Def Of Vacuum Forming . Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry.

from saopaulovidracaria.com.br

The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. A vacuum is applied sucking the sheet into the mould. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and.

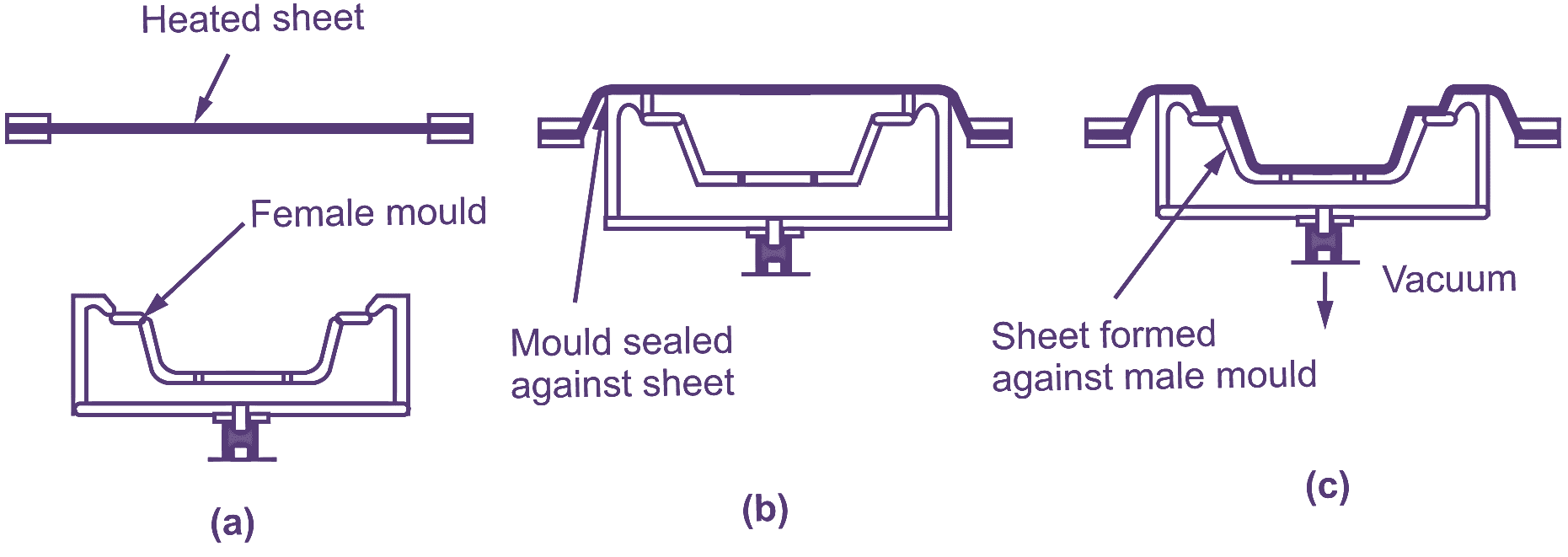

Per National flag Out of date vacuum forming diagram lecture Asser Peruse

Def Of Vacuum Forming The sheet is then ejected from the mould. The sheet is then ejected from the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. A vacuum is applied sucking the sheet into the mould. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic.

From celestron102sltbuynow.blogspot.com

Diy Vacuum Forming Kydex Def Of Vacuum Forming In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. Def Of Vacuum Forming.

From birdsaustra.blogspot.com

Vacuum Forming Facts Vacuum Forming 1/4" ABS plastic Deep Draw Def Of Vacuum Forming In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to. Def Of Vacuum Forming.

From www.indiamart.com

Single Base plate Vacuum forming machine at Rs 950000 in Bhiwadi ID Def Of Vacuum Forming Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. The sheet is then ejected from the mould. The. Def Of Vacuum Forming.

From www.pinterest.com

vacuum forming PROPS Pinterest Vacuums and Vacuum forming Def Of Vacuum Forming The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material. Def Of Vacuum Forming.

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles Def Of Vacuum Forming Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. The sheet is then ejected from the mould. A vacuum is applied sucking the sheet into the mould. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum. Def Of Vacuum Forming.

From 3-dtechnicalservices.com

Vacuum Forming Services 3D Technical Services Def Of Vacuum Forming Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. A vacuum is applied. Def Of Vacuum Forming.

From advancedplastiform.com

Comprehensive Guide to Vacuum Forming Def Of Vacuum Forming A vacuum is applied sucking the sheet into the mould. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of. Def Of Vacuum Forming.

From blog.thepipingmart.com

Vacuum forming Advantages and Disadvantages Def Of Vacuum Forming The sheet is then ejected from the mould. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming. Def Of Vacuum Forming.

From schoutengroup.com

Vacuum forming Schouten Group Def Of Vacuum Forming The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. A. Def Of Vacuum Forming.

From www.la-plastic.com

Which Material is Most Commonly Used in Vacuum Forming? Def Of Vacuum Forming The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The sheet is then ejected from the mould. In its. Def Of Vacuum Forming.

From phase-2.org

What are the benefits of vacuum forming? Move to a new phase Def Of Vacuum Forming The sheet is then ejected from the mould. A vacuum is applied sucking the sheet into the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the. Def Of Vacuum Forming.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Def Of Vacuum Forming In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. A vacuum is applied sucking the sheet into the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling. Def Of Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Def Of Vacuum Forming In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. A vacuum is applied sucking the sheet into the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. The sheet is then ejected from the mould. The vacuum forming process works by heating. Def Of Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. The sheet is then ejected from the mould. The vacuum forming process works by heating a plastic sheet,. Def Of Vacuum Forming.

From blog.thepipingmart.com

Vacuum Forming vs Thermoforming What's the Difference Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming is a thermoforming process that offers benefits. Def Of Vacuum Forming.

From blog.thepipingmart.com

Vacuum Forming vs Pressure Forming What's the Difference Def Of Vacuum Forming The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a thermoforming. Def Of Vacuum Forming.

From medium.com

vacuum forming. Up until now, I had been forming with a… by Annie Def Of Vacuum Forming The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. The sheet is then ejected from the mould. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming. Def Of Vacuum Forming.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material Def Of Vacuum Forming The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming is a thermoforming. Def Of Vacuum Forming.

From spottingit.com

The advantages of vacuum forming Spotting IT Def Of Vacuum Forming In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming is a thermoforming process that. Def Of Vacuum Forming.

From ryobe.co.uk

Vacuum Forming Service Variety of materials Ryobe UK LTD Def Of Vacuum Forming A vacuum is applied sucking the sheet into the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The sheet is then ejected. Def Of Vacuum Forming.

From shop3duniverse.com

Comparison Vacuum Forming vs Pressure Forming Def Of Vacuum Forming A vacuum is applied sucking the sheet into the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a manufacturing process that uses heat. Def Of Vacuum Forming.

From boleroplastics.com

Radiology Thermoformed Plastic Application Bolero Plastics Def Of Vacuum Forming Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. A vacuum is applied sucking the sheet into the mould.. Def Of Vacuum Forming.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Def Of Vacuum Forming Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the. Def Of Vacuum Forming.

From blog.thepipingmart.com

What is Vacuum Forming? Uses and Process Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming is a thermoforming process that offers benefits. Def Of Vacuum Forming.

From formlabs.com

Introduction to Vacuum Forming Def Of Vacuum Forming Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. A vacuum is applied sucking the sheet into the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it. Def Of Vacuum Forming.

From www.youtube.com

Introduction To Vacuum Forming What is vacuum Forming and What Can I Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. A vacuum is applied sucking the sheet into the mould. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced. Def Of Vacuum Forming.

From theprodesigngroup.com

6 Simple Steps to Vacuum Forming The Pro Design Group Gardena, CA Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. The sheet. Def Of Vacuum Forming.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics Def Of Vacuum Forming The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. The sheet is then ejected from the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. Vacuum forming is a manufacturing process that uses heat and vacuum. Def Of Vacuum Forming.

From www.slideshare.net

Vacuum forming Def Of Vacuum Forming A vacuum is applied sucking the sheet into the mould. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of. Def Of Vacuum Forming.

From mavink.com

Parts Of A Vacuum Former Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. The vacuum forming process works by heating. Def Of Vacuum Forming.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Def Of Vacuum Forming Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three.. Def Of Vacuum Forming.

From www.productiveplastics.com

What is Thermoforming? Plastic Thermoforming Explained Productive Def Of Vacuum Forming Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape. Def Of Vacuum Forming.

From saopaulovidracaria.com.br

Per National flag Out of date vacuum forming diagram lecture Asser Peruse Def Of Vacuum Forming A vacuum is applied sucking the sheet into the mould. Vacuum forming is a thermoforming process that offers benefits such as low manufacturing cost, reduced molding costs, and. The sheet is then ejected from the mould. Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three.. Def Of Vacuum Forming.

From blog.adafruit.com

How to Make a Vacuum Forming Machine « Adafruit Industries Makers Def Of Vacuum Forming Vacuum forming is a manufacturing process that uses heat and vacuum pressure to shape plastic sheets over a mold, creating a variety of three. Vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part geometry. The vacuum forming process works by heating a plastic. Def Of Vacuum Forming.

From designitforyou.com

WHAT IS VACUUM FORMING Def Of Vacuum Forming The sheet is then ejected from the mould. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. A vacuum is applied sucking the sheet into the mould. In its advanced form, the vacuum forming process utilizes sophisticated pneumatic,. Vacuum forming heats a plastic sheet until it. Def Of Vacuum Forming.