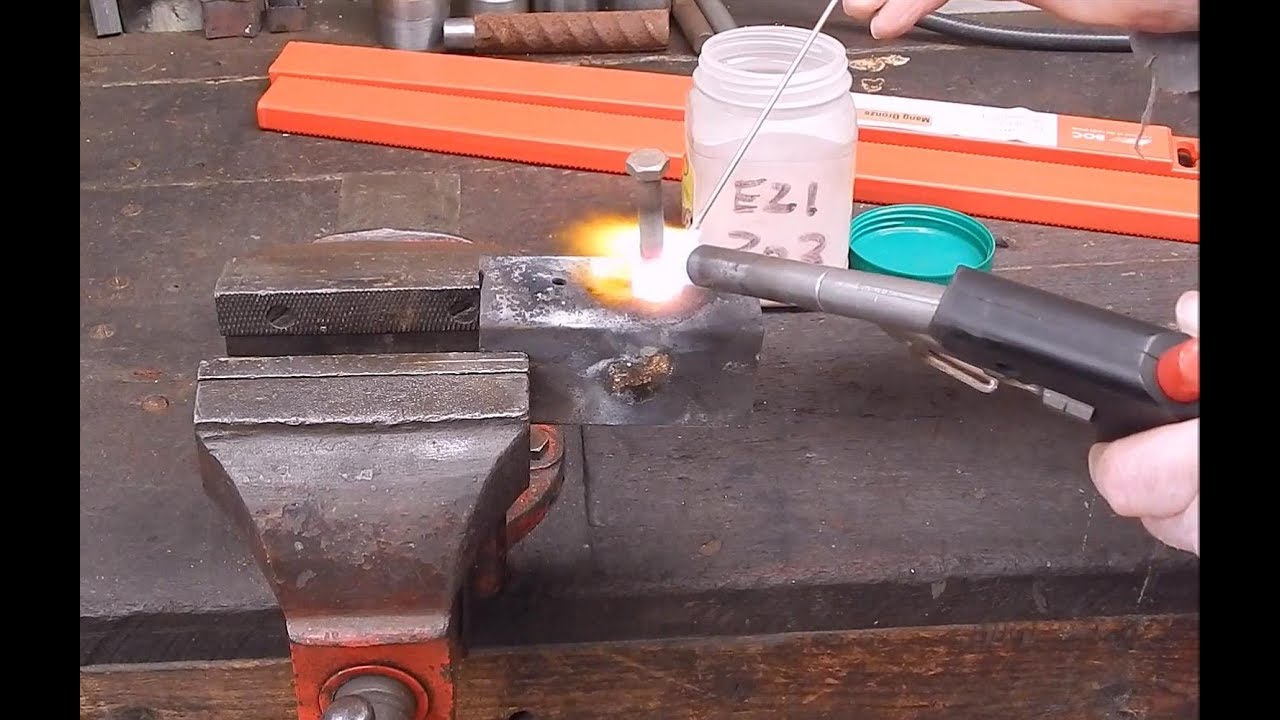

How To Braze Weld Cast Iron . braze welding is a great way to join cast iron when joint strength is not paramount. Brazing doesn’t melt the base metal. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. One of the most significant advantages of brazing cast iron is the limited heating. They are chosen for their capability to produce durable joints. This will help you choose the best solution for you. brazing cast iron is one of the best solutions. Braze welding of cast iron. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. In this article, we’ll explain. choosing the right filler materials. Copper alloy can also join dissimilar metals together.

from www.youtube.com

brazing cast iron is one of the best solutions. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. They are chosen for their capability to produce durable joints. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. Brazing doesn’t melt the base metal. Braze welding of cast iron. choosing the right filler materials. This will help you choose the best solution for you. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined.

How to do simple bronze brazing in the YouTube

How To Braze Weld Cast Iron braze welding is a great way to join cast iron when joint strength is not paramount. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. Braze welding of cast iron. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. Copper alloy can also join dissimilar metals together. One of the most significant advantages of brazing cast iron is the limited heating. Brazing doesn’t melt the base metal. braze welding is a great way to join cast iron when joint strength is not paramount. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. They are chosen for their capability to produce durable joints. This will help you choose the best solution for you. brazing cast iron is one of the best solutions. In this article, we’ll explain. choosing the right filler materials.

From www.youtube.com

Always learning Brazing Cast Iron YouTube How To Braze Weld Cast Iron This will help you choose the best solution for you. Braze welding of cast iron. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. In this article, we’ll explain. They are chosen. How To Braze Weld Cast Iron.

From www.youtube.com

Cast Iron Welding Repair with Copper and Stainless TIG Brazing YouTube How To Braze Weld Cast Iron Braze welding of cast iron. brazing cast iron is one of the best solutions. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. choosing the right filler materials. This will help you choose the best solution for you. They are chosen for their capability to produce durable joints.. How To Braze Weld Cast Iron.

From exownvsyp.blob.core.windows.net

Brazing Iron Welding at Bruce Heffington blog How To Braze Weld Cast Iron Copper alloy can also join dissimilar metals together. Braze welding of cast iron. They are chosen for their capability to produce durable joints. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. Brazing doesn’t melt the base metal. This will help you choose the best solution for you. One. How To Braze Weld Cast Iron.

From tammy.ai

Mastering Cast Iron Welding Tips and Techniques How To Braze Weld Cast Iron brazing cast iron is one of the best solutions. This will help you choose the best solution for you. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. Braze welding of cast iron. They are chosen for their capability to produce durable joints. One of the most significant advantages of brazing. How To Braze Weld Cast Iron.

From weldinginsider.com

How to Weld Cast Iron Effectively[Cast Iron Welders Guide] How To Braze Weld Cast Iron Brazing doesn’t melt the base metal. braze welding is a great way to join cast iron when joint strength is not paramount. This will help you choose the best solution for you. choosing the right filler materials. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. Braze welding of cast. How To Braze Weld Cast Iron.

From www.youtube.com

How to do simple bronze brazing in the YouTube How To Braze Weld Cast Iron This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. One of the most significant advantages of brazing cast iron is the limited heating. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. They are chosen for their capability to produce durable. How To Braze Weld Cast Iron.

From blog.thepipingmart.com

How To Weld Cast Iron A Complete Guide How To Braze Weld Cast Iron They are chosen for their capability to produce durable joints. brazing cast iron is one of the best solutions. This will help you choose the best solution for you. One of the most significant advantages of brazing cast iron is the limited heating. choosing the right filler materials. to master the art of braze welding techniques for. How To Braze Weld Cast Iron.

From notifemo.blogspot.com

How To Braze Cast Iron / How To Braze Cast Iron Soldering Building How To Braze Weld Cast Iron Brazing doesn’t melt the base metal. This will help you choose the best solution for you. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. Copper alloy can also join dissimilar metals together. Braze welding of cast iron. They are chosen for their capability to produce durable joints. . How To Braze Weld Cast Iron.

From www.pinterest.com

What Are The Types Of Brazing? "7 Brazing Types Explained" Brazing How To Braze Weld Cast Iron brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. braze welding is a great way to join cast iron when joint strength is not paramount. This will help you. How To Braze Weld Cast Iron.

From www.youtube.com

EASILY Braze, Steel, Iron, Brass, Bronze, Or Copper YouTube How To Braze Weld Cast Iron Braze welding of cast iron. This will help you choose the best solution for you. braze welding is a great way to join cast iron when joint strength is not paramount. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. brazing cast iron is one of the best solutions. This. How To Braze Weld Cast Iron.

From weldersadvice.com

How to Braze Weld Thin Metal A Beginner's Guide How To Braze Weld Cast Iron choosing the right filler materials. This will help you choose the best solution for you. One of the most significant advantages of brazing cast iron is the limited heating. brazing cast iron is one of the best solutions. Copper alloy can also join dissimilar metals together. brazing cast iron requires specific techniques and materials to achieve a. How To Braze Weld Cast Iron.

From exownvsyp.blob.core.windows.net

Brazing Iron Welding at Bruce Heffington blog How To Braze Weld Cast Iron brazing cast iron is one of the best solutions. This will help you choose the best solution for you. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. One. How To Braze Weld Cast Iron.

From weldinghelmetreviews.com

How to Weld Cast Iron Complete Welding Guide How To Braze Weld Cast Iron braze welding is a great way to join cast iron when joint strength is not paramount. They are chosen for their capability to produce durable joints. One of the most significant advantages of brazing cast iron is the limited heating. choosing the right filler materials. This will help you choose the best solution for you. This would be. How To Braze Weld Cast Iron.

From www.machines4u.com.au

Welding Cast Iron The HowTo Guide How To Braze Weld Cast Iron This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. choosing the right filler materials. Brazing doesn’t melt the base metal. brazing cast iron is one of the. How To Braze Weld Cast Iron.

From weldguru.com

How To Weld Cast Iron (The Best Ways) How To Braze Weld Cast Iron brazing cast iron is one of the best solutions. Copper alloy can also join dissimilar metals together. This will help you choose the best solution for you. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. In this article, we’ll explain. Braze welding of cast iron. One of the most significant. How To Braze Weld Cast Iron.

From beststudwelders.com

How to Braze Cast Iron Complete Guide best stud welders How To Braze Weld Cast Iron In this article, we’ll explain. They are chosen for their capability to produce durable joints. This will help you choose the best solution for you. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. One of the most significant advantages of brazing cast iron is the limited heating. This would be a. How To Braze Weld Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques How To Braze Weld Cast Iron Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. choosing the right filler materials. This will help you choose the best solution for you. Copper alloy can also join dissimilar metals. How To Braze Weld Cast Iron.

From notifemo.blogspot.com

How To Braze Cast Iron / How To Braze Cast Iron Soldering Building How To Braze Weld Cast Iron choosing the right filler materials. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. In this article, we’ll explain. brazing cast iron is one of the best. How To Braze Weld Cast Iron.

From www.cruxweld.com

Cast Iron Welding Procedure [StepByStep Guide] cruxweld How To Braze Weld Cast Iron Brazing doesn’t melt the base metal. Copper alloy can also join dissimilar metals together. In this article, we’ll explain. This will help you choose the best solution for you. brazing cast iron is one of the best solutions. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. Brazing. How To Braze Weld Cast Iron.

From weldersadvice.com

How To Braze Weld Cast Iron Welders Advice How To Braze Weld Cast Iron Copper alloy can also join dissimilar metals together. choosing the right filler materials. They are chosen for their capability to produce durable joints. This will help you choose the best solution for you. In this article, we’ll explain. Braze welding of cast iron. One of the most significant advantages of brazing cast iron is the limited heating. Brazing uses. How To Braze Weld Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques How To Braze Weld Cast Iron Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. choosing the right filler materials. brazing cast iron is one of the best solutions. This will help you choose the best solution for you. Braze welding of cast iron. One of the most significant advantages of brazing cast iron is the. How To Braze Weld Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques How To Braze Weld Cast Iron Braze welding of cast iron. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. They are chosen for their capability to produce durable joints. brazing cast iron is one of the best solutions. braze welding is a great way to join cast iron when joint strength is. How To Braze Weld Cast Iron.

From houseandbeyond.org

How to Weld Cast Iron Detailed Instructions and Techniques How To Braze Weld Cast Iron choosing the right filler materials. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. In this article, we’ll explain. brazing cast iron is one of the best solutions. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined.. How To Braze Weld Cast Iron.

From www.youtube.com

MIG Brazing Welding Cast Iron with Silicon Bronze Repair YouTube How To Braze Weld Cast Iron to master the art of braze welding techniques for cast iron, you need to understand the different methods available. They are chosen for their capability to produce durable joints. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. One of the most significant advantages of brazing cast iron. How To Braze Weld Cast Iron.

From blog.thepipingmart.com

Brazing Brass to Cast Iron A Complete Guide How To Braze Weld Cast Iron This will help you choose the best solution for you. braze welding is a great way to join cast iron when joint strength is not paramount. brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. to master the art of braze welding techniques for cast iron, you need. How To Braze Weld Cast Iron.

From weldguru.com

How To Weld Cast Iron (The Best Ways) How To Braze Weld Cast Iron Brazing doesn’t melt the base metal. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. choosing the right filler materials. brazing cast iron requires specific techniques and materials to achieve. How To Braze Weld Cast Iron.

From weldsmartly.com

How To Weld Cast Iron With MIG Welder Comprehensive Guide How To Braze Weld Cast Iron One of the most significant advantages of brazing cast iron is the limited heating. choosing the right filler materials. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. braze welding is a great way to join cast iron when joint strength is not paramount. Copper alloy can. How To Braze Weld Cast Iron.

From weldingtroop.com

How to Weld Cast Iron (Helpful Guide & Best Tips You Need To Know) How To Braze Weld Cast Iron This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. One of the most significant advantages of brazing cast iron is the limited heating. Brazing doesn’t melt the base metal. choosing the. How To Braze Weld Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques How To Braze Weld Cast Iron In this article, we’ll explain. They are chosen for their capability to produce durable joints. braze welding is a great way to join cast iron when joint strength is not paramount. One of the most significant advantages of brazing cast iron is the limited heating. Copper alloy can also join dissimilar metals together. Brazing doesn’t melt the base metal.. How To Braze Weld Cast Iron.

From weldingpros.net

Brazing cast iron HowTo Guide, Tips & Techniques How To Braze Weld Cast Iron This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. In this article, we’ll explain. They are chosen for their capability to produce durable joints. Braze welding of cast iron. to master the art of braze welding techniques for cast iron, you need to understand the different methods available.. How To Braze Weld Cast Iron.

From allaboutweldingjobs.com

Brazing Cast Iron Super Helpful Guide & How To Braze Weld Cast Iron choosing the right filler materials. One of the most significant advantages of brazing cast iron is the limited heating. This will help you choose the best solution for you. Braze welding of cast iron. brazing cast iron is one of the best solutions. They are chosen for their capability to produce durable joints. Brazing uses filler metal that. How To Braze Weld Cast Iron.

From www.youtube.com

Brazing Cast Iron YouTube How To Braze Weld Cast Iron Brazing uses filler metal that melts above 840 °f (450 °c), but the base metal remains unaffected. Braze welding of cast iron. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. Brazing doesn’t melt the base metal. brazing cast iron is one of the best solutions. They are. How To Braze Weld Cast Iron.

From www.youtube.com

Tig Welding/Brazing with Silicon Bronze YouTube How To Braze Weld Cast Iron They are chosen for their capability to produce durable joints. Brazing doesn’t melt the base metal. This would be a seal weld only, not structural, and therefore it should only be used to fix a leak. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. choosing the right. How To Braze Weld Cast Iron.

From www.youtube.com

Tig Welding/Brazing Cast Iron to 409 Stainless YouTube How To Braze Weld Cast Iron brazing cast iron requires specific techniques and materials to achieve a strong bond between the pieces being joined. In this article, we’ll explain. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. Braze welding of cast iron. Brazing uses filler metal that melts above 840 °f (450 °c),. How To Braze Weld Cast Iron.

From notifemo.blogspot.com

How To Braze Cast Iron / How To Braze Cast Iron Soldering Building How To Braze Weld Cast Iron brazing cast iron is one of the best solutions. to master the art of braze welding techniques for cast iron, you need to understand the different methods available. In this article, we’ll explain. One of the most significant advantages of brazing cast iron is the limited heating. This will help you choose the best solution for you. . How To Braze Weld Cast Iron.