Equalization Tank In Cetp . | schematic flow diagram of integrated cetp (25. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of coagulation flocculation unit.35 table 28:. Design of equalization tank for tanning & post tanning effluent.35 table 27: The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Alization tank effluent while under mixing with aeration t neutralize.

from medium.com

In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Design of equalization tank for tanning & post tanning effluent.35 table 27: Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of coagulation flocculation unit.35 table 28:. Alization tank effluent while under mixing with aeration t neutralize. | schematic flow diagram of integrated cetp (25.

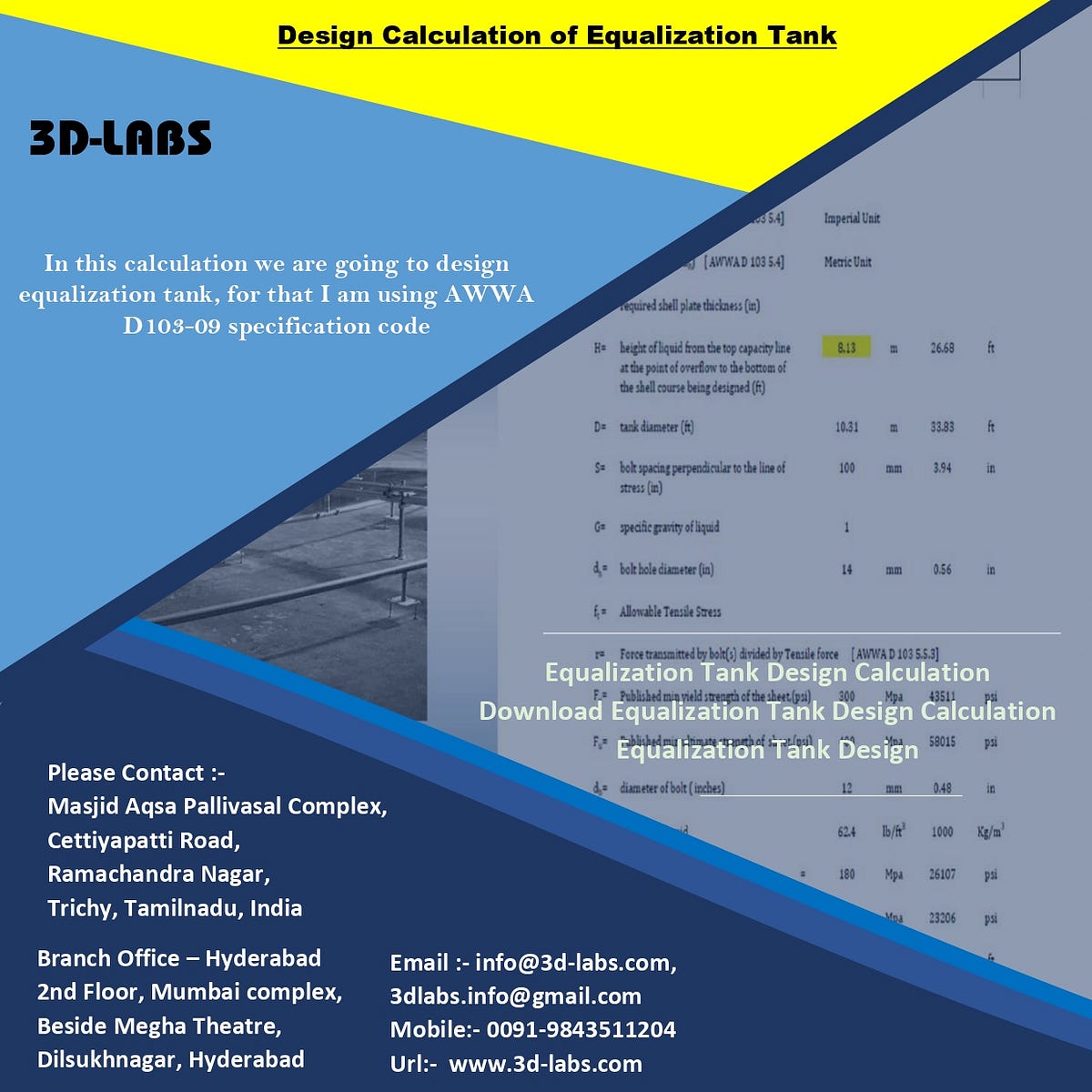

design calculation of equalization tank Design manager Medium

Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. Design of equalization tank for tanning & post tanning effluent.35 table 27: The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Alization tank effluent while under mixing with aeration t neutralize. | schematic flow diagram of integrated cetp (25. Design of coagulation flocculation unit.35 table 28:. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a.

From enviro-mix.com

view resources Equalization Tank In Cetp The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due. Equalization Tank In Cetp.

From www.youtube.com

BioMix for Equalization Tanks YouTube Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. | schematic flow diagram of integrated cetp (25. Design of coagulation flocculation. Equalization Tank In Cetp.

From www.youtube.com

Equalization Tank in Wastewater II Description and Design YouTube Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of equalization tank for tanning & post tanning effluent.35 table 27:. Equalization Tank In Cetp.

From netsolwater.com

What is an Equalization tank Netsol Water Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of equalization tank for tanning & post tanning effluent.35 table 27: In the cetp under study, the influent was treated using. Equalization Tank In Cetp.

From www.chegg.com

Solved Equalization Tank Design Example The average Equalization Tank In Cetp The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of equalization tank for tanning & post tanning effluent.35 table 27: | schematic flow diagram of integrated cetp (25. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. In the cetp under study, the influent was treated using. Equalization Tank In Cetp.

From fgtsolutions.com

Equalization Tanks Fiberglass Tank Solutions Equalization Tank In Cetp The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due. Equalization Tank In Cetp.

From www.slideserve.com

PPT Flow Equalization Tanks PowerPoint Presentation, free download ID6798771 Equalization Tank In Cetp Alization tank effluent while under mixing with aeration t neutralize. | schematic flow diagram of integrated cetp (25. Design of coagulation flocculation unit.35 table 28:. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. The ph is bought to approximately 7.0 (between 6.0 & 8.0). The. Equalization Tank In Cetp.

From netsolwater.com

Difference between ETP, CETP and STP with process flow diagram Equalization Tank In Cetp In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Design of coagulation flocculation unit.35 table 28:. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent. Equalization Tank In Cetp.

From modutank.com

Equalization Tanks Modutank Equalization Tank In Cetp In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. | schematic flow diagram of integrated cetp (25. Alization tank effluent while under mixing with aeration t neutralize. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and. Equalization Tank In Cetp.

From smsbutiboricetp.co.in

Common Effluent Treatment Plant (CETP) Butibori CETP Pvt. Ltd. Equalization Tank In Cetp The ph is bought to approximately 7.0 (between 6.0 & 8.0). In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. | schematic flow diagram of integrated cetp. Equalization Tank In Cetp.

From portfolio.cept.ac.in

EQUALIZATION TANK CEPT Portfolio Equalization Tank In Cetp In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Alization tank effluent while under mixing with aeration t neutralize. Design of coagulation flocculation unit.35 table 28:. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. |. Equalization Tank In Cetp.

From www.aboutcivil.org

Flow Equalization Tank Uses & Design of Flow Equalization Tank Equalization Tank In Cetp Design of equalization tank for tanning & post tanning effluent.35 table 27: Alization tank effluent while under mixing with aeration t neutralize. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. | schematic flow diagram of integrated cetp (25. Regulating agencies have observed that cetps do. Equalization Tank In Cetp.

From www.snyder-associates.com

DisinfectionFlow Equalization Tank Snyder & Associates Engineers and Planners Equalization Tank In Cetp In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Alization tank effluent while under mixing with aeration t neutralize. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. | schematic flow diagram of integrated cetp (25.. Equalization Tank In Cetp.

From portfolio.cept.ac.in

EQUALIZATION TANK CEPT Portfolio Equalization Tank In Cetp Design of equalization tank for tanning & post tanning effluent.35 table 27: In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Design of coagulation flocculation unit.35 table 28:. | schematic flow diagram of integrated cetp (25. The collective treatment of effluent at a common effluent treatment. Equalization Tank In Cetp.

From www.westlakeenv.com

APPLICATION Equalization tank Westlake Environmental Industrial Wastewater Treatment Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. Alization tank effluent while under mixing with aeration t neutralize. Design of equalization tank for tanning & post tanning effluent.35 table 27: The ph is bought to approximately 7.0 (between 6.0 & 8.0). The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for.. Equalization Tank In Cetp.

From www.onsiteinstaller.com

Installing Multiple Flow Equalization Tanks Onsite Installer Equalization Tank In Cetp The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. | schematic flow diagram of integrated cetp (25. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which. Equalization Tank In Cetp.

From fgtsolutions.com

Equalization Tanks → Fiberglass Tank Solutions Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of equalization tank for tanning & post tanning effluent.35 table 27:. Equalization Tank In Cetp.

From www.ssr-inc.com

Davidson Branch Pump Station & Equalization Tank (4) SSR Equalization Tank In Cetp The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Alization tank effluent while under mixing with aeration t neutralize. | schematic flow diagram of integrated cetp (25. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of equalization tank for tanning & post tanning effluent.35 table 27:. Equalization Tank In Cetp.

From www.pulsair.com

Wastewater Equalization Tank Mixing PH Equalization Tank Mixing Equalization Tank In Cetp Design of coagulation flocculation unit.35 table 28:. The ph is bought to approximately 7.0 (between 6.0 & 8.0). The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Alization tank effluent while under mixing with aeration t neutralize. In the cetp under study, the influent was treated using a conventional mode. Equalization Tank In Cetp.

From www.youtube.com

Equalization Tank by Abhay ETP Plant Effulent treatment Plant YouTube Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of equalization tank for tanning & post tanning effluent.35 table 27:. Equalization Tank In Cetp.

From www.elliscorp.com

Equalization Tanks For Wastewater Storage Ellis Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Design of coagulation flocculation unit.35 table 28:. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. The ph is. Equalization Tank In Cetp.

From netsolwater.com

What is Equalization tank for Primary treatment in STP Equalization Tank In Cetp The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of equalization tank for tanning & post tanning effluent.35 table 27: The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations. Equalization Tank In Cetp.

From www.emerson.com

Level Measurement in Equalization tanks Emerson US Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. Design of equalization tank for tanning & post tanning effluent.35 table 27: The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put. Equalization Tank In Cetp.

From medium.com

design calculation of equalization tank Design manager Medium Equalization Tank In Cetp The ph is bought to approximately 7.0 (between 6.0 & 8.0). | schematic flow diagram of integrated cetp (25. In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations. Equalization Tank In Cetp.

From www.youtube.com

Sludge equalization tank at Guarau Water Treatment Plant YouTube Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. The ph is bought to approximately 7.0 (between 6.0 & 8.0). The. Equalization Tank In Cetp.

From netsolwater.com

How to design Equalization tank? How is equalization tank calculated? Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. | schematic flow diagram of integrated cetp (25. Design of coagulation flocculation. Equalization Tank In Cetp.

From www.youtube.com

Equalization tank and role of coarse bubble diffusers in Sewage Treatment Plant Sandeep Khoba Equalization Tank In Cetp In the cetp under study, the influent was treated using a conventional mode of treatment in which it was first put through a. Design of coagulation flocculation unit.35 table 28:. The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. Alization tank effluent while under mixing with aeration t neutralize. Regulating. Equalization Tank In Cetp.

From netsolwater.com

How do you make an equalization tank Netsol Water Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. The collective treatment of effluent at a common effluent treatment plant (cetp). Equalization Tank In Cetp.

From www.slideserve.com

PPT Flow Equalization Tanks PowerPoint Presentation ID2002803 Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. Design of coagulation flocculation unit.35 table 28:. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and. Equalization Tank In Cetp.

From www.artofit.org

The equalization tank section details are given in this autocad dwg drawing download the autocad Equalization Tank In Cetp The ph is bought to approximately 7.0 (between 6.0 & 8.0). The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. | schematic flow diagram of integrated cetp (25. Design of equalization tank for tanning & post tanning effluent.35 table 27: Alization tank effluent while under mixing with aeration t neutralize.. Equalization Tank In Cetp.

From www.youtube.com

Equalization Tank Lecture YouTube Equalization Tank In Cetp Design of coagulation flocculation unit.35 table 28:. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of equalization tank for. Equalization Tank In Cetp.

From www.slideserve.com

PPT Wastewater Treatment Plants PowerPoint Presentation, free download ID1810594 Equalization Tank In Cetp | schematic flow diagram of integrated cetp (25. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. Design of equalization tank. Equalization Tank In Cetp.

From hndonahoo.com

DOWR Equalization Tank H. N. Donahoo Contracting Co., Inc. Equalization Tank In Cetp Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries, which hampers the biological activity of aeration tanks due to varied ph and other operational parameters. In the cetp under study, the influent was treated using a conventional. Equalization Tank In Cetp.

From www.researchgate.net

The FCF unit. 1, wastewater equalization tank; 2, multiphase... Download Scientific Diagram Equalization Tank In Cetp Design of coagulation flocculation unit.35 table 28:. Design of equalization tank for tanning & post tanning effluent.35 table 27: The collective treatment of effluent at a common effluent treatment plant (cetp) is the suitable and recommended solution for. | schematic flow diagram of integrated cetp (25. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because. Equalization Tank In Cetp.

From www.emerson.com

Level Measurement in Equalization tanks Emerson US Equalization Tank In Cetp Alization tank effluent while under mixing with aeration t neutralize. The ph is bought to approximately 7.0 (between 6.0 & 8.0). Design of coagulation flocculation unit.35 table 28:. Regulating agencies have observed that cetps do not discharge satisfactory effluent for reuse, because of technological/process design limitations and the massive fluctuation in the organic load of primary treated effluent from industries,. Equalization Tank In Cetp.