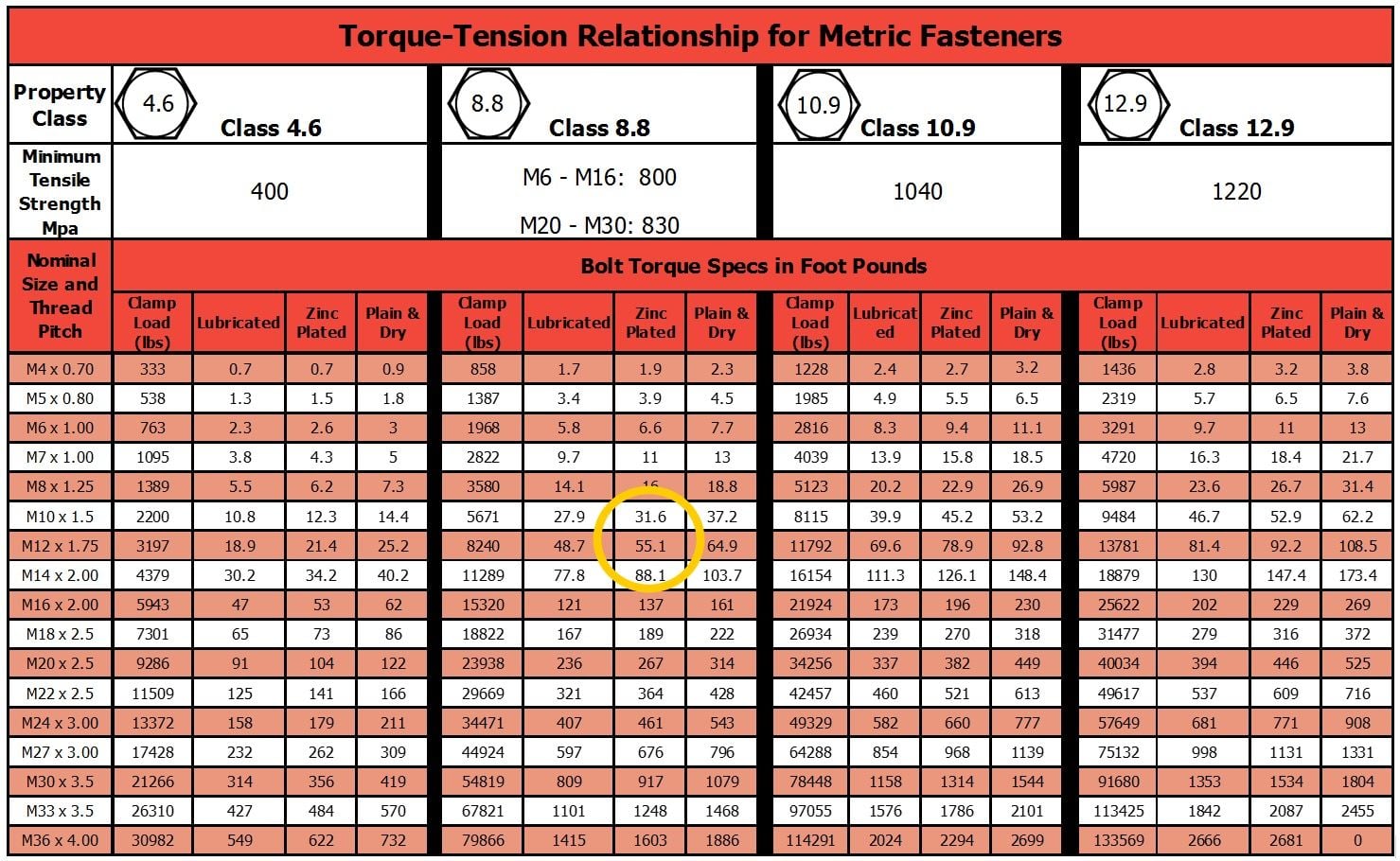

Bolt Chart Torque . The bolt’s class indicates its material strength, with higher. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Look up torque specification — use a torque chart specific to the. The size column also includes the thread count. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Determine bolt size — find the diameter and thread pitch of the bolt. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Identify the grade, size, and thread density of your. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. = clamp load for j429 grade 5 and 8,. To calculate the torque required to tighten a bolt:

from

The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. Look up torque specification — use a torque chart specific to the. = clamp load for j429 grade 5 and 8,. The bolt’s class indicates its material strength, with higher. The size column also includes the thread count. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Determine bolt size — find the diameter and thread pitch of the bolt. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Identify the grade, size, and thread density of your.

Bolt Chart Torque The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. To calculate the torque required to tighten a bolt: The size column also includes the thread count. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. = clamp load for j429 grade 5 and 8,. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Determine bolt size — find the diameter and thread pitch of the bolt. Look up torque specification — use a torque chart specific to the. Identify the grade, size, and thread density of your. The bolt’s class indicates its material strength, with higher.

From repairfixmenyeid50.z4.web.core.windows.net

Torque Chart For Ss Bolts Bolt Chart Torque = clamp load for j429 grade 5 and 8,. To calculate the torque required to tighten a bolt: The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Determine bolt size — find the diameter and thread pitch of. Bolt Chart Torque.

From

Bolt Chart Torque Look up torque specification — use a torque chart specific to the. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. To calculate the torque required to tighten a bolt: The bolt’s class indicates its material strength, with higher. Determine bolt size — find the diameter and thread pitch of the bolt. The size column. Bolt Chart Torque.

From

Bolt Chart Torque Look up torque specification — use a torque chart specific to the. Determine bolt size — find the diameter and thread pitch of the bolt. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The size column also includes the thread count. The. Bolt Chart Torque.

From mavink.com

Lubricated Bolt Torque Chart Bolt Chart Torque The bolt’s class indicates its material strength, with higher. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The charts below show the ideal tightening torque for each bolt. Bolt Chart Torque.

From www.bustinyournuts.com

Torque Charts Industrial Bolting and Torque Tools Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The size column also includes the thread count. The charts below show the ideal tightening torque for each bolt grade for a variety. Bolt Chart Torque.

From exyhlnkat.blob.core.windows.net

Torque Specs For Bolts at Evelyn Miles blog Bolt Chart Torque The bolt’s class indicates its material strength, with higher. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The size column also includes the thread count. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. = clamp load. Bolt Chart Torque.

From

Bolt Chart Torque = clamp load for j429 grade 5 and 8,. To calculate the torque required to tighten a bolt: Identify the grade, size, and thread density of your. Determine bolt size — find the diameter and thread pitch of the bolt. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The size column. Bolt Chart Torque.

From mungfali.com

Metric Bolt Torque Chart By Size Bolt Chart Torque To calculate the torque required to tighten a bolt: The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Identify the grade, size, and thread density of your. The size column also includes the thread count. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet. Bolt Chart Torque.

From

Bolt Chart Torque To calculate the torque required to tighten a bolt: Look up torque specification — use a torque chart specific to the. Determine bolt size — find the diameter and thread pitch of the bolt. The size column also includes the thread count. The bolt’s class indicates its material strength, with higher. These metric bolt torque charts show the ideal tightening. Bolt Chart Torque.

From

Bolt Chart Torque The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The size column also includes the thread count. The bolt’s class indicates its material strength, with higher. Look up torque specification — use a torque chart specific to the. Determine bolt size — find. Bolt Chart Torque.

From

Bolt Chart Torque Look up torque specification — use a torque chart specific to the. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The charts below show the ideal tightening torque. Bolt Chart Torque.

From giobtfcup.blob.core.windows.net

Engine Cylinder Head Bolt Torque Specs at Jean Freeman blog Bolt Chart Torque These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. Determine bolt size — find the diameter and thread pitch of. Bolt Chart Torque.

From rtstools.com

Useful Bolt Charts torque, Conversion charts, Head Bolt to Bolt Chart Torque These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The size column also includes the thread count. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The charts below show the ideal tightening torque for each bolt grade for a variety. Bolt Chart Torque.

From garagefixcononena.z13.web.core.windows.net

Sae Grade 5 Bolt Torque Chart Bolt Chart Torque The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. = clamp load for j429 grade 5 and 8,. Look up. Bolt Chart Torque.

From

Bolt Chart Torque To calculate the torque required to tighten a bolt: These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Look up torque specification — use a torque chart specific to the. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The charts. Bolt Chart Torque.

From www.bustinyournuts.com

IndustrialBoltingsquare_drive_torque_chart Industrial Bolting and Bolt Chart Torque Look up torque specification — use a torque chart specific to the. = clamp load for j429 grade 5 and 8,. Identify the grade, size, and thread density of your. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The following chart appears in the 2019 atlas copco industrial tools and solutions. Bolt Chart Torque.

From bafihlelaws9workshopfix.z14.web.core.windows.net

Lug Nut Torque Specification Chart Bolt Chart Torque The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. The bolt’s class indicates its material strength, with higher. Identify the grade, size, and thread density of your. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. = clamp. Bolt Chart Torque.

From

Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. Determine bolt size — find the diameter and thread pitch of the bolt. The size column also includes the thread count. Look up torque specification — use a torque. Bolt Chart Torque.

From www.repairengineering.com

Bolt Torque Chart Bolt Chart Torque To calculate the torque required to tighten a bolt: The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The size column also includes the thread count. Determine bolt size — find the diameter and thread pitch of the bolt. The following chart appears. Bolt Chart Torque.

From mungfali.com

Screw Torque Specs Chart Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Determine bolt size — find the diameter and thread pitch of the bolt. The size column also includes the thread count. Look up torque specification — use a torque chart specific to the. These metric bolt torque charts show the ideal tightening torque for class 8.8,. Bolt Chart Torque.

From mungfali.com

Grade 8 Metric Bolt Torque Chart Bolt Chart Torque The bolt’s class indicates its material strength, with higher. The size column also includes the thread count. = clamp load for j429 grade 5 and 8,. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The charts below show the ideal tightening torque for each bolt. Bolt Chart Torque.

From

Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. To calculate the torque required to tighten a bolt: The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The size column also includes the thread count. Determine bolt size. Bolt Chart Torque.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Chart Torque The size column also includes the thread count. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. To calculate the torque required to tighten a bolt: = clamp load for j429 grade 5 and 8,. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet. Bolt Chart Torque.

From

Bolt Chart Torque Determine bolt size — find the diameter and thread pitch of the bolt. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. To calculate the torque required to tighten. Bolt Chart Torque.

From

Bolt Chart Torque The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The bolt’s class indicates its material strength, with higher. To calculate the torque required to tighten a bolt: These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9. Bolt Chart Torque.

From mungfali.com

Metric Bolt Torque Chart By Size Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The size column also includes the thread count. Look up torque specification — use a torque chart specific to the. To calculate the torque required to tighten a bolt: The bolt’s class indicates its material strength, with higher. Determine bolt size — find the diameter and. Bolt Chart Torque.

From

Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. The size column also includes the thread count. Identify the grade, size, and thread density of your. The bolt’s class indicates its material strength, with higher. Look up torque specification — use a torque chart specific to the. The charts below show the ideal tightening torque. Bolt Chart Torque.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word Bolt Chart Torque The bolt’s class indicates its material strength, with higher. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Identify the grade, size, and thread density of your. To calculate the torque required to tighten a bolt: The charts below show the ideal tightening torque for each. Bolt Chart Torque.

From aussiegiftsonline.com

Torque Tightening Chart SAE & Metric Bolt Conversions Wrench Bolt Chart Torque The charts below show the ideal tightening torque for each bolt grade for a variety of sizes. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Look up torque specification — use a torque chart specific to the. The following chart appears in the 2019 atlas. Bolt Chart Torque.

From

Bolt Chart Torque The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. = clamp load for j429 grade 5 and 8,. The bolt’s class indicates its material strength, with higher. To calculate the torque required to tighten a bolt: The following chart appears in the 2019. Bolt Chart Torque.

From

Bolt Chart Torque The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Identify the grade, size, and thread density of your. The bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. The size column also includes the thread count. To calculate the. Bolt Chart Torque.

From

Bolt Chart Torque The size column also includes the thread count. Look up torque specification — use a torque chart specific to the. The following chart appears in the 2019 atlas copco industrial tools and solutions catalog. Identify the grade, size, and thread density of your. To calculate the torque required to tighten a bolt: Determine bolt size — find the diameter and. Bolt Chart Torque.

From

Bolt Chart Torque The bolt’s class indicates its material strength, with higher. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Look up torque specification — use a torque chart specific to the. The charts below show the ideal tightening torque for each bolt grade for a variety of. Bolt Chart Torque.

From

Bolt Chart Torque Look up torque specification — use a torque chart specific to the. To calculate the torque required to tighten a bolt: Determine bolt size — find the diameter and thread pitch of the bolt. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. The size column. Bolt Chart Torque.

From repairmachineuncursed.z21.web.core.windows.net

Torque Specs For A 3/8 Bolt Bolt Chart Torque = clamp load for j429 grade 5 and 8,. The size column also includes the thread count. These metric bolt torque charts show the ideal tightening torque for class 8.8, 10.9, and 12.9 bolts for both wet and dry tightening. Look up torque specification — use a torque chart specific to the. The charts below show the ideal tightening torque. Bolt Chart Torque.