Ksb Pump Failure . Make this diagnosis a part of your routine. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Perhaps you’re baffled by excess energy usage. Don’t let a few millimetres cause premature failure in your pumps. Each hrsg has two 100% capacity pumps with 5kv drive motors. We’ve put together an easy. Protect your investment by making sure your pumps are getting the preventive maintenance they need. A repair was initiated during periods when pump operation was not. Here are some common reasons why your slurry pump may not be operating correctly: Incorrect pump — if your pump experiences flange. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Or, possibly most obvious of all, you.

from www.canadianminingjournal.com

Each hrsg has two 100% capacity pumps with 5kv drive motors. Incorrect pump — if your pump experiences flange. Make this diagnosis a part of your routine. A repair was initiated during periods when pump operation was not. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Or, possibly most obvious of all, you. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Perhaps you’re baffled by excess energy usage. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Here are some common reasons why your slurry pump may not be operating correctly:

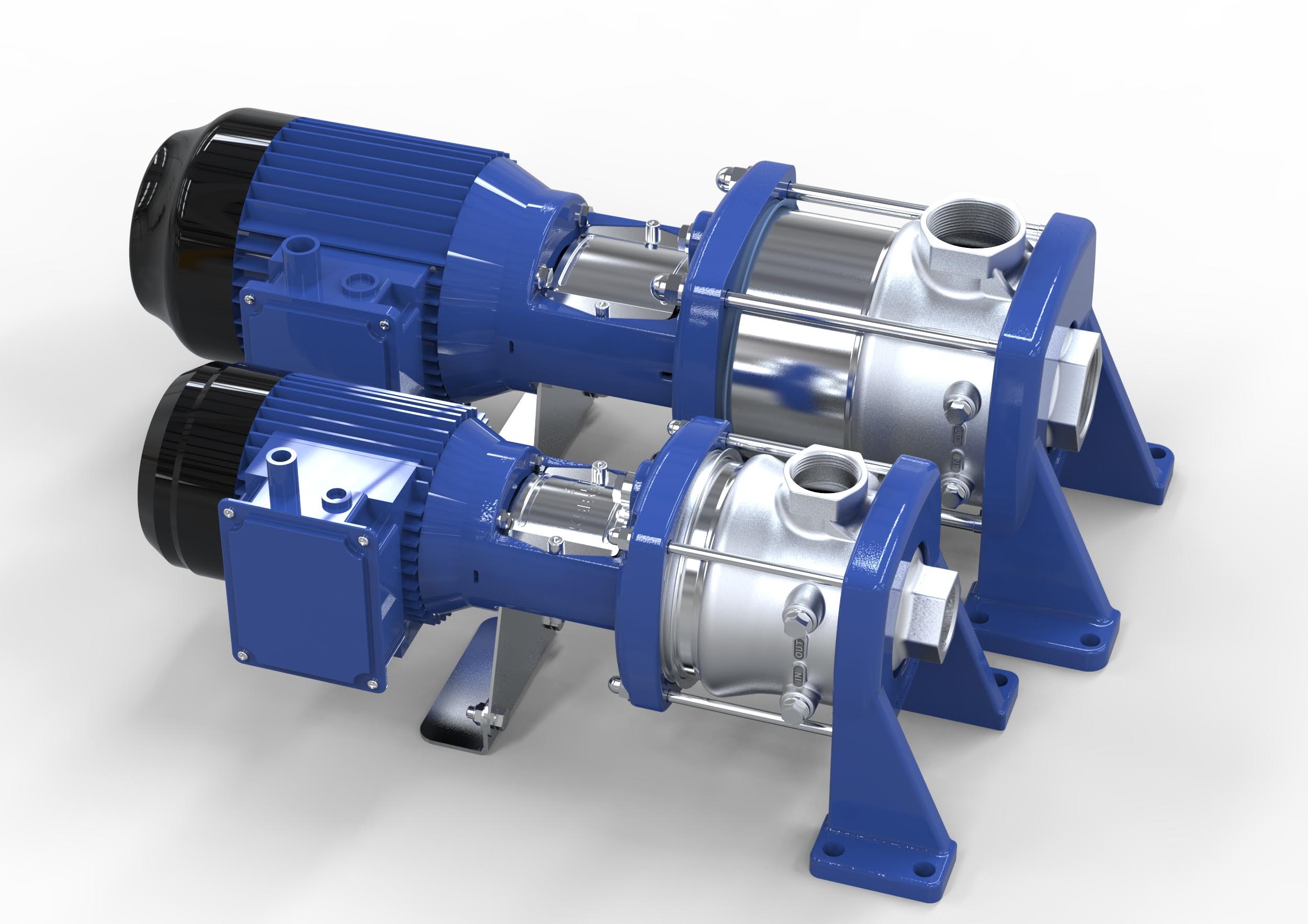

PUMPS KSB’s Movitec H high pressure pumps now configured for

Ksb Pump Failure Perhaps you’re baffled by excess energy usage. Here are some common reasons why your slurry pump may not be operating correctly: A repair was initiated during periods when pump operation was not. Make this diagnosis a part of your routine. Or, possibly most obvious of all, you. We’ve put together an easy. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Perhaps you’re baffled by excess energy usage. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Each hrsg has two 100% capacity pumps with 5kv drive motors. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Don’t let a few millimetres cause premature failure in your pumps. Incorrect pump — if your pump experiences flange.

From ildanatraining.ie

Understanding Pumps in a System and Understanding the Common Pump Failures Ksb Pump Failure An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Make this diagnosis a part of your routine. A repair was initiated during periods when pump operation was not. Or, possibly most obvious of all, you. Each hrsg has two 100% capacity pumps with 5kv drive motors.. Ksb Pump Failure.

From www.indiamart.com

Ksb Pump Dealer In Delhi, Power 3 HP at best price in New Delhi ID Ksb Pump Failure A repair was initiated during periods when pump operation was not. Incorrect pump — if your pump experiences flange. Don’t let a few millimetres cause premature failure in your pumps. Perhaps you’re baffled by excess energy usage. Make this diagnosis a part of your routine. Protect your investment by making sure your pumps are getting the preventive maintenance they need.. Ksb Pump Failure.

From www.prestigepumps.co.uk

KSB LCC R Slurry Pump Prestige Pumps Ksb Pump Failure We’ve put together an easy. A repair was initiated during periods when pump operation was not. Protect your investment by making sure your pumps are getting the preventive maintenance they need. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Don’t let a few millimetres. Ksb Pump Failure.

From www.ebay.com

KSB ETSCHROM BC 025160/402 Centrifugal Pump eBay Ksb Pump Failure Each hrsg has two 100% capacity pumps with 5kv drive motors. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Don’t let a few millimetres cause premature failure in your pumps. Or, possibly most obvious of all, you. Incorrect pump — if your pump experiences flange. To prevent failure from occurring, you can take. Ksb Pump Failure.

From braamdstore.com

KSB ETANORM Standardized Water Pump BRAAMD Store Ksb Pump Failure Don’t let a few millimetres cause premature failure in your pumps. Or, possibly most obvious of all, you. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Incorrect pump — if your pump experiences flange. Perhaps you’re baffled by excess energy usage. Protect your investment by making sure your pumps are getting the preventive. Ksb Pump Failure.

From magnatexpumps.com

ANSI Drive PFA Lined Pumps Mag Drive Pump for Chemical and Ksb Pump Failure Or, possibly most obvious of all, you. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Perhaps you’re baffled by excess energy usage. Make this diagnosis a part of your routine. To prevent failure from occurring, you can take a few steps to diagnose and solve. Ksb Pump Failure.

From jualboileridm.com

PUMP KSB ETANORM Jual Speare part Boiler Burner Ksb Pump Failure To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Incorrect pump — if your pump experiences flange. Make this diagnosis a part of your routine. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting. Ksb Pump Failure.

From www.canadianminingjournal.com

PUMPS KSB’s Movitec H high pressure pumps now configured for Ksb Pump Failure Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Don’t let a few millimetres cause premature failure in your pumps. Incorrect pump — if your pump experiences flange. Or, possibly most obvious of all, you. Here are some common reasons why your slurry pump may not be operating correctly: Each hrsg has two 100%. Ksb Pump Failure.

From braamdstore.com

Dryinstalled pump KSB Etabloc BRAAMD Store Ksb Pump Failure Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Here are some common reasons why your slurry pump may not be operating correctly: Don’t let a few millimetres cause premature failure in your pumps. Incorrect pump — if your pump experiences flange. Each hrsg has two 100% capacity pumps with 5kv drive motors. To. Ksb Pump Failure.

From foodnewsinternational.com

Europe KSB releases highpressure pumps for fluids Food News Ksb Pump Failure We’ve put together an easy. Don’t let a few millimetres cause premature failure in your pumps. Make this diagnosis a part of your routine. Incorrect pump — if your pump experiences flange. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Or, possibly most obvious. Ksb Pump Failure.

From www.pumpsandcouplings.com

Common failure of pump and motor Pumps & Couplings Ksb Pump Failure Protect your investment by making sure your pumps are getting the preventive maintenance they need. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Perhaps you’re baffled by excess energy usage. Incorrect pump — if your pump experiences flange. Each hrsg has two 100% capacity pumps. Ksb Pump Failure.

From www.financialexpress.com

KSB net rises 25.91; co reports surge in demand for pumps, valves Ksb Pump Failure Here are some common reasons why your slurry pump may not be operating correctly: We’ve put together an easy. Incorrect pump — if your pump experiences flange. Each hrsg has two 100% capacity pumps with 5kv drive motors. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Don’t let a few millimetres cause premature. Ksb Pump Failure.

From giw.ksb.com

KSB Pumps Deliver Efficiency and Sustainability Ksb Pump Failure To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Perhaps you’re baffled by excess energy usage. An effective pump troubleshooting tool will always begin with the question when did this. Ksb Pump Failure.

From braamdstore.com

KSB Etaline Singlestage Volute Casing InLine Pump BRAAMD Store Ksb Pump Failure Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Perhaps you’re baffled by excess energy usage. Protect your investment by making sure your pumps are getting the preventive maintenance they need. We’ve put together an easy. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring. Ksb Pump Failure.

From giw.ksb.com

Why Can’t I Remove My Impeller from My Pump Shaft? Ksb Pump Failure Perhaps you’re baffled by excess energy usage. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. We’ve put together an easy. Make this diagnosis a part of your routine. Each hrsg has two 100% capacity pumps with 5kv drive motors. An effective pump troubleshooting tool will always begin with the question when did this. Ksb Pump Failure.

From braamdstore.com

KSB Submersible motor pump Amarex KRT BRAAMD Store Ksb Pump Failure Each hrsg has two 100% capacity pumps with 5kv drive motors. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Perhaps you’re baffled by excess energy usage. Incorrect pump — if your pump experiences flange. Make this diagnosis a part of your routine. Here are some. Ksb Pump Failure.

From cooperind.com

KSB PUMP VERTICAL MULTISTAGE CENTRIFUGAL PUMP, UNUSED Cooper Ksb Pump Failure Perhaps you’re baffled by excess energy usage. Don’t let a few millimetres cause premature failure in your pumps. We’ve put together an easy. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. A repair was initiated during periods when pump operation was not. Make this diagnosis. Ksb Pump Failure.

From www.scribd.com

Operating Data WTPM A B KSB Pump PDF Pump Bearing (Mechanical) Ksb Pump Failure Here are some common reasons why your slurry pump may not be operating correctly: Each hrsg has two 100% capacity pumps with 5kv drive motors. We’ve put together an easy. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. A repair was initiated during periods when. Ksb Pump Failure.

From jerryshomemade.com

Comandante Riconoscimento Divertimento pompe ksb italia grado luce del Ksb Pump Failure We’ve put together an easy. Or, possibly most obvious of all, you. Each hrsg has two 100% capacity pumps with 5kv drive motors. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Make this diagnosis a part of your routine. Incorrect pump — if your pump experiences flange. To prevent failure from occurring, you. Ksb Pump Failure.

From www.manualslib.com

KSB GIW LCC SERIES MAINTENANCE MANUAL Pdf Download ManualsLib Ksb Pump Failure To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. Perhaps you’re baffled by excess energy usage. Protect your investment by making sure your pumps are getting the preventive maintenance they need. We’ve put together an easy. Incorrect pump — if your pump experiences flange. Each. Ksb Pump Failure.

From machineryline.info

KSB HPKLS 050200 industrial pump for sale Spain Barcelona, WK33440 Ksb Pump Failure Perhaps you’re baffled by excess energy usage. We’ve put together an easy. Make this diagnosis a part of your routine. Or, possibly most obvious of all, you. Each hrsg has two 100% capacity pumps with 5kv drive motors. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Don’t let a few millimetres cause premature. Ksb Pump Failure.

From giw.ksb.com

KSB Pumps Deliver Efficiency and Sustainability Ksb Pump Failure Perhaps you’re baffled by excess energy usage. Don’t let a few millimetres cause premature failure in your pumps. We’ve put together an easy. Protect your investment by making sure your pumps are getting the preventive maintenance they need. A repair was initiated during periods when pump operation was not. To prevent failure from occurring, you can take a few steps. Ksb Pump Failure.

From braamdstore.com

KSB Amarex KRT Horizontal or vertical singlestage submersible motor Ksb Pump Failure Protect your investment by making sure your pumps are getting the preventive maintenance they need. Don’t let a few millimetres cause premature failure in your pumps. We’ve put together an easy. Here are some common reasons why your slurry pump may not be operating correctly: Each hrsg has two 100% capacity pumps with 5kv drive motors. To prevent failure from. Ksb Pump Failure.

From mepca-engineering.com

Massive expansion of KSB chemical pump series Mepca Engineering Ksb Pump Failure Incorrect pump — if your pump experiences flange. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Or, possibly most obvious of all, you. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Perhaps you’re baffled by excess energy usage.. Ksb Pump Failure.

From www.mechanical-knowledge.com

KSB Pump Training Manual Ksb Pump Failure Perhaps you’re baffled by excess energy usage. We’ve put together an easy. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Each hrsg has two 100% capacity pumps with 5kv drive. Ksb Pump Failure.

From jualthermaloil.com

DISTRIBUTOR POMPA THERMAL OIL KSB ETANORM SYT SPAREPART BOILER & BURNER Ksb Pump Failure Perhaps you’re baffled by excess energy usage. Or, possibly most obvious of all, you. Protect your investment by making sure your pumps are getting the preventive maintenance they need. A repair was initiated during periods when pump operation was not. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting. Ksb Pump Failure.

From dir.indiamart.com

KSB Pressure Pumps Latest Price, Dealers & Retailers in India Ksb Pump Failure Or, possibly most obvious of all, you. Don’t let a few millimetres cause premature failure in your pumps. Incorrect pump — if your pump experiences flange. Perhaps you’re baffled by excess energy usage. Make this diagnosis a part of your routine. Each hrsg has two 100% capacity pumps with 5kv drive motors. We’ve put together an easy. To prevent failure. Ksb Pump Failure.

From braamdstore.com

Dryinstalled KSB MegaCPK Chemical Pump BRAAMD Store Ksb Pump Failure Don’t let a few millimetres cause premature failure in your pumps. Protect your investment by making sure your pumps are getting the preventive maintenance they need. We’ve put together an easy. Perhaps you’re baffled by excess energy usage. Incorrect pump — if your pump experiences flange. A repair was initiated during periods when pump operation was not. To prevent failure. Ksb Pump Failure.

From pump.su

Консольномоноблочные насосы из нержавеющей стали AISI 304 KSB ETB 065 Ksb Pump Failure Don’t let a few millimetres cause premature failure in your pumps. Each hrsg has two 100% capacity pumps with 5kv drive motors. To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. We’ve put together an easy. Maybe you’re dealing with serious pump damage, ranging from. Ksb Pump Failure.

From www.simscale.com

Design & Optimization of KSB Pump Blog SimScale Ksb Pump Failure Protect your investment by making sure your pumps are getting the preventive maintenance they need. Here are some common reasons why your slurry pump may not be operating correctly: Make this diagnosis a part of your routine. Incorrect pump — if your pump experiences flange. Or, possibly most obvious of all, you. An effective pump troubleshooting tool will always begin. Ksb Pump Failure.

From www.ipmpumps.co.uk

Industrial Pumps and Motor Supply, Repairs, Sales Ksb Pump Failure To prevent failure from occurring, you can take a few steps to diagnose and solve problems with the shaft sleeve before it wears out. We’ve put together an easy. Perhaps you’re baffled by excess energy usage. Maybe you’re dealing with serious pump damage, ranging from pump housing failure to impeller destruction. Don’t let a few millimetres cause premature failure in. Ksb Pump Failure.

From www.machines4u.com.au

Used 2011 ksb 2011 75 KW Rpm 1485 KSB Electric Centrifugal Water Pump Ksb Pump Failure Incorrect pump — if your pump experiences flange. Perhaps you’re baffled by excess energy usage. Protect your investment by making sure your pumps are getting the preventive maintenance they need. Here are some common reasons why your slurry pump may not be operating correctly: We’ve put together an easy. To prevent failure from occurring, you can take a few steps. Ksb Pump Failure.

From www.karroxgroup.co.za

KSB Pumps Products , , Kwazulu Natal Slurry Pumps South Africa Ksb Pump Failure Here are some common reasons why your slurry pump may not be operating correctly: A repair was initiated during periods when pump operation was not. Each hrsg has two 100% capacity pumps with 5kv drive motors. Perhaps you’re baffled by excess energy usage. Make this diagnosis a part of your routine. We’ve put together an easy. Maybe you’re dealing with. Ksb Pump Failure.

From www.ksb.com

KSB SupremeServ and 3D Printing for EAM Energie GmbH KSB Ksb Pump Failure A repair was initiated during periods when pump operation was not. Or, possibly most obvious of all, you. An effective pump troubleshooting tool will always begin with the question when did this start? common conditions requiring pump troubleshooting expertise are cavitation,. Each hrsg has two 100% capacity pumps with 5kv drive motors. Don’t let a few millimetres cause premature failure. Ksb Pump Failure.

From www.geigerinc.com

KSB Geiger Pump & Equipment Ksb Pump Failure A repair was initiated during periods when pump operation was not. Here are some common reasons why your slurry pump may not be operating correctly: We’ve put together an easy. Or, possibly most obvious of all, you. Each hrsg has two 100% capacity pumps with 5kv drive motors. Don’t let a few millimetres cause premature failure in your pumps. Protect. Ksb Pump Failure.