Spiral Baffle Jacket Design . Spirally baffled jackets/ conventional jackets. Panel type/ plate type coil jackets. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. A conventional jacket should be fitted with baffles (see figure 1a). Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Construction investigation for “jacketed” pressure vessel, material selection, design data and. The spiral path helps to achieve velocities in the. A spiral baffle consists of metal strip spiral wound around the reactor wall. Matching jacket types to heat transfer media.

from eureka.patsnap.com

A spiral baffle consists of metal strip spiral wound around the reactor wall. A conventional jacket should be fitted with baffles (see figure 1a). The spiral path helps to achieve velocities in the. Matching jacket types to heat transfer media. Spirally baffled jackets/ conventional jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Panel type/ plate type coil jackets. Construction investigation for “jacketed” pressure vessel, material selection, design data and. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces.

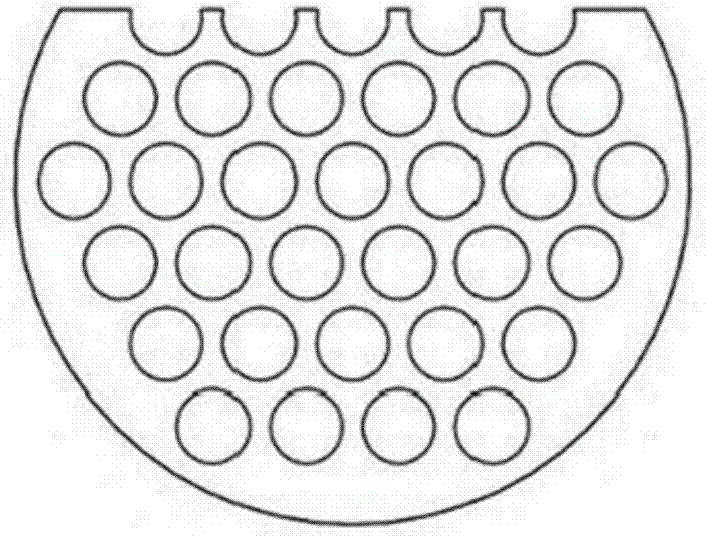

Stepped spiral baffle and heat exchanger thereof Eureka Patsnap

Spiral Baffle Jacket Design A conventional jacket should be fitted with baffles (see figure 1a). Panel type/ plate type coil jackets. A spiral baffle consists of metal strip spiral wound around the reactor wall. Matching jacket types to heat transfer media. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Spirally baffled jackets/ conventional jackets. The spiral path helps to achieve velocities in the. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. A conventional jacket should be fitted with baffles (see figure 1a). Construction investigation for “jacketed” pressure vessel, material selection, design data and. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor.

From www.researchgate.net

2 Continuous stirredtank reactors (Fermenter Equipment design Spiral Baffle Jacket Design Panel type/ plate type coil jackets. Spirally baffled jackets/ conventional jackets. Construction investigation for “jacketed” pressure vessel, material selection, design data and. Matching jacket types to heat transfer media. The spiral path helps to achieve velocities in the. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets,. Spiral Baffle Jacket Design.

From www.shutterstock.com

Vector Illustration Spirally Wound Baffled Jacket Stock Vector (Royalty Spiral Baffle Jacket Design Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Matching. Spiral Baffle Jacket Design.

From us.misumi-ec.com

Spiral Baffle Boards Nylon with Glass Fiber, For Separate Plates Spiral Baffle Jacket Design The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. A spiral baffle consists of metal strip spiral wound around the reactor wall. Commonly used heat transfer medias include. Spiral Baffle Jacket Design.

From educationalmaterialsfactory.blogspot.com

Types of Jackets for Reaction Vessel Engineering Muse Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s. Spiral Baffle Jacket Design.

From indonesian.molding-part.com

Spiral Cooling Baffles Spiral Brass Plug Baffle Untuk Cetakan Injeksi Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. Matching jacket types to heat transfer media. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Panel type/ plate type coil jackets. The spiral path helps to achieve. Spiral Baffle Jacket Design.

From www.yubomold.com

Spiral Baffle Tube Yubo Mold Parts Spiral Baffle Jacket Design Matching jacket types to heat transfer media. Spirally baffled jackets/ conventional jackets. The spiral path helps to achieve velocities in the. Panel type/ plate type coil jackets. A conventional jacket should be fitted with baffles (see figure 1a). Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Construction investigation for “jacketed”. Spiral Baffle Jacket Design.

From design.udlvirtual.edu.pe

Types Of Baffles In Fermenter Design Talk Spiral Baffle Jacket Design Matching jacket types to heat transfer media. A spiral baffle consists of metal strip spiral wound around the reactor wall. The spiral path helps to achieve velocities in the. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. A conventional jacket should be fitted with baffles (see figure 1a). Construction investigation. Spiral Baffle Jacket Design.

From www.youtube.com

Anaerobic Baffled Reactor (ABR) for Wastewater Treatment Advanced Spiral Baffle Jacket Design The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Construction investigation for “jacketed” pressure vessel, material selection, design data and. Spirally baffled jackets/ conventional jackets. Panel type/ plate. Spiral Baffle Jacket Design.

From www.pinterest.com

Types of Jackets for Reaction Vessel Different types of jackets used Spiral Baffle Jacket Design A conventional jacket should be fitted with baffles (see figure 1a). A spiral baffle consists of metal strip spiral wound around the reactor wall. Panel type/ plate type coil jackets. The spiral path helps to achieve velocities in the. Matching jacket types to heat transfer media. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with. Spiral Baffle Jacket Design.

From www.widia.com

Baffles Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. The spiral path helps to achieve velocities in the. A conventional jacket should be fitted with baffles (see figure 1a). Matching jacket types to heat transfer media. The aim of this chapter is to present a summary. Spiral Baffle Jacket Design.

From lp.durlum.com

POLYLAM vertical baffle system durlum North America Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. The spiral path helps to achieve velocities in the. Construction investigation for “jacketed” pressure vessel, material selection, design data and. Matching jacket types to heat transfer media. Panel type/ plate type coil jackets. A conventional jacket should be fitted with baffles (see figure 1a). The aim of this chapter is to present a summary for. Spiral Baffle Jacket Design.

From www.harrods.com

Barbour Newland Baffle Puffer Jacket Harrods AU Spiral Baffle Jacket Design A conventional jacket should be fitted with baffles (see figure 1a). Spirally baffled jackets/ conventional jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Construction investigation for “jacketed” pressure vessel, material selection, design data and. The aim of this chapter is to present a summary for the literature concerning heat. Spiral Baffle Jacket Design.

From design.udlvirtual.edu.pe

Suppressor Baffle Design Design Talk Spiral Baffle Jacket Design A spiral baffle consists of metal strip spiral wound around the reactor wall. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Panel type/ plate type coil jackets.. Spiral Baffle Jacket Design.

From silvercore-firearms-training.blogspot.com

Silvercore Firearms Training BC Suppressor Baffles and Spacers Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Panel type/ plate type coil jackets. A spiral baffle consists of metal strip spiral wound around the reactor wall. The spiral path helps to achieve velocities in the. Jacketed vessel heat transfer calculation estimates overall heat transfer. Spiral Baffle Jacket Design.

From www.researchgate.net

Structural and setup sketch of spiral baffle. Download Scientific Diagram Spiral Baffle Jacket Design Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Panel type/ plate type coil jackets. Spirally baffled jackets/ conventional jackets. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. A spiral baffle consists of metal strip spiral wound around the reactor wall.. Spiral Baffle Jacket Design.

From www.shutterstock.com

32 imágenes de Spiral baffle Imágenes, fotos y vectores de stock Spiral Baffle Jacket Design The spiral path helps to achieve velocities in the. Spirally baffled jackets/ conventional jackets. A conventional jacket should be fitted with baffles (see figure 1a). Panel type/ plate type coil jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Matching jacket types to heat transfer media. Jacketed vessel heat transfer. Spiral Baffle Jacket Design.

From www.flannels.ie

Barbour Venture Baffle Quilted Jacket Men Parka Jackets Spiral Baffle Jacket Design Matching jacket types to heat transfer media. A conventional jacket should be fitted with baffles (see figure 1a). Spirally baffled jackets/ conventional jackets. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s. Spiral Baffle Jacket Design.

From www.couponxoo.com

Suppressor Baffle Designs With Dimensions 02/2022 Spiral Baffle Jacket Design The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Spirally baffled jackets/ conventional jackets. A conventional jacket should be fitted with baffles (see figure 1a). Panel type/ plate. Spiral Baffle Jacket Design.

From www.agi-glassplant.com

Why you should choose the AGI Glassplant Ring Baffle Spiral Baffle Jacket Design Matching jacket types to heat transfer media. Construction investigation for “jacketed” pressure vessel, material selection, design data and. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. The. Spiral Baffle Jacket Design.

From www.mouldshop.co.uk

Spiral Blade Baffles Fittings Spiral Baffle Jacket Design Matching jacket types to heat transfer media. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters. Spiral Baffle Jacket Design.

From chempedia.info

Spiral baffle, jacket with Big Chemical Encyclopedia Spiral Baffle Jacket Design A spiral baffle consists of metal strip spiral wound around the reactor wall. Matching jacket types to heat transfer media. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets,. Spiral Baffle Jacket Design.

From www.tretorn.dk

BAFFLE JACKET VANDTÆTTE JAKKE Spiral Baffle Jacket Design Panel type/ plate type coil jackets. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such. Spiral Baffle Jacket Design.

From www.f1technical.net

Fuel tanks, baffles and assymetry. Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. Matching jacket types to heat transfer media. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles). Spiral Baffle Jacket Design.

From yourautoworld.com

Replacement Spiral Baffle for 2.5 Inch Pipe The Your Auto Spiral Baffle Jacket Design A conventional jacket should be fitted with baffles (see figure 1a). Matching jacket types to heat transfer media. A spiral baffle consists of metal strip spiral wound around the reactor wall. Spirally baffled jackets/ conventional jackets. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils,. Spiral Baffle Jacket Design.

From se.tretorn.com

BAFFLE JACKET VATTENTÄT JACKA Tretorn Spiral Baffle Jacket Design Construction investigation for “jacketed” pressure vessel, material selection, design data and. The spiral path helps to achieve velocities in the. Matching jacket types to heat transfer media. Panel type/ plate type coil jackets. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and. Spiral Baffle Jacket Design.

From se.tretorn.com

BAFFLE JACKET VATTENTÄT JACKA Tretorn Spiral Baffle Jacket Design Spirally baffled jackets/ conventional jackets. The spiral path helps to achieve velocities in the. Matching jacket types to heat transfer media. A spiral baffle consists of metal strip spiral wound around the reactor wall. Panel type/ plate type coil jackets. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Construction investigation. Spiral Baffle Jacket Design.

From www.cheresources.com

Jacketed Heat Exchanger Process Heat Transfer Spiral Baffle Jacket Design A conventional jacket should be fitted with baffles (see figure 1a). Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Matching jacket types to heat transfer media. The spiral path helps to achieve velocities in the. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™),. Spiral Baffle Jacket Design.

From bizpro-x.com

Exploring Different Baffle Designs in Men's Down Jackets Fashion and Spiral Baffle Jacket Design The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Panel type/ plate type coil jackets. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel. Spiral Baffle Jacket Design.

From designpict.github.io

48 Creative 9mm suppressor baffle design for New Ideas All Design and Spiral Baffle Jacket Design Construction investigation for “jacketed” pressure vessel, material selection, design data and. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. A spiral baffle consists of metal strip spiral. Spiral Baffle Jacket Design.

From lob-gmbh.de

Baffles with WTPSystem® for perfect temperature LOB Spiral Baffle Jacket Design Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. Construction investigation for “jacketed” pressure vessel, material selection, design data and. Panel type/ plate type coil jackets. The spiral path helps to achieve velocities in the. Matching jacket types to heat transfer media. A spiral baffle consists of metal strip spiral wound. Spiral Baffle Jacket Design.

From slideplayer.com

REBOILERS AND VAPORISERS ppt download Spiral Baffle Jacket Design A spiral baffle consists of metal strip spiral wound around the reactor wall. A conventional jacket should be fitted with baffles (see figure 1a). Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Matching jacket types to heat transfer media. The aim of this chapter is to present a summary for. Spiral Baffle Jacket Design.

From hales.com.au

Brass Baffles Turbo (Spiral) CTB16x4 Hales Australia Spiral Baffle Jacket Design Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. The spiral path helps to achieve velocities in the. A spiral baffle consists of metal strip spiral wound around the reactor wall. The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped. Spiral Baffle Jacket Design.

From www.sidharvey.com

6341.25X17 by Sid Harvey is Boiler Spiral Baffle 11/4" x 17 Spiral Baffle Jacket Design Commonly used heat transfer medias include water, steam (various pressures), hot oil (such as therminol™), and dowtherm™ vapor. The spiral path helps to achieve velocities in the. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Panel type/ plate type coil jackets. The aim of this chapter is to present a. Spiral Baffle Jacket Design.

From www.modalite.net

Adidas Big Baffle Down Jacket HN9930 Spiral Baffle Jacket Design Panel type/ plate type coil jackets. A conventional jacket should be fitted with baffles (see figure 1a). Spirally baffled jackets/ conventional jackets. Matching jacket types to heat transfer media. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with. Commonly used heat transfer medias include water, steam (various pressures), hot oil (such. Spiral Baffle Jacket Design.

From eureka.patsnap.com

Stepped spiral baffle and heat exchanger thereof Eureka Patsnap Spiral Baffle Jacket Design The aim of this chapter is to present a summary for the literature concerning heat transfer in agitated vessels (equipped with jackets, helical coils, spiral coils, and vertical tube baffles) and also the many parameters of nusselt’s equation for these surfaces. Panel type/ plate type coil jackets. The spiral path helps to achieve velocities in the. Matching jacket types to. Spiral Baffle Jacket Design.