Cleaning Agent Residue Limits . The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: The level of cleanliness that a production unit must maintain at a minimum with every cleaning. • limits for the active drug.

from pharmadevils.com

This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. • limits for the active drug. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api.

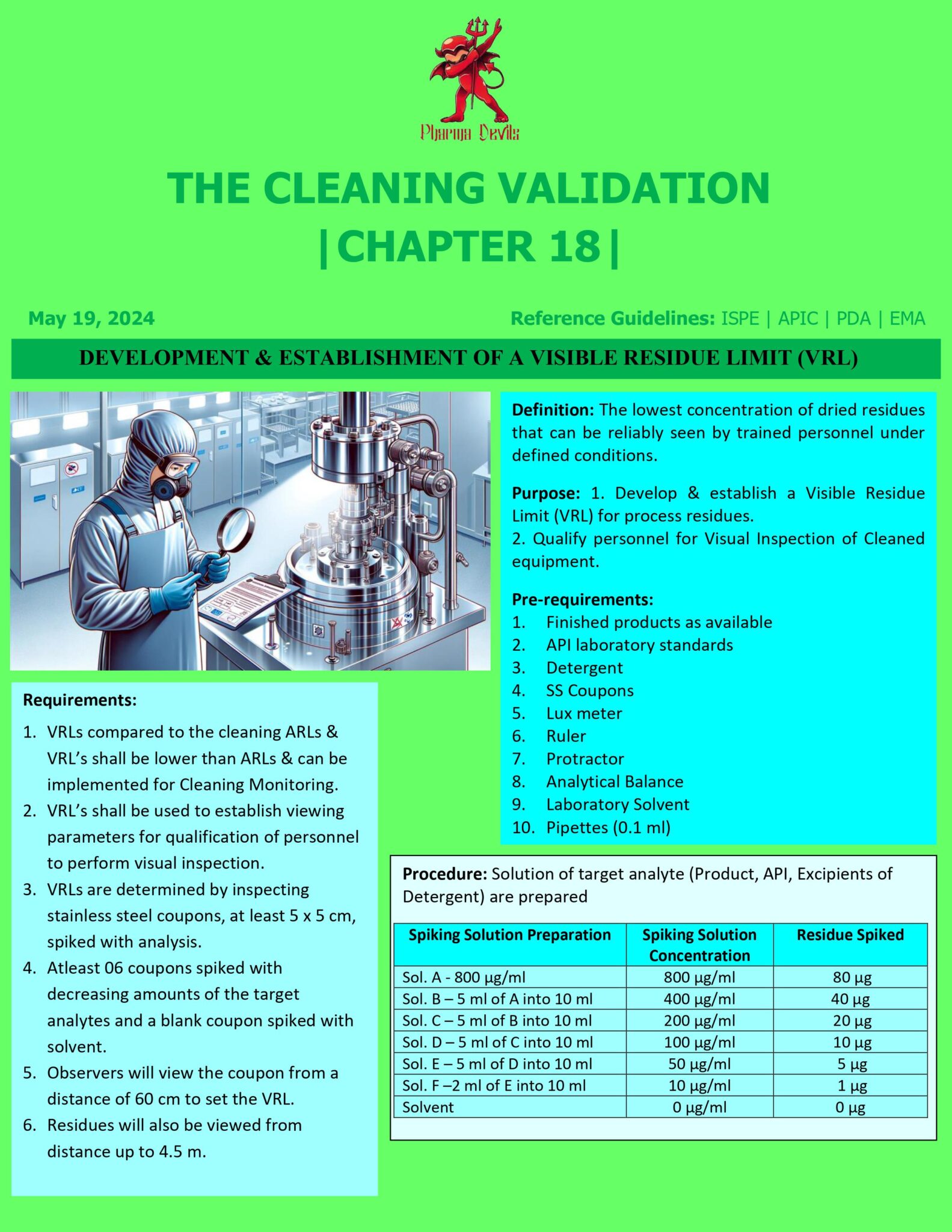

Cleaning Validation (Chapter 18) Development & Establishment of a

Cleaning Agent Residue Limits Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). • limits for the active drug. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: The level of cleanliness that a production unit must maintain at a minimum with every cleaning.

From eureka.patsnap.com

Energysaving and environmentfriendly gunpowder residue cleaning agent Cleaning Agent Residue Limits This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot. Cleaning Agent Residue Limits.

From www.outsourcedpharma.com

Introduction To The ASTM E3106 “Standard Guide To ScienceBased And Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: The. Cleaning Agent Residue Limits.

From www.pharmacalculation.com

Limit of Residual Solvents Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. The. Cleaning Agent Residue Limits.

From www.scribd.com

Ruggedness of Visible Residue Limits For Cleaning Validation PDF Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Learn to set cleaning. Cleaning Agent Residue Limits.

From www.researchgate.net

Examples of maximum allowed residue limits of formaldehyde in textiles Cleaning Agent Residue Limits Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in. Cleaning Agent Residue Limits.

From www.chemanager-online.com

Disinfectant residues in cleanrooms CHEManager Cleaning Agent Residue Limits Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. The level of cleanliness that a production unit must maintain at a minimum with every cleaning.. Cleaning Agent Residue Limits.

From saskpulse.com

Keep it Clean!, Maximum Residue Limits & You Saskatchewan Pulse Growers Cleaning Agent Residue Limits Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2).. Cleaning Agent Residue Limits.

From www.researchgate.net

The usage, chemical group and maximum residue limit (MRL) of the Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: This guideline provides equations and. Cleaning Agent Residue Limits.

From exoukbspl.blob.core.windows.net

Cleaning Agent Journal at Joshua Sharp blog Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Pharmaceutical product manufacturing requires. Cleaning Agent Residue Limits.

From www.yumpu.com

VisibleResidue Limit for Cleaning Validation Spectroscopy Cleaning Agent Residue Limits Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). • limits for the active drug. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Pharmaceutical product. Cleaning Agent Residue Limits.

From www.slideshare.net

New EMA Requirements Cleaning Validation Limits based on PDE Cleaning Agent Residue Limits Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). This guideline provides equations. Cleaning Agent Residue Limits.

From www.researchgate.net

(PDF) Nonspecific methods for detecting residues of cleaning agents Cleaning Agent Residue Limits Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Pharmaceutical product manufacturing. Cleaning Agent Residue Limits.

From www.pharmamanufacturing.com

Pharma Industry Cleaning Agent Residue Detection with UHPLC Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. • limits for the active drug. This guideline provides equations and examples for calculating the. Cleaning Agent Residue Limits.

From www.scribd.com

RiskManagement Assessment of VisibleResidue Limits in Cleaning Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). •. Cleaning Agent Residue Limits.

From www.slideserve.com

PPT SafeBridge Consultants, Inc. PowerPoint Presentation, free Cleaning Agent Residue Limits Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Pharmaceutical product manufacturing. Cleaning Agent Residue Limits.

From pharmadevils.com

Cleaning Validation (Chapter 18) Development & Establishment of a Cleaning Agent Residue Limits Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Acceptable residue. Cleaning Agent Residue Limits.

From cultofsea.com

Discharge Standards Garbage Marpol Annex V Cleaning Agent Residue Limits This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). • limits for the active drug. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Learn to set cleaning agent residue limits in pharma manufacturing,. Cleaning Agent Residue Limits.

From ntint.com

Cleaning Validation Frequently Asked Questions Novatek International Cleaning Agent Residue Limits The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). •. Cleaning Agent Residue Limits.

From www.researchgate.net

(PDF) Introduction to the New ASTM E3418 "Standard Practice For Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated.. Cleaning Agent Residue Limits.

From www.slideshare.net

Cleaning validation PPT Cleaning Agent Residue Limits Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of.. Cleaning Agent Residue Limits.

From www.pharmacalculation.com

MACO Calculation in Cleaning Validation Cleaning Agent Residue Limits Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Relevant residue limits, derived. Cleaning Agent Residue Limits.

From en-be.ecolab.com

Establishing Effective Visual Residue Limits in Cleaning Validation Cleaning Agent Residue Limits The level of cleanliness that a production unit must maintain at a minimum with every cleaning. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Learn. Cleaning Agent Residue Limits.

From pharmadevils.com

Cleaning Validation (Chapter 18) Development & Establishment of a Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. Acceptable residue limits (arls) must be defined prior to. Cleaning Agent Residue Limits.

From www.scribd.com

Validation of Cleaning Procedures Establishing Acceptable Limits for Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). The level of cleanliness that a production unit must maintain at a minimum with every cleaning. This guideline. Cleaning Agent Residue Limits.

From technotes.alconox.com

Calculating Cleaning Agent Safety Based Limits TechNotes Critical Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: • limits for the active drug. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a. Cleaning Agent Residue Limits.

From www.pharmamanufacturing.com

Pharma Industry Cleaning Agent Residue Detection with UHPLC Cleaning Agent Residue Limits The authors believe that the new astm e3418 standard provides the first comprehensive guide to setting limits for use in cleaning validation for all types of. The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning. Cleaning Agent Residue Limits.

From www.pharmaspecialists.com

Cleaning Validation in Pharmaceutical Industry Cleaning Agent Residue Limits Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). • limits for the active drug. The level of. Cleaning Agent Residue Limits.

From slideplayer.com

Factors for a Green Cleaning Process ppt download Cleaning Agent Residue Limits Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The level of cleanliness that a production unit must maintain. Cleaning Agent Residue Limits.

From www.semanticscholar.org

[PDF] A RiskBased Approach to Cleaning Validation using Visible Cleaning Agent Residue Limits The level of cleanliness that a production unit must maintain at a minimum with every cleaning. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue. Cleaning Agent Residue Limits.

From www.scribd.com

A RiskBased Approach To Cleaning Validation Using Visible Residue Cleaning Agent Residue Limits • limits for the active drug. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits,. Cleaning Agent Residue Limits.

From www.semanticscholar.org

Figure 2 from A RiskBased Approach to Cleaning Validation using Cleaning Agent Residue Limits Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Residue limits were recommended to be practical, achievable, verifiable, and based on the most deleterious residue, based on pharmacological or physiological activity of the api. The. Cleaning Agent Residue Limits.

From www.linkedin.com

How to Set Acceptable Residue Limits for Cleaning Validation Cleaning Agent Residue Limits Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The level of cleanliness that a production unit must maintain at a minimum with every cleaning. The authors believe that the new astm e3418 standard provides the first comprehensive guide to. Cleaning Agent Residue Limits.

From www.semanticscholar.org

Figure 2 from A RiskBased Approach to Cleaning Validation using Cleaning Agent Residue Limits The level of cleanliness that a production unit must maintain at a minimum with every cleaning. This guideline provides equations and examples for calculating the maximum allowable residue (mar), and residue acceptability limits (ral). Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. The authors believe that the new astm e3418 standard provides the. Cleaning Agent Residue Limits.

From www.researchgate.net

Comparisons of Antimicrobial Residues Above Maximum Residue Cleaning Agent Residue Limits Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. • limits for the active drug. Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Acceptable residue limits (arls) must be defined prior to any cleaning validation and development work (1,2). Residue limits were recommended. Cleaning Agent Residue Limits.

From studylib.es

Maximum Residue Limits for Pesticides Health Canadaesparagus Cleaning Agent Residue Limits Relevant residue limits, derived from the toxicological evaluation, cannot be satisfactorily determined by a validated. Pharmaceutical product manufacturing requires identifying and setting acceptable residue limits for potential residues, including: Learn to set cleaning agent residue limits in pharma manufacturing, ensuring product safety, purity, and compliance with cleaning validation. • limits for the active drug. This guideline provides equations and examples. Cleaning Agent Residue Limits.