Feeler Gauge Z Offset . Move the nozzle on top of one of the leveling screws (any of the four corners). With the feeler gauges i try this: the gauge size does not matter. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. You want to get the nozzle to zero, right on the bed. i have tried paper and feeler gauges. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. With paper i get inconsistent results. Place a piece of paper between the nozzle. These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. Set z offset to 0.0mm auto. Because of how the v2 is designed, this process may be slightly. To get there you offset the nozzle height by the thickness of your feeler.

from homefourexperts.com

if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. Set z offset to 0.0mm auto. the gauge size does not matter. You want to get the nozzle to zero, right on the bed. With paper i get inconsistent results. Place a piece of paper between the nozzle. Because of how the v2 is designed, this process may be slightly. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. With the feeler gauges i try this:

Feeler Gauge Sets Types & Uses Analysis

Feeler Gauge Z Offset Place a piece of paper between the nozzle. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. i have tried paper and feeler gauges. With paper i get inconsistent results. Move the nozzle on top of one of the leveling screws (any of the four corners). Set z offset to 0.0mm auto. Place a piece of paper between the nozzle. Because of how the v2 is designed, this process may be slightly. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. You want to get the nozzle to zero, right on the bed. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. To get there you offset the nozzle height by the thickness of your feeler. the gauge size does not matter. With the feeler gauges i try this:

From www.forcetools.co.za

9pc Offset Feeler Gauge Force Tools South Africa Feeler Gauge Z Offset Place a piece of paper between the nozzle. i have tried paper and feeler gauges. With the feeler gauges i try this: the gauge size does not matter. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. if. Feeler Gauge Z Offset.

From www.wantitall.co.za

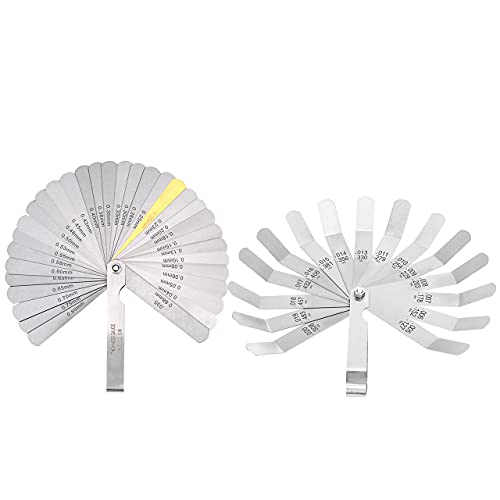

Feeler Gauge Set, JYEASTZ Feeler Gauges with 32 Blades and Offset Feeler Gauge Z Offset the gauge size does not matter. i have tried paper and feeler gauges. Place a piece of paper between the nozzle. You want to get the nozzle to zero, right on the bed. To get there you offset the nozzle height by the thickness of your feeler. Because of how the v2 is designed, this process may be. Feeler Gauge Z Offset.

From www.accud.com

OFFSET DUAL SCALE FEELER GAUGE ACCUD Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. With the feeler gauges i try this: These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. Because of how the v2 is designed, this process may. Feeler Gauge Z Offset.

From www.amazon.co.uk

OriGlam Offset Feeler Gauge Set with 16 Blades, Standard Metric Offset Feeler Gauge Z Offset With paper i get inconsistent results. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. Because of how the v2 is designed, this process may be slightly. the gauge size does not matter. You want to get the nozzle to zero, right on the bed. Move the nozzle. Feeler Gauge Z Offset.

From www.ebay.co.uk

12 Blades Offset Feeler Gauges Offset Metric / Imperial Easy to Use Feeler Gauge Z Offset Place a piece of paper between the nozzle. With the feeler gauges i try this: Move the nozzle on top of one of the leveling screws (any of the four corners). Set z offset to 0.0mm auto. the gauge size does not matter. Because of how the v2 is designed, this process may be slightly. setting the z. Feeler Gauge Z Offset.

From www.vehiclegeni.com

Lang Valve Tappet Gauge Set 2 Ez Grip Handles 11 Offset Feeler Blades Feeler Gauge Z Offset With paper i get inconsistent results. Set z offset to 0.0mm auto. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. You want to get the nozzle to zero, right on the bed. Place a piece of paper between the nozzle. Because of how the v2 is designed, this. Feeler Gauge Z Offset.

From www.accud.com

OFFSET DUAL SCALE FEELER GAUGE ACCUD Feeler Gauge Z Offset These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. Place a piece of paper between the nozzle. You want to get the nozzle to zero, right on the bed. Because of how the v2 is designed, this process may be slightly. To get there you offset. Feeler Gauge Z Offset.

From www.anviltool.co.uk

Feeler Gauge 26 Blade Offset Dual Marked Anvil Tool Feeler Gauge Z Offset You want to get the nozzle to zero, right on the bed. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. With paper i get inconsistent results. These areas are the foundation for a successful print and without any one of them, your print will be set up for. Feeler Gauge Z Offset.

From www.electronicpro.co.za

Drillpro Stainless Steel 16 Blade Valve Offset Feeler Gauge Metric 0.0 Feeler Gauge Z Offset i have tried paper and feeler gauges. With paper i get inconsistent results. To get there you offset the nozzle height by the thickness of your feeler. Set z offset to 0.0mm auto. You want to get the nozzle to zero, right on the bed. the gauge size does not matter. Move the nozzle on top of one. Feeler Gauge Z Offset.

From leroymerlin.co.za

Force 9 Piece Offset Feeler Gauge LEROY MERLIN South Africa Feeler Gauge Z Offset These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. setting the z offset is a a key. Feeler Gauge Z Offset.

From www.nepal.ubuy.com

Buy Stainless Steel Feeler Gauge Universal Standard SAE and Metric Feeler Gauge Z Offset Because of how the v2 is designed, this process may be slightly. the gauge size does not matter. With the feeler gauges i try this: Move the nozzle on top of one of the leveling screws (any of the four corners). To get there you offset the nozzle height by the thickness of your feeler. With paper i get. Feeler Gauge Z Offset.

From www.anviltool.co.uk

Feeler Gauge 26 Blade Offset Dual Marked Anvil Tool Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. i have tried paper and feeler gauges. Move the nozzle on top of one of the leveling screws (any of the four corners). heat the nozzle and the bed to the temperatures you usually utilize for the filament. Feeler Gauge Z Offset.

From www.ebay.com

ABN Universal Standard SAE and Metric Offset Valve Feeler Gauge 16 Feeler Gauge Z Offset heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. Move the nozzle on top of one of the leveling screws (any of the four corners). With the feeler gauges i try this: You want to get the nozzle to zero, right. Feeler Gauge Z Offset.

From www.carid.com

Lang Tools® 3275A 26 Blade Offset Feeler Gauge Feeler Gauge Z Offset i have tried paper and feeler gauges. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. Set z offset to 0.0mm auto. These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. heat the. Feeler Gauge Z Offset.

From www.masseyenergyco.com

How to Read a Feeler Gauge 5 Steps Process Massey Energy Co Feeler Gauge Z Offset if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. To get there you. Feeler Gauge Z Offset.

From www.amazon.co.uk

Feeler Gauge Set Stainless Steel Valve Lash Adjustment Tool Imperial Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. Set z offset to 0.0mm auto. the gauge size does not. Feeler Gauge Z Offset.

From www.desertcart.ph

Buy Offset Feeler Gauge Set by EAGems, for Measuring Gap Width or Feeler Gauge Z Offset if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. i have tried paper and feeler gauges. setting the z offset is a a key step in the process of configuring and tuning any fdm printer. heat the nozzle. Feeler Gauge Z Offset.

From www.australianonlinecarparts.com.au

Buy 9 Blade Offset Feeler Gauge Online T&E Tools TE7008 Feeler Gauge Z Offset the gauge size does not matter. To get there you offset the nozzle height by the thickness of your feeler. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. With the feeler gauges i try this: These areas are the. Feeler Gauge Z Offset.

From www.partsgiant.com

Lang Offset Feeler Gauge Set Parts Giant Feeler Gauge Z Offset Because of how the v2 is designed, this process may be slightly. You want to get the nozzle to zero, right on the bed. i have tried paper and feeler gauges. the gauge size does not matter. Set z offset to 0.0mm auto. These areas are the foundation for a successful print and without any one of them,. Feeler Gauge Z Offset.

From bigamart.com

2 Pack Feeler Gauge with 32/26 Blades and 1 Pack Offset Feeler Gauge Feeler Gauge Z Offset Because of how the v2 is designed, this process may be slightly. With paper i get inconsistent results. You want to get the nozzle to zero, right on the bed. With the feeler gauges i try this: if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the. Feeler Gauge Z Offset.

From www.toolsource.com

Feeler Gauge Set 12 Bld Offset A310 Feeler Gauge Z Offset With paper i get inconsistent results. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. the gauge size does not matter. These areas are the foundation for a successful print and without any one of them, your print will be. Feeler Gauge Z Offset.

From www.lasertools.co.uk

Laser Tools 2482 Offset Feeler Gauge 26 Blades Feeler Gauge Z Offset if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. Because of how the v2 is designed, this process may be slightly. Place a piece of paper between the nozzle. With paper i get inconsistent results. To get there you offset the. Feeler Gauge Z Offset.

From www.sptools.com

SP Tools Double Sided Offset Feeler Gauge 25pc Feeler Gauge Z Offset Place a piece of paper between the nozzle. i have tried paper and feeler gauges. Set z offset to 0.0mm auto. Move the nozzle on top of one of the leveling screws (any of the four corners). the gauge size does not matter. setting the z offset is a a key step in the process of configuring. Feeler Gauge Z Offset.

From www.arestool.com

2Piece Tapered Feeler Gauge and Offset Feeler Gauge Set ARES Tool Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. i have tried paper and feeler gauges. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. Set z offset to. Feeler Gauge Z Offset.

From www.matcotools.com

26 BLADE OFFSET FEELER GAUGE SET FG275 Matco Tools Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. heat the nozzle and the bed to the temperatures you usually. Feeler Gauge Z Offset.

From www.huttie.com

Feeler Gauge 12 Blade Offset Dual Marked Huttie Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. Because of how the v2 is designed, this process may be slightly. To get there you offset the nozzle height by the thickness of your feeler. With paper i get inconsistent results. You want to get the nozzle to zero,. Feeler Gauge Z Offset.

From www.thebossshop.com.au

K080007 Offset Feeler Gauge 12 Blade Imperial & Metric The Boss Shop Feeler Gauge Z Offset To get there you offset the nozzle height by the thickness of your feeler. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. Because of how the v2 is designed, this process may be slightly. the gauge size does not. Feeler Gauge Z Offset.

From www.carid.com

CTA® A308 11 Blade Offset Feeler Gauge Set Feeler Gauge Z Offset You want to get the nozzle to zero, right on the bed. i have tried paper and feeler gauges. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. To get there you offset the nozzle height by the thickness of. Feeler Gauge Z Offset.

From powertecproducts.com

80012 16 Blade Offset Feeler Gauge Set Thickness Gauge for Multi Use Feeler Gauge Z Offset With paper i get inconsistent results. Because of how the v2 is designed, this process may be slightly. To get there you offset the nozzle height by the thickness of your feeler. the gauge size does not matter. With the feeler gauges i try this: i have tried paper and feeler gauges. Place a piece of paper between. Feeler Gauge Z Offset.

From www.aliexpress.com

Offset Feeler Gauge Curved 16 Blades Metric MM Imperial Inch Gap Width Feeler Gauge Z Offset i have tried paper and feeler gauges. Set z offset to 0.0mm auto. You want to get the nozzle to zero, right on the bed. With paper i get inconsistent results. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and.. Feeler Gauge Z Offset.

From www.neervelta.nl

9pc Offset feeler gauge Neervelta Feeler Gauge Z Offset setting the z offset is a a key step in the process of configuring and tuning any fdm printer. Because of how the v2 is designed, this process may be slightly. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and.. Feeler Gauge Z Offset.

From www.lasertools.co.uk

Laser Tools 2482 Offset Feeler Gauge 26 Blades Feeler Gauge Z Offset With paper i get inconsistent results. These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. if the fit isn't quite right, you just move up or down the feeler gauge set, then adjust z offset by the difference between the expected and. You want to. Feeler Gauge Z Offset.

From www.toolking.com.au

Offset feeler Gauge KC Tools Robson's Tool King Store Feeler Gauge Z Offset These areas are the foundation for a successful print and without any one of them, your print will be set up for failure. Set z offset to 0.0mm auto. the gauge size does not matter. Place a piece of paper between the nozzle. To get there you offset the nozzle height by the thickness of your feeler. setting. Feeler Gauge Z Offset.

From www.discounttrader.com.au

SP Tools SP64036 Feeler Gauge Set 12 Piece Offset Feeler Gauges Feeler Gauge Z Offset Move the nozzle on top of one of the leveling screws (any of the four corners). heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. Because of how the v2 is designed, this process may be slightly. With the feeler gauges. Feeler Gauge Z Offset.

From homefourexperts.com

Feeler Gauge Sets Types & Uses Analysis Feeler Gauge Z Offset the gauge size does not matter. heat the nozzle and the bed to the temperatures you usually utilize for the filament you will be printing with to create the same conditions as the. i have tried paper and feeler gauges. setting the z offset is a a key step in the process of configuring and tuning. Feeler Gauge Z Offset.