Helical Worm Gear Design . The teeth on a helical gear cut at an angle to the. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. 9.1 worm mesh geometry. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. However, in particular applications, it is preferred to have worm. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. helical worm gearbox. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. This addition not only improves the efficiency but also significantly reduces operational noise. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth.

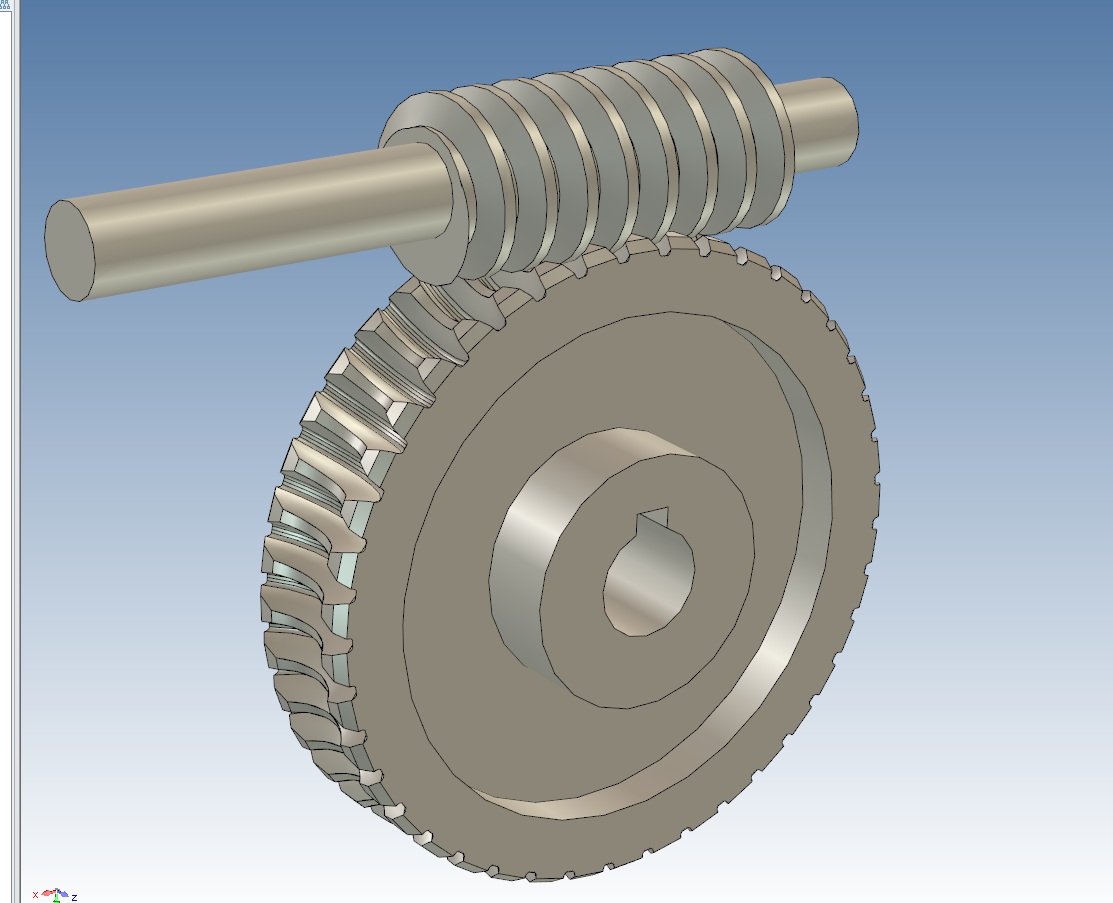

from community.ironcad.com

helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. However, in particular applications, it is preferred to have worm. helical worm gearbox. This addition not only improves the efficiency but also significantly reduces operational noise. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. 9.1 worm mesh geometry. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. The teeth on a helical gear cut at an angle to the.

worm gear design how? Tips and Tricks IronCAD Community

Helical Worm Gear Design a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. This addition not only improves the efficiency but also significantly reduces operational noise. The teeth on a helical gear cut at an angle to the. 9.1 worm mesh geometry. However, in particular applications, it is preferred to have worm. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical worm gearbox. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications.

From www.scribd.com

Helical Bevel & Worm Gear AGMA FME3_Ch15.pdf Gear Mechanical Helical Worm Gear Design 9.1 worm mesh geometry. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. a worm gear is used when a large speed reduction ratio is required. Helical Worm Gear Design.

From www.eastgearpart.com

Machining fiber Helical Worm Gear for New Design Helical Worm Gear Design the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. This addition not only improves the efficiency but also significantly reduces operational noise. However, in particular applications, it is preferred to have worm. . Helical Worm Gear Design.

From si-unit-for-displacement-in-physics.blogspot.com

globoid worm gear design siunitfordisplacementinphysics Helical Worm Gear Design The teeth on a helical gear cut at an angle to the. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. a worm gear is used when a large speed reduction ratio. Helical Worm Gear Design.

From engineering.stackexchange.com

Design a worm gear that works with a straight wheel Engineering Stack Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. 9.1 worm mesh geometry. The teeth. Helical Worm Gear Design.

From www.indiamart.com

Stainless Steel Worm Gear Set at Rs 200/piece in Rajkot ID 21479712655 Helical Worm Gear Design Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical worm gearbox. The teeth on a helical gear cut at an angle to the. 9.1 worm mesh. Helical Worm Gear Design.

From community.ironcad.com

worm gear design how? Tips and Tricks IronCAD Community Helical Worm Gear Design a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. The teeth on a helical gear cut at an angle to the. This addition not only improves the efficiency but also significantly reduces operational noise. However, in particular applications, it is preferred to have worm. the purpose. Helical Worm Gear Design.

From www.machinedesign.com

What’s the Difference Between Spur, Helical, Bevel, and Worm Gears Helical Worm Gear Design helical worm gearbox. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. 9.1 worm mesh geometry. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The teeth on a helical gear cut at an angle. Helical Worm Gear Design.

From www.youtube.com

Worm and Worm Gear Design in SolidWorks 2022 Part 1 (Worm Gear Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. helical worm gearbox. helical gears. Helical Worm Gear Design.

From www.guomaodrive.com

High quality Horizontal helical worm worm gear in stock Blog Helical Worm Gear Design helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. 9.1 worm mesh geometry. However, in particular applications, it is preferred to have worm. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. This addition not only improves the efficiency but. Helical Worm Gear Design.

From boyanmfg.com

Custom plastic helical gears Boyan Manufacturing Solutions Helical Worm Gear Design Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. helical worm gearbox. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. This addition not only improves the efficiency but also significantly reduces operational noise. the purpose. Helical Worm Gear Design.

From www.motiontech.com.au

BONENG S SERIES HELICALWORM GEARMOTOR Motion Technologies Pty Limited Helical Worm Gear Design the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. However, in particular applications, it is preferred to have worm. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. The teeth on a helical gear cut at an angle. Helical Worm Gear Design.

From engineering.stackexchange.com

gears Helical Worm Drive Engineering Stack Exchange Helical Worm Gear Design The teeth on a helical gear cut at an angle to the. This addition not only improves the efficiency but also significantly reduces operational noise. However, in particular applications, it is preferred to have worm. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical worm. Helical Worm Gear Design.

From exoyqkhax.blob.core.windows.net

Worm Gear System Efficiency at Larry London blog Helical Worm Gear Design the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. This addition not only improves. Helical Worm Gear Design.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Worm Gear Design However, in particular applications, it is preferred to have worm. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The teeth on a helical gear cut at an angle to the. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes. Helical Worm Gear Design.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Helical Worm Gear Design helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. The teeth on a helical gear cut at an angle to the. 9.1 worm mesh geometry. helical. Helical Worm Gear Design.

From www.parker-eng.co.uk

NORD Helical Worm Gear Unit Parker Engineering Gearbox Specialists Helical Worm Gear Design helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. 9.1 worm mesh geometry. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage.. Helical Worm Gear Design.

From gasesaver.weebly.com

Worm gear design calculation pdf editor gasesaver Helical Worm Gear Design the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. 9.1 worm mesh geometry. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical gears have a smoother operation due to the angle twist creating instant contact. Helical Worm Gear Design.

From cextfphn.blob.core.windows.net

Helical Gears Functions at Mary Gomez blog Helical Worm Gear Design helical worm gearbox. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. However, in particular applications, it is preferred to have worm. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. This addition not only improves. Helical Worm Gear Design.

From vocal.media

Types Of Gears And Their use In The Automotive Industry Wheel Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. The teeth on a helical gear cut at an angle to the. 9.1 worm mesh geometry. helical worm gearbox. the purpose of these examples is. Helical Worm Gear Design.

From exoschqxs.blob.core.windows.net

Helical Gear Module Formula Pdf at Carolyn Tapia blog Helical Worm Gear Design helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes. Helical Worm Gear Design.

From www.reddit.com

Help with API to automate worm gears design. r/Fusion360 Helical Worm Gear Design The teeth on a helical gear cut at an angle to the. 9.1 worm mesh geometry. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. helical worm gearbox. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear. Helical Worm Gear Design.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Helical Worm Gear Design a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. 9.1 worm mesh geometry. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. The teeth on a helical gear cut at an angle to. Helical Worm Gear Design.

From www.iqsdirectory.com

Worm Gear What Is It? How Is it Made? Types Of, Uses Helical Worm Gear Design 9.1 worm mesh geometry. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. However, in particular applications, it is preferred to have worm. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. the helical gear. Helical Worm Gear Design.

From ibuildit.ca

How To Make A Wooden Worm Gear Drive IBUILDIT.CA Helical Worm Gear Design helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. However, in particular applications, it is preferred to have worm. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage. Helical Worm Gear Design.

From www.zhygear.com

Parametric Modeling of Helical Gear with Locking Function ZHY Gear Helical Worm Gear Design The teeth on a helical gear cut at an angle to the. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. 9.1 worm mesh geometry. the purpose of these examples. Helical Worm Gear Design.

From www.wbsgear.com

brass helical worm gearManufacturer of Customized Machining Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. helical worm gearbox. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. However, in particular applications, it is. Helical Worm Gear Design.

From www.zhygear.com

Worm Gears vs. Internal Gears ZHY Gear Helical Worm Gear Design 9.1 worm mesh geometry. This addition not only improves the efficiency but also significantly reduces operational noise. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical worm gearbox. The teeth on a helical gear cut at an angle to the. the helical gear. Helical Worm Gear Design.

From www.indiamart.com

Helical Worm Gear at best price in Howrah by D.S. Engineers ID Helical Worm Gear Design a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. This addition not only improves the efficiency but also significantly reduces operational noise. helical worm gearbox. The teeth on a helical gear cut at an angle to the. helical gears have a smoother operation due to. Helical Worm Gear Design.

From www.hkdivedi.com

BASIC OF HELICAL GEAR ENGINEERING APPLICATIONS Helical Worm Gear Design a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. This addition not only improves the efficiency but also significantly reduces operational noise. Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. the purpose of these examples is. Helical Worm Gear Design.

From goodtextmoto.web.fc2.com

Worm Gear Design Calculation Pdf Files Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. helical gears have a smoother operation. Helical Worm Gear Design.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Helical Worm Gear Design helical worm gearbox. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. a worm gear is used when a large speed reduction ratio is required between crossed axis shafts which do not intersect. 9.1 worm mesh geometry. Enhancing the standard design, the helical worm. Helical Worm Gear Design.

From cevfyptl.blob.core.windows.net

What Is A Helical at Sigler blog Helical Worm Gear Design the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. However, in particular applications, it is preferred to have worm. This addition not only improves the efficiency but also significantly reduces operational noise. The teeth on a helical gear cut at an angle to the. a worm. Helical Worm Gear Design.

From www.kebamerica.com

Helical Worm Integral Gearmotor KEB Helical Worm Gear Design This addition not only improves the efficiency but also significantly reduces operational noise. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. the helical gear design provides a larger contact area between the gears, resulting in improved torque transmission. Enhancing the standard design, the helical worm. Helical Worm Gear Design.

From www.vrogue.co

Helix Angle Definition Formula Calculation Video Less vrogue.co Helical Worm Gear Design Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. However, in particular applications, it is preferred to have worm. helical worm gearbox. The teeth on a helical gear cut at an angle to the. the helical gear design provides a larger contact area between the gears, resulting in improved. Helical Worm Gear Design.

From www.researchgate.net

Solid models of Agroup from bevel to crossed helical gear (worm Helical Worm Gear Design Enhancing the standard design, the helical worm gearbox integrates a helical gear stage before the worm gear stage. the purpose of these examples is not to imply that worm gearboxes are more suitable than helical gearboxes in all applications. This addition not only improves the efficiency but also significantly reduces operational noise. helical gears have a smoother operation. Helical Worm Gear Design.