How To Calculate Cycle Time For Cnc Turning Pdf . Combine cycle time with takt time and available work time to schedule production and labor allocation. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Detailed information on formula for turning. In addition to an overview of cutting tools, safety and precautions, information on calculation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. Create a detailed action plan that.

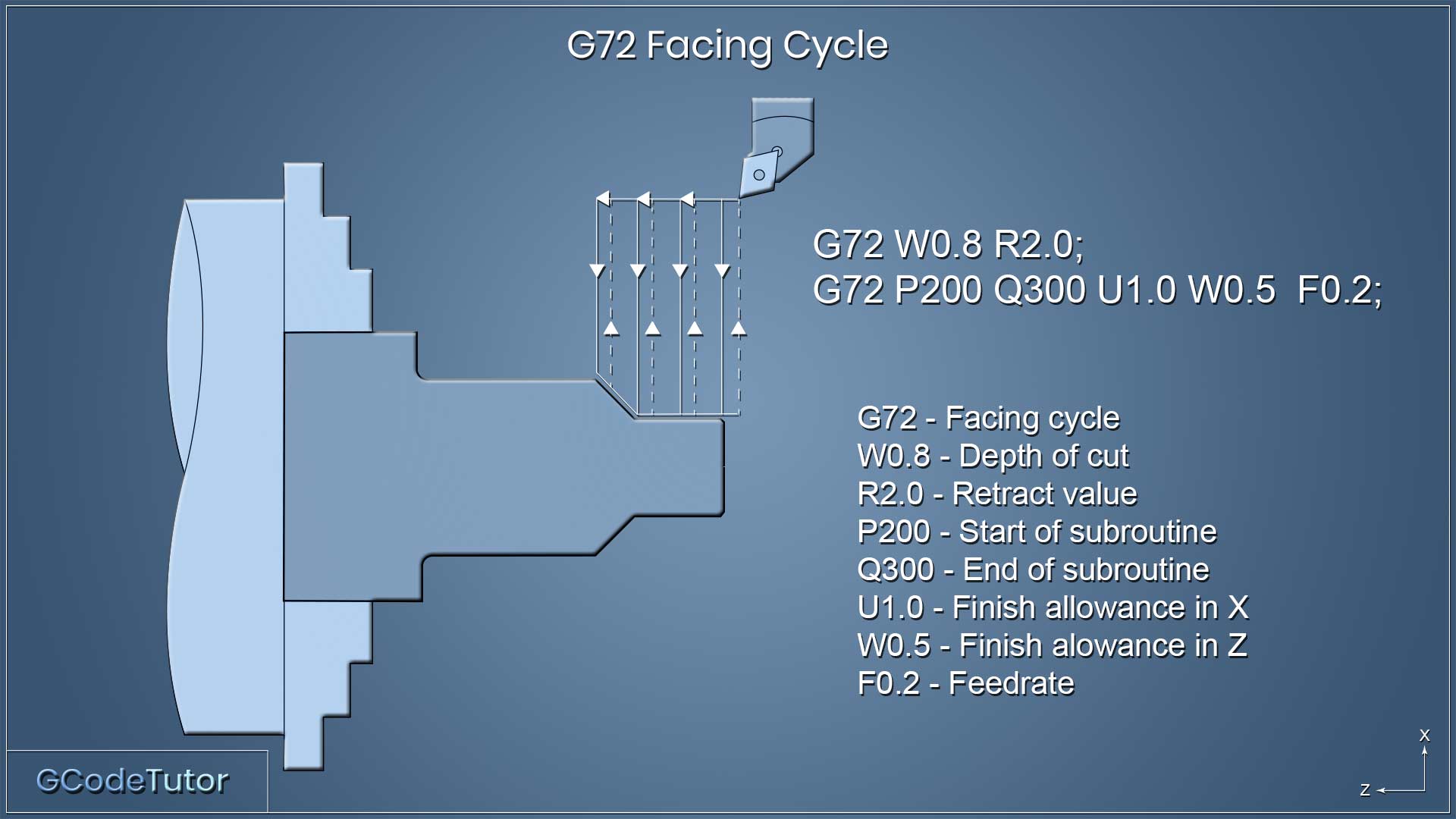

from gcodetutor.com

Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. Combine cycle time with takt time and available work time to schedule production and labor allocation. Detailed information on formula for turning. In addition to an overview of cutting tools, safety and precautions, information on calculation. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Create a detailed action plan that. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom.

G72 facing cycle CNC Lathe tutorial

How To Calculate Cycle Time For Cnc Turning Pdf One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Detailed information on formula for turning. Create a detailed action plan that. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. Combine cycle time with takt time and available work time to schedule production and labor allocation. In addition to an overview of cutting tools, safety and precautions, information on calculation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including.

From www.youtube.com

Manufacturing Economics The Production Cycle Time Analysis. YouTube How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. Combine cycle time with takt time and available work time to schedule production and labor allocation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Create a detailed action plan that. Turning. How To Calculate Cycle Time For Cnc Turning Pdf.

From microest.com

CNC Milling Cycle Time Calculator Micro Estimating How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including.. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.researchgate.net

(PDF) Simulating turning cycles on CNC lathe machines How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. Combine cycle time with takt time and available work time to schedule production and labor allocation. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Detailed information on formula for turning. Create a detailed. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

The G71 Roughing cycle on a CNC lathe explained! YouTube How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Combine cycle time with takt time and available work time. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.longshengmfg.com

how to calculate cnc turning cycle time?Its calculation formula How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Create a detailed action plan that. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.usemotion.com

Everything You Need to Know About Agile Cycle Time Motion Motion How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. Create a detailed action plan that. Combine cycle time with takt time and available work time to schedule production and labor allocation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. One. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.helmancnc.com

Taper Turning with G90 Modal Turning Cycle CNC Example Code Helman CNC How To Calculate Cycle Time For Cnc Turning Pdf By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Detailed information on formula for turning. In addition to an overview of cutting tools, safety and precautions,. How To Calculate Cycle Time For Cnc Turning Pdf.

From gcodetutor.com

G72 facing cycle CNC Lathe tutorial How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput,. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

Profiles Turning cycle in shop turn programming method Siemens CNC How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. In addition to an overview of cutting tools, safety and precautions, information on calculation. Detailed information on formula for turning. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Create a detailed. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

CNC Programming / G04 Dwell Code / How to calculate dwell time / G04 How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. Create a detailed action plan that. Combine cycle time with takt time and available work time to schedule production and labor allocation. One. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

Takt Time Calculation, Cycle Time and Bottleneck YouTube How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Combine cycle. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

02_04_P2 Cutting Speed, Feed, and Machining Time for Turning a Part on How To Calculate Cycle Time For Cnc Turning Pdf One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Combine cycle time with takt time and available work time to schedule production and labor allocation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

CNC Turning program Canned cycle CNC Programming Explained with How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. Combine cycle time with takt time and available work time to schedule production and labor allocation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal. How To Calculate Cycle Time For Cnc Turning Pdf.

From be-cu.com

Calculating CNC Machining Time For Milling,Turning,5 Axis,TurnMilling How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Create a detailed action plan that. In addition to an overview of cutting tools, safety and precautions, information on calculation. One crucial aspect of cnc turning is cycle time calculation, which plays a. How To Calculate Cycle Time For Cnc Turning Pdf.

From hjyhardware.com

How to calculate rpm in cnc turning HJY How To Calculate Cycle Time For Cnc Turning Pdf Create a detailed action plan that. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Combine cycle time with takt time and available work time to. How To Calculate Cycle Time For Cnc Turning Pdf.

From unitymanufacture.com

How To Calculate CNC Turning Cycle Time? Unity Manufacture How To Calculate Cycle Time For Cnc Turning Pdf Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Create a detailed action plan that. In addition to. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.machining-custom.com

CNC Machining How to Calculate the CNC Machining Time? How To Calculate Cycle Time For Cnc Turning Pdf One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Detailed information on formula for turning. Create a detailed action plan that. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. One way to calculate cnc. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

How to calculate injection molding cycle times. YouTube How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. Create a detailed action plan that. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.exceldemy.com

How to Calculate Cycle Time in Excel (7 Examples) ExcelDemy How To Calculate Cycle Time For Cnc Turning Pdf Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Detailed information on formula for turning. One crucial. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.longshengmfg.com

how to calculate cnc turning cycle time?Its calculation formula How To Calculate Cycle Time For Cnc Turning Pdf By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Combine cycle time with takt time and available work time to schedule production and labor allocation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.keypup.io

Calculating Cycle Time Templates and Tutorials Keypup How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. Combine cycle time with takt time and available work time to schedule production and labor allocation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. One crucial aspect of cnc turning is. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

CYCLE TIME CALCULATION FOR CNC MACHINE CYCLE TIME CALCULATION FOR CNC How To Calculate Cycle Time For Cnc Turning Pdf By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. In addition to an overview of cutting tools, safety and precautions, information on calculation. Detailed information on formula for turning. Combine cycle time with takt time and available work time to schedule production and labor allocation. Create. How To Calculate Cycle Time For Cnc Turning Pdf.

From microest.com

CNC Turning Cycle Time Calculator Micro Estimating How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. Detailed information on formula for turning. In addition to an overview of cutting tools, safety and precautions, information on calculation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

How to use Dwell time code G04 in cnc programming How to calculate How To Calculate Cycle Time For Cnc Turning Pdf One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. In addition to an overview of cutting tools, safety and precautions, information on calculation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Detailed information. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.cncmasters.com

CNC Lathe Machine 1340 Turning Center for Sale CNC Masters How To Calculate Cycle Time For Cnc Turning Pdf By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. In addition to an overview of. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.quidlo.com

Takt Time vs Cycle Time vs Lead Time (+ Calculators) Quidlo How To Calculate Cycle Time For Cnc Turning Pdf Create a detailed action plan that. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Combine cycle time with takt time and available work time to schedule production. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

cnc machining cost calculation 2 machining time calculation & its How To Calculate Cycle Time For Cnc Turning Pdf One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Detailed information on formula for turning. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Create a detailed action plan that. Turning equations machining time (min.). How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

Cnc Rpm Calculation Formula Cnc Speed & Feed Rate Calculation Cnc How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.presentationeze.com

How to calculate cycle time.PresentationEZE How To Calculate Cycle Time For Cnc Turning Pdf Detailed information on formula for turning. One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Combine cycle time with takt time and available work time to schedule production and labor allocation. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes,. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.scribd.com

Calculate Cycle Time PDF How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. Detailed information on formula for turning. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. One crucial aspect of cnc turning is. How To Calculate Cycle Time For Cnc Turning Pdf.

From robodk.com

Robot Cycle Time How to Calculate and Optimize Your Time RoboDK blog How To Calculate Cycle Time For Cnc Turning Pdf One way to calculate cnc turning cycle time is by manually calculating the various elements required for the calculation formula, including. By understanding how to calculate the cycle time in cnc turning, it*s simpler to optimize your cnc processes, increase throughput, and see bottom. Combine cycle time with takt time and available work time to schedule production and labor allocation.. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

How to calculate cutting time Cnc program time CNC Machining Cutting How To Calculate Cycle Time For Cnc Turning Pdf Combine cycle time with takt time and available work time to schedule production and labor allocation. In addition to an overview of cutting tools, safety and precautions, information on calculation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal. How To Calculate Cycle Time For Cnc Turning Pdf.

From www.youtube.com

How To Calculate Speeds and Feeds and RPM Basic Programming How To Calculate Cycle Time For Cnc Turning Pdf One crucial aspect of cnc turning is cycle time calculation, which plays a significant role in optimizing productivity and efficiency. Detailed information on formula for turning. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. One way to. How To Calculate Cycle Time For Cnc Turning Pdf.

From prostech.vn

Cycle Time (C/T) How to Calculate & Improve PROSTECH How To Calculate Cycle Time For Cnc Turning Pdf In addition to an overview of cutting tools, safety and precautions, information on calculation. Create a detailed action plan that. Combine cycle time with takt time and available work time to schedule production and labor allocation. Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r. How To Calculate Cycle Time For Cnc Turning Pdf.

From answer2questn.blogspot.com

Questions Answers Machining Time of Facing Operation in a CNC How To Calculate Cycle Time For Cnc Turning Pdf Turning equations machining time (min.) t m = m l f r t = machining time (min.) l = length of cut f r = feed rate (in.min.) material removal rate. Create a detailed action plan that. In addition to an overview of cutting tools, safety and precautions, information on calculation. One crucial aspect of cnc turning is cycle time. How To Calculate Cycle Time For Cnc Turning Pdf.