Bevel Welding Definition . The cut is usually “v” shaped, so the surface to be welded becomes larger. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. So, we will weld the inner. Welding bevel refers to the angular edge shape on the base metal of the welding. In welding, a bevel is an edge preparation presented as an angle. A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. The angle of bevel, root face,. This makes the welding area bigger so it can spread out the weight better, making a stronger. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Bevel in welding is an angled flat surface at the end of the material. By beveling at least one piece, you can create a larger surface, which allows for a more. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other.

from localrevive.com

A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. The cut is usually “v” shaped, so the surface to be welded becomes larger. By beveling at least one piece, you can create a larger surface, which allows for a more. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. Welding bevel refers to the angular edge shape on the base metal of the welding. This makes the welding area bigger so it can spread out the weight better, making a stronger. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. So, we will weld the inner. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. In welding, a bevel is an edge preparation presented as an angle.

Welding Symbols Guide Meanings, Examples + Free PDF chart (2022)

Bevel Welding Definition This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. The angle of bevel, root face,. A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. The cut is usually “v” shaped, so the surface to be welded becomes larger. This makes the welding area bigger so it can spread out the weight better, making a stronger. By beveling at least one piece, you can create a larger surface, which allows for a more. So, we will weld the inner. Bevel in welding is an angled flat surface at the end of the material. In welding, a bevel is an edge preparation presented as an angle. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Welding bevel refers to the angular edge shape on the base metal of the welding.

From www.slideserve.com

PPT CHAPTER 25 PowerPoint Presentation, free download ID969154 Bevel Welding Definition Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. The cut is usually “v” shaped, so the surface to be welded becomes larger. Weld beveling is the process. Bevel Welding Definition.

From materialwelding.com

Welding Bevel Types and Symbols you NEED to know! Bevel Welding Definition Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. By beveling at least one piece, you can create a larger surface, which allows for a more. Welding bevel refers to the angular edge shape on the base metal of the welding. So, we will weld the inner. The cut is usually. Bevel Welding Definition.

From localrevive.com

Welding Symbols Guide Meanings, Examples + Free PDF chart (2022) Bevel Welding Definition This makes the welding area bigger so it can spread out the weight better, making a stronger. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Welding bevel refers to the angular edge shape on the base metal of the welding. Bevel in welding is an angled flat surface at the. Bevel Welding Definition.

From engineersblog.net

What is Bevel Groove Joint? Explain in details step by step procedure Bevel Welding Definition Welding bevel refers to the angular edge shape on the base metal of the welding. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. In welding, a bevel is an edge preparation presented as an angle. Bevel in welding is an angled flat surface at the end of the material. A bevel weld. Bevel Welding Definition.

From weldinglogic.com

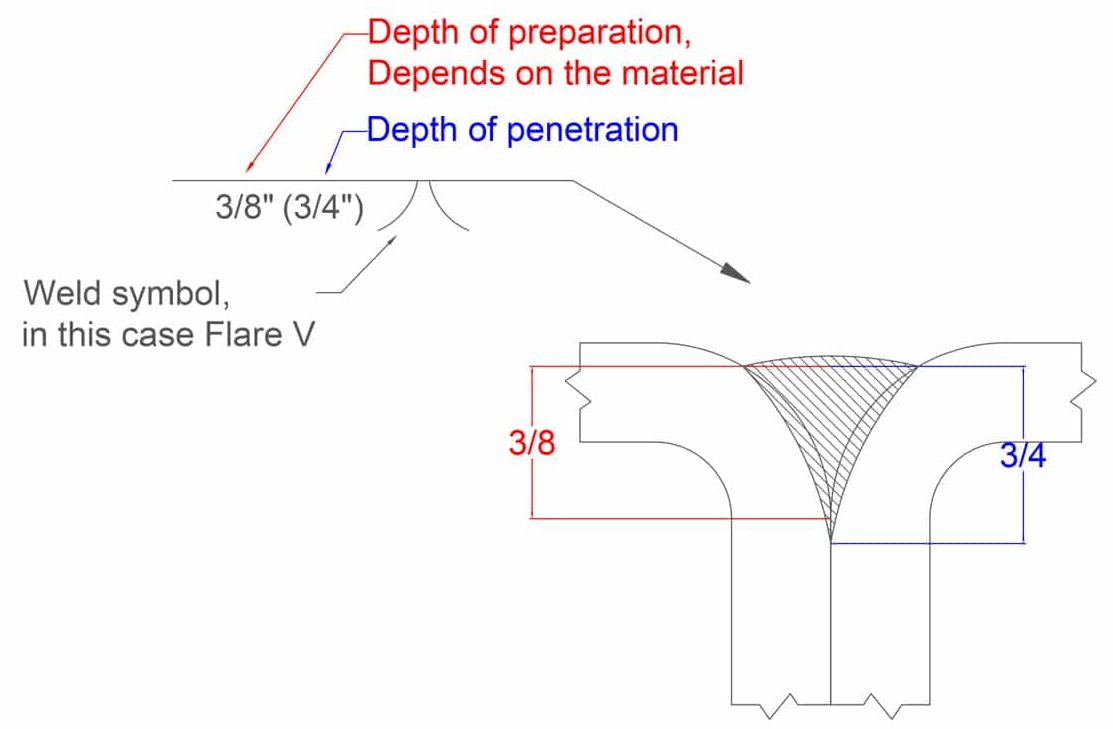

Flare Bevel Weld Overview, Symbol, Size, Callout & More Welding Logic Bevel Welding Definition By beveling at least one piece, you can create a larger surface, which allows for a more. This makes the welding area bigger so it can spread out the weight better, making a stronger. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. The angle of bevel, root face,. So, we will weld. Bevel Welding Definition.

From www.weldingmania.com

What Is Bevel In Welding And When It Is Used? WeldingMania Bevel Welding Definition Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. The angle of bevel, root face,. A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. So, we will weld the inner. Welding bevel refers. Bevel Welding Definition.

From weldinginsider.com

Understanding the Basic Welding Symbols Bevel Welding Definition This makes the welding area bigger so it can spread out the weight better, making a stronger. By beveling at least one piece, you can create a larger surface, which allows for a more. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. So, we will weld the inner. The cut is usually “v” shaped,. Bevel Welding Definition.

From materialwelding.com

Welding Bevel Types and Symbols you NEED to know! Bevel Welding Definition This makes the welding area bigger so it can spread out the weight better, making a stronger. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. In welding, a bevel is an edge preparation presented as an angle. This opening made by gives the welder access to the total thickness of the material. Bevel Welding Definition.

From weldingclarity.com

What is Bevel in Welding? Understanding the Important Bevel Welding Definition Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. In welding, a bevel is an edge preparation presented as an angle. Bevelling is preparing for welding. Bevel Welding Definition.

From pholder.com

841 best Bevel images on Pholder Bladesmith, Knifemaking and Blacksmith Bevel Welding Definition A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. The cut is usually “v” shaped, so the surface to be welded becomes larger. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. This. Bevel Welding Definition.

From learnweldingsymbols.com

Understanding Bevel Groove Welding Symbols A Comprehensive Guide Bevel Welding Definition Bevel in welding is an angled flat surface at the end of the material. This makes the welding area bigger so it can spread out the weight better, making a stronger. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevelling is preparing for welding by cutting an angled slope on the edge of the. Bevel Welding Definition.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Bevel Welding Definition This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. By beveling at least one piece, you can create a larger surface, which allows for a more. So, we will weld the inner. Bevelling is preparing for welding by cutting an angled slope on the. Bevel Welding Definition.

From finwise.edu.vn

Albums 96+ Pictures What Is A Welded Sound Sharp Bevel Welding Definition Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. This makes the welding area bigger so it can spread out the weight better, making a stronger. A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape. Bevel Welding Definition.

From jubrau.biz

Welding Symbols Types, Sample Diagrams, Free PDF Diagrams (2023) Bevel Welding Definition Welding bevel refers to the angular edge shape on the base metal of the welding. Bevel in welding is an angled flat surface at the end of the material. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. This opening made by gives the welder access to the total thickness of the material. Bevel Welding Definition.

From exykunfnx.blob.core.windows.net

What Is Bevel Length at John Rochelle blog Bevel Welding Definition The angle of bevel, root face,. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. So, we will weld the inner. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Welding bevel refers to the angular edge shape on the base. Bevel Welding Definition.

From www.researchgate.net

Plates beveling for welding. Download Scientific Diagram Bevel Welding Definition Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. By beveling at least one piece, you can create a larger surface, which allows for a more. This makes the welding area bigger so it can spread out the weight better, making a stronger. The cut is usually “v”. Bevel Welding Definition.

From www.slideserve.com

PPT Weld Joint Geometry and Weld Symbols PowerPoint Presentation Bevel Welding Definition Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. The cut is usually “v” shaped, so the surface to be welded becomes larger. The angle of bevel, root face,. Welding bevel refers to the angular edge shape on the base metal of the welding. Weld beveling is the process of creating a bevel. Bevel Welding Definition.

From in.pinterest.com

Groove weld Weld, Groove, Technical Bevel Welding Definition In welding, a bevel is an edge preparation presented as an angle. This makes the welding area bigger so it can spread out the weight better, making a stronger. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevel in welding is an angled flat surface at the end of the material. Bevel welds are. Bevel Welding Definition.

From www.slideserve.com

PPT WELD JOINT GEOMETERY AND WELDING SYMBOLS PowerPoint Presentation Bevel Welding Definition The angle of bevel, root face,. The cut is usually “v” shaped, so the surface to be welded becomes larger. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. This makes the welding area bigger so it. Bevel Welding Definition.

From www.youtube.com

CJP Weld With Double Bevel Use FCAW Process 1 YouTube Bevel Welding Definition Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. By beveling at least one piece, you can create a larger surface, which allows for a more. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Bevelling is preparing for. Bevel Welding Definition.

From www.youtube.com

When To Bevel Metal Before Welding YouTube Bevel Welding Definition Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Bevel in welding is an angled flat surface at the end of the material. This opening made by gives the welder access to the total. Bevel Welding Definition.

From www.thefabricator.com

The next generation of portable beveling The Fabricator Bevel Welding Definition The cut is usually “v” shaped, so the surface to be welded becomes larger. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. This makes the welding area bigger so it can spread out the weight better, making a. Bevel Welding Definition.

From inchbyinch.de

INCH Technical English weld types Bevel Welding Definition So, we will weld the inner. By beveling at least one piece, you can create a larger surface, which allows for a more. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. A bevel weld is when you cut the edge of one piece to slant it into. Bevel Welding Definition.

From welditu.com

Main Types of Welds Used in Welding WelditU Bevel Welding Definition So, we will weld the inner. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Welding bevel refers to the angular edge shape on the base metal of the welding. This makes the welding area bigger so it can. Bevel Welding Definition.

From www.cwbgroup.org

How It Works What is a Backing Strip for a Welded Joint? CWB Group Bevel Welding Definition The angle of bevel, root face,. This makes the welding area bigger so it can spread out the weight better, making a stronger. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevel in. Bevel Welding Definition.

From manualdatafrondent.z14.web.core.windows.net

Types Of Welding Process With Diagram Bevel Welding Definition Welding bevel refers to the angular edge shape on the base metal of the welding. Bevel in welding is an angled flat surface at the end of the material. Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. This opening made by gives the welder access to the total thickness of. Bevel Welding Definition.

From materialwelding.com

Flare Bevel Weld Overview, Types & Welding symbol with examples (With PDF) Bevel Welding Definition Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. This makes the welding area bigger so it can spread out the weight better, making a stronger. In welding, a bevel is an. Bevel Welding Definition.

From rickyswelding.com

What Are The Common Types Of Welding? Ricky's Welding Equipment Bevel Welding Definition Bevel in welding is an angled flat surface at the end of the material. This makes the welding area bigger so it can spread out the weight better, making a stronger. In welding, a bevel is an edge preparation presented as an angle. This opening made by gives the welder access to the total thickness of the material wall and. Bevel Welding Definition.

From www.fabricatingandmetalworking.com

What You Must Know About Beveling or Weld Preparation Fabricating and Bevel Welding Definition This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. By beveling at least one piece, you can create a larger surface, which allows for a more. The angle of bevel, root face,. So, we will weld the inner. Bevelling is preparing for welding by. Bevel Welding Definition.

From mungfali.com

Single Bevel Weld Joint Bevel Welding Definition Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. This makes the welding area bigger so it can spread out the weight better, making a stronger. Bevel in welding is an angled flat surface at the end of the material. Weld beveling is the process of creating a bevel on the edge of a base. Bevel Welding Definition.

From www.youtube.com

Mastering Steel Tube Fabrication Prep, Bevel, Weld, and Finish YouTube Bevel Welding Definition Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevel in welding is an angled flat surface at the end of the material. The cut is usually “v” shaped, so the surface to be welded becomes larger. Bevel welds. Bevel Welding Definition.

From engineersfield.com

Welding Terms and Symbols Basic welding symbols Engineersfield Bevel Welding Definition A bevel weld is when you cut the edge of one piece to slant it into a v, u, or j shape before welding. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Bevelling is preparing for welding by cutting an angled slope on the edge of the. Bevel Welding Definition.

From weldinganswers.com

Learning Welding Symbols Groove Welds WELDING ANSWERS Bevel Welding Definition Bevel welds are weld joints made between metal pieces that are not parallel or perpendicular to each other. The cut is usually “v” shaped, so the surface to be welded becomes larger. Understanding groove design and bevel preparation is essential for achieving strong and reliable welds. Bevel in welding is an angled flat surface at the end of the material.. Bevel Welding Definition.

From www.bgstructuralengineering.com

Welding Intro Bevel Welding Definition By beveling at least one piece, you can create a larger surface, which allows for a more. Bevelling is preparing for welding by cutting an angled slope on the edge of the metal. The cut is usually “v” shaped, so the surface to be welded becomes larger. Bevel in welding is an angled flat surface at the end of the. Bevel Welding Definition.

From www.weldingis.com

Welding Symbols Guide and Chart All Type Joint (Fillet and Groove Weld) Bevel Welding Definition This opening made by gives the welder access to the total thickness of the material wall and allows him to create a uniform weld using. Weld beveling is the process of creating a bevel on the edge of a base metal for welding & joining applications. Welding bevel refers to the angular edge shape on the base metal of the. Bevel Welding Definition.