Threading Meaning Machining . Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. It is a subtractive method used in making external and internal threads of different. Threads can generally be categorized into two main types: Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Depending on the application, threads are. This refers to threads that are on the outer surface of a component. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. This technique is used to produce intricate. Thread machining is one of the most important applications in a cnc machining center. Each threading method and tool has its own advantages in certain. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece.

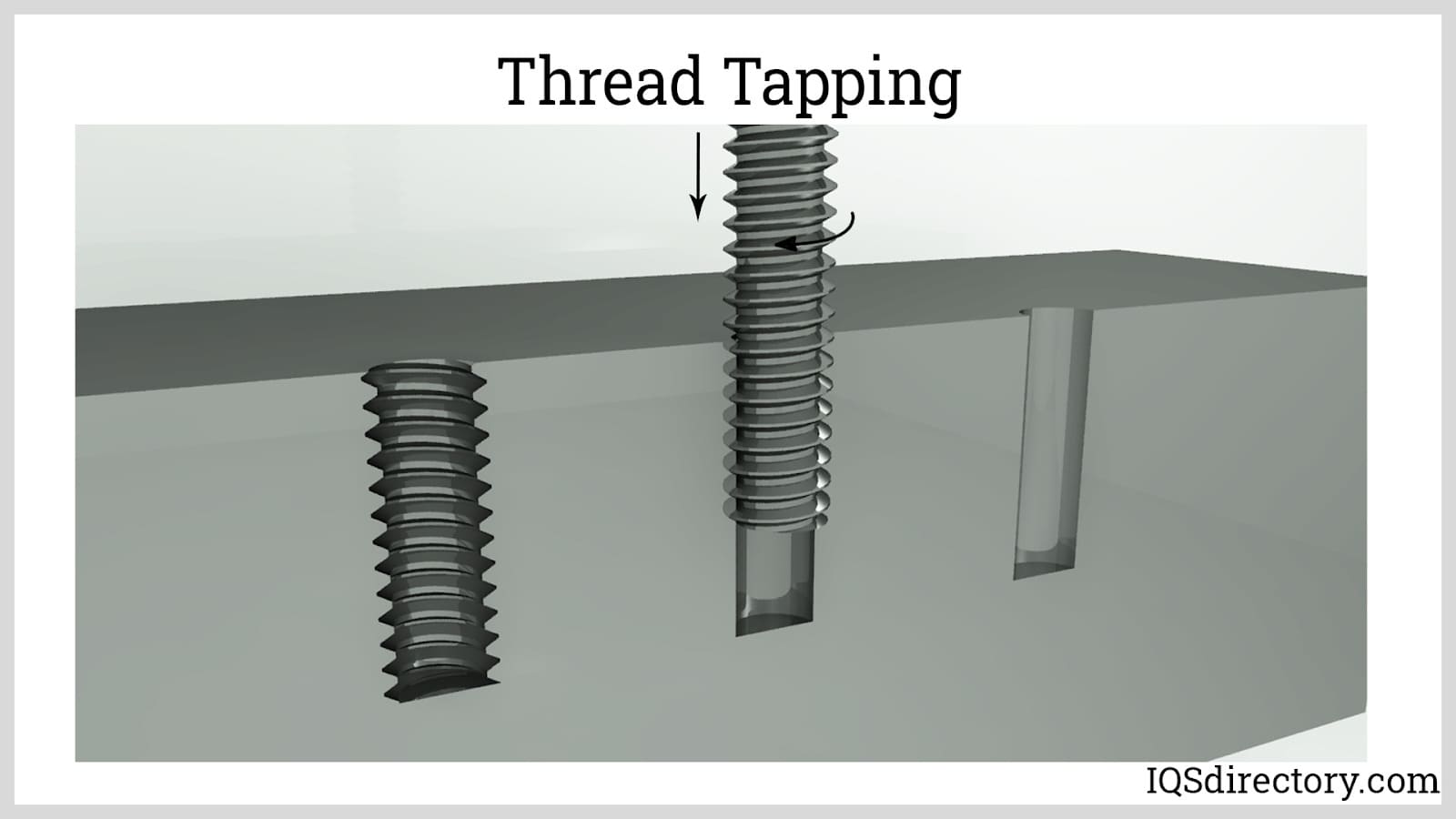

from www.iqsdirectory.com

This refers to threads that are on the outer surface of a component. Depending on the application, threads are. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Threads can generally be categorized into two main types: This technique is used to produce intricate. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread machining is one of the most important applications in a cnc machining center. It is a subtractive method used in making external and internal threads of different.

Thread Rolling What Is It? How Does It Work? Process, Types

Threading Meaning Machining Each threading method and tool has its own advantages in certain. This technique is used to produce intricate. Threads can generally be categorized into two main types: Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Thread machining is one of the most important applications in a cnc machining center. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. This refers to threads that are on the outer surface of a component. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Each threading method and tool has its own advantages in certain. Depending on the application, threads are. It is a subtractive method used in making external and internal threads of different.

From www.youtube.com

Multiple tool programming practical Turning grooving and Threading Threading Meaning Machining Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. This technique is used to produce intricate. Depending on the application, threads are. It is a subtractive method used in making external and internal threads of different. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical. Threading Meaning Machining.

From www.alamy.com

Threading die in tap wrench on technical drawing detail. Steel cutting Threading Meaning Machining This refers to threads that are on the outer surface of a component. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Depending on the application, threads are. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread machining is one. Threading Meaning Machining.

From www.rapiddirect.com

The Ultimate Guide to Machining Thread RapidDirect Blog Threading Meaning Machining This technique is used to produce intricate. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Each threading. Threading Meaning Machining.

From www.scribd.com

Thread Data Charts Cutting Tools Machining Threading Meaning Machining Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Each threading method and tool has its own advantages in certain. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. This refers to threads that are on the outer surface of a component. Threads can. Threading Meaning Machining.

From www.youtube.com

left hand threading vs right hand threading on cnc lathe cnc Threading Meaning Machining Threads can generally be categorized into two main types: There are a variety of threading methods and tools suited to different components, thread profiles and pitches. It is a subtractive method used in making external and internal threads of different. Thread machining is one of the most important applications in a cnc machining center. This refers to threads that are. Threading Meaning Machining.

From at-machining.com

Mastering the Concept of Thread Machining ATMachining Threading Meaning Machining Thread machining is one of the most important applications in a cnc machining center. Threads can generally be categorized into two main types: Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. This technique is used to produce intricate. Threads are continuous helical edges on cylindrical and conical surfaces. Threading Meaning Machining.

From www.dreamstime.com

Closeup Process of Metal Machining by Threading Stock Photo Image of Threading Meaning Machining Threads can generally be categorized into two main types: There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread machining is a vital subtractive process that involves removing material to create threads. Threading Meaning Machining.

From www.frankminnella.com

MACHINE DRAWINGS Threading Meaning Machining Depending on the application, threads are. Thread machining is one of the most important applications in a cnc machining center. Each threading method and tool has its own advantages in certain. Threads can generally be categorized into two main types: This refers to threads that are on the outer surface of a component. Threads are continuous helical edges on cylindrical. Threading Meaning Machining.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Meaning Machining Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Each threading method and tool has its own advantages in certain. Depending on the application, threads are. Threads can generally be categorized into two main types: Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece.. Threading Meaning Machining.

From www.dreamstime.com

Closeup Process of Metal Threading Stock Photo Image of machine Threading Meaning Machining This technique is used to produce intricate. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Each threading method and tool has its own advantages in certain. Thread machining is one of the most important applications in a cnc machining center. This refers to threads that are on the outer surface of. Threading Meaning Machining.

From www.harveyperformance.com

MultiStart Thread Reference Guide In The Loupe Machinist Blog Threading Meaning Machining Depending on the application, threads are. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Thread machining is one of the most important applications in a cnc machining center. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. This technique is used to produce. Threading Meaning Machining.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Threading Meaning Machining It is a subtractive method used in making external and internal threads of different. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Thread machining is one of the most important applications in a cnc machining center. Threads can generally be categorized into two main types: Threads are continuous helical edges on. Threading Meaning Machining.

From facfox.com

Threaded Holes Guidelines for CNC Machining FacFox Docs Threading Meaning Machining This refers to threads that are on the outer surface of a component. It is a subtractive method used in making external and internal threads of different. Each threading method and tool has its own advantages in certain. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. This technique is used to. Threading Meaning Machining.

From www.machiningdoctor.com

Thread Methods An introduction by the Machining Doctor Threading Meaning Machining Depending on the application, threads are. This refers to threads that are on the outer surface of a component. Thread machining is one of the most important applications in a cnc machining center. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Threading is a crucial process in manufacturing that involves creating. Threading Meaning Machining.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Threading Meaning Machining There are a variety of threading methods and tools suited to different components, thread profiles and pitches. This technique is used to produce intricate. Depending on the application, threads are. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Each threading method and tool has its own advantages in certain. This refers. Threading Meaning Machining.

From www.dreamstime.com

Closeup Process of Metal Threading Stock Image Image of industrial Threading Meaning Machining Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Depending on the application, threads are. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Thread machining is. Threading Meaning Machining.

From www.worthyhardware.com

Everything you need to know about Machining Thread CNC Precision Threading Meaning Machining Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. This technique is used to produce intricate. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. There are a variety of threading methods and tools suited to different components, thread profiles and. Threading Meaning Machining.

From www.smaco-intl.com

THREADING MACHINE 60 Threading Meaning Machining This technique is used to produce intricate. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Threads can generally be categorized into two main types: Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in. Threading Meaning Machining.

From woodworkingset.com

Threading Lathe Tool A Beginner's Guide to Perfect Thread Cuts. Threading Meaning Machining Thread machining is one of the most important applications in a cnc machining center. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different. This technique is used to produce intricate. Depending on the application, threads. Threading Meaning Machining.

From proleantech.com

A Comprehensive Comparison of Grooving and Threading Techniques CNC Threading Meaning Machining Threads can generally be categorized into two main types: Depending on the application, threads are. Each threading method and tool has its own advantages in certain. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. This technique is used to produce intricate. It is a subtractive method used in making external and. Threading Meaning Machining.

From machiningtool.blogspot.com

Machining Turning thread on a Lathe Threading Meaning Machining Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. It is a subtractive method used in making external and internal threads of different. Thread machining is one of the most important applications. Threading Meaning Machining.

From facfox.com

Everything You Need to Know About CNC Machining FacFox Docs Threading Meaning Machining This technique is used to produce intricate. Each threading method and tool has its own advantages in certain. Depending on the application, threads are. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different. Thread machining. Threading Meaning Machining.

From www.iqsdirectory.com

Screw Machined Parts & Products What Are They? Types & Uses Threading Meaning Machining Thread machining is one of the most important applications in a cnc machining center. Threads can generally be categorized into two main types: Each threading method and tool has its own advantages in certain. Depending on the application, threads are. This technique is used to produce intricate. This refers to threads that are on the outer surface of a component.. Threading Meaning Machining.

From www.slideserve.com

PPT Topics PowerPoint Presentation, free download ID345512 Threading Meaning Machining This refers to threads that are on the outer surface of a component. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different. Threads can generally be categorized into two main types: This technique is used. Threading Meaning Machining.

From engineeringlearn.com

13 Types of Threads Definition, Parts and Thread Identifying Tools Threading Meaning Machining Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Depending on the application, threads are. There are a. Threading Meaning Machining.

From www.slideserve.com

PPT Machining Module 5 Lathe Setup and Operations PowerPoint Threading Meaning Machining Thread machining is one of the most important applications in a cnc machining center. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. It is a subtractive method used in making external and internal threads of different. Threads can generally be categorized into two main types: Threading is a crucial process in. Threading Meaning Machining.

From jbcmachine.com

Threading Services JBC Machine, Inc. Threading Meaning Machining There are a variety of threading methods and tools suited to different components, thread profiles and pitches. This technique is used to produce intricate. Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a. Threading Meaning Machining.

From www.nextgentooling.com

Thread Milling Techniques NEXT GENERATION TOOLING Threading Meaning Machining Thread machining is one of the most important applications in a cnc machining center. This refers to threads that are on the outer surface of a component. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Thread machining is a vital subtractive process that involves removing material to create threads on a. Threading Meaning Machining.

From www.nov.com

Premium Threading, Machining and Testing Services NOV Threading Meaning Machining This technique is used to produce intricate. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. This refers to threads that are on the outer surface of a component. It is a subtractive method used in making external and internal threads of different. Thread machining is a vital subtractive process that involves. Threading Meaning Machining.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Meaning Machining Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. This refers to threads that are on the outer surface of a component. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread machining is a vital subtractive process that involves removing. Threading Meaning Machining.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Meaning Machining Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. It is a subtractive method used in making external and internal threads of different. This technique is used to produce intricate. Threads can generally be categorized into two main types: Threading is a crucial process in manufacturing that involves creating a helical structure,. Threading Meaning Machining.

From www.researchgate.net

Schematic diagram of thread machining process. Download Scientific Threading Meaning Machining Threads can generally be categorized into two main types: Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. It is a subtractive method used in making external and internal threads of different.. Threading Meaning Machining.

From www.sandvik.coromant.com

Threading in machining Threading Meaning Machining This technique is used to produce intricate. Each threading method and tool has its own advantages in certain. There are a variety of threading methods and tools suited to different components, thread profiles and pitches. Thread machining is one of the most important applications in a cnc machining center. Depending on the application, threads are. Threading is a crucial process. Threading Meaning Machining.

From www.youtube.com

Oster Bolt Threading Machine YouTube Threading Meaning Machining Threading is a crucial process in manufacturing that involves creating a helical structure, known as a thread, on a workpiece. Thread machining is one of the most important applications in a cnc machining center. Depending on the application, threads are. Threads can generally be categorized into two main types: This refers to threads that are on the outer surface of. Threading Meaning Machining.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Threading Meaning Machining Thread machining is a vital subtractive process that involves removing material to create threads on a workpiece. This technique is used to produce intricate. Threads are continuous helical edges on cylindrical and conical surfaces used for mechanical and product part coupling. Each threading method and tool has its own advantages in certain. There are a variety of threading methods and. Threading Meaning Machining.