Rigid Box Dimensions . Rigid packaging boxes normally consist of two parts: Before manufacturing a rigid box, you have to design it with computer software. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Prepare a 2d or 3d design that you may follow afterward to create the best. This article will go into. Use a ruler or measuring tape to accurately. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. Measure from front to back.

from www.alamy.com

Before manufacturing a rigid box, you have to design it with computer software. This article will go into. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. Rigid packaging boxes normally consist of two parts: Use a ruler or measuring tape to accurately.

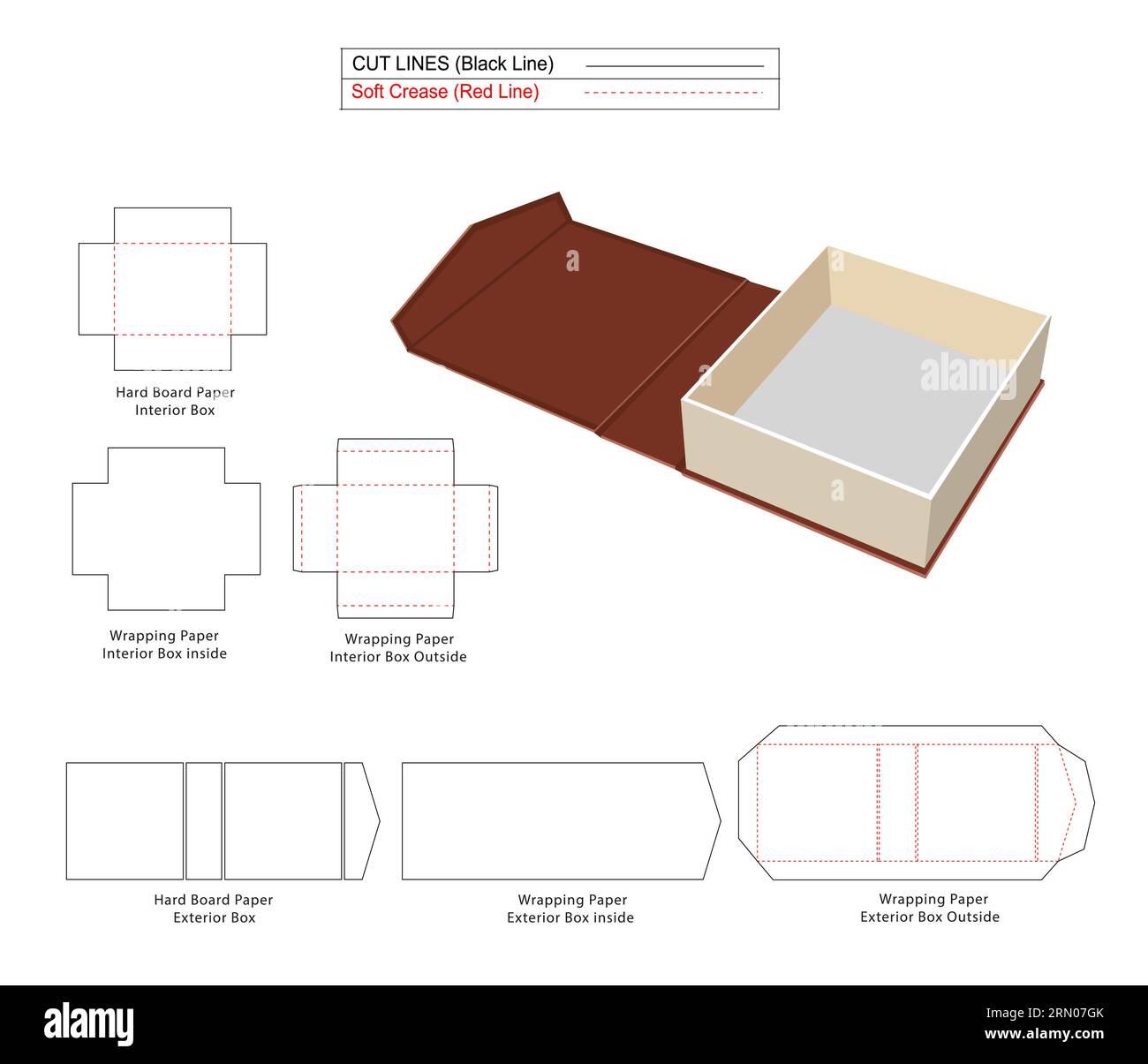

Rigid Box, luxury angle face rigid boxes die line template and

Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. Rigid packaging boxes normally consist of two parts: For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into. Prepare a 2d or 3d design that you may follow afterward to create the best. Use a ruler or measuring tape to accurately. Before manufacturing a rigid box, you have to design it with computer software. Measure from front to back. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box.

From www.dreamstime.com

Rigid Luxury Box, Custom Rigid Boxes Dieline Template Stock Rigid Box Dimensions Measure from front to back. This article will go into. Use a ruler or measuring tape to accurately. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Prepare a 2d or 3d design that you may follow afterward to create the best. For. Rigid Box Dimensions.

From www.dreamstime.com

Rigid Box Drawer Hard Board Paper Thicknes 1.5mm Internal Measurement Rigid Box Dimensions Use a ruler or measuring tape to accurately. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Measure from front to back. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the. Rigid Box Dimensions.

From www.pacdora.com

Luxury box rigid box box mockup 360130 Rigid Box Dimensions Before manufacturing a rigid box, you have to design it with computer software. Measure from front to back. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Use a ruler or measuring tape to accurately. With the right tools and approach, you can quickly get precise measurements. Rigid Box Dimensions.

From packoi.com

How to Read Box Dimensions? A Guide to Box Packaging Packoi Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. Rigid packaging boxes normally consist of two parts: The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. For measuring this box style, you just need to position the. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Measure from front to. Rigid Box Dimensions.

From www.pacdora.com

Double door open luxury box rigid box mockup 362081 Rigid Box Dimensions This article will go into. Use a ruler or measuring tape to accurately. Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. With the right tools and. Rigid Box Dimensions.

From www.pacdora.com

Custom dimensions luxury box rigid box dieline 361010 Rigid Box Dimensions Before manufacturing a rigid box, you have to design it with computer software. Prepare a 2d or 3d design that you may follow afterward to create the best. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Rigid packaging boxes normally consist of two parts: With the. Rigid Box Dimensions.

From www.vecteezy.com

Rigid Box, closer luxury 3 side cover rigid boxes dieline Rigid Box Dimensions With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into. Rigid packaging boxes normally consist of two parts: Prepare a 2d or 3d design that you may follow afterward to create the best. Measure from front. Rigid Box Dimensions.

From www.pacdora.com

Luxury box rigid box box mockup 361010 Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. Rigid packaging boxes normally consist of two parts: Use a ruler or measuring tape to accurately. Before manufacturing a rigid box, you have to design it with computer software. This article will go into. The first step in making a rigid box is to measure. Rigid Box Dimensions.

From www.pacdora.com

Box with lid luxury box rigid box mockup 360010 Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Rigid packaging boxes normally consist of two parts: Before manufacturing a rigid box, you have to design it with. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions Use a ruler or measuring tape to accurately. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions This article will go into. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Before manufacturing a rigid box, you have to design it with computer software. Prepare a 2d or 3d design that you may follow afterward to create the best. Rigid packaging boxes normally consist. Rigid Box Dimensions.

From packmojo.com

Custom Rigid Boxes Rigid Box Packaging PackMojo Rigid Box Dimensions Use a ruler or measuring tape to accurately. Prepare a 2d or 3d design that you may follow afterward to create the best. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into. Rigid packaging boxes. Rigid Box Dimensions.

From www.pacdora.com

Custom dimensions luxury box rigid box dieline 360090 Rigid Box Dimensions Before manufacturing a rigid box, you have to design it with computer software. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. With the right tools and. Rigid Box Dimensions.

From cartoondealer.com

Custom Rigid Box, Rigid Luxury Boxes Dieline Template Royalty Rigid Box Dimensions This article will go into. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Use a ruler or measuring tape to accurately. Before manufacturing a rigid box, you have to design it with computer software. Prepare a 2d or 3d design that you. Rigid Box Dimensions.

From www.sti-group.com

Rigid Boxes Rigid Box Dimensions Before manufacturing a rigid box, you have to design it with computer software. Rigid packaging boxes normally consist of two parts: For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Use a ruler or measuring tape to accurately. With the right tools and approach, you can quickly. Rigid Box Dimensions.

From www.vecteezy.com

Custom collapsible rigid box, foldable rigid box dieline template with Rigid Box Dimensions For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. This article will go into. Use a ruler or measuring tape to accurately. Prepare a 2d or 3d design that you may follow afterward to create the best. The first step in making a rigid box is to. Rigid Box Dimensions.

From www.pacdora.com

Book boxes luxury box rigid box mockup 360110 Rigid Box Dimensions Use a ruler or measuring tape to accurately. This article will go into. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. Use a ruler or measuring tape to accurately. Measure from front to back. Before manufacturing a rigid box, you have to design it with computer software. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Before manufacturing a rigid box, you have to design it with computer software. This. Rigid Box Dimensions.

From depositphotos.com

Rigid Box Packaging Die Cut Template Mockup Stock Vector Image by Rigid Box Dimensions For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Use a ruler or measuring tape to accurately. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Prepare a 2d or. Rigid Box Dimensions.

From edu.svet.gob.gt

Standard Carton Box Dimensions edu.svet.gob.gt Rigid Box Dimensions Before manufacturing a rigid box, you have to design it with computer software. Prepare a 2d or 3d design that you may follow afterward to create the best. Use a ruler or measuring tape to accurately. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of. Rigid Box Dimensions.

From boxeurobox.com

How to Measure Box & Packaging Dimensions Custom packaging,cardboard Rigid Box Dimensions For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Before manufacturing a rigid box, you have to design it with computer software. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. Use a ruler or measuring tape to accurately. Rigid packaging boxes normally consist of two parts: With the. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions This article will go into. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box.. Rigid Box Dimensions.

From www.packagingplace.com.au

Custom Rigid Boxes Rigid Box Dimensions The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. This article will go into. Rigid packaging boxes normally consist of two. Rigid Box Dimensions.

From www.pacdora.com

Box with lid luxury box rigid box mockup 366010 Rigid Box Dimensions This article will go into. Prepare a 2d or 3d design that you may follow afterward to create the best. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. Rigid packaging boxes normally consist of two parts: Use a ruler. Rigid Box Dimensions.

From www.pacdora.com

Luxury box rigid box box mockup 360090 Rigid Box Dimensions The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into.. Rigid Box Dimensions.

From www.alamy.com

Rigid Box, luxury angle face rigid boxes die line template and Rigid Box Dimensions The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. This article will go into.. Rigid Box Dimensions.

From www.alamy.com

Triangle face luxury rigid box, Rigid Boxes die line template Rigid Box Dimensions Use a ruler or measuring tape to accurately. Rigid packaging boxes normally consist of two parts: For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. This article will go into. The first step in making a rigid box is to measure and cut the rigid cardboard or. Rigid Box Dimensions.

From www.pacdora.com

Book box luxury box rigid box mockup 361011 Rigid Box Dimensions Rigid packaging boxes normally consist of two parts: Measure from front to back. Prepare a 2d or 3d design that you may follow afterward to create the best. For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Before manufacturing a rigid box, you have to design it. Rigid Box Dimensions.

From www.pacdora.com

Double door open luxury box rigid box mockup 362080 Rigid Box Dimensions This article will go into. The first step in making a rigid box is to measure and cut the rigid cardboard or chipboard according to the desired size of the box. Measure from front to back. Use a ruler or measuring tape to accurately. Rigid packaging boxes normally consist of two parts: For measuring this box style, you just need. Rigid Box Dimensions.

From www.deluxeboxes.com

Collapsible Rigid Boxes Foldable Folding Boxes Wholesale Rigid Box Dimensions Use a ruler or measuring tape to accurately. This article will go into. Rigid packaging boxes normally consist of two parts: Measure from front to back. Before manufacturing a rigid box, you have to design it with computer software. Prepare a 2d or 3d design that you may follow afterward to create the best. The first step in making a. Rigid Box Dimensions.

From www.alamy.com

Custom rigid box, Luxury closer rigid boxes die line template Rigid Box Dimensions For measuring this box style, you just need to position the side with a ribbon tab or thumb notch face to you. Use a ruler or measuring tape to accurately. With the right tools and approach, you can quickly get precise measurements that will help you in selecting the right box size for your needs or calculating shipping costs. Measure. Rigid Box Dimensions.

From packmojo.com

How To Measure Box & Package Dimensions PackMojo Rigid Box Dimensions Prepare a 2d or 3d design that you may follow afterward to create the best. Measure from front to back. This article will go into. Use a ruler or measuring tape to accurately. Before manufacturing a rigid box, you have to design it with computer software. With the right tools and approach, you can quickly get precise measurements that will. Rigid Box Dimensions.