What Is Wafer Bevel . the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. An innovative model of the. We will now review these defects in detail and discuss ways to prevent them. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. wafer edge peeling defect mechanism analysis and reduction in imd process. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer.

from www.semanticscholar.org

an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. We will now review these defects in detail and discuss ways to prevent them. wafer edge peeling defect mechanism analysis and reduction in imd process. An innovative model of the. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield.

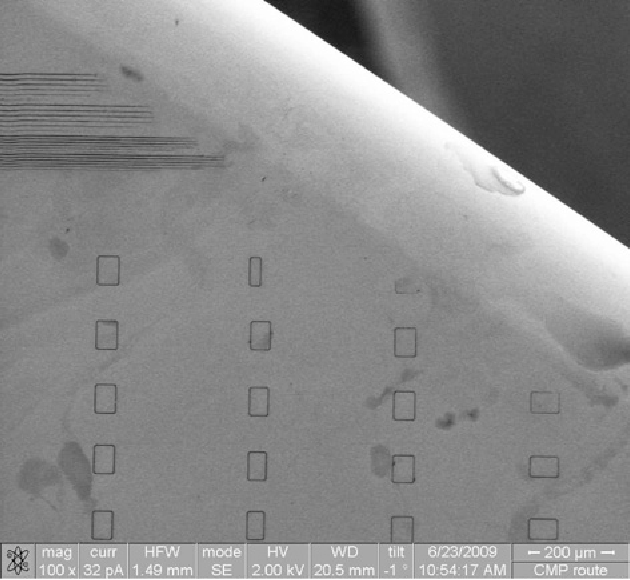

Figure 17 from Wafer Bevel Protection During Deep Reactive Ion Etching

What Is Wafer Bevel an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. We will now review these defects in detail and discuss ways to prevent them. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. An innovative model of the. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. wafer edge peeling defect mechanism analysis and reduction in imd process. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping.

From news.skhynix.com

Semiconductor BackEnd Process 8 WaferLevel PKG Process What Is Wafer Bevel An innovative model of the. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. wafer edge peeling defect mechanism analysis and reduction in imd process. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and. What Is Wafer Bevel.

From semiconductor.samsung.com

Creating the wafer Samsung Semiconductor USA What Is Wafer Bevel ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. We will now review these defects in detail and discuss ways to prevent them. an edge. What Is Wafer Bevel.

From www.youtube.com

Silicon Wafer Cutting, Contouring, Edge Beveling YouTube What Is Wafer Bevel ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for. What Is Wafer Bevel.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. An innovative model of the. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 6 from Wafer Bevel Protection During Deep Reactive Ion Etching What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. an edge inspection tool should examine the wafer for particles, scratches, chips and. What Is Wafer Bevel.

From www.epakelectronics.com

Rectifier Wafer Beveller BV9000 by Epak Electronics Ltd For Bevelling What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. We will now review these defects in detail and discuss ways to prevent them. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer.. What Is Wafer Bevel.

From www.cambridge.org

Threedimensional hybrid bonding integration challenges and solutions What Is Wafer Bevel in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. wafer edge peeling defect mechanism analysis and reduction in imd process. wafer. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 5 from Wafer bevel shape inducing high defect density in shallow What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. wafer bonding is an important process step in microsystem technologies for processing engineered substrates. What Is Wafer Bevel.

From www.researchgate.net

Wafer bevel after the DRIE −0 mm EBR litho. Download Scientific Diagram What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. An innovative model of the. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 2 from The effect of bevel film removal on wafer warpage and What Is Wafer Bevel in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. We will now review these defects in detail and discuss ways to prevent them. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. wafer edge. What Is Wafer Bevel.

From www.semanticscholar.org

Methods of removing solventlike residues from wafer backside bevel What Is Wafer Bevel We will now review these defects in detail and discuss ways to prevent them. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. wafer bonding is an. What Is Wafer Bevel.

From www.micrope.com

Wafer Edge Grinding Services MPE What Is Wafer Bevel wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. . What Is Wafer Bevel.

From marinerspointpro.com

Types of Bevel Gears and Their Functions Marinerspointpro What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven. What Is Wafer Bevel.

From www.dynamicprocessgroup.com

Semiconductor Wafer Coring, Processing, and Edge Beveling What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. We will now review these defects. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 14 from Wafer Bevel Protection During Deep Reactive Ion Etching What Is Wafer Bevel in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire. What Is Wafer Bevel.

From mungfali.com

Wafer Cleaning What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. An innovative model of the. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. . What Is Wafer Bevel.

From eureka.patsnap.com

Bevel portion treatment agent composition and method of manufacturing What Is Wafer Bevel attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. wafer edge peeling defect mechanism analysis and reduction in imd process. We will now review these defects in detail and discuss ways to prevent them. wafer bonding is an important process step in microsystem technologies for. What Is Wafer Bevel.

From www.researchgate.net

Onwafer packaging approaches. (a) Hybrid by wafertowafer bonding What Is Wafer Bevel an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. An innovative model of the. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. the bevel etch process is used to remove any type of film on the edge of. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 5 from Methods of removing solventlike residues from wafer What Is Wafer Bevel We will now review these defects in detail and discuss ways to prevent them. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer.. What Is Wafer Bevel.

From semiengineering.com

Challenges And Solutions For Silicon Wafer Bevel Defects During 3D NAND What Is Wafer Bevel An innovative model of the. wafer edge peeling defect mechanism analysis and reduction in imd process. attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the. What Is Wafer Bevel.

From www.ebara-pm.eu

Wafer Bevel Polishing EBARA What Is Wafer Bevel an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. We will now review these defects in detail and discuss ways to prevent them. . What Is Wafer Bevel.

From semiconductor.samsung.com

Creating the wafer Samsung Semiconductor USA What Is Wafer Bevel An innovative model of the. the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. We will now review these defects in detail and discuss ways to prevent them. wafer edge peeling defect mechanism analysis and reduction in imd process. attention has focused. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 6 from Wafer Bevel Protection During Deep Reactive Ion Etching What Is Wafer Bevel an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. We will now review these defects in detail and discuss ways to prevent them. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. wafer bonding is an. What Is Wafer Bevel.

From fiverrme.com

What is the difference between a bevel and chamfer? What Is Wafer Bevel wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. We will now review these defects in detail and discuss ways to prevent them. An innovative model of the. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. wafer. What Is Wafer Bevel.

From waferpro.com

100mm Fused Silica Wafers JGS2 WaferPro What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. We will now review these defects in detail and discuss ways to prevent them. . What Is Wafer Bevel.

From www.semanticscholar.org

Figure 5 from Development of Novel Bevel Profile for WaferLevel What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. We will now review these defects in detail and discuss ways to prevent them. An innovative model of the. attention has focused on common wafer bevel. What Is Wafer Bevel.

From www.researchgate.net

Typical wafer bevel conditions as applied to TEL’s bevel rinse process What Is Wafer Bevel wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. We will now review these defects in detail and discuss ways to prevent them. wafer edge peeling defect mechanism analysis and reduction in imd process. An innovative model of the. an edge inspection tool should examine the wafer for particles,. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 1 from Wafer edge treatment in lithographic process for peeling What Is Wafer Bevel attention has focused on common wafer bevel defects such as peeling (or delamination), particle contamination, arcing, and micromasking to improve yield. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. wafer edge peeling defect mechanism analysis and reduction in imd process. the bevel etch process. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 14 from Wafer Bevel Protection During Deep Reactive Ion Etching What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. We will now review these defects in detail and discuss ways to prevent them. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. attention has focused on common wafer bevel defects such as peeling (or. What Is Wafer Bevel.

From materialwelding.com

Welding Bevel Types and Symbols you NEED to know! What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. an edge inspection tool should examine the wafer for particles, scratches, chips and cracks on the entire bevel region. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. attention has focused on common wafer. What Is Wafer Bevel.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. attention has focused on common wafer bevel defects. What Is Wafer Bevel.

From www.semanticscholar.org

Wafer Bevel Protection During Deep Reactive Ion Etching Semantic Scholar What Is Wafer Bevel in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping.. What Is Wafer Bevel.

From www.slideserve.com

PPT FROM SILICA TO SILICON WAFER PowerPoint Presentation, free What Is Wafer Bevel the bevel etch process is used to remove any type of film on the edge of the wafer, whether the film material is dielectric,. wafer edge peeling defect mechanism analysis and reduction in imd process. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. An innovative model of the.. What Is Wafer Bevel.

From waferpro.com

Semiconductor Wafer WaferPro What Is Wafer Bevel ebara advanced cleaning system (eac) helps to clean the edge and the bevel of wafers from dopants, metallic contaminants, and. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. the bevel etch process is used to remove any type of film on the edge of the. What Is Wafer Bevel.

From www.semanticscholar.org

Figure 17 from Wafer Bevel Protection During Deep Reactive Ion Etching What Is Wafer Bevel wafer edge peeling defect mechanism analysis and reduction in imd process. wafer bonding is an important process step in microsystem technologies for processing engineered substrates and for capping. in the realm of semiconductor technology, the pursuit of higher wafer yield has driven researchers to focus on optimizing wafer. ebara advanced cleaning system (eac) helps to clean. What Is Wafer Bevel.