Ball Screw Gear Reduction Ratio . Thrust force (the sum of all. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Design and calculation of a ball screw. If you know the torque applied to a ballscrew, then you can. Load analysis, life calculation and tolerances. A ball screw transforms rotational motion into transitional motion. As a result, the shaft is subject to. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: A ball screw transforms rotational motion into translational motion. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Check for tension/pressure, buckling and critical speed As a result, the shaft is subject to loads:

from engineconstalaranceqtt.z21.web.core.windows.net

As a result, the shaft is subject to loads: ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Load analysis, life calculation and tolerances. A ball screw transforms rotational motion into translational motion. A ball screw transforms rotational motion into transitional motion. Thrust force (the sum of all. If you know the torque applied to a ballscrew, then you can. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Check for tension/pressure, buckling and critical speed Driving with a 200 step motor, what would be a good reduction ratio for the belt drive?

Gear Reduction Variable Ratio

Ball Screw Gear Reduction Ratio Design and calculation of a ball screw. Design and calculation of a ball screw. A ball screw transforms rotational motion into transitional motion. Thrust force (the sum of all. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. As a result, the shaft is subject to. Load analysis, life calculation and tolerances. A ball screw transforms rotational motion into translational motion. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? As a result, the shaft is subject to loads: If you know the torque applied to a ballscrew, then you can. Check for tension/pressure, buckling and critical speed

From boji-machinery.en.made-in-china.com

Zlyj PVC Plastic Extruder Ball Screw Gear Reducer Extruder Gearbox Ball Screw Gear Reduction Ratio This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. A ball screw transforms rotational motion into translational motion. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Load analysis, life calculation and tolerances. Driving with a 200 step motor, what would be a good. Ball Screw Gear Reduction Ratio.

From electronicspanga.com

KAMOSEIKO KAMO 201 Ratio BR 65SH BR65SH Ball Reducer Gearbox G443 Ball Screw Gear Reduction Ratio Thrust force (the sum of all. As a result, the shaft is subject to loads: Design and calculation of a ball screw. A ball screw transforms rotational motion into transitional motion. A ball screw transforms rotational motion into translational motion. Load analysis, life calculation and tolerances. As a result, the shaft is subject to. Driving with a 200 step motor,. Ball Screw Gear Reduction Ratio.

From screwgear.net

screwgear Ball Screw Gear Reduction Ratio As a result, the shaft is subject to. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: A ball screw transforms rotational motion into translational motion. Thrust force (the sum of all. As a result, the shaft is subject to loads: A ball screw transforms rotational motion into transitional motion. Check for tension/pressure,. Ball Screw Gear Reduction Ratio.

From engineeringlearner.com

Types of Reduction Gear Engineering Learner Ball Screw Gear Reduction Ratio Thrust force (the sum of all. If you know the torque applied to a ballscrew, then you can. As a result, the shaft is subject to loads: This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Torque = force x lead x %eff / (2 x pi x gear reduction ratio). Ball Screw Gear Reduction Ratio.

From www.researchgate.net

Effect of change of the ballscrew pitch and the gear reduction ratio Ball Screw Gear Reduction Ratio Design and calculation of a ball screw. Check for tension/pressure, buckling and critical speed This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Thrust force (the sum of all. A ball screw transforms rotational motion into transitional motion. A ball screw transforms rotational motion into translational motion. As a result, the. Ball Screw Gear Reduction Ratio.

From rockfordballscrew.com

Ball Screws and Ball Screw Assemblies Rockford Ball Screw Ball Screw Gear Reduction Ratio As a result, the shaft is subject to loads: Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? A ball screw transforms rotational motion into translational motion. Load analysis, life calculation and tolerances. ② reduction ratio. Ball Screw Gear Reduction Ratio.

From electronicspanga.com

KAMO KAMOSEIKO 201 Ratio BR100SH20G14K5 Ball Reducer GearBox G406 Ball Screw Gear Reduction Ratio Check for tension/pressure, buckling and critical speed Design and calculation of a ball screw. Load analysis, life calculation and tolerances. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: A ball screw transforms rotational motion into translational motion. As a result, the shaft is subject to. ② reduction ratio (calculated value at ①). Ball Screw Gear Reduction Ratio.

From engineconstalaranceqtt.z21.web.core.windows.net

Gear Reduction Variable Ratio Ball Screw Gear Reduction Ratio As a result, the shaft is subject to loads: Thrust force (the sum of all. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Check for tension/pressure, buckling and critical speed A ball screw transforms rotational motion into translational motion. This article provides an online calculator for common screw mechanisms to quickly. Ball Screw Gear Reduction Ratio.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know Ball Screw Gear Reduction Ratio Load analysis, life calculation and tolerances. As a result, the shaft is subject to loads: As a result, the shaft is subject to. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? A ball screw transforms. Ball Screw Gear Reduction Ratio.

From servomotorgearbox.com

TQG AAWBS screw reducer, right angle reducer, screw servo gearbox Ball Screw Gear Reduction Ratio Load analysis, life calculation and tolerances. Check for tension/pressure, buckling and critical speed This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Thrust force (the sum of all. Design and calculation of a ball screw. If you know the torque applied to a ballscrew, then you can. As a result, the. Ball Screw Gear Reduction Ratio.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Ball Screw Gear Reduction Ratio This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. A ball screw transforms rotational motion into translational motion. Design and calculation of a ball screw. As a result, the shaft is subject to. If you know the torque applied to a ballscrew, then you can. Check for tension/pressure, buckling and critical. Ball Screw Gear Reduction Ratio.

From www.researchgate.net

Effect of change of the ballscrew pitch and the gear reduction ratio Ball Screw Gear Reduction Ratio Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Load analysis, life calculation and tolerances. If you know the torque applied to a ballscrew, then you can. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. A ball screw transforms rotational motion into translational. Ball Screw Gear Reduction Ratio.

From screw-jacks.en.made-in-china.com

Mitre Gear Boxes for Machine Screw or Ball Screw Actuators Offered in 1 Ball Screw Gear Reduction Ratio If you know the torque applied to a ballscrew, then you can. Load analysis, life calculation and tolerances. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Design and calculation of a ball screw. As a result, the shaft is subject to. Driving with a 200 step motor, what would be a good reduction. Ball Screw Gear Reduction Ratio.

From pdfslide.net

(PDF) SCREW JACK Duff Norton Australia · SCREW JACK POWERED ACTUATORS Ball Screw Gear Reduction Ratio This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. As a result, the shaft is subject to loads: As a result, the shaft is subject to. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Check for tension/pressure, buckling and critical speed If you know. Ball Screw Gear Reduction Ratio.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know Ball Screw Gear Reduction Ratio As a result, the shaft is subject to loads: Design and calculation of a ball screw. Thrust force (the sum of all. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Driving with a 200. Ball Screw Gear Reduction Ratio.

From www.bigstockphoto.com

Linear Ball Screw Gear Image & Photo (Free Trial) Bigstock Ball Screw Gear Reduction Ratio A ball screw transforms rotational motion into transitional motion. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: If you know the torque applied to a ballscrew, then you can. As a result, the shaft is. Ball Screw Gear Reduction Ratio.

From hxezlmcyo.blob.core.windows.net

Lead Screw Gear Ratio Calculator at Michael Pires blog Ball Screw Gear Reduction Ratio Thrust force (the sum of all. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? A ball screw transforms rotational motion into translational motion. As a result, the shaft is subject to loads: As a result, the shaft is subject to. This article provides an online calculator for common screw mechanisms to. Ball Screw Gear Reduction Ratio.

From hxezlmcyo.blob.core.windows.net

Lead Screw Gear Ratio Calculator at Michael Pires blog Ball Screw Gear Reduction Ratio Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: As a result, the shaft is subject to. Thrust force (the sum of all. As a result, the shaft is subject to loads: This article provides an. Ball Screw Gear Reduction Ratio.

From www.profess.co.th

BALL SCREW Ball Screw Gear Reduction Ratio This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. As a result, the shaft is subject to. As a result, the shaft is subject to loads: ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. A ball screw transforms rotational motion into translational motion. Design. Ball Screw Gear Reduction Ratio.

From www.motioncontroltips.com

How to Size and Select Ball Screws An Engineer's Guide Ball Screw Gear Reduction Ratio Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Thrust force (the sum of all. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: A ball screw transforms rotational motion into transitional motion. Check for tension/pressure, buckling and critical speed Design and calculation of a. Ball Screw Gear Reduction Ratio.

From blog.orientalmotor.com

Motor Sizing Basics Part 3 How to Calculate Speed, Acceleration Torque Ball Screw Gear Reduction Ratio ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Load analysis, life calculation and tolerances. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Thrust force (the sum of all. A ball screw transforms rotational motion into transitional motion. This article provides an online calculator for common. Ball Screw Gear Reduction Ratio.

From www.alibaba.com

Wpwx 140 Ratio Gearbox Spiral Bevel Helical Gear Box 90 Degree Ball Screw Gear Reduction Ratio Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Check for tension/pressure, buckling and critical speed Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. A ball screw transforms rotational. Ball Screw Gear Reduction Ratio.

From mechdiploma.com

Worm and Worm Gear Theory Q&A Mechanical Engg Simple Notes ,Solved Ball Screw Gear Reduction Ratio Load analysis, life calculation and tolerances. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Thrust force (the sum of all. A ball screw transforms rotational motion into translational motion. If you know the torque applied to a ballscrew, then you can. As a result, the shaft is subject to loads:. Ball Screw Gear Reduction Ratio.

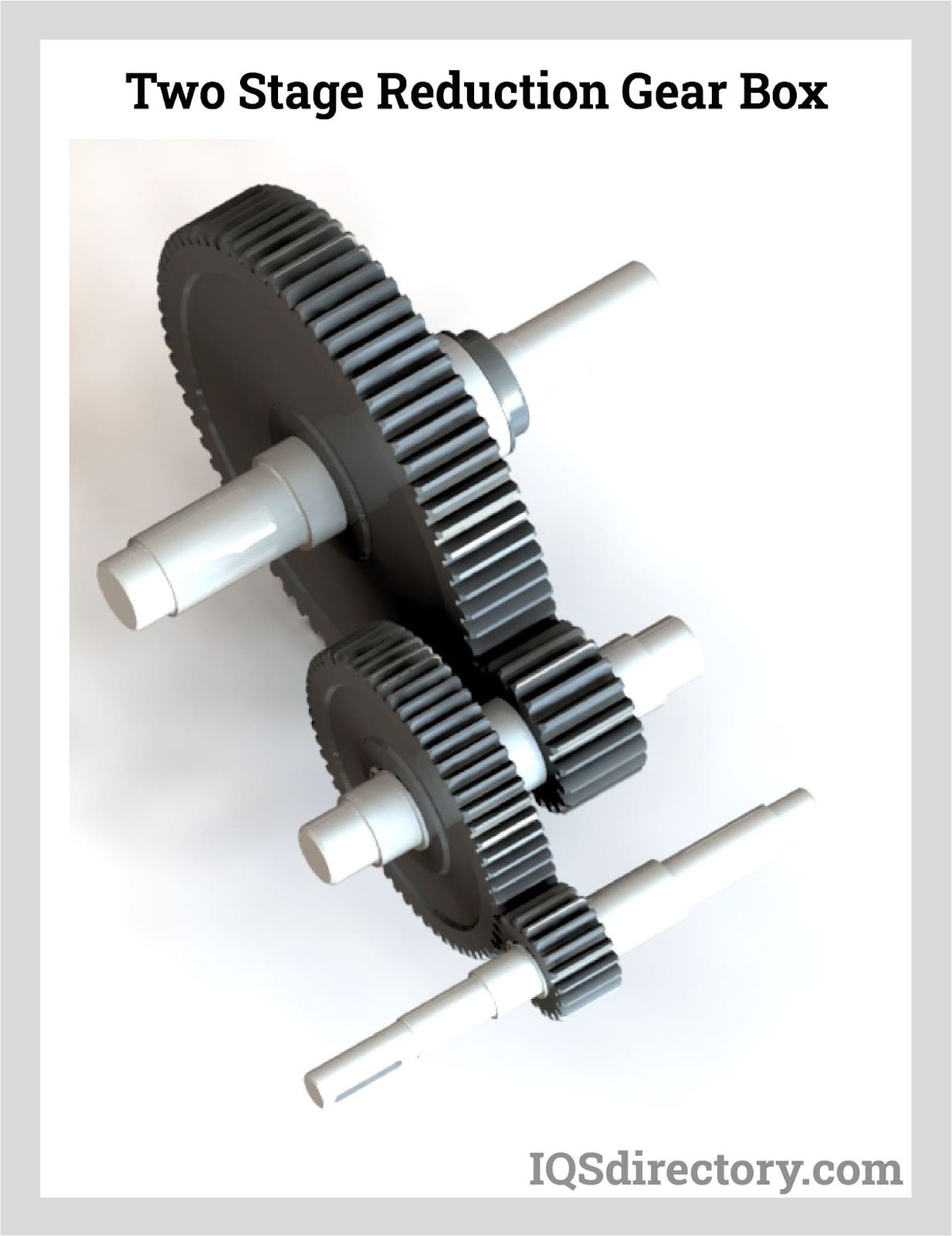

From www.iqsdirectory.com

Speed Reducers Types, Efficiency, Maintenance, and Gear Ratio Ball Screw Gear Reduction Ratio Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: A ball screw transforms rotational motion into translational motion. Load analysis, life. Ball Screw Gear Reduction Ratio.

From www.chegg.com

Solved Q2. A Ball Screw mechanism is driven by stepping Ball Screw Gear Reduction Ratio A ball screw transforms rotational motion into transitional motion. As a result, the shaft is subject to. Thrust force (the sum of all. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Load analysis, life calculation and tolerances. Torque = force x lead x %eff / (2 x pi x gear. Ball Screw Gear Reduction Ratio.

From www.researchgate.net

Effect of change of the ballscrew pitch and the gear reduction ratio Ball Screw Gear Reduction Ratio As a result, the shaft is subject to. Design and calculation of a ball screw. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Load analysis, life calculation and tolerances. A ball screw transforms rotational motion into transitional motion. A ball screw transforms rotational motion into translational motion. As a result,. Ball Screw Gear Reduction Ratio.

From fubaoelectrical.en.made-in-china.com

High Precision Screw Elevator Bevel Gear Ball Screw Precision Fast and Ball Screw Gear Reduction Ratio Thrust force (the sum of all. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. If you know the torque applied to a ballscrew, then you can. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Check for tension/pressure, buckling and critical speed As a. Ball Screw Gear Reduction Ratio.

From www.screw-jack.com

3 1 speed reduction ratio gear box,3 1 speed reduction ratio gear boxes Ball Screw Gear Reduction Ratio A ball screw transforms rotational motion into transitional motion. Thrust force (the sum of all. If you know the torque applied to a ballscrew, then you can. A ball screw transforms rotational motion into translational motion. Load analysis, life calculation and tolerances. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Check for. Ball Screw Gear Reduction Ratio.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Gear Reduction Ratio ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. As a result, the shaft is subject to loads: Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? A ball screw transforms rotational motion into translational motion. Torque = force x lead x %eff / (2 x. Ball Screw Gear Reduction Ratio.

From fubaoelectrical.en.made-in-china.com

32mm750W Optimized Moment of Inertia Speedup Gearbox for Ball Screw Ball Screw Gear Reduction Ratio Thrust force (the sum of all. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive? Check for tension/pressure, buckling and critical speed Load analysis, life calculation and tolerances. This article provides an online calculator for common screw. Ball Screw Gear Reduction Ratio.

From www.youtube.com

How to Design Single Stage Reduction Helical Gear Box 344 Ball Screw Gear Reduction Ratio Load analysis, life calculation and tolerances. A ball screw transforms rotational motion into transitional motion. Design and calculation of a ball screw. ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. Thrust force (the sum of all. Driving with a 200 step motor, what would be a good reduction ratio for the belt drive?. Ball Screw Gear Reduction Ratio.

From www.youtube.com

gear ration 2 tpi lead screw, threading chart YouTube Ball Screw Gear Reduction Ratio A ball screw transforms rotational motion into translational motion. If you know the torque applied to a ballscrew, then you can. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: Thrust force (the sum of all. As a result, the shaft is subject to. Load analysis, life calculation and tolerances. ② reduction ratio. Ball Screw Gear Reduction Ratio.

From www.slideshare.net

Jtb 25 kn ball screw jack, 2.5 t worm gear ball jack reduction ratio,… Ball Screw Gear Reduction Ratio As a result, the shaft is subject to loads: This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. Torque = force x lead x %eff / (2 x pi x gear reduction ratio) derivation: If you know the torque applied to a ballscrew, then you can. Design and calculation of a. Ball Screw Gear Reduction Ratio.

From workshopfixalbinojmefic.z21.web.core.windows.net

Gear Reduction Variable Ratio Ball Screw Gear Reduction Ratio ② reduction ratio (calculated value at ①) z = z=l×n×p2/ (60×p1×v) caluclation of lead torque. A ball screw transforms rotational motion into translational motion. This article provides an online calculator for common screw mechanisms to quickly find the servo’s electronic gear ratio. A ball screw transforms rotational motion into transitional motion. As a result, the shaft is subject to loads:. Ball Screw Gear Reduction Ratio.

From stock.adobe.com

Linear ball screw gear. Drive for moving working parts of metal cutting Ball Screw Gear Reduction Ratio Thrust force (the sum of all. As a result, the shaft is subject to loads: Check for tension/pressure, buckling and critical speed A ball screw transforms rotational motion into translational motion. A ball screw transforms rotational motion into transitional motion. Design and calculation of a ball screw. Driving with a 200 step motor, what would be a good reduction ratio. Ball Screw Gear Reduction Ratio.