Aluminum C Channel Welding . Suitable filler metal grades are listed. Causes and avoidance of porosity,. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Welding any material is a challenging process, but. Tig welding, with its non. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. The aluminium block is heated and forced through a die, extruding. In the realm of aluminum welding, two techniques reign supreme:

from www.alibaba.com

Welding any material is a challenging process, but. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Suitable filler metal grades are listed. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. In the realm of aluminum welding, two techniques reign supreme: The aluminium block is heated and forced through a die, extruding. Causes and avoidance of porosity,. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys.

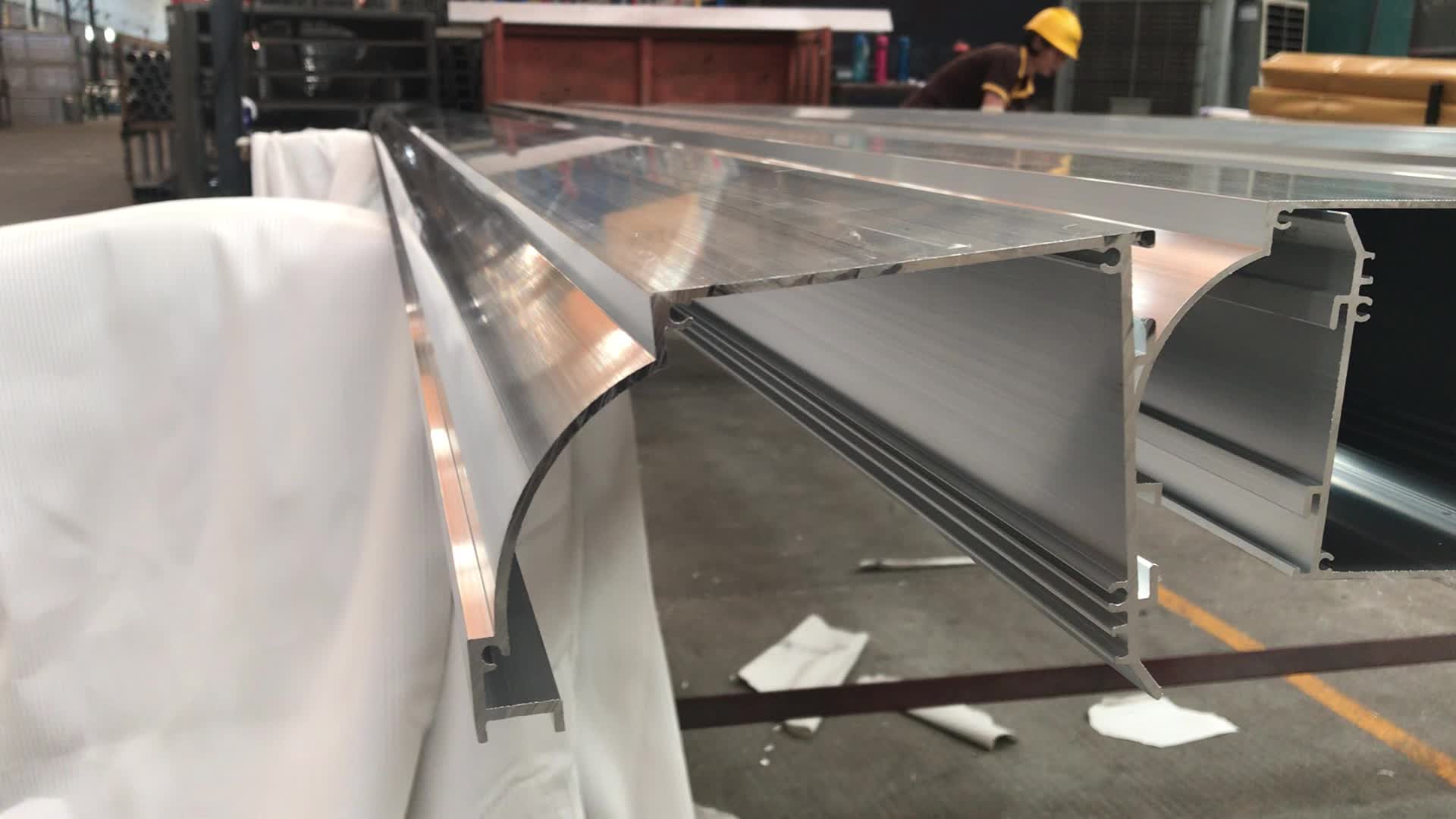

Mill Finish Aluminum C Channel Extrusion Profile Custom Aluminum

Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. Causes and avoidance of porosity,. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Suitable filler metal grades are listed. Tig welding, with its non. The aluminium block is heated and forced through a die, extruding. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Welding any material is a challenging process, but. In the realm of aluminum welding, two techniques reign supreme: Tig (tungsten inert gas) welding and mig (metal inert gas) welding. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner.

From www.alibaba.com

Manufacturer Supply Fabricated Customized Weld C Channel Buy Weld C Aluminum C Channel Welding Causes and avoidance of porosity,. In the realm of aluminum welding, two techniques reign supreme: Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Aluminium channel, also referred to as aluminium u channel or c. Aluminum C Channel Welding.

From www.iqsdirectory.com

Aluminum Channels Types, Finishes, Grades & Characteristics Aluminum C Channel Welding Tig welding, with its non. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. The aluminium block is heated and forced through a die, extruding. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. In the realm of aluminum welding, two techniques reign supreme: Characteristics. Aluminum C Channel Welding.

From www.iqsdirectory.com

Aluminum Channels Types, Finishes, Grades & Characteristics Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. Suitable filler metal grades are listed. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Causes and avoidance of porosity,. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. This article explores the. Aluminum C Channel Welding.

From www.youtube.com

C channel measurement and welding YouTube Aluminum C Channel Welding Welding any material is a challenging process, but. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. In the realm of aluminum welding, two techniques reign supreme: You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety. Aluminum C Channel Welding.

From www.youtube.com

Joining Channel Iron At 90 Degrees Using An Easy Joint YouTube Aluminum C Channel Welding This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Suitable filler metal grades are listed. Causes and avoidance of porosity,. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Tig welding, with its. Aluminum C Channel Welding.

From metalscut4u.com

Aluminum C Channel Size Chart Aluminum C Channel Welding Welding any material is a challenging process, but. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. The aluminium block is heated and forced through a die, extruding. In the realm of aluminum welding, two techniques reign supreme: Tig welding, with its non. Causes and avoidance. Aluminum C Channel Welding.

From www.isocleanroomchina.com

Aluminum C Channel, Aluminum Profile Manufacturer in China Sunnyda Aluminum C Channel Welding In the realm of aluminum welding, two techniques reign supreme: Tig welding, with its non. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Welding any material is a challenging process, but. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. This article explores the intricacies. Aluminum C Channel Welding.

From www.uaac.us

UAAC United Appalachian Aluminum CompanyAluminum CChannel 1 1/2 x 6 Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Tig welding, with its non. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Welding any material is a challenging process, but. Suitable filler metal grades. Aluminum C Channel Welding.

From eagle-aluminum.com

Aluminum C Channels Aluminum Slide Track Channels Eagle Mouldings Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Tig welding, with its. Aluminum C Channel Welding.

From www.practicalmachinist.com

C channel top welding table Aluminum C Channel Welding Suitable filler metal grades are listed. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Tig welding, with its non. Aluminium channel, also referred to as. Aluminum C Channel Welding.

From www.wileymetal.com

Why You Might Consider Csection channel for a Metal fabrication Aluminum C Channel Welding Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Tig welding, with its non. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. In the realm of aluminum welding, two techniques reign supreme: You can join aluminium channel using a variety of techniques. Aluminum C Channel Welding.

From www.alibaba.com

C Channel Q235 Cchannel Csection Ctype Channel Cshape C Buy C Aluminum C Channel Welding The aluminium block is heated and forced through a die, extruding. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Tig welding, with its non. Causes and avoidance of porosity,. This article explores the intricacies of. Aluminum C Channel Welding.

From www.aluminium-online.co.uk

Aluminium Channel50mm x 50mm x 2mm (A x B x C) Aluminium Online Aluminum C Channel Welding Tig welding, with its non. Causes and avoidance of porosity,. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Welding any material is a challenging. Aluminum C Channel Welding.

From metalfabricationsvcs.com

CChannel Metal Fabrication Services Aluminum C Channel Welding Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. The aluminium block is heated and forced through a die, extruding. This article explores the intricacies of. Aluminum C Channel Welding.

From www.indiamart.com

Aluminum C Channel at Rs 180/kilogram Aluminium Channels in Chennai Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Causes and avoidance of porosity,. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Proper filler metal selection (filler wire or filler rod), carefully selected. Aluminum C Channel Welding.

From www.emiworks.com

EMI CChannel Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Suitable filler metal grades are listed. This article explores the intricacies of welding aluminum, from material classification. Aluminum C Channel Welding.

From www.iqsdirectory.com

Metal (Molding) Moulding Types, Considerations & Benefits Aluminum C Channel Welding Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding. Aluminum C Channel Welding.

From artefex.biz

Aluminum CChannel Hanging System Artefex Aluminum C Channel Welding Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Welding any material is a challenging process, but. Tig welding, with its non. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters. Aluminum C Channel Welding.

From blog.thepipingmart.com

What is C channel steel? Aluminum C Channel Welding Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Tig welding, with its non. Suitable filler metal grades are listed. Causes and avoidance of porosity,. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Tig (tungsten inert gas) welding and mig (metal inert gas) welding.. Aluminum C Channel Welding.

From diamondlifegear.com

Aluminum Channels Aluminum C Channel Welding Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. The aluminium block is heated and forced through a die, extruding. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. This article explores the intricacies. Aluminum C Channel Welding.

From www.iqsdirectory.com

Aluminum Channels Types, Finishes, Grades & Characteristics Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. In the realm of aluminum welding, two techniques reign supreme: Tig welding, with its. Aluminum C Channel Welding.

From csonkascustomrustics.com

C Channel Support Bracing Aluminum C Channel Welding Suitable filler metal grades are listed. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Causes and avoidance of porosity,. In the realm of aluminum welding, two techniques reign supreme: Aluminium channel, also referred to as. Aluminum C Channel Welding.

From www.practicalmachinist.com

C channel top welding table Aluminum C Channel Welding Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. In the realm of aluminum welding, two techniques reign supreme: Tig welding, with its non. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. This article. Aluminum C Channel Welding.

From www.kinderboerderijdebuiktuin.com

Building Materials & Supplies Business, Office & Industrial Business Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Causes and avoidance of porosity,. Welding any material is a challenging process, but. This article explores the. Aluminum C Channel Welding.

From www.youtube.com

How to "Weld" Aluminum for Beginners YouTube Aluminum C Channel Welding The aluminium block is heated and forced through a die, extruding. Welding any material is a challenging process, but. This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using. Aluminum C Channel Welding.

From metal-fabrication.en.made-in-china.com

Mild Steel or Stainless Metal C Channel with Fabrication and Welding Aluminum C Channel Welding Suitable filler metal grades are listed. In the realm of aluminum welding, two techniques reign supreme: You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. The aluminium block is heated and forced through a die, extruding. Causes. Aluminum C Channel Welding.

From www.alibaba.com

Mill Finish Aluminum C Channel Extrusion Profile Custom Aluminum Aluminum C Channel Welding Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Suitable filler metal grades are listed. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Welding any material is a challenging process, but. The aluminium block is heated and forced through a die, extruding. Proper. Aluminum C Channel Welding.

From www.colegiosantainescampestre.edu.co

Aluminum C Channel Size Chart, 50 OFF Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. In the realm of aluminum welding, two techniques reign supreme: Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Welding any material is a challenging process,. Aluminum C Channel Welding.

From weldingweb.com

Looking for best approach to stick fillet inside C channel. Aluminum C Channel Welding The aluminium block is heated and forced through a die, extruding. Tig welding, with its non. You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. In the realm of aluminum welding, two techniques reign supreme: Causes. Aluminum C Channel Welding.

From www.solutionsantenaturelle.com

The Aluminum C Channel Aluminum C Channel Welding Causes and avoidance of porosity,. The aluminium block is heated and forced through a die, extruding. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. Tig welding, with its non. Tig (tungsten inert gas) welding and mig (metal inert gas) welding. This article explores the intricacies of welding aluminum, from material classification and preparation to the various. Aluminum C Channel Welding.

From www.practicalmachinist.com

C channel top welding table Aluminum C Channel Welding You can join aluminium channel using a variety of techniques including welding, brazing and adhesive bonding, or using a variety of. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. In the realm of aluminum. Aluminum C Channel Welding.

From eagle-aluminum.com

Aluminum C Channels Aluminum Slide Track Channels Eagle Mouldings Aluminum C Channel Welding Suitable filler metal grades are listed. Causes and avoidance of porosity,. The aluminium block is heated and forced through a die, extruding. In the realm of aluminum welding, two techniques reign supreme: Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Tig welding, with its non. This. Aluminum C Channel Welding.

From www.youtube.com

c channel welding tricks welding for beginners YouTube Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. Suitable filler metal grades are listed. Aluminium channel, also referred to as aluminium u channel or c channel, has the right shape and right angles on each corner. Welding any material is a challenging process, but. You can join aluminium channel using a variety of techniques including welding, brazing. Aluminum C Channel Welding.

From www.pinterest.com

Metal C Channel Welding consumables, Pipeline welding, Stainless Aluminum C Channel Welding Tig (tungsten inert gas) welding and mig (metal inert gas) welding. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential in order to minimise. Tig welding, with its non. Characteristics of aluminium alloys are discussed with emphasis on their fusion weldability. You can join aluminium channel using a variety of techniques. Aluminum C Channel Welding.

From eagle-aluminum.com

Aluminum C Channels Aluminum Slide Track Channels Eagle Mouldings Aluminum C Channel Welding This article explores the intricacies of welding aluminum, from material classification and preparation to the various welding methods best suited for aluminum alloys. Welding any material is a challenging process, but. Causes and avoidance of porosity,. Suitable filler metal grades are listed. Proper filler metal selection (filler wire or filler rod), carefully selected welding parameters and joint design are essential. Aluminum C Channel Welding.