Coating Valve Definition . intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. In this article, we attempt to clarify and. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coating specifications consist of three parts that constitute the complete coating process. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows:

from www.entechinst.com

coating specifications consist of three parts that constitute the complete coating process. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. In this article, we attempt to clarify and. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: intake and exhaust valves are available today in a staggering range of choices.

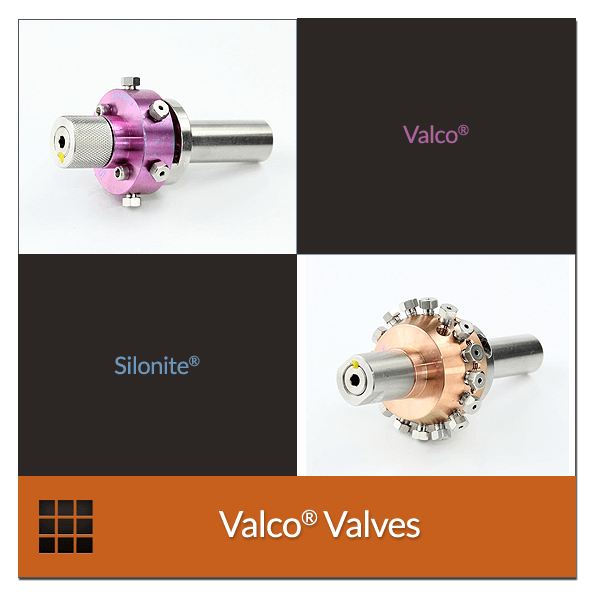

Silonite® Coated Valco® Valves Entech Instruments

Coating Valve Definition coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. In this article, we attempt to clarify and. intake and exhaust valves are available today in a staggering range of choices. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coating specifications consist of three parts that constitute the complete coating process.

From www.researchgate.net

Coating of valve seat using the laser cladding process. Download Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. In this article, we attempt to clarify and. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. intake and exhaust. Coating Valve Definition.

From www.youtube.com

Full automatic coating of valves YouTube Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. In this article, we attempt to clarify and. the main coating systems used for industrial. Coating Valve Definition.

From engineeringdiscoveries.com

Types Of Valves, Their Functions And Symbols Engineering Discoveries Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. intake and exhaust valves are available today in a. Coating Valve Definition.

From asi-tech.co.il

PVA FCS300 Selective Conformal Coating / Valves ASI Technologies Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. the main coating systems used for. Coating Valve Definition.

From www.cor-pro.com

Valve Coatings Houston Cor Pro Coating Valve Definition In this article, we attempt to clarify and. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coating specifications consist of three parts that constitute the complete coating process.. Coating Valve Definition.

From kermetico.com

Valve Coating GasTight Tungsten Carbide 1600HV+ Ductile Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces. Coating Valve Definition.

From www.belzona-kuwait.com

Repair materials and coatings for valves, pipes and fittings Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: In this article, we attempt to clarify and. coating specifications consist of three parts that constitute the complete coating process. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. intake. Coating Valve Definition.

From www.reliavalve.com

A105+ENP Ball Valve, ENP Coating Ball Valves, ENP Trim Ball Valve Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. In this article, we attempt to clarify and. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. intake and exhaust. Coating Valve Definition.

From en.asi-tech.co.il

PVA FCS300ES Selective Conformal Coating / Valves ASI Technologies Coating Valve Definition In this article, we attempt to clarify and. intake and exhaust valves are available today in a staggering range of choices. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface. Coating Valve Definition.

From engineeringlearn.com

Types of Valves Application, Working, Design & Methods Engineering Learn Coating Valve Definition coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. intake and exhaust valves are available today in a staggering range of choices. coating specifications consist of three parts that constitute the complete coating process. coatings are available which can provide suitable protection to valves and actuators, both internally and. Coating Valve Definition.

From kimray.com

How Valve Coating Can Limit Corrosion and Erosion in Control Valves Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: In this article, we attempt to clarify and. coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are available today in a staggering range of choices. the coatings widely used for. Coating Valve Definition.

From blog.eaglegroupmanufacturers.com

Anatomy of Industrial Valves Coating Valve Definition the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: intake. Coating Valve Definition.

From en.asi-tech.co.il

PVA FCM100 Selective Conformal Coating / Valves ASI Technologies Coating Valve Definition coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coating specifications consist of three parts that constitute the complete coating process. In this article, we attempt to clarify and. the main coating. Coating Valve Definition.

From www.ipccoatings.com

Electroless Nickel Coating For Oil & Gas Industries IPC Integrated Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coating specifications consist of three parts that constitute the complete coating process. In this article, we attempt to clarify and. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. the. Coating Valve Definition.

From www.pva.net

FC100CF NonAtomized Film Coating Valve PVA Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. intake and exhaust valves are. Coating Valve Definition.

From www.belzona.co.uk

Repair materials and coatings for valves, pipes and fittings Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. In this article, we attempt to clarify and. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: the coatings. Coating Valve Definition.

From www.ablazelining.com

What are the basics of Flush Bottom Valve? Ablaze Polymer Lining Coating Valve Definition the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. In this article, we attempt to clarify and. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the main coating systems used for industrial valves are 1, 2a, and. Coating Valve Definition.

From www.youtube.com

FBE Fusion Bonded Epoxy coating and lining on valves YouTube Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. coating specifications consist of three parts that constitute the complete coating process. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. In this article, we attempt to clarify and. the main. Coating Valve Definition.

From www.water-controlvalve.com

EN10745 DN50 FBE Coated Pressure Sustaining Valve With SS304 Pilot Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coating specifications consist of three. Coating Valve Definition.

From mechanicstips.blogspot.com

Types of Valves MechanicsTips Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. intake and exhaust valves are available. Coating Valve Definition.

From www.youtube.com

Flush Bottom Valve Definition, Types, Components, Working, Application Coating Valve Definition the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. intake and exhaust valves are available today in a staggering range of choices. In this article, we attempt to clarify and. the main coating systems used for industrial valves are 1, 2a, and 6c, which are. Coating Valve Definition.

From www.adamantvalves.com

What are the Effects of the Coating on the Valve Surface? Adamant Valves Coating Valve Definition the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. In this article, we attempt to clarify and. the main coating systems used for industrial valves are 1, 2a, and. Coating Valve Definition.

From www.hawavalves.com

Fusion Bond Epoxy (FBE) Coating Fastener Coating Pipe, Valve Coating Coating Valve Definition In this article, we attempt to clarify and. intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. the coatings. Coating Valve Definition.

From www.artofit.org

How valves work Artofit Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. In this article, we attempt to clarify and. the coatings widely used for valves include chemical and thermical coatings, all of which. Coating Valve Definition.

From ndapl.com

New Dispensing Automation Home Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. coating specifications consist of three parts that constitute the complete coating process. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. In this article, we attempt to clarify and. the main coating systems used for. Coating Valve Definition.

From www.entechinst.com

Silonite® Coated Valco® Valves Entech Instruments Coating Valve Definition coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: . Coating Valve Definition.

From en.asi-tech.co.il

PVA FCS300ES Selective Conformal Coating / Valves ASI Technologies Coating Valve Definition In this article, we attempt to clarify and. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coating specifications consist of three parts that constitute the complete coating process. the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much. Coating Valve Definition.

From www.watts.com

ArmorTek Coating Protects Valve Against Corrosion Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: In this article, we attempt to clarify and. coating specifications consist of three parts that constitute the complete coating process. the coatings widely used for. Coating Valve Definition.

From kermetico.com

Valve Coating GasTight Tungsten Carbide 1600HV+ Ductile Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. In this article, we attempt to clarify and. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. the coatings widely. Coating Valve Definition.

From www.ipccoatings.com

Electroless Nickel Coating For Oil & Gas Industries IPC Integrated Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. intake and exhaust valves are available today in a. Coating Valve Definition.

From anda.us

Conformal Coating System Anda Technologies USA Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. the coatings widely used for valves include chemical and. Coating Valve Definition.

From engineeringlearn.com

Flow Control Valve Definition, Types, Components & Working Principle Coating Valve Definition the coatings widely used for valves include chemical and thermical coatings, all of which provide a hard surface with much better. the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are. Coating Valve Definition.

From www.ipccoatings.com

Electroless Nickel Coating For Oil & Gas Industries IPC Integrated Coating Valve Definition the main coating systems used for industrial valves are 1, 2a, and 6c, which are explained as follows: In this article, we attempt to clarify and. coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are available today in a staggering range of choices. coatings are available which can. Coating Valve Definition.

From www.water-controlvalve.com

EPOXY Coating Modulating Float Control Valve DN800 Coating Valve Definition coating specifications consist of three parts that constitute the complete coating process. intake and exhaust valves are available today in a staggering range of choices. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. the main coating systems used for industrial valves are 1, 2a, and 6c, which. Coating Valve Definition.

From engineeringlearn.com

Jacketed Valves Definition, Types, Construction, Materials Coating Valve Definition intake and exhaust valves are available today in a staggering range of choices. coatings protect valves and actuators against wear, erosion, chemical attack and other forces that threaten their. coatings are available which can provide suitable protection to valves and actuators, both internally and externally, in. coating specifications consist of three parts that constitute the complete. Coating Valve Definition.