Mold Making Iron Casting . This mold is generally cut from cast iron or steel (and historically stone or. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. A replica pattern is used to create a mold out of rubber, metal, or resin. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. The metal then cools and hardens into the form given to it by this shaped. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Iron melts at 2750°f and.

from www.alamy.com

Iron melts at 2750°f and. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. A replica pattern is used to create a mold out of rubber, metal, or resin. This mold is generally cut from cast iron or steel (and historically stone or. The metal then cools and hardens into the form given to it by this shaped. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax.

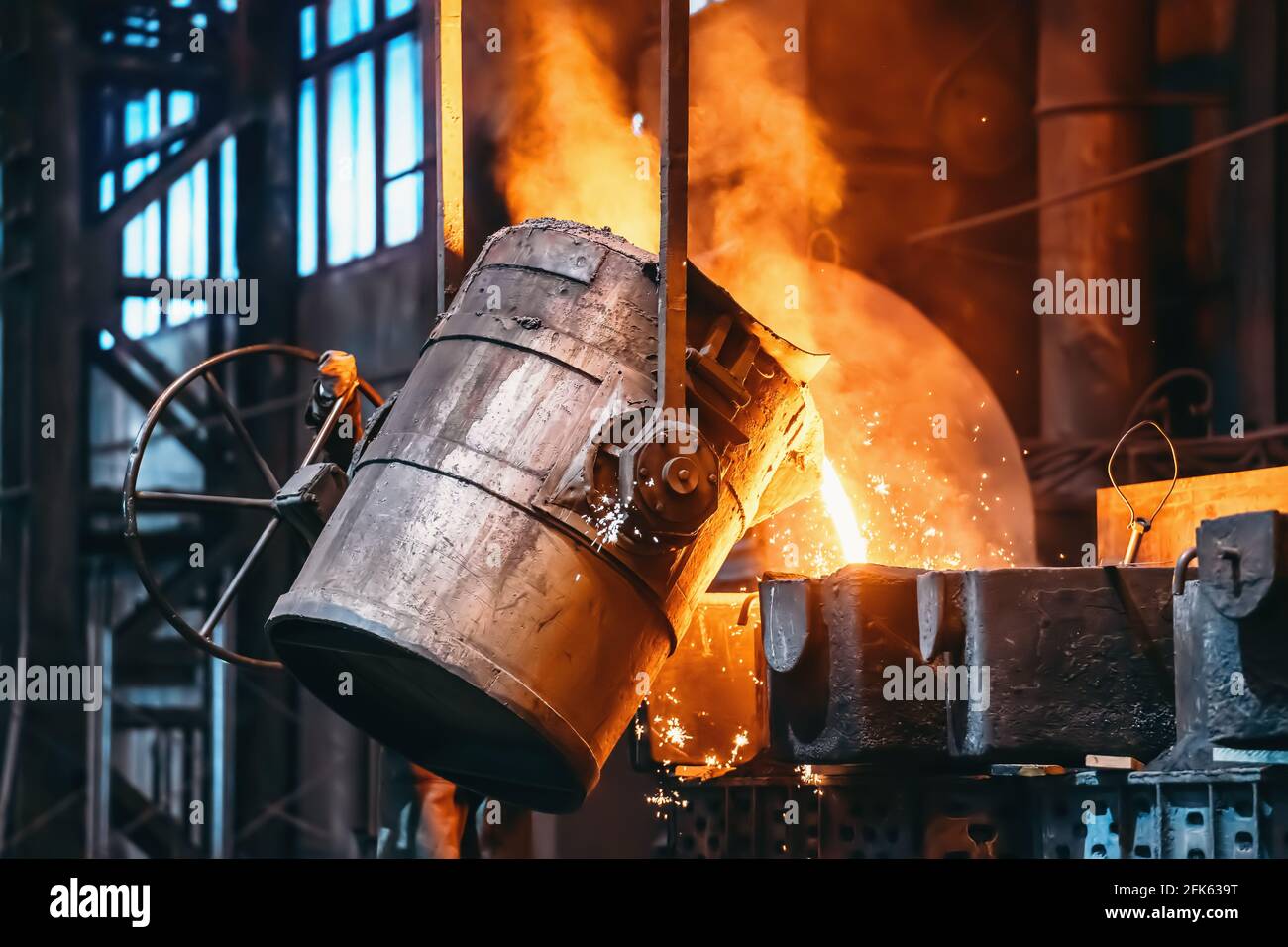

Metal casting process in foundry, liquid metal pouring from container

Mold Making Iron Casting This mold is generally cut from cast iron or steel (and historically stone or. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. A replica pattern is used to create a mold out of rubber, metal, or resin. Iron melts at 2750°f and. The metal then cools and hardens into the form given to it by this shaped. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. This mold is generally cut from cast iron or steel (and historically stone or.

From sites.google.com

Metal Casting Process eer Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. This mold is generally cut from cast iron or steel (and historically stone or. This series follows a cast iron. Mold Making Iron Casting.

From buntyllc.com

Custom Metal Casting Molds Bunty LLC Mold Making Iron Casting These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. A replica pattern is used to create a mold out of rubber, metal, or resin. Iron melts at 2750°f and. Common types. Mold Making Iron Casting.

From www.diecastingcompany.com

The Method And Application Of SandCoated Iron Mold Casting Minghe Mold Making Iron Casting The metal then cools and hardens into the form given to it by this shaped. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. This mold is generally cut from cast iron or steel (and historically stone or. These cast patterns are coated with a resin or ceramic. Mold Making Iron Casting.

From www.westend61.de

Crop of group of professional male artisans working in weathered Mold Making Iron Casting From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Iron melts at 2750°f and. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand.. Mold Making Iron Casting.

From making-a-mold.blogspot.com

Mold making and Casting products through EnvironMolds, LLC Backdating Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. A replica pattern is used to create a mold out of rubber, metal, or resin. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Foundry pattern making is the process of designing and creating a. Mold Making Iron Casting.

From cejzvipy.blob.core.windows.net

How To Cast A Mold at Mary Monahan blog Mold Making Iron Casting This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. The metal then cools and hardens into the form given to it by this shaped. This series follows a cast iron or steel product through the metal casting process. Mold Making Iron Casting.

From atelier-yuwa.ciao.jp

Casting And Molding atelieryuwa.ciao.jp Mold Making Iron Casting From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. This mold is generally cut from cast iron or steel (and historically stone or. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold. Mold Making Iron Casting.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. A replica pattern is used to create a mold out of rubber, metal, or resin. Foundry pattern making is the process of designing and creating. Mold Making Iron Casting.

From klaiwfluu.blob.core.windows.net

Casting The Molding at Oswaldo Perkins blog Mold Making Iron Casting Iron melts at 2750°f and. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. A replica pattern is used to create a mold out of rubber, metal, or resin. Foundry pattern making is the process. Mold Making Iron Casting.

From www.dreamstime.com

Cast Iron Making Process by Using Sand Mold Stock Photo Image of sand Mold Making Iron Casting A replica pattern is used to create a mold out of rubber, metal, or resin. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Iron melts at 2750°f and. Common types of. Mold Making Iron Casting.

From www.alamy.com

Gaziantep, iron casting / Turkey cast in a Mold Making Iron Casting A replica pattern is used to create a mold out of rubber, metal, or resin. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. Common types of metal casting that utilize. Mold Making Iron Casting.

From www.reliance-foundry.com

Metal Melt & Pour Life of a Casting Reliance Foundry Mold Making Iron Casting The metal then cools and hardens into the form given to it by this shaped. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. This series follows a cast iron or. Mold Making Iron Casting.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Mold Making Iron Casting Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Iron melts at 2750°f and. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if. Mold Making Iron Casting.

From cejzvipy.blob.core.windows.net

How To Cast A Mold at Mary Monahan blog Mold Making Iron Casting This mold is generally cut from cast iron or steel (and historically stone or. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. A replica pattern is used to. Mold Making Iron Casting.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Mold Making Iron Casting Iron melts at 2750°f and. A replica pattern is used to create a mold out of rubber, metal, or resin. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Foundry pattern making is the process. Mold Making Iron Casting.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. These cast patterns are. Mold Making Iron Casting.

From www.youtube.com

Casting Iron Mold for Ingots! 2000°+ (MattMakes Mold Part 1/4) YouTube Mold Making Iron Casting Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. This mold is generally cut from cast iron or steel (and historically stone or. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Metal casting is the process of making objects by. Mold Making Iron Casting.

From www.youtube.com

Ch 5 Expendable Mold Casting YouTube Mold Making Iron Casting Iron melts at 2750°f and. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern. Mold Making Iron Casting.

From www.youtube.com

Cast iron mold making. YouTube Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Iron melts at 2750°f and. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Metal casting is the process of making objects by pouring molten metal into an empty. Mold Making Iron Casting.

From www.clinchrivercasting.com

Molding NoBake Iron Foundry Clinch River Casting Mold Making Iron Casting These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and. Mold Making Iron Casting.

From www.tfgusa.com

Custom Permanent Mold Casting Supplier TFG USA Mold Making Iron Casting This mold is generally cut from cast iron or steel (and historically stone or. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. These cast patterns are coated with. Mold Making Iron Casting.

From www.dreamstime.com

The Liquid Metal or Cast Iron Poured into Molds. Metal Casting Process Mold Making Iron Casting This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this shaped. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. Metal casting is the process of making objects by. Mold Making Iron Casting.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Mold Making Iron Casting A replica pattern is used to create a mold out of rubber, metal, or resin. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is the process of making objects by pouring molten metal into an empty. Mold Making Iron Casting.

From www.dreamstime.com

Liquid Metal or Cast Iron Poured into Molds. Metal Casting Process with Mold Making Iron Casting Metal casting is the process of making objects by pouring molten metal into an empty shaped space. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. A replica pattern is used to create. Mold Making Iron Casting.

From stonybrookmass.org

Mold Making and Metal Casting Stonybrook Metal Arts & Sculpture School Mold Making Iron Casting Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is the process of making objects by. Mold Making Iron Casting.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Mold Making Iron Casting These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if. Mold Making Iron Casting.

From www.alibaba.com

High Quality Mold Making Iron Casting Aluminum Sand Casting Mould Buy Mold Making Iron Casting This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. A replica pattern is used to create a mold out of rubber, metal, or resin. This mold is generally cut from cast iron or steel. Mold Making Iron Casting.

From novastevensville.com

Molding Manufacturing Creating the World's Most Useful Products Mold Making Iron Casting Metal casting is the process of making objects by pouring molten metal into an empty shaped space. A replica pattern is used to create a mold out of rubber, metal, or resin. The metal then cools and hardens into the form given to it by this shaped. Common types of metal casting that utilize expendable molds are lost wax casting,. Mold Making Iron Casting.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Mold Making Iron Casting Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. A replica pattern is used to create a mold out of rubber, metal, or resin. Iron melts at 2750°f and. These cast patterns. Mold Making Iron Casting.

From www.alamy.com

Iron Foundry. Casting steel into molds Stock Video Footage Alamy Mold Making Iron Casting The metal then cools and hardens into the form given to it by this shaped. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. A replica pattern is used to create a mold out. Mold Making Iron Casting.

From www.weld2cast.com

Shell Moulding Casting Weld2Cast Mold Making Iron Casting A replica pattern is used to create a mold out of rubber, metal, or resin. This mold is generally cut from cast iron or steel (and historically stone or. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern,. Mold Making Iron Casting.

From kobachjs.com

How is Cast Iron Cookware Manufactured? KÖBACH Mold Making Iron Casting Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. These. Mold Making Iron Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Mold Making Iron Casting From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. These cast patterns are coated with a resin or. Mold Making Iron Casting.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. The metal then cools. Mold Making Iron Casting.

From www.dreamstime.com

Molten Metal Pour from Ladle into Sand Mold. Iron Casting Process in Mold Making Iron Casting Common types of metal casting that utilize expendable molds are lost wax casting, investment casting, and sand casting. The metal then cools and hardens into the form given to it by this shaped. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. This series follows a cast iron. Mold Making Iron Casting.