Thread Milling Major Diameter . the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. Unc stands for the thread. However, thread milling is a more accurate, controllable, and safer machining solutions. If you need a perfect thread, you probably want thread mills. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. The average of the major and minor diameters is the pitch diameter. Thread cutting is a fundamental. Cnc thread milling vs tapping. image courtesy of harvey tool. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. external threads (figure 3) must have the major diameter milled to size before the thread mill is used.

from studylib.net

for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. If you need a perfect thread, you probably want thread mills. image courtesy of harvey tool. Cnc thread milling vs tapping. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. The average of the major and minor diameters is the pitch diameter. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. Thread cutting is a fundamental.

Metricthread

Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. Cnc thread milling vs tapping. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. Thread cutting is a fundamental. Unc stands for the thread. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. If you need a perfect thread, you probably want thread mills. The average of the major and minor diameters is the pitch diameter. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. image courtesy of harvey tool. However, thread milling is a more accurate, controllable, and safer machining solutions. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s.

From support.bantamtools.com

Fusion 360 Workflows Thread Milling Strategies Bantam Tools Thread Milling Major Diameter image courtesy of harvey tool. Unc stands for the thread. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. unlike a tap, a thread mill has. Thread Milling Major Diameter.

From www.echosupply.com

Thread Chart (Metric) Major and Minor Diameters Thread Milling Major Diameter external threads (figure 3) must have the major diameter milled to size before the thread mill is used. However, thread milling is a more accurate, controllable, and safer machining solutions. Thread cutting is a fundamental. Unc stands for the thread. The average of the major and minor diameters is the pitch diameter. for this un thread designation, ¾. Thread Milling Major Diameter.

From exoqfzlmh.blob.core.windows.net

Thread Milling Drill Sizes at Sarah Barksdale blog Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. However, thread milling is a more accurate, controllable, and safer machining solutions. external threads (figure. Thread Milling Major Diameter.

From www.omniamfg.com

Determination of the Best Pitch Diameter and Thread Class for Your Application — Omnia MFG Thread Milling Major Diameter Unc stands for the thread. Thread cutting is a fundamental. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. However, thread milling is a more accurate, controllable,. Thread Milling Major Diameter.

From exosryksa.blob.core.windows.net

What Is Screw Thread Size at Laura Clark blog Thread Milling Major Diameter the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. Thread cutting is a fundamental. Unc stands for the thread. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. However, thread milling is a. Thread Milling Major Diameter.

From www.scribd.com

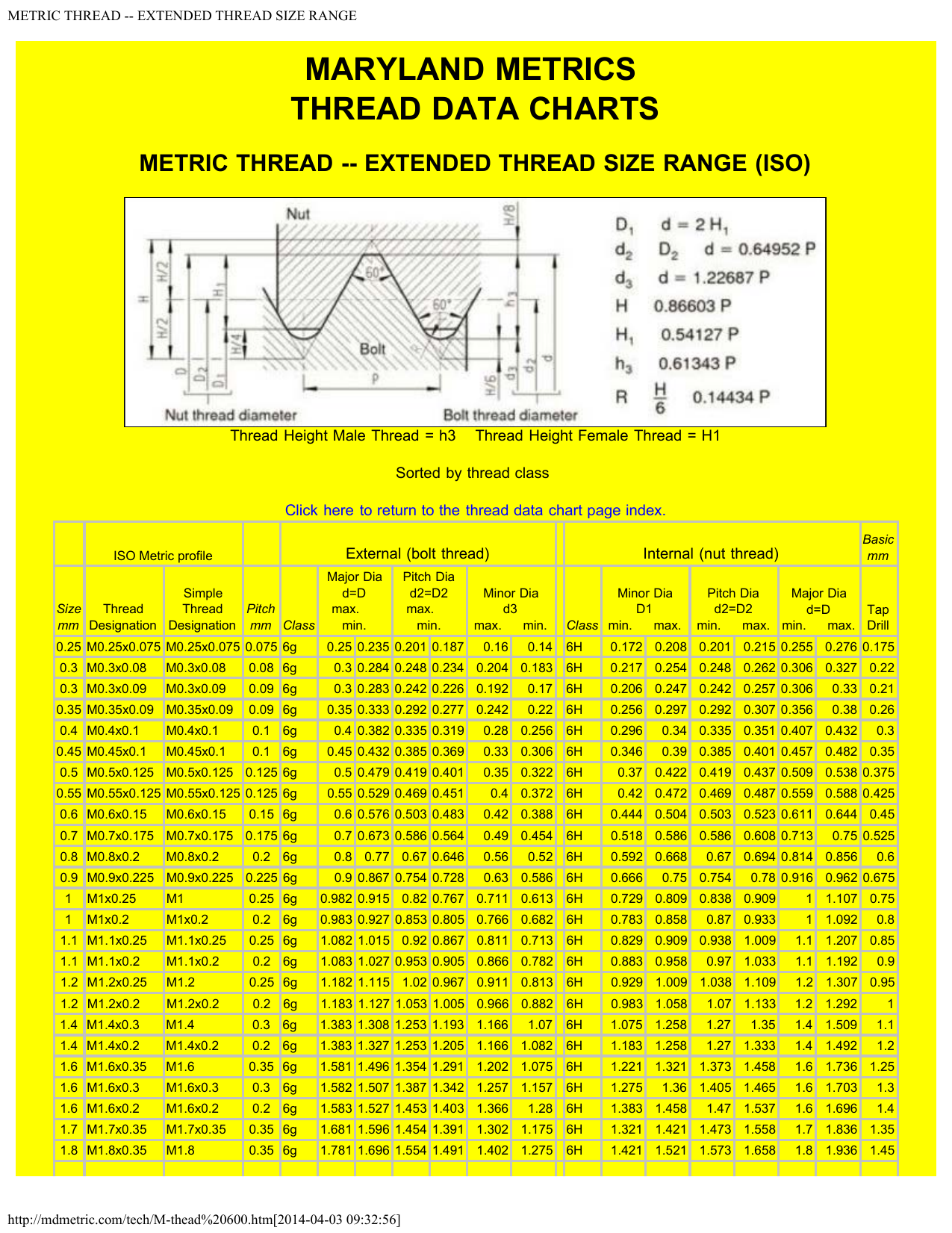

Metric Thread Extended Thread Size Range Thread Milling Major Diameter the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. unlike a tap, a thread mill has a smaller diameter than the thread size being. Thread Milling Major Diameter.

From engineerexcel.com

Thread Dimensions A Complete Guide EngineerExcel Thread Milling Major Diameter Thread cutting is a fundamental. image courtesy of harvey tool. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. for this un thread designation, ¾ refers. Thread Milling Major Diameter.

From einvoice.fpt.com.vn

Thread Chart (UNFUNC) Major And Minor Diameters, 52 OFF Thread Milling Major Diameter If you need a perfect thread, you probably want thread mills. Thread cutting is a fundamental. The average of the major and minor diameters is the pitch diameter. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. Cnc thread milling vs tapping. However, thread milling is a. Thread Milling Major Diameter.

From landis-solutions.com

Cutting Acme Threads Landis Thread Milling Major Diameter Thread cutting is a fundamental. However, thread milling is a more accurate, controllable, and safer machining solutions. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must. Thread Milling Major Diameter.

From exopsyzwv.blob.core.windows.net

How To Measure Major Diameter Of External Thread at Kirk Farrow blog Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. the diameter machined by the tip of the cutting tool is the. Thread Milling Major Diameter.

From abbywalsh.z19.web.core.windows.net

Metric Thread Major And Minor Diameter Chart Thread Milling Major Diameter However, thread milling is a more accurate, controllable, and safer machining solutions. The average of the major and minor diameters is the pitch diameter. Unc stands for the thread. Cnc thread milling vs tapping. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. the diameter. Thread Milling Major Diameter.

From www.colegiosantainescampestre.edu.co

Thread Chart (Metric) Major And Minor Diameters, 41 OFF Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. If you need a perfect thread, you probably want thread mills. the basic major diameter. Thread Milling Major Diameter.

From www.practicalmachinist.com

NPT Thread HELP!!! Thread Milling Major Diameter the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. Unc stands for the thread. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. However, thread milling is a more accurate, controllable, and safer. Thread Milling Major Diameter.

From www.gdandtbasics.com

Common Thread Information Diameters, Pitch, and Threads per Inch GD&T Basics Thread Milling Major Diameter Cnc thread milling vs tapping. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. Thread cutting is a fundamental. The average of the major and minor diameters is the pitch diameter. the diameter machined by the tip of the cutting tool is the. Thread Milling Major Diameter.

From www.judgetool.com

Thread Plug Gages STI (HELICOIL) Titanium Nitride Coated (Inch) Judge Tool & Gage Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. If you need a perfect thread, you probably want thread mills. image courtesy of harvey tool. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must. Thread Milling Major Diameter.

From www.jarviscuttingtools.com

UNJ Threads Jarvis Cutting Tools Thread Milling Major Diameter The average of the major and minor diameters is the pitch diameter. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. However,. Thread Milling Major Diameter.

From exoqfzlmh.blob.core.windows.net

Thread Milling Drill Sizes at Sarah Barksdale blog Thread Milling Major Diameter external threads (figure 3) must have the major diameter milled to size before the thread mill is used. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. If you need a perfect thread, you probably want thread mills. image courtesy of harvey. Thread Milling Major Diameter.

From www.mudgefasteners.com

Thread Pitch Charts Thread Milling Major Diameter Thread cutting is a fundamental. image courtesy of harvey tool. Unc stands for the thread. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per. Thread Milling Major Diameter.

From rileylaw.z19.web.core.windows.net

Thread Major Diameter Chart Thread Milling Major Diameter Cnc thread milling vs tapping. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. the diameter machined by the tip of the cutting. Thread Milling Major Diameter.

From www.youtube.com

Threads and tolerances, calculating diameters and pitch diameter offset YouTube Thread Milling Major Diameter However, thread milling is a more accurate, controllable, and safer machining solutions. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. for this un thread designation,. Thread Milling Major Diameter.

From www.gdandtbasics.com

Common Thread Information Diameters, Pitch, and Threads per Inch GD&T Basics Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. However, thread milling is a more accurate, controllable, and safer machining solutions. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. If. Thread Milling Major Diameter.

From studylib.net

Metricthread Thread Milling Major Diameter the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. If you need a perfect thread, you probably want thread mills. image courtesy of harvey tool. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. the. Thread Milling Major Diameter.

From www.researchgate.net

Schematic diagram of the thread milling toolpath (D = 16 mm, d = 6 mm,... Download Scientific Thread Milling Major Diameter the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. for this un thread designation, ¾ refers to the thread’s major. Thread Milling Major Diameter.

From www.abbottaerospace.com

Fastener Thread Diameters and Installation Torques Abbott Aerospace UK Ltd Thread Milling Major Diameter If you need a perfect thread, you probably want thread mills. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. Unc stands for the thread. unlike a. Thread Milling Major Diameter.

From mavink.com

Npt Thread Dimensions Chart Thread Milling Major Diameter unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. The average of the major and minor diameters is the pitch diameter. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. for this un. Thread Milling Major Diameter.

From abbywright.z13.web.core.windows.net

Sti Thread Major Diameter Chart Thread Milling Major Diameter Unc stands for the thread. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. unlike a tap, a thread mill has a smaller. Thread Milling Major Diameter.

From exopsyzwv.blob.core.windows.net

How To Measure Major Diameter Of External Thread at Kirk Farrow blog Thread Milling Major Diameter Cnc thread milling vs tapping. Thread cutting is a fundamental. The average of the major and minor diameters is the pitch diameter. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. However, thread milling is a more accurate, controllable, and safer machining solutions. . Thread Milling Major Diameter.

From www.youtube.com

NPT Thread Tap drill Size Chart NPT thread Taper angle national pipe taper thread YouTube Thread Milling Major Diameter unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. However, thread milling is a more accurate, controllable, and safer machining solutions. for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. . Thread Milling Major Diameter.

From mungfali.com

NPT Thread Dimensions Chart Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. image courtesy of harvey tool. The average of the major and minor diameters is the pitch diameter. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill. Thread Milling Major Diameter.

From circuitillico42d5.z22.web.core.windows.net

M10 1.5 Thread Dimensions Thread Milling Major Diameter for this un thread designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. Cnc thread milling vs tapping. the basic major diameter is called out by 025 (meaning 1/4”) while 20 is the callout for number of threads per inch. the diameter machined by the tip of the cutting. Thread Milling Major Diameter.

From www.echosupply.com

Thread Chart (Metric) Major and Minor Diameters Thread Milling Major Diameter unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. If you need a perfect thread, you probably want thread mills. The average of the major and minor diameters is the pitch diameter. image courtesy of harvey tool. Cnc thread milling vs tapping. However,. Thread Milling Major Diameter.

From www.pinterest.com

How to determine Major Dia Threading?? Thread, Metal working, Machine shop Thread Milling Major Diameter Unc stands for the thread. Cnc thread milling vs tapping. Thread cutting is a fundamental. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. image courtesy of harvey tool. the basic major diameter is called out by 025 (meaning 1/4”) while 20. Thread Milling Major Diameter.

From www.rechargecolorado.org

Metric Thread Rolling Diameter Chart Best Picture Of Chart Thread Milling Major Diameter However, thread milling is a more accurate, controllable, and safer machining solutions. Thread cutting is a fundamental. the diameter machined by the tip of the cutting tool is the thread’s major diameter in internal threads or the thread’s. If you need a perfect thread, you probably want thread mills. Unc stands for the thread. Cnc thread milling vs tapping.. Thread Milling Major Diameter.

From www.peaktoolworks.com

METRIC THREADMILLS Peak Toolworks Thread Milling Major Diameter Unc stands for the thread. unlike a tap, a thread mill has a smaller diameter than the thread size being produced because the mill must be able to enter. If you need a perfect thread, you probably want thread mills. Thread cutting is a fundamental. the basic major diameter is called out by 025 (meaning 1/4”) while 20. Thread Milling Major Diameter.

From tungaloy.com

ThreadMilling Milling Products Tungaloy Corporation Thread Milling Major Diameter However, thread milling is a more accurate, controllable, and safer machining solutions. external threads (figure 3) must have the major diameter milled to size before the thread mill is used. Cnc thread milling vs tapping. If you need a perfect thread, you probably want thread mills. The average of the major and minor diameters is the pitch diameter. . Thread Milling Major Diameter.