Equipment Lock Out Tag Out Procedures . One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. The process of tagging out a system involves. In this article, we’ll look. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. Tag out is a labelling process that is always used when lockout is required.

from www.mysafetysign.com

Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. In this article, we’ll look. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. The process of tagging out a system involves. Tag out is a labelling process that is always used when lockout is required. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery.

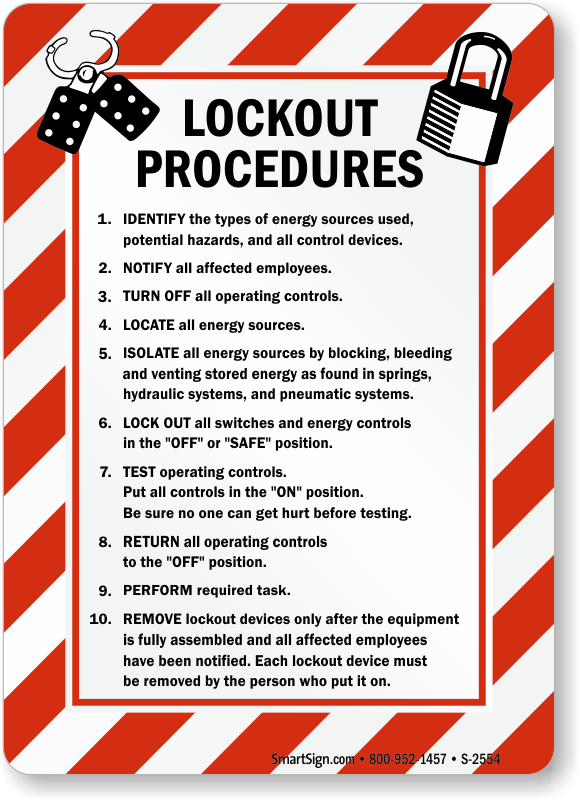

Lockout Procedures Sign with Graphic, SKU S2554

Equipment Lock Out Tag Out Procedures One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Tag out is a labelling process that is always used when lockout is required. The process of tagging out a system involves. In this article, we’ll look. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm.

From 1contactsafety.ca

Lockout Tagout Equipment Lock Out Tag Out Procedures When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. “lockout/tagout” refers to specific practices and procedures to safeguard employees from. Equipment Lock Out Tag Out Procedures.

From eliteagrisolutions.ca

Lock Out Tag Out Procedures Elite Agri Solutions Equipment Lock Out Tag Out Procedures Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. In this article, we’ll look. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost. Equipment Lock Out Tag Out Procedures.

From insurecompliance.net

The Step by Step Guide to Lock out Tag out Procedure Insure Compliance Equipment Lock Out Tag Out Procedures In this article, we’ll look. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Tag out is a labelling process that is always used when lockout is required. The process of tagging out a system involves.. Equipment Lock Out Tag Out Procedures.

From www.bradycanada.ca

Equipment Specific Lockout Tagout Procedure Example BRADY Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. In this article, we’ll look. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. When done properly before. Equipment Lock Out Tag Out Procedures.

From limblecmms.com

How To Write Lockout Tagout Procedure And LOTO Program Equipment Lock Out Tag Out Procedures “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Tag out is a labelling process that is always used when lockout is required. When done properly before equipment service. Equipment Lock Out Tag Out Procedures.

From trdsf.com

The Benefits of a Lockout Tagout Station TRADESAFE Equipment Lock Out Tag Out Procedures “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. In this article, we’ll look. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Lockout/tagout procedures save lives by. Equipment Lock Out Tag Out Procedures.

From www.safetyimages365.com

Lock Out Tag Out Safety Poster. Lock Out Tag Out for Safety Equipment Lock Out Tag Out Procedures Tag out is a labelling process that is always used when lockout is required. The process of tagging out a system involves. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto). Equipment Lock Out Tag Out Procedures.

From www.compliancesigns.com

Safety Poster Always Follow Lockout Procedures CS235011 Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Learn. Equipment Lock Out Tag Out Procedures.

From www.liveabout.com

Lockout/Tagout (LOTO) Procedures for Electrical Equipment Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. When done properly before equipment service or maintenance,. Equipment Lock Out Tag Out Procedures.

From insurecompliance.net

The Step by Step Guide to Lock out Tag out Procedure Insure Compliance Equipment Lock Out Tag Out Procedures When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. “lockout/tagout” refers to specific practices and procedures. Equipment Lock Out Tag Out Procedures.

From safestart.com

Lockout/Tagout Best Practices SafeStart Equipment Lock Out Tag Out Procedures When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. The process of tagging out a system involves. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Tag out is. Equipment Lock Out Tag Out Procedures.

From www.vecteezy.com

Danger Sign Lockout ,Tagout Required Before Entering 3684107 Vector Art Equipment Lock Out Tag Out Procedures Tag out is a labelling process that is always used when lockout is required. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected. Equipment Lock Out Tag Out Procedures.

From dev.youngvic.org

Lock Out Tag Out Procedure Template, Low To Medium General Information Equipment Lock Out Tag Out Procedures Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Tag out is a labelling process that is always used when lockout is required. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect. Equipment Lock Out Tag Out Procedures.

From specificationonline.co.uk

Lockout/Tagout within Construction Specification Online Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Tag out is a labelling process that is always used when lockout is required. Learn the importance of lockout/tagout procedures and best practices in. Equipment Lock Out Tag Out Procedures.

From brennaf-bootee.blogspot.com

Loto Safety / Typical Lockout Tagout ProceduresFire magazine Safety Equipment Lock Out Tag Out Procedures Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. In this article, we’ll look. The process of tagging out a system involves. Tag out is a labelling process that is always used when lockout. Equipment Lock Out Tag Out Procedures.

From gantt-chart-excel.com

Download Lockout Tagout Procedures Template Images And Template Gantt Equipment Lock Out Tag Out Procedures In this article, we’ll look. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by. Equipment Lock Out Tag Out Procedures.

From naspweb.com

Guide to Lockout Tagout Procedures NASP Equipment Lock Out Tag Out Procedures Tag out is a labelling process that is always used when lockout is required. The process of tagging out a system involves. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. Learn. Equipment Lock Out Tag Out Procedures.

From www.calpaclab.com

Lockout/Tagout SignLockout Procedures List, 20" x 14", Each Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Tag out is a labelling process that is always used when lockout is required. In this article, we’ll look. The process of tagging out a. Equipment Lock Out Tag Out Procedures.

From www.esfi.org

Lockout / Tagout Your Life Depends On It Electrical Safety Equipment Lock Out Tag Out Procedures One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Tag out is a labelling process that is always used when lockout is required. In this article, we’ll look. “lockout/tagout” refers to specific practices and procedures. Equipment Lock Out Tag Out Procedures.

From gantt-chart-excel.com

Download Lockout Tagout Procedures Template Images And Template Gantt Equipment Lock Out Tag Out Procedures Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. In this article, we’ll look. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. The process of tagging. Equipment Lock Out Tag Out Procedures.

From www.pinterest.se

Simple lock out tag procedure. Read the Article attached!!! Workplace Equipment Lock Out Tag Out Procedures Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. The process of tagging out a system involves. Learn how to prevent serious injury or death from hazardous energy sources during servicing. Equipment Lock Out Tag Out Procedures.

From www.amazon.com

Accuform Lockout/Tagout Procedures Laminated Safety Poster, 22" x 17 Equipment Lock Out Tag Out Procedures Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of.. Equipment Lock Out Tag Out Procedures.

From www.mysafetysign.com

Lockout Procedures Sign with Graphic, SKU S2554 Equipment Lock Out Tag Out Procedures One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. The process of tagging out a system involves. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Tag. Equipment Lock Out Tag Out Procedures.

From lpmanagementservices.com

Lockout Tagout Procedures Development LP Management Services Equipment Lock Out Tag Out Procedures When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Tag out is a labelling process that is always used when lockout is required. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn how to prevent serious injury or death from hazardous energy. Equipment Lock Out Tag Out Procedures.

From aegex.com

Benefits Of Digitizing Lockout Tagout Procedures Equipment Lock Out Tag Out Procedures “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. The process of tagging out a system involves. In this article, we’ll look. Tag out is a labelling process that is always used when lockout. Equipment Lock Out Tag Out Procedures.

From www.accuformnmc.com

Follow Procedures OSHA Danger Lockout/Tagout Label LLKT003 Equipment Lock Out Tag Out Procedures The process of tagging out a system involves. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost. Equipment Lock Out Tag Out Procedures.

From www.seably.com

Lock Out/Tag Out Procedures Seably Equipment Lock Out Tag Out Procedures In this article, we’ll look. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. Tag out is a labelling process that is always used when lockout is required. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Learn how to. Equipment Lock Out Tag Out Procedures.

From www.researchgate.net

Lockout Tagout Procedure [4] Download Scientific Diagram Equipment Lock Out Tag Out Procedures “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. The process of tagging out a system involves. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect. Equipment Lock Out Tag Out Procedures.

From data1.skinnyms.com

Lock Out Tag Out Training Certificate Template Equipment Lock Out Tag Out Procedures Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. In this article, we’ll look. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. The process of tagging out a system involves. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance. Equipment Lock Out Tag Out Procedures.

From www.roadtrafficsigns.com

Lockout Stations Lock Out Tags Kit Equipment Lock Out Tag Out Procedures Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. The process of tagging out a system involves. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output. Equipment Lock Out Tag Out Procedures.

From blog.creativesafetysupply.com

Lockout Tagout Creative Safety Supply Blog Equipment Lock Out Tag Out Procedures “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. The process of tagging out a system involves. Tag out. Equipment Lock Out Tag Out Procedures.

From www.cmisafety.com

Lockout/Tagout EquipmentSpecific Procedures Equipment Lock Out Tag Out Procedures Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance, and boost output by decreasing. One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. When. Equipment Lock Out Tag Out Procedures.

From www.compliancesigns.com

Safety Poster Lockout Tagout Procedures CS700841 Equipment Lock Out Tag Out Procedures When done properly before equipment service or maintenance, lockout/tagout procedures control hazardous energy and protect workers from harm. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. “lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of. The process of tagging out a system involves. Lockout/tagout procedures. Equipment Lock Out Tag Out Procedures.

From www.lockouttag.com

Lockout Stations Lock Out Tags Kit Equipment Lock Out Tag Out Procedures One important safety measure to prevent such accidents is the implementation of lockout tagout (loto) procedures. In this article, we’ll look. Learn the importance of lockout/tagout procedures and best practices in ensuring employee safety during machinery. Tag out is a labelling process that is always used when lockout is required. Learn how to prevent serious injury or death from hazardous. Equipment Lock Out Tag Out Procedures.

From cloudassess.com

Lockout/Tagout Procedures Free Course & Assessment Equipment Lock Out Tag Out Procedures The process of tagging out a system involves. Tag out is a labelling process that is always used when lockout is required. Learn how to prevent serious injury or death from hazardous energy sources during servicing and maintenance of machines and equipment. Lockout/tagout procedures save lives by avoiding fatalities and injuries, reduce expenses by decreasing lost employee time and insurance,. Equipment Lock Out Tag Out Procedures.