Carbide Drill Surface Speed . Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. “calculate optimal carbide drill speed using this formula: 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Slide the diameter back and forth and the table will update for the various. This calculator gives guideline cutting speeds for a specified diameter. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Rpm = (cutting speed × 12) / (π × drill diameter). Adjust the cutting speed and/or feed based on your cutting.

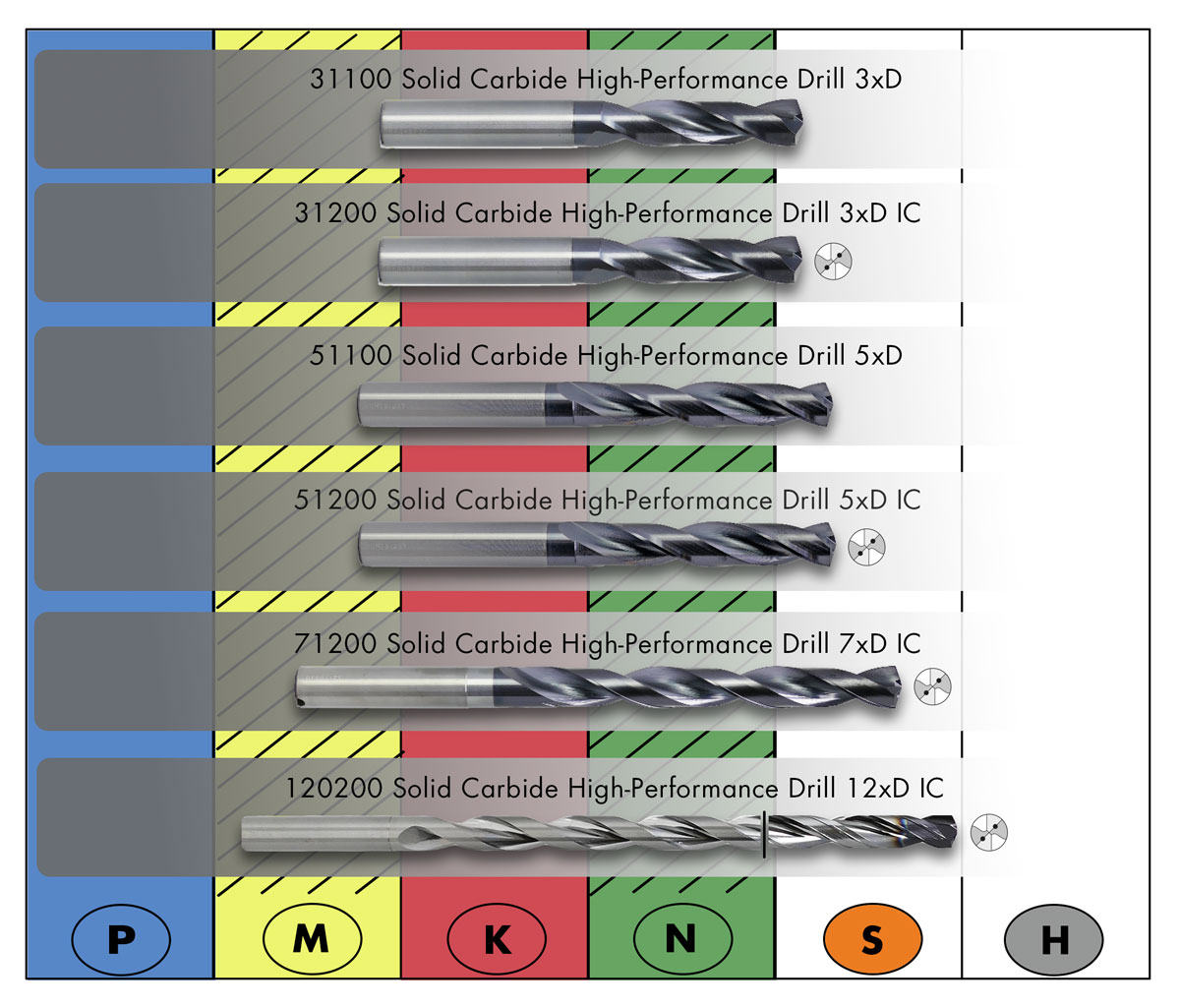

from www.tool-factory.de

Adjust the cutting speed and/or feed based on your cutting. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Rpm = (cutting speed × 12) / (π × drill diameter). 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). “calculate optimal carbide drill speed using this formula: Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Slide the diameter back and forth and the table will update for the various. This calculator gives guideline cutting speeds for a specified diameter.

Solid carbide drills Tool Factory

Carbide Drill Surface Speed Rpm = (cutting speed × 12) / (π × drill diameter). 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). This calculator gives guideline cutting speeds for a specified diameter. “calculate optimal carbide drill speed using this formula: Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Rpm = (cutting speed × 12) / (π × drill diameter). Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Slide the diameter back and forth and the table will update for the various. Adjust the cutting speed and/or feed based on your cutting.

From www.big-tools.com

Solid Carbide Drill with Cylindrical Shank (3xD)No.1 Bigtools Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Rpm = (cutting speed × 12) / (π × drill diameter). Adjust the cutting speed and/or feed based on your cutting. This calculator gives guideline cutting. Carbide Drill Surface Speed.

From exomlutrb.blob.core.windows.net

Morse Carbide Drill Speeds And Feeds at Jose Fierro blog Carbide Drill Surface Speed “calculate optimal carbide drill speed using this formula: This calculator gives guideline cutting speeds for a specified diameter. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the. Carbide Drill Surface Speed.

From www.canadianmetalworking.com

What’s involved with carbide drill hole quality? Carbide Drill Surface Speed Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. “calculate optimal carbide drill speed using this formula: Adjust the cutting speed and/or feed based on your cutting. Rpm =. Carbide Drill Surface Speed.

From www.hillindustrialtools.com

Carbide Reamers Speeds and Feeds Hill Industrial Tools Carbide Drill Surface Speed The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Rpm = (cutting speed × 12) / (π × drill diameter). This calculator gives guideline cutting speeds for a specified diameter. “calculate optimal carbide drill speed using this formula: 2) start with a middle/average value for cutting. Carbide Drill Surface Speed.

From mavink.com

Drilling Speed Chart Carbide Drill Surface Speed Slide the diameter back and forth and the table will update for the various. “calculate optimal carbide drill speed using this formula: Adjust the cutting speed and/or feed based on your cutting. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed for. Carbide Drill Surface Speed.

From ar.inspiredpencil.com

End Mill Speed Chart Carbide Drill Surface Speed Rpm = (cutting speed × 12) / (π × drill diameter). “calculate optimal carbide drill speed using this formula: Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The speeds and. Carbide Drill Surface Speed.

From mavink.com

Tabel Cutting Speed Carbide Drill Surface Speed Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Slide the diameter back and forth and the table will update for the various. This calculator gives guideline cutting speeds for a specified diameter. “calculate optimal carbide drill speed using this formula: Rpm = (cutting speed × 12) /. Carbide Drill Surface Speed.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Carbide Drill Surface Speed The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. “calculate optimal carbide drill speed using this formula: Rpm = (cutting speed × 12) / (π × drill diameter). 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). This. Carbide Drill Surface Speed.

From mungfali.com

Drill Feed Speed Chart Carbide Drill Surface Speed Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Adjust the cutting speed and/or feed based on your cutting. “calculate optimal carbide drill speed using this formula: Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Slide the diameter back. Carbide Drill Surface Speed.

From huanatools.com

Carbide Drill A Basic Introduction Huana Tools Carbide Drill Surface Speed Adjust the cutting speed and/or feed based on your cutting. “calculate optimal carbide drill speed using this formula: This calculator gives guideline cutting speeds for a specified diameter. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material. Carbide Drill Surface Speed.

From sumicarbide.com

GS & HGS Solid Carbide Drills Drilling Tools Sumitomo Electric Carbide Carbide Drill Surface Speed Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Rpm = (cutting speed ×. Carbide Drill Surface Speed.

From huanatools.com

How To Make A Great Carbide Drills? Huana Tools Carbide Drill Surface Speed The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. This calculator gives guideline cutting speeds for a specified diameter. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Adjust the cutting speed and/or feed based on your cutting.. Carbide Drill Surface Speed.

From protocutter.com

Drilling and Reaming Speeds and Feed Rates for Carbide End Mills Carbide Drill Surface Speed Rpm = (cutting speed × 12) / (π × drill diameter). Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Slide the diameter back and forth and the table will update for the various. This calculator gives guideline cutting speeds for a specified diameter. The speeds and feeds calculator may be employed. Carbide Drill Surface Speed.

From www.tool-factory.de

Solid carbide drills Tool Factory Carbide Drill Surface Speed Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc. Carbide Drill Surface Speed.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Carbide Drill Surface Speed The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. This calculator gives guideline cutting speeds for a specified diameter. Slide the diameter back and forth and the table will update for the various. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡. Carbide Drill Surface Speed.

From www.ebay.com

GUHRING CARBIDE FEED & SPEED TWIST DRILLS CHART, GS200s eBay Carbide Drill Surface Speed Adjust the cutting speed and/or feed based on your cutting. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. 2) start with a middle/average value for cutting speed, v c (ft/min). Carbide Drill Surface Speed.

From mungfali.com

Drill Feed Speed Chart Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. “calculate optimal carbide drill speed using this formula: Adjust the cutting speed and/or feed based on your cutting. This calculator. Carbide Drill Surface Speed.

From www.vrogue.co

Sfm Chart Surface Drill It Cast vrogue.co Carbide Drill Surface Speed Adjust the cutting speed and/or feed based on your cutting. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). “calculate optimal carbide drill speed using this formula: Slide the diameter back and forth and the table will update for the various. Rpm = (cutting speed × 12) / (π × drill diameter).. Carbide Drill Surface Speed.

From exomlutrb.blob.core.windows.net

Morse Carbide Drill Speeds And Feeds at Jose Fierro blog Carbide Drill Surface Speed Rpm = (cutting speed × 12) / (π × drill diameter). Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Slide the diameter back and forth and the table will update. Carbide Drill Surface Speed.

From www.carbidedepot.com

Carbide Depot Technical Resources Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Rpm = (cutting speed × 12) / (π × drill diameter). Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. This calculator gives guideline cutting speeds for a specified diameter. The speeds and feeds calculator. Carbide Drill Surface Speed.

From sumicarbide.com

SMD Replaceable Tip Drills Drilling Tools Sumitomo Electric Carbide Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. This calculator gives guideline cutting speeds for a specified diameter. “calculate optimal carbide drill speed using this formula: Adjust the. Carbide Drill Surface Speed.

From giooejbls.blob.core.windows.net

Carbide Drill Speeds And Feeds Chart Pdf at Jean Kaminski blog Carbide Drill Surface Speed Slide the diameter back and forth and the table will update for the various. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Rpm = (cutting speed × 12) / (π × drill diameter). Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min). Carbide Drill Surface Speed.

From www.cnccarbideinserts.com

High Precision Solid Carbide Drill , Carbide Micro Drills With High Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Adjust the cutting speed and/or feed based on your cutting. Slide the diameter back and forth and the table will update for the various. This calculator gives guideline cutting speeds for a specified diameter. Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed. Carbide Drill Surface Speed.

From atlascuttingtools.com

Speeds and Feeds for Carbide Drilling Carbide Drill Surface Speed This calculator gives guideline cutting speeds for a specified diameter. Slide the diameter back and forth and the table will update for the various. Rpm = (cutting speed × 12) / (π × drill diameter). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. “calculate optimal. Carbide Drill Surface Speed.

From www.youtube.com

(HighSpeed Video) Solid Carbide Drill 4140 Steel YouTube Carbide Drill Surface Speed This calculator gives guideline cutting speeds for a specified diameter. Rpm = (cutting speed × 12) / (π × drill diameter). “calculate optimal carbide drill speed using this formula: Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. 2) start with a middle/average value for cutting speed, v. Carbide Drill Surface Speed.

From exomlutrb.blob.core.windows.net

Morse Carbide Drill Speeds And Feeds at Jose Fierro blog Carbide Drill Surface Speed Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. This calculator gives guideline cutting speeds for a specified diameter. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal. Carbide Drill Surface Speed.

From precimactool.com

Custom Designed Carbide Drills Precimac Tool Ltd. Carbide Drill Surface Speed Rpm = (cutting speed × 12) / (π × drill diameter). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. This calculator gives guideline cutting speeds for a specified. Carbide Drill Surface Speed.

From giotsrboi.blob.core.windows.net

Kyocera Carbide Drill Speeds And Feeds at Kevin Rueb blog Carbide Drill Surface Speed The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Rpm = (cutting speed × 12) / (π × drill diameter). Slide the diameter back and forth and the table. Carbide Drill Surface Speed.

From www.ebay.com

GUHRING CARBIDE FEED & SPEED TWIST DRILLS CHART, GS200s eBay Carbide Drill Surface Speed “calculate optimal carbide drill speed using this formula: Slide the diameter back and forth and the table will update for the various. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the. Carbide Drill Surface Speed.

From www.lakeshorecarbide.com

Variable Rougher Speeds & Feeds Lakeshore Carbide Inc. Carbide Drill Surface Speed Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Adjust the cutting speed and/or feed based on your cutting. Rpm = (cutting speed × 12) / (π × drill diameter). This calculator gives guideline cutting speeds for a specified diameter. Determine the spindle speed for turning, milling, drilling,. Carbide Drill Surface Speed.

From www.cnccookbook.com

Carbide Drill Speeds and Feeds [Plus Tips and Techniques] Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Adjust the cutting speed and/or feed based on your cutting. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. “calculate optimal carbide drill speed using this formula: This calculator. Carbide Drill Surface Speed.

From mavink.com

Drilling Speed Chart Carbide Drill Surface Speed Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. “calculate optimal carbide drill speed using this formula: Rpm = (cutting speed × 12) / (π × drill diameter). The speeds and. Carbide Drill Surface Speed.

From sumicarbide.com

WDX Indexable Drill Drilling Tools Sumitomo Electric Carbide, Inc. Carbide Drill Surface Speed “calculate optimal carbide drill speed using this formula: Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. This calculator gives guideline cutting speeds for a specified diameter. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Slide the diameter back. Carbide Drill Surface Speed.

From www.tool-factory.de

Solid carbide drills Tool Factory Carbide Drill Surface Speed Slide the diameter back and forth and the table will update for the various. Adjust the cutting speed and/or feed based on your cutting. Rpm = (cutting speed × 12) / (π × drill diameter). This calculator gives guideline cutting speeds for a specified diameter. 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f. Carbide Drill Surface Speed.

From www.metadental.com

Carbide Drill Bits Carbide Drill Surface Speed 2) start with a middle/average value for cutting speed, v c (ft/min) and feed, f n (in/rev). Cutting speed (m/min) 𝑣𝑐= 𝜋⋅𝐷𝑡 𝑙⋅𝑛 1000 spindle speed (rev/min) 𝑛= 𝑣𝑐⋅1000 𝜋⋅𝐷𝑡 𝑙 material removal rate (cm3/min) 𝑀𝑅𝑅= dtool⋅fn⋅vc 4. Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Adjust the cutting speed and/or. Carbide Drill Surface Speed.