more about face milling vs. In this guide, we will look at some critical processes in the end milling process. Cutting edges are only on a top. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates.. End Milling Diagram.

From www.rapiddirect.com

CNC Machining vs Manual Machining Which is Better RapidDirect Blog End Milling Diagram Learn more about face milling vs. This feature is produced by a dish angle produced on the cutter. Face milling and end milling are two similar milling processes with distinct tooling and applications. From definition, classification, advantages to. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. End milling operation. End Milling Diagram.

From www.researchgate.net

Schematic diagram of the end milling experimental setup. Download End Milling Diagram The sharp edge of the end mill tooth. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. All the details on these. Learn more about face milling vs. Square,. End Milling Diagram.

From technologystudent.com

The Horizontal Milling Machine End Milling Diagram Square, corner radius, and ball. Learn more about face milling vs. The sharp edge of the end mill tooth. The profile refers to the shape of the cutting end of the tool. Cutting edges are only on a top. This feature is produced by a dish angle produced on the cutter. Diagram of the end milling process. The size measured. End Milling Diagram.

From toolnotes.com

End Mills ToolNotes End Milling Diagram Learn more about face milling vs. From definition, classification, advantages to. Diagram of the end milling process. The purpose of end milling is to precisely cut and shape materials to create specific features, profiles, and surfaces. Square, corner radius, and ball. Side milling, curved surface milling. Face milling and end milling are two similar milling processes with distinct tooling and. End Milling Diagram.

From www.toptechdiamond.com

All About Drilling and Milling Special Carbide and Diamond Tools End Milling Diagram The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Cutting edges are only on a top. This feature is produced by a dish angle produced on the cutter. The sharp edge of the end mill tooth. Face milling and end milling are two similar milling. End Milling Diagram.

From atelier-yuwa.ciao.jp

Slot Milling Diagram atelieryuwa.ciao.jp End Milling Diagram Square, corner radius, and ball. The sharp edge of the end mill tooth. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. From definition, classification, advantages to. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from. End Milling Diagram.

From www.mechical.com

Types of Milling Cutters and Their Uses,Cutting Principle,Feed End Milling Diagram The sharp edge of the end mill tooth. The size measured as a straight line across the center of a theoretical circle formed by the cutting edges as the end mill rotates. Side milling, curved surface milling. All the details on these. End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from. End Milling Diagram.

From mungfali.com

End Mill Drawings End Milling Diagram From definition, classification, advantages to. The profile refers to the shape of the cutting end of the tool. Side milling, curved surface milling. Learn more about face milling vs. It is typically one of three options: Diagram of the end milling process. The size measured as a straight line across the center of a theoretical circle formed by the cutting. End Milling Diagram.

From www.researchgate.net

Coordinate system involved in ballend milling operation as shown with End Milling Diagram The profile refers to the shape of the cutting end of the tool. Cutting edges are only on a top. The sharp edge of the end mill tooth. From definition, classification, advantages to. It is typically one of three options: Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. Face milling and end. End Milling Diagram.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures End Milling Diagram End milling operation produces flat vertical surfaces, flat horizontal surfaces, and other flat surfaces making an angle from table surface using milling cutter named as an end mill. Diagram of the end milling process. The sharp edge of the end mill tooth. The size measured as a straight line across the center of a theoretical circle formed by the cutting. End Milling Diagram.

From themechanicalengineering.com

Milling Machine Definition, Parts, Operation, Working Principle End Milling Diagram The sharp edge of the end mill tooth. Square profile tooling features flutes with sharp corners that are squared off at a 90° angle. All the details on these. Face milling and end milling are two similar milling processes with distinct tooling and applications. Diagram of the end milling process. Learn more about face milling vs. Cutting edges are only. End Milling Diagram.