How To Calculate Runner Diameter . Runner extension length is the distance from the end of the gate to the entry to. The following formula is initially used to determine runner diameters in a graduated runner. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. There are three basic parameters for runner geometry: Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. Simply input your measurements and hit the calculate button at. To help you calculate runners, we have provided this free calculator. Despite my disdain for rules of thumb, the following guidelines are. These are then verified via moldflow®. Notice that amorphous materials require a larger diameter than the rule calls for. I have found that if this rule is not followed, sinks and voids don’t pack out. However, a circular shape is most common, as it has the lowest flow resistance. The runner diameter must be adjusted accordingly.

from www.slideserve.com

Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. However, a circular shape is most common, as it has the lowest flow resistance. Despite my disdain for rules of thumb, the following guidelines are. These are then verified via moldflow®. To help you calculate runners, we have provided this free calculator. The runner diameter must be adjusted accordingly. Notice that amorphous materials require a larger diameter than the rule calls for. Simply input your measurements and hit the calculate button at. The following formula is initially used to determine runner diameters in a graduated runner. Runner extension length is the distance from the end of the gate to the entry to.

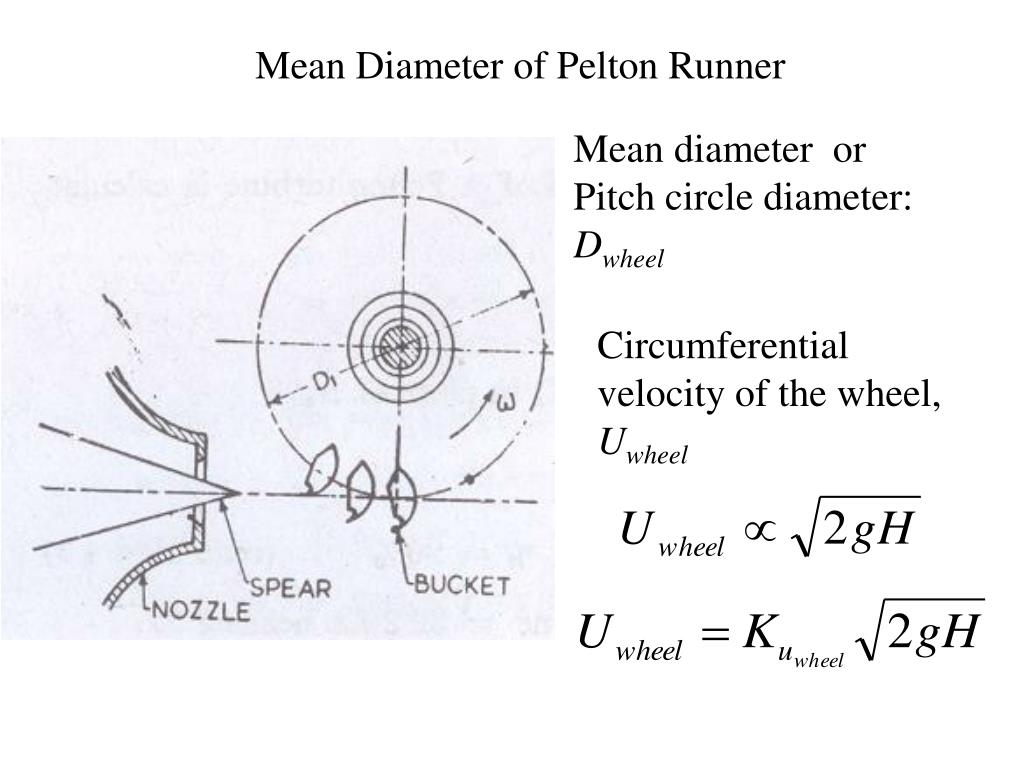

PPT Design Analysis of Parts of Pelton Wheel Turbine PowerPoint

How To Calculate Runner Diameter These are then verified via moldflow®. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. Runner extension length is the distance from the end of the gate to the entry to. I have found that if this rule is not followed, sinks and voids don’t pack out. However, a circular shape is most common, as it has the lowest flow resistance. There are three basic parameters for runner geometry: The following formula is initially used to determine runner diameters in a graduated runner. The runner diameter must be adjusted accordingly. Notice that amorphous materials require a larger diameter than the rule calls for. Despite my disdain for rules of thumb, the following guidelines are. These are then verified via moldflow®. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. Simply input your measurements and hit the calculate button at. To help you calculate runners, we have provided this free calculator.

From www.cuemath.com

Diameter Formula Circle Diameter Formula Formula of Diameter How To Calculate Runner Diameter Simply input your measurements and hit the calculate button at. To help you calculate runners, we have provided this free calculator. These are then verified via moldflow®. There are three basic parameters for runner geometry: I have found that if this rule is not followed, sinks and voids don’t pack out. Runner extension length is the distance from the end. How To Calculate Runner Diameter.

From www.slideshare.net

Pelton turbine (1) How To Calculate Runner Diameter The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. Runner extension length is the distance from the end of the gate to the entry to. However, a circular shape is most common, as it has the lowest flow resistance. Despite my disdain for rules of thumb, the following. How To Calculate Runner Diameter.

From www.cuemath.com

Diameter of Circle Definition, Formula, Examples & Worksheets Cuemath How To Calculate Runner Diameter However, a circular shape is most common, as it has the lowest flow resistance. Despite my disdain for rules of thumb, the following guidelines are. The runner diameter must be adjusted accordingly. Notice that amorphous materials require a larger diameter than the rule calls for. Runner width and runner depth or runner diameter, refer to the dimensions of the runner. How To Calculate Runner Diameter.

From slidetodoc.com

DPT 321 INJECTION MOLD DESIGN School of Manufacturing How To Calculate Runner Diameter Despite my disdain for rules of thumb, the following guidelines are. I have found that if this rule is not followed, sinks and voids don’t pack out. The following formula is initially used to determine runner diameters in a graduated runner. Runner extension length is the distance from the end of the gate to the entry to. The basic rule. How To Calculate Runner Diameter.

From www.coursehero.com

[Solved] A reaction turbine runner diameter is 3.5 m at inlet and 2.5 m How To Calculate Runner Diameter The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. There are three basic parameters for runner geometry: Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. Runner extension length is the distance from the end of the gate to the entry. How To Calculate Runner Diameter.

From www.slideserve.com

PPT 塑料注射成型工艺基础 PowerPoint Presentation, free download ID6555848 How To Calculate Runner Diameter To help you calculate runners, we have provided this free calculator. The following formula is initially used to determine runner diameters in a graduated runner. Simply input your measurements and hit the calculate button at. These are then verified via moldflow®. There are three basic parameters for runner geometry: Notice that amorphous materials require a larger diameter than the rule. How To Calculate Runner Diameter.

From ryanwallace.z19.web.core.windows.net

Size Guide Table Runner Size Chart How To Calculate Runner Diameter Runner extension length is the distance from the end of the gate to the entry to. Simply input your measurements and hit the calculate button at. There are three basic parameters for runner geometry: Despite my disdain for rules of thumb, the following guidelines are. The following formula is initially used to determine runner diameters in a graduated runner. These. How To Calculate Runner Diameter.

From www.youtube.com

Problem 1 Kaplan Turbine Determine Diameter of Runner and Diameter How To Calculate Runner Diameter The following formula is initially used to determine runner diameters in a graduated runner. Simply input your measurements and hit the calculate button at. To help you calculate runners, we have provided this free calculator. I have found that if this rule is not followed, sinks and voids don’t pack out. However, a circular shape is most common, as it. How To Calculate Runner Diameter.

From www.youtube.com

How to Calculate the Diameter of a Circle YouTube How To Calculate Runner Diameter Runner extension length is the distance from the end of the gate to the entry to. However, a circular shape is most common, as it has the lowest flow resistance. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. These are then verified via moldflow®. Notice that amorphous materials require a larger diameter. How To Calculate Runner Diameter.

From www.youtube.com

Threads and tolerances, calculating diameters and pitch diameter offset How To Calculate Runner Diameter Notice that amorphous materials require a larger diameter than the rule calls for. To help you calculate runners, we have provided this free calculator. However, a circular shape is most common, as it has the lowest flow resistance. There are three basic parameters for runner geometry: The basic rule for this calculation is that the runner diameter must be 1.5. How To Calculate Runner Diameter.

From www.researchgate.net

2) Design of runner. Outlet diameter í µí°· 1 ≅ í µí°· 1 2 = 0.08125í How To Calculate Runner Diameter Runner extension length is the distance from the end of the gate to the entry to. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. Notice that amorphous materials require a larger diameter than the rule calls for. However, a circular shape is most common, as it has the lowest flow resistance. Simply. How To Calculate Runner Diameter.

From americanelitewheels.com

Overall Tire Diameter Calculator American Elite Wheels How To Calculate Runner Diameter I have found that if this rule is not followed, sinks and voids don’t pack out. Runner extension length is the distance from the end of the gate to the entry to. Notice that amorphous materials require a larger diameter than the rule calls for. There are three basic parameters for runner geometry: However, a circular shape is most common,. How To Calculate Runner Diameter.

From www.youtube.com

Problem 1 Francis Turbine Determine Rate of Flow, Diameter of Runner How To Calculate Runner Diameter Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The runner diameter must be adjusted accordingly. Runner extension length is the distance from the end of the gate to the entry to. Simply input your measurements and hit the calculate button at. These are then verified via moldflow®. To help you calculate runners,. How To Calculate Runner Diameter.

From www.mdpi.com

Polymers Free FullText A SemiAnalytical Method for Designing a How To Calculate Runner Diameter Notice that amorphous materials require a larger diameter than the rule calls for. The following formula is initially used to determine runner diameters in a graduated runner. Simply input your measurements and hit the calculate button at. I have found that if this rule is not followed, sinks and voids don’t pack out. The basic rule for this calculation is. How To Calculate Runner Diameter.

From www.chegg.com

, Find a) Primary and Secondary runner diameters, How To Calculate Runner Diameter I have found that if this rule is not followed, sinks and voids don’t pack out. These are then verified via moldflow®. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. The following formula is initially used to determine runner diameters in a graduated runner. To help you. How To Calculate Runner Diameter.

From www.dailymotion.com

How to Determine Rate of Flow, Diameter of Runner and Blade Angle of How To Calculate Runner Diameter These are then verified via moldflow®. There are three basic parameters for runner geometry: Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. I have found that if this rule is not followed, sinks and voids don’t pack out. Despite my disdain for rules of thumb, the following guidelines are. The following formula. How To Calculate Runner Diameter.

From www.researchgate.net

Best configuration for diameter and length for the intake runner for How To Calculate Runner Diameter However, a circular shape is most common, as it has the lowest flow resistance. To help you calculate runners, we have provided this free calculator. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of. How To Calculate Runner Diameter.

From www.wikihow.com

How to Find the Diameter of a Circle wikiHow How To Calculate Runner Diameter Notice that amorphous materials require a larger diameter than the rule calls for. The runner diameter must be adjusted accordingly. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. Simply input your measurements and hit the calculate button at. However, a circular shape is most common, as it has the lowest flow resistance.. How To Calculate Runner Diameter.

From www.slideshare.net

How to calculate the diameter of a circle How To Calculate Runner Diameter The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. To help you calculate runners, we have provided this free calculator. However, a circular shape is most common, as it has the lowest. How To Calculate Runner Diameter.

From www.dailymotion.com

How to Determine Diameter of Runner and Diameter of Hub of Kaplan How To Calculate Runner Diameter Despite my disdain for rules of thumb, the following guidelines are. Runner extension length is the distance from the end of the gate to the entry to. To help you calculate runners, we have provided this free calculator. The following formula is initially used to determine runner diameters in a graduated runner. Notice that amorphous materials require a larger diameter. How To Calculate Runner Diameter.

From www.learntocalculate.com

How to Calculate Diameter from Circumference. How To Calculate Runner Diameter The following formula is initially used to determine runner diameters in a graduated runner. The runner diameter must be adjusted accordingly. These are then verified via moldflow®. Notice that amorphous materials require a larger diameter than the rule calls for. However, a circular shape is most common, as it has the lowest flow resistance. There are three basic parameters for. How To Calculate Runner Diameter.

From www.cuemath.com

Diameter of Circle Definition, Formula, Examples & Worksheets Cuemath How To Calculate Runner Diameter To help you calculate runners, we have provided this free calculator. There are three basic parameters for runner geometry: However, a circular shape is most common, as it has the lowest flow resistance. I have found that if this rule is not followed, sinks and voids don’t pack out. Runner width and runner depth or runner diameter, refer to the. How To Calculate Runner Diameter.

From www.chegg.com

Solved Question 4 For a primary diameter of 0.25inches and How To Calculate Runner Diameter Despite my disdain for rules of thumb, the following guidelines are. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The following formula is initially used to determine runner diameters in a graduated runner. Runner extension length is the distance from the end of the gate to the entry to. These are then. How To Calculate Runner Diameter.

From www.youtube.com

Runner Calculation for Mold/ Mold Calculation Contact 8871511975 For How To Calculate Runner Diameter These are then verified via moldflow®. Notice that amorphous materials require a larger diameter than the rule calls for. However, a circular shape is most common, as it has the lowest flow resistance. The following formula is initially used to determine runner diameters in a graduated runner. The runner diameter must be adjusted accordingly. Runner extension length is the distance. How To Calculate Runner Diameter.

From www.slideserve.com

PPT Design Analysis of Parts of Pelton Wheel Turbine PowerPoint How To Calculate Runner Diameter These are then verified via moldflow®. To help you calculate runners, we have provided this free calculator. Despite my disdain for rules of thumb, the following guidelines are. The runner diameter must be adjusted accordingly. Simply input your measurements and hit the calculate button at. However, a circular shape is most common, as it has the lowest flow resistance. Notice. How To Calculate Runner Diameter.

From www.youtube.com

An athlete completes a round of a circular track of diameter 200m in 20 How To Calculate Runner Diameter Simply input your measurements and hit the calculate button at. However, a circular shape is most common, as it has the lowest flow resistance. Despite my disdain for rules of thumb, the following guidelines are. Runner extension length is the distance from the end of the gate to the entry to. Notice that amorphous materials require a larger diameter than. How To Calculate Runner Diameter.

From www.slideserve.com

PPT Kaplan turbine PowerPoint Presentation, free download ID409058 How To Calculate Runner Diameter Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The runner diameter must be adjusted accordingly. Simply input your measurements and hit the calculate button at. Despite my disdain for rules of thumb, the following guidelines are. Notice that amorphous materials require a larger diameter than the rule calls for. The basic rule. How To Calculate Runner Diameter.

From www.wikihow.com

How to Find the Diameter of a Circle wikiHow How To Calculate Runner Diameter The runner diameter must be adjusted accordingly. There are three basic parameters for runner geometry: However, a circular shape is most common, as it has the lowest flow resistance. Despite my disdain for rules of thumb, the following guidelines are. Notice that amorphous materials require a larger diameter than the rule calls for. I have found that if this rule. How To Calculate Runner Diameter.

From www.chegg.com

Solved Find the diameter of the runners AB and AG to achieve How To Calculate Runner Diameter Notice that amorphous materials require a larger diameter than the rule calls for. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. To help you calculate runners, we have provided this free calculator. The runner diameter must be adjusted accordingly. There are three basic parameters for runner geometry: Despite my disdain for rules. How To Calculate Runner Diameter.

From www.researchgate.net

Variation of Runner diameter with Head and Discharge Download How To Calculate Runner Diameter The runner diameter must be adjusted accordingly. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. There are three basic parameters for runner geometry: However, a circular shape is most common, as it has the lowest flow resistance. Runner extension length is the distance from the end of the gate to the entry. How To Calculate Runner Diameter.

From extrudesign.com

Example Problem on Calculating Shaft Diameter ExtruDesign How To Calculate Runner Diameter The following formula is initially used to determine runner diameters in a graduated runner. There are three basic parameters for runner geometry: Despite my disdain for rules of thumb, the following guidelines are. These are then verified via moldflow®. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. However, a circular shape is. How To Calculate Runner Diameter.

From www.plasticmoulds.net

Sprues,runners And Gates Of Plastic Mold Topworks Plastic Molding How To Calculate Runner Diameter Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The runner diameter must be adjusted accordingly. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest section of the part. Simply input your measurements and hit the calculate button at. The following formula is initially used. How To Calculate Runner Diameter.

From www.slideserve.com

PPT Gates and Runners Chapter 10 PowerPoint Presentation, free How To Calculate Runner Diameter Runner extension length is the distance from the end of the gate to the entry to. Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. The runner diameter must be adjusted accordingly. To help you calculate runners, we have provided this free calculator. Notice that amorphous materials require a larger diameter than the. How To Calculate Runner Diameter.

From unitymanufacture.com

How To Determine Gate Size Injection Molding? Unity Manufacture How To Calculate Runner Diameter Runner width and runner depth or runner diameter, refer to the dimensions of the runner extension. There are three basic parameters for runner geometry: These are then verified via moldflow®. Despite my disdain for rules of thumb, the following guidelines are. However, a circular shape is most common, as it has the lowest flow resistance. Notice that amorphous materials require. How To Calculate Runner Diameter.

From slidetodoc.com

DPT 321 INJECTION MOLD DESIGN School of Manufacturing How To Calculate Runner Diameter I have found that if this rule is not followed, sinks and voids don’t pack out. To help you calculate runners, we have provided this free calculator. Runner extension length is the distance from the end of the gate to the entry to. The basic rule for this calculation is that the runner diameter must be 1.5 times the thickest. How To Calculate Runner Diameter.