Procedures For Equipment And Plant Maintenance . Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. However, our goal should be to set up the proper foundations or the “right work” before we worry about. If we are doing the wrong work, we can still improve upon it. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment.

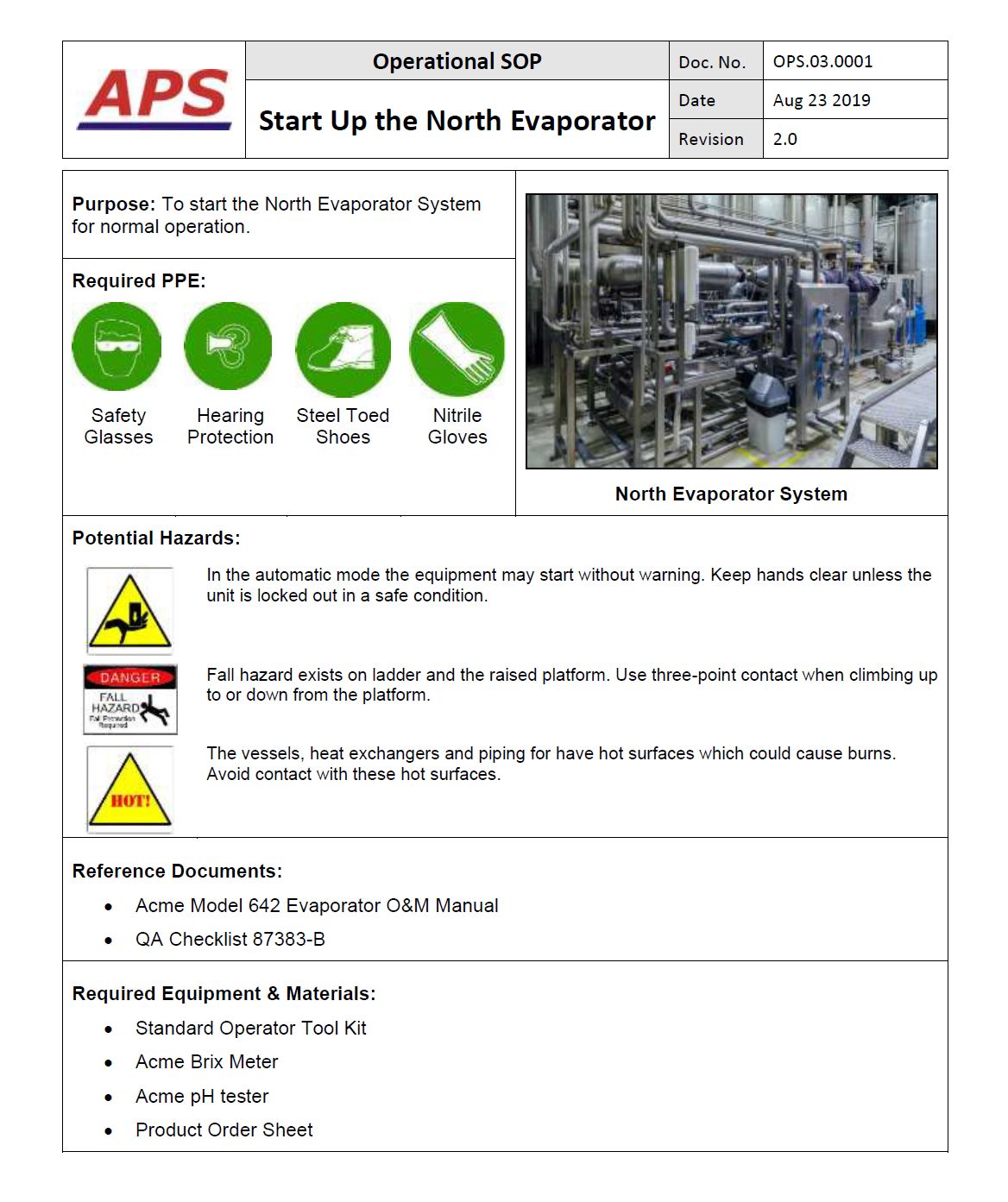

from aps-online.net

The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. If we are doing the wrong work, we can still improve upon it. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. However, our goal should be to set up the proper foundations or the “right work” before we worry about.

Standard Operating Procedure (SOP) and Work Instruction (WI) Writing

Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. However, our goal should be to set up the proper foundations or the “right work” before we worry about. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. If we are doing the wrong work, we can still improve upon it.

From aps-online.net

Standard Operating Procedure (SOP) and Work Instruction (WI) Writing Procedures For Equipment And Plant Maintenance This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. If we are doing the wrong work, we can still improve upon it. Inspection and maintenance of plant and equipment is. Procedures For Equipment And Plant Maintenance.

From www.marshallindtech.com

Plant Maintenance Services Marshall Industrial Technologies Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Maintenance of plant and equipment is carried out to prevent problems arising,. Procedures For Equipment And Plant Maintenance.

From shirazul-sap.blogspot.com

SAP Consultant,Bangladesh SAP Plant Maintenance Process Flow. Procedures For Equipment And Plant Maintenance Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and. Procedures For Equipment And Plant Maintenance.

From limblecmms.com

Hacking Plant Maintenance Strategies for Any Industry Procedures For Equipment And Plant Maintenance Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of. Procedures For Equipment And Plant Maintenance.

From www.pdffiller.com

Plant and equipment maintenance HSEFree Equipment Schedule Templates Procedures For Equipment And Plant Maintenance The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. If we are doing the wrong work, we can still improve upon it. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance. Procedures For Equipment And Plant Maintenance.

From manje1.fra1.cdn.digitaloceanspaces.com

Discover The 4 Types Of Maintenance And Unlock Equipment Efficiency Procedures For Equipment And Plant Maintenance If we are doing the wrong work, we can still improve upon it. However, our goal should be to set up the proper foundations or the “right work” before we worry about. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Creating a list of premises, plant and equipment that need to. Procedures For Equipment And Plant Maintenance.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Procedures For Equipment And Plant Maintenance If we are doing the wrong work, we can still improve upon it. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. Inspection and maintenance of plant and equipment is a fundamental process that needs to. Procedures For Equipment And Plant Maintenance.

From www.slideshare.net

Plant maintenance Procedures For Equipment And Plant Maintenance Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. However, our goal should be to set up the proper foundations or the “right work” before we worry about. If we. Procedures For Equipment And Plant Maintenance.

From www.template.net

Equipment Maintenance Schedule Template 10+ Free Word, PDF Format Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place. Procedures For Equipment And Plant Maintenance.

From www.researchgate.net

Proposed flowchart model of the maintenance management system in EXMS Procedures For Equipment And Plant Maintenance The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Inspection and maintenance of. Procedures For Equipment And Plant Maintenance.

From www.rasmech.com

What is Plant Maintenance? Rasmussen Mechanical Procedures For Equipment And Plant Maintenance This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. However, our goal should be to set up the proper foundations or. Procedures For Equipment And Plant Maintenance.

From www.techtransfer.com

Maintenance Excellence » Technology Transfer Services Procedures For Equipment And Plant Maintenance This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. However, our goal should be to set up the proper foundations or the “right work” before we worry about. Where upkeep and repair are concerned, standard operating procedure. Procedures For Equipment And Plant Maintenance.

From www.slideshare.net

Plant Maintenance Procedures For Equipment And Plant Maintenance Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. However, our goal should be to set up the proper foundations or the “right work” before we worry about. The purpose. Procedures For Equipment And Plant Maintenance.

From www.reliableplant.com

Preventive Maintenance An Overview Reliable Plant Procedures For Equipment And Plant Maintenance If we are doing the wrong work, we can still improve upon it. However, our goal should be to set up the proper foundations or the “right work” before we worry about. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Creating a list of premises,. Procedures For Equipment And Plant Maintenance.

From www.scribd.com

Sample Maintenance Policy Procedures Procedures For Equipment And Plant Maintenance Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. If we are doing the wrong work, we can still improve upon it. Where upkeep. Procedures For Equipment And Plant Maintenance.

From treatmentdiariesblog.com

Activities of the Plant Maintenance Service Treatment Diaries Blog Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. However, our goal should. Procedures For Equipment And Plant Maintenance.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Procedures For Equipment And Plant Maintenance Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay. Procedures For Equipment And Plant Maintenance.

From www.slideshare.net

Plant Maintenance Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put. Procedures For Equipment And Plant Maintenance.

From studylib.net

Plant and Equipment Maintenance Procedures For Equipment And Plant Maintenance Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. If we are doing the wrong work, we can still improve upon it. However, our goal should be to set up. Procedures For Equipment And Plant Maintenance.

From sap-certification.info

SAP Preventative Maintenance Tutorial Free SAP PM Training Procedures For Equipment And Plant Maintenance This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. If we are doing the wrong work, we can still improve upon it. However, our goal should be to set up the. Procedures For Equipment And Plant Maintenance.

From ebrary.net

Manage Operation and Maintenance Quality Procedures For Equipment And Plant Maintenance Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. However, our goal should be to set up the proper foundations or the “right work” before we worry about. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help. Procedures For Equipment And Plant Maintenance.

From www.erpgreat.com

Plant Maintenance Process Flow Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Maintenance of plant. Procedures For Equipment And Plant Maintenance.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Procedures For Equipment And Plant Maintenance Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. However, our goal should be to set up the proper foundations or the “right work” before we worry about. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Creating. Procedures For Equipment And Plant Maintenance.

From www.vrogue.co

Types Of Maintenance The 9 Different Strategies Expla vrogue.co Procedures For Equipment And Plant Maintenance The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant. Procedures For Equipment And Plant Maintenance.

From shirazul-sap.blogspot.com

SAP Consultant,Bangladesh SAP Plant Maintenance Process Flow. Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. If we are doing. Procedures For Equipment And Plant Maintenance.

From worksafetyqld.com

Plant & Equipment Maintenance Policy & Procedure Template Work Safety QLD Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. If we are doing the wrong work, we can still improve upon it. Maintenance of plant and equipment is carried out to prevent problems arising, to put. Procedures For Equipment And Plant Maintenance.

From sample-excel.blogspot.com

15+ Machine Maintenance Checklist Template Sample Excel Templates Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on. Procedures For Equipment And Plant Maintenance.

From www.xenia.team

Landscape Maintenance Checklist Xenia Templates Procedures For Equipment And Plant Maintenance Maintenance of plant and equipment is carried out to prevent problems arising, to put faults right, and to ensure equipment is working effectively. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out. Procedures For Equipment And Plant Maintenance.

From www.gofmx.com

Maintenance SOP FMX Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. If we are doing the wrong work, we can still improve upon it. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Maintenance of plant and equipment is carried out to prevent problems arising, to. Procedures For Equipment And Plant Maintenance.

From www.slideshare.net

Plant maintenance Procedures For Equipment And Plant Maintenance This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. Where upkeep and repair. Procedures For Equipment And Plant Maintenance.

From www.geeksforgeeks.org

Plant Maintenance Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Creating a list of premises, plant and equipment that need to be maintained (and how often) will help plan and risk assess the work. If we. Procedures For Equipment And Plant Maintenance.

From document360.com

How to Create an Operation & Maintenance Manual Procedures For Equipment And Plant Maintenance Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and preventive maintenance tasks for equipment. If we are doing the wrong work, we can still improve upon it. Maintenance of plant and equipment is carried out to prevent problems arising, to put. Procedures For Equipment And Plant Maintenance.

From sitemate.com

How to create a preventative maintenance plan (an efficient one) Procedures For Equipment And Plant Maintenance The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. However, our goal should be to. Procedures For Equipment And Plant Maintenance.

From www.sampletemplates.com

FREE 61+ SOP Templates in PDF MS Word Procedures For Equipment And Plant Maintenance Inspection and maintenance of plant and equipment is a fundamental process that needs to be carried out on all plant and equipment. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained. Maintenance of plant and equipment is. Procedures For Equipment And Plant Maintenance.

From www.sapnoob.com

SAP Plant Maintenance Process Free SAP Online Training Tutorial Procedures For Equipment And Plant Maintenance However, our goal should be to set up the proper foundations or the “right work” before we worry about. This information document covers safe working procedures associated with equipment maintenance, cleaning, setting and operation,. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective. Procedures For Equipment And Plant Maintenance.