Glass Tubing Manufacturing Process . The danner process was developed for the continuous production of glass tubing and rods. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to equipment design the process can make tubing of 1.6mm to. The float glass production process can be divided into five universal steps: The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries.

from www.eastern-steels.com

Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. The danner process was developed for the continuous production of glass tubing and rods. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Subject to equipment design the process can make tubing of 1.6mm to. The float glass production process can be divided into five universal steps:

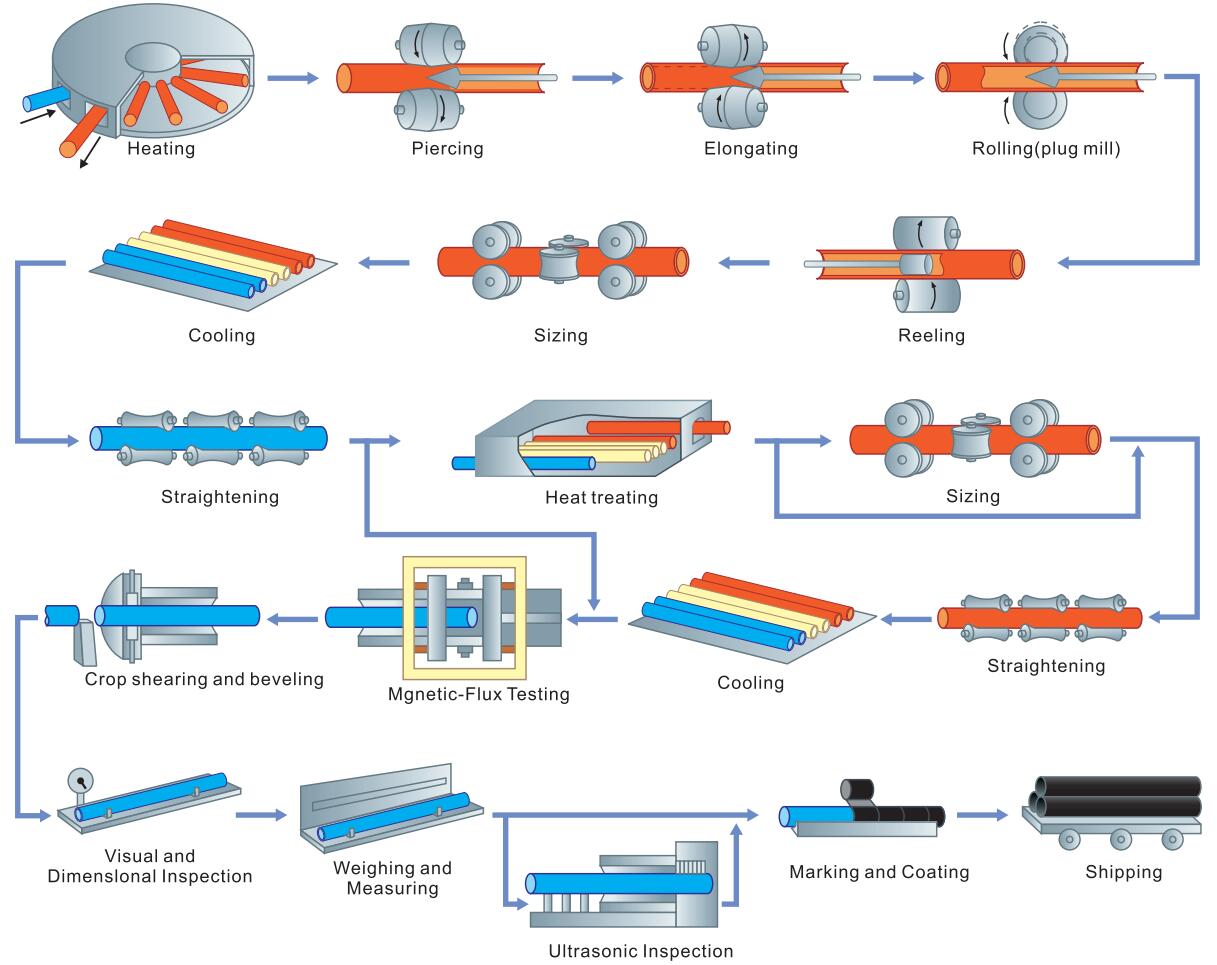

Pipe Manufacturing Process

Glass Tubing Manufacturing Process Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. Subject to equipment design the process can make tubing of 1.6mm to. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. The float glass production process can be divided into five universal steps: Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The danner process was developed for the continuous production of glass tubing and rods. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality.

From www.permanentsteel.com

ERW Pipe Manufacturing Process Glass Tubing Manufacturing Process Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The main components, comprising silica. Glass Tubing Manufacturing Process.

From www.ashtapadoverseas.com

Stainless Steel welded pipe & tubes manufacturing process Glass Tubing Manufacturing Process The danner process was developed for the continuous production of glass tubing and rods. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Schott has been. Glass Tubing Manufacturing Process.

From www.offersteels.com

Rectangular & Square TubingPipe with full sizesAHL STEEL Glass Tubing Manufacturing Process The danner process was developed for the continuous production of glass tubing and rods. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range. Glass Tubing Manufacturing Process.

From www.researchgate.net

Glass tube during production process. Download Scientific Diagram Glass Tubing Manufacturing Process The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. The float glass production process can be divided into five universal steps: Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The danner process was developed for the continuous. Glass Tubing Manufacturing Process.

From www.researchgate.net

Glass tube drawing during tubing process Download Scientific Diagram Glass Tubing Manufacturing Process The float glass production process can be divided into five universal steps: Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. Subject to equipment design the process can make tubing of 1.6mm to. How tubular glass manufacturing processes can affect the final. Glass Tubing Manufacturing Process.

From www.pennarindia.com

Precision Tubes Precision Excellence By Pennar Industries Glass Tubing Manufacturing Process Subject to equipment design the process can make tubing of 1.6mm to. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Glass forming is the. Glass Tubing Manufacturing Process.

From www.fibrex.com

FIBERGLASS PIPE (FRP Pipe) FIBREX Fiberglass Pipe Manufacturer, FRP Glass Tubing Manufacturing Process Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The danner process was developed for the continuous production of glass tubing and rods. Subject to equipment design the process can make tubing of 1.6mm to. Tubing produces more than 60 different glass types. Glass Tubing Manufacturing Process.

From designwanted.com

What is Machine Glass Blowing? Let us tell you... DesignWanted Glass Tubing Manufacturing Process The float glass production process can be divided into five universal steps: The danner process was developed for the continuous production of glass tubing and rods. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is. Glass Tubing Manufacturing Process.

From kombis.net

Tube Making Machines (TMM) Categories Glass Tubing Manufacturing Process Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. Tube drawing is a. Glass Tubing Manufacturing Process.

From novopac.it

Glass Solutions Novopac Glass Tubing Manufacturing Process The float glass production process can be divided into five universal steps: Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine. Glass Tubing Manufacturing Process.

From www.nipro-group.com

eNable NSV51 glass tubing Nipro Glass Tubing Manufacturing Process Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. The danner process was developed for the continuous production of glass tubing and rods. How tubular glass manufacturing processes. Glass Tubing Manufacturing Process.

From www.youtube.com

LEARN AND GROW !! TUBE DRAWING PROCESS ! YouTube Glass Tubing Manufacturing Process How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to equipment design the process can make tubing of 1.6mm to. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Tubing produces. Glass Tubing Manufacturing Process.

From merkantilaklubben.org

Top 106+ Glass manufacturing process animation Glass Tubing Manufacturing Process The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Subject to equipment design the process can make tubing of 1.6mm to. The danner process was developed for the continuous. Glass Tubing Manufacturing Process.

From read.cholonautas.edu.pe

Pvc Pipe Manufacturing Process Flow Chart Pdf Printable Templates Free Glass Tubing Manufacturing Process Subject to equipment design the process can make tubing of 1.6mm to. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one,. Glass Tubing Manufacturing Process.

From glassed.vitroglazings.com

Float Glass Process Glass Tubing Manufacturing Process Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. The danner process was developed for the continuous production of glass tubing and rods. Subject to equipment design the process can make tubing of 1.6mm to. The float glass production process can be. Glass Tubing Manufacturing Process.

From www.johnmoncrieff.co.uk

The advantages of using the Glass Forming manufacturing process Glass Tubing Manufacturing Process Subject to equipment design the process can make tubing of 1.6mm to. The danner process was developed for the continuous production of glass tubing and rods. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of. Glass Tubing Manufacturing Process.

From bedfordreinforced.com

The Pultrusion Process How Pultrusion Works (Pultruded Profiles) Glass Tubing Manufacturing Process Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to. Glass Tubing Manufacturing Process.

From www.glassfurnaceengineering.com

Laboratory Tube 2.23g/Cm3 380V Glass Processing Plant Glass Tubing Manufacturing Process Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one,. Glass Tubing Manufacturing Process.

From espadcompany.ir

Seamless فیدار اسپاد Glass Tubing Manufacturing Process Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. Subject to equipment design the process can make tubing of 1.6mm to. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size. Glass Tubing Manufacturing Process.

From blogs.sw.siemens.com

Video Plant Simulation in tube glass manufacturing Tecnomatix Glass Tubing Manufacturing Process Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. The float glass production process can be divided into five universal steps: How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Tubing produces. Glass Tubing Manufacturing Process.

From www.eastern-steels.com

Pipe Manufacturing Process Glass Tubing Manufacturing Process Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. The danner process was developed for the. Glass Tubing Manufacturing Process.

From novopac.it

Glass Solutions Novopac Glass Tubing Manufacturing Process How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to equipment design the process can make tubing of 1.6mm to. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The danner process was developed. Glass Tubing Manufacturing Process.

From www.researchgate.net

2 Data set used for the identification of the glass tube production Glass Tubing Manufacturing Process The float glass production process can be divided into five universal steps: Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The main components, comprising. Glass Tubing Manufacturing Process.

From www.manufacturingguide.com

Tube drawing Find suppliers, processes & material Glass Tubing Manufacturing Process The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of. Glass Tubing Manufacturing Process.

From www.youtube.com

Cosmetic Tube Manufacturing Process Step by Step Extruded Tube YouTube Glass Tubing Manufacturing Process The danner process was developed for the continuous production of glass tubing and rods. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Subject to equipment design the process can make tubing of 1.6mm to. Schott has been manufacturing glass. Glass Tubing Manufacturing Process.

From mpl.mpg.de

Stackanddraw Glass Tubing Manufacturing Process The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to equipment. Glass Tubing Manufacturing Process.

From www.strongwell.com

Pultrusion Industry Pultruded Fiber Reinforced Polymer Glass Tubing Manufacturing Process The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Schott has been manufacturing glass using the continuous tank melting process since 1911, consistently striving to improve and refine its techniques to produce products that are as. The danner process was developed for the continuous production of glass tubing and rods. How tubular glass manufacturing processes. Glass Tubing Manufacturing Process.

From slidetodoc.com

Chapter 18 Processing of Ceramics Glass and Superconductors Glass Tubing Manufacturing Process How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The danner process was developed for the continuous production of glass tubing and rods. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Subject to equipment. Glass Tubing Manufacturing Process.

From www.nipponsteel.com

Manufacturing Process Pipes and Tubes Products Nippon Steel Glass Tubing Manufacturing Process Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The float glass production process can be divided into five universal steps: Schott has. Glass Tubing Manufacturing Process.

From snailglass.en.made-in-china.com

Glass Tubing Neutral Glass Tubing 5.0 for Making Vials and Ampoules Glass Tubing Manufacturing Process Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. The main components, comprising silica sand, calcium. Glass Tubing Manufacturing Process.

From novopac.it

Glass Solutions Novopac Glass Tubing Manufacturing Process The danner process was developed for the continuous production of glass tubing and rods. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The float glass production process can. Glass Tubing Manufacturing Process.

From www.steelpipesfactory.com

Seamless Pipes Manufacturing How to Produce Seamless Steel Pipes? Glass Tubing Manufacturing Process Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. Subject to equipment design the process can make tubing of 1.6mm to. How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. The danner. Glass Tubing Manufacturing Process.

From novopac.it

Glass Solutions Novopac Glass Tubing Manufacturing Process How tubular glass manufacturing processes can affect the final product stability and technological improvement to mitigate it. Subject to equipment design the process can make tubing of 1.6mm to. Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. Glass forming is the. Glass Tubing Manufacturing Process.

From slidetodoc.com

Chapter 18 Ceramics Glasses Superconductors Processing and Equipment Glass Tubing Manufacturing Process The float glass production process can be divided into five universal steps: Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. The main components, comprising silica sand, calcium oxide, soda & magnesium are weighed and. Subject to equipment design the process can make. Glass Tubing Manufacturing Process.

From www.yizengpipe.com

How to make seamless pipes? Knowledge Cangzhou Yizeng Industry Co.,LTD Glass Tubing Manufacturing Process Tubing produces more than 60 different glass types in a large variety of dimensional and cosmetic specifications based on a standardized production process and a global quality. Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. How tubular glass manufacturing. Glass Tubing Manufacturing Process.