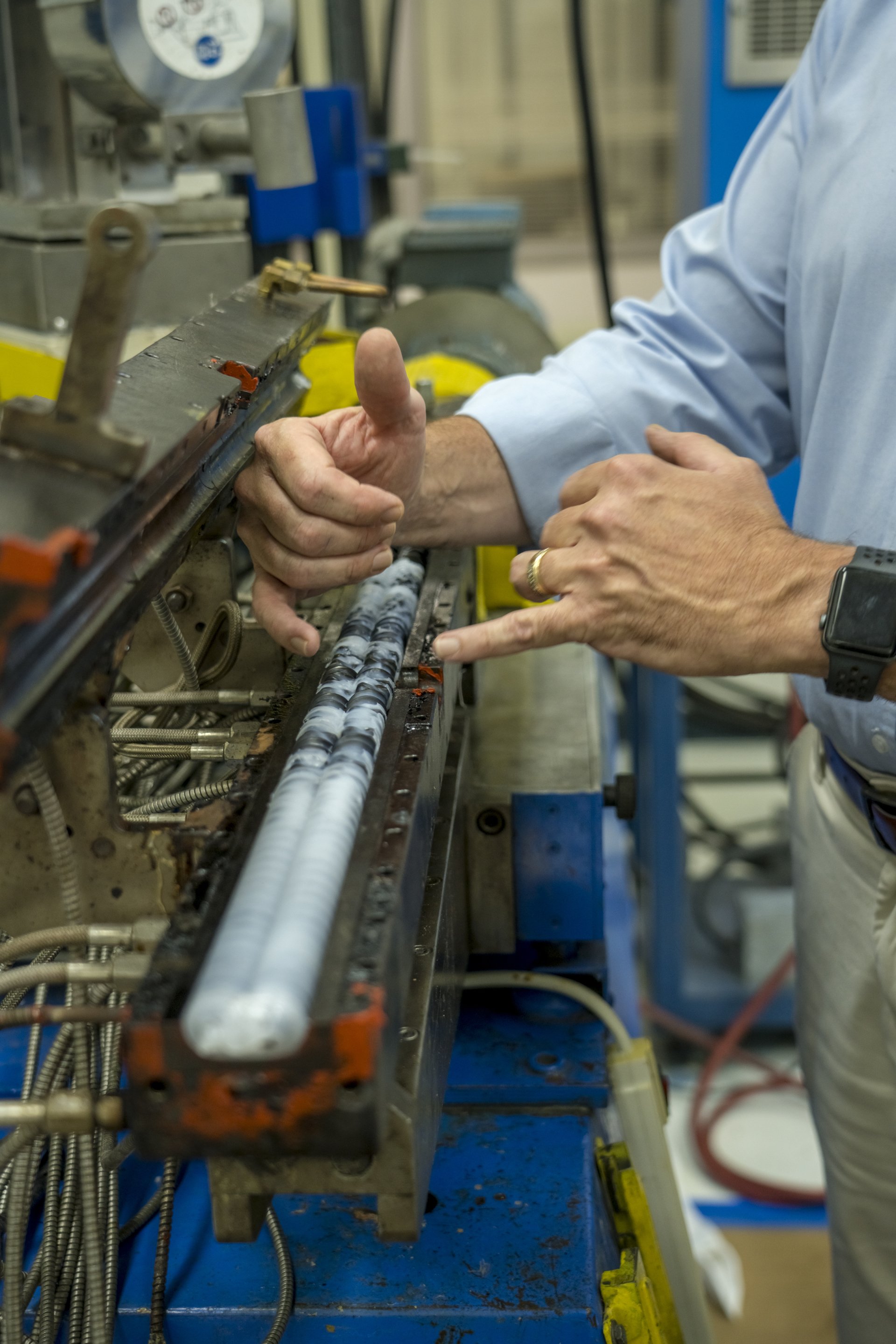

What Is Polymer Extrusion . This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. To understand the process better, it’s important to first understand the extruder and how it works. The combination of a rotating screw inside a barrel produces the pressure. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. It involves heating, shaping, cooling, and cutting the plastic. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure.

from www.polymers-tech-center.com

This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. It involves heating, shaping, cooling, and cutting the plastic. The material is gradually melted. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. The combination of a rotating screw inside a barrel produces the pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden.

Polymer Extrusion Polymers Technology Center

What Is Polymer Extrusion The combination of a rotating screw inside a barrel produces the pressure. It involves heating, shaping, cooling, and cutting the plastic. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. The process involves melting plastic, shaping it, and then cooling it to harden. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The combination of a rotating screw inside a barrel produces the pressure. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics What Is Polymer Extrusion The material is gradually melted. To understand the process better, it’s important to first understand the extruder and how it works. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. It involves heating, shaping, cooling, and cutting the plastic. The combination of a rotating screw inside a barrel. What Is Polymer Extrusion.

From www.researchgate.net

Sectional view of liquidpolymer coextrusion spin pack. Download What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. The combination of a rotating screw inside a barrel produces the pressure. It involves heating, shaping, cooling, and cutting the plastic. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. This process starts by feeding plastic material (pellets, granules, flakes or. What Is Polymer Extrusion.

From www.polymers-tech-center.com

Polymer Extrusion Polymers Technology Center What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. The combination of a rotating screw inside a. What Is Polymer Extrusion.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? What Is Polymer Extrusion This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. The material is gradually melted. It involves heating, shaping, cooling, and. What Is Polymer Extrusion.

From www.youtube.com

Basic Of Extrusion Process I Type of extrusion technique YouTube What Is Polymer Extrusion In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a. What Is Polymer Extrusion.

From www.polychlor.ca

The Extrusion Process PolyChlor Plastic Profile Extrusion Basics What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. The material is gradually melted. To understand the process better, it’s important to first understand the extruder and how it works. It involves heating, shaping, cooling, and cutting the plastic. This method involves heating thermoplastic materials to their melting point and then using pressure to force the. What Is Polymer Extrusion.

From www.youtube.com

Polymer Extrusion Manufacturers, Suppliers, and Industry Information What Is Polymer Extrusion The material is gradually melted. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. It involves heating, shaping, cooling, and cutting the plastic. The process involves melting plastic, shaping it, and then cooling it to harden. To understand the process better, it’s important to. What Is Polymer Extrusion.

From www.xometry.com

All About Plastic Extrusion Xometry What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. The process involves melting. What Is Polymer Extrusion.

From www.slideserve.com

PPT Example Polymer Extrusion PowerPoint Presentation, free download What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. The process involves melting plastic, shaping it, and then cooling it to harden. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into. What Is Polymer Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works. This method involves heating thermoplastic materials to their melting point and then using. What Is Polymer Extrusion.

From www.pinnaxis.com

Plastic Extrusion What Is It? How Does It Work? Process, 47 OFF What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works. The combination of a rotating screw inside a barrel produces the pressure. This. What Is Polymer Extrusion.

From resource.download.wjec.co.uk.s3.amazonaws.com

Design and Technology What Is Polymer Extrusion This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. To understand the process better, it’s important to first understand the extruder and how it works. The material is gradually melted. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves. What Is Polymer Extrusion.

From www.mdpi.com

Polymers Free FullText Fundamentals of Global Modeling for Polymer What Is Polymer Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves. What Is Polymer Extrusion.

From www.essaii.com

What is a plastic extrusion process in a stepbystep guide? What Is Polymer Extrusion Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. To understand the process better, it’s important to first understand the extruder and how it works. This method involves heating thermoplastic materials to their. What Is Polymer Extrusion.

From onlytrainings.com

Polymer Extrusion Quick Overview Of Extrusion Process & Parameters What Is Polymer Extrusion It involves heating, shaping, cooling, and cutting the plastic. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the. What Is Polymer Extrusion.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips What Is Polymer Extrusion The material is gradually melted. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. To understand the process better, it’s important to first understand the extruder and how it works. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel. What Is Polymer Extrusion.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and What Is Polymer Extrusion Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. To understand the process better, it’s important to first understand the extruder and how. What Is Polymer Extrusion.

From extrudedplastics.com

Polymer Extrusion Manufacturers Polymer Extrusion Supplier What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. It involves heating, shaping, cooling, and cutting the plastic. The material. What Is Polymer Extrusion.

From present5.com

POLYMER PROCESSING Processing is the source of What Is Polymer Extrusion This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. The process involves melting plastic, shaping it, and then cooling it to harden. Components. What Is Polymer Extrusion.

From www.polymers-tech-center.com

Polymer Extrusion Polymers Technology Center What Is Polymer Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process involves melting plastic, shaping it, and then cooling it to harden. The material is gradually melted. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process. What Is Polymer Extrusion.

From mungfali.com

Polymer Extrusion Process What Is Polymer Extrusion It involves heating, shaping, cooling, and cutting the plastic. The material is gradually melted. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper. What Is Polymer Extrusion.

From www.mdpi.com

Polymers Free FullText Fundamentals of Global Modeling for Polymer What Is Polymer Extrusion To understand the process better, it’s important to first understand the extruder and how it works. The material is gradually melted. The combination of a rotating screw inside a barrel produces the pressure. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help. What Is Polymer Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Is Polymer Extrusion The combination of a rotating screw inside a barrel produces the pressure. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. The. What Is Polymer Extrusion.

From www.fukuvi-usa.com

EXTRUSION 101 Fukuvi USA, manufacturer of highquality extruded What Is Polymer Extrusion It involves heating, shaping, cooling, and cutting the plastic. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves melting plastic, shaping it, and then cooling it to harden. The combination of a rotating screw inside a barrel produces the pressure. In the simplest definition, plastic extrusion is a process that melts. What Is Polymer Extrusion.

From www.youtube.com

Extrusion Animation of the polymer extrusion process YouTube What Is Polymer Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process involves melting plastic, shaping it, and then cooling it to harden. The material is gradually melted. The combination of a rotating screw inside a barrel produces the pressure. Plastic extrusion is a process where granular pieces of. What Is Polymer Extrusion.

From fabacademy.org

What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. The. What Is Polymer Extrusion.

From engineeringlearn.com

Types of Extrusion Process Working, Advantages & Disadvantages What Is Polymer Extrusion Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The combination of a rotating screw inside a barrel produces the pressure. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. It involves. What Is Polymer Extrusion.

From www.elastron.com

What is Extrusion? Plastic Extrusion Process Elastron TPE What Is Polymer Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. Plastic extrusion is a process where granular pieces of plastics go through different components. What Is Polymer Extrusion.

From www.mdpi.com

Polymers Free FullText Fundamentals of Global Modeling for Polymer What Is Polymer Extrusion This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. The process involves melting plastic, shaping it, and then cooling it to harden. To understand the process better, it’s important to first understand the extruder and how it works. The material is gradually melted. Plastic extrusion is a process. What Is Polymer Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Is Polymer Extrusion This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. It involves heating, shaping, cooling, and cutting the plastic. To understand the process better, it’s important to first understand the extruder and how it works. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a. What Is Polymer Extrusion.

From www.mdpi.com

Polymers Free FullText Fundamentals of Global Modeling for Polymer What Is Polymer Extrusion The combination of a rotating screw inside a barrel produces the pressure. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material. What Is Polymer Extrusion.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. What Is Polymer Extrusion.

From ramextrusion.co.uk

Plastic Extrusion Process Explained Thoroughly By RAM Extrusion What Is Polymer Extrusion Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. This method involves heating thermoplastic materials to their melting point and then using pressure to force the plastic through a die. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process involves. What Is Polymer Extrusion.

From www.slideserve.com

PPT Polymer Processing Techniques PowerPoint Presentation, free What Is Polymer Extrusion The process involves melting plastic, shaping it, and then cooling it to harden. The material is gradually melted. In the simplest definition, plastic extrusion is a process that melts and molds plastic into different shapes and is done on a pretty large scale. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The combination. What Is Polymer Extrusion.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits What Is Polymer Extrusion The material is gradually melted. The process involves melting plastic, shaping it, and then cooling it to harden. Components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. It involves heating, shaping, cooling, and cutting the plastic. The combination of a rotating screw inside a barrel produces the pressure. This method involves heating thermoplastic materials. What Is Polymer Extrusion.