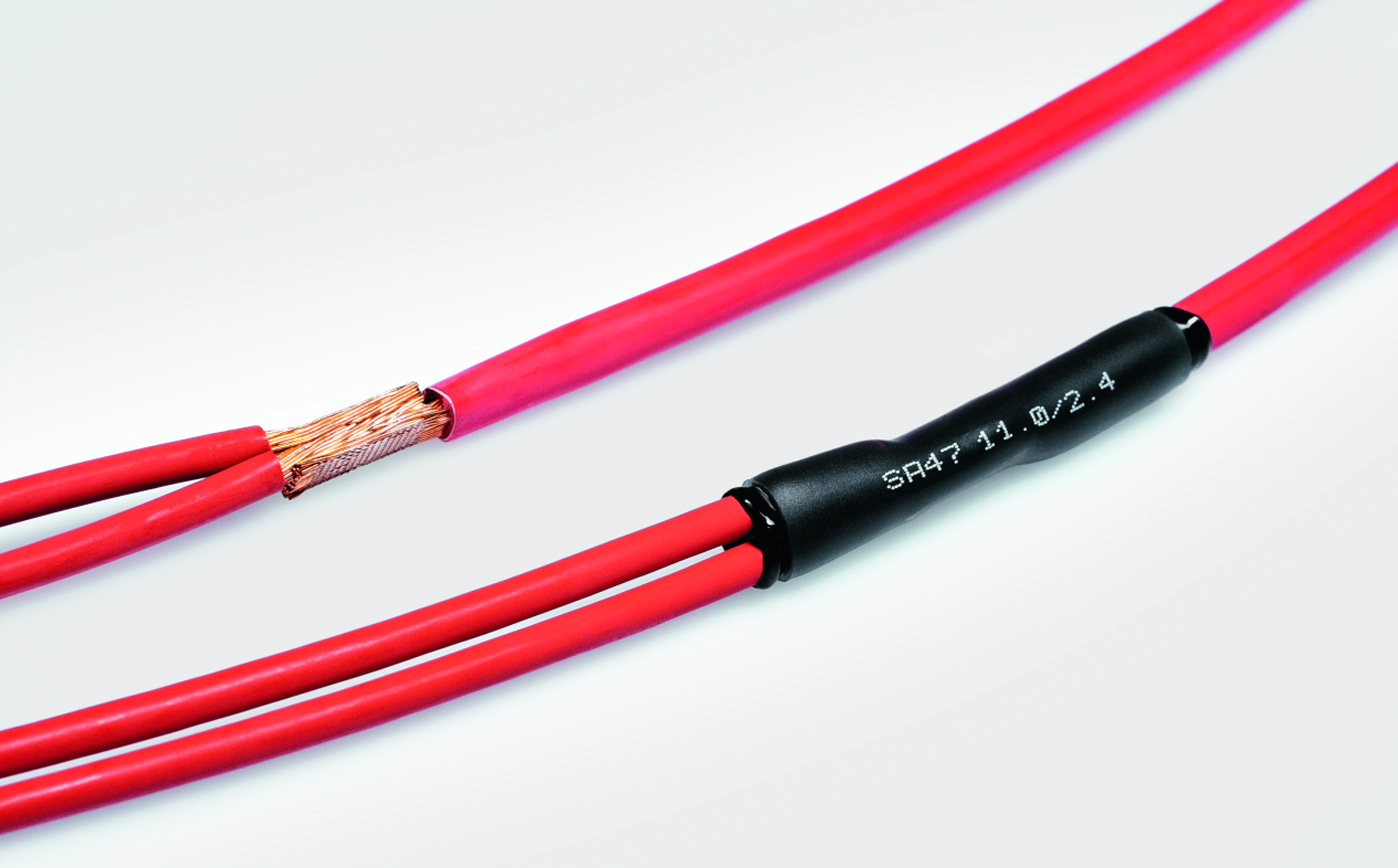

Heat Shrink Tube After Solder . Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. After you slide the tubing onto the cable. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Single or thin wall tubing is reliable and physically robust. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables.

from www.eeworldonline.com

Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. After you slide the tubing onto the cable. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Single or thin wall tubing is reliable and physically robust.

The basics of heat shrink tubing, Part 1 Electrical Engineering News

Heat Shrink Tube After Solder Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Single or thin wall tubing is reliable and physically robust. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. After you slide the tubing onto the cable.

From www.aliexpress.com

Waterproof 100pcs Solder Heat Shrink Tube Solder Sleeve Tubing Wires Heat Shrink Tube After Solder After you slide the tubing onto the cable. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Single or thin wall tubing is reliable and physically robust. Heat shrink tubing, also. Heat Shrink Tube After Solder.

From www.eeworldonline.com

The basics of heat shrink tubing, Part 1 Electrical Engineering News Heat Shrink Tube After Solder Single or thin wall tubing is reliable and physically robust. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. After you slide the tubing onto the cable. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Generally, when doing things by the book/ipc, then shrink. Heat Shrink Tube After Solder.

From www.bonanza.com

100pcs Mixed Heat Shrink Sordering Terminals Waterproof Solder Sleeve Heat Shrink Tube After Solder Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall.. Heat Shrink Tube After Solder.

From pro-iroda.com

Heat Shrink Application Pro Iroda Heat Shrink Tube After Solder After you slide the tubing onto the cable. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Single or thin wall tubing is reliable and physically robust. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Generally, when doing things by the book/ipc,. Heat Shrink Tube After Solder.

From www.walmart.com

Heat Shrink Tubing Heat Shrink Tube After Solder Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Single or thin wall tubing is reliable and physically robust. Slide the heat shrink tubing over the wire connection, ensuring it. Heat Shrink Tube After Solder.

From www.truckelectrics.com

Solder Heat Shrink Wire Connectors White Pack of 25 Truck Electrics Heat Shrink Tube After Solder After you slide the tubing onto the cable. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Heat shrink tubing is available in two basic types, single or. Heat Shrink Tube After Solder.

From www.marine-deals.com.au

Buy Solder Splice Heat Shrink Tubes Qty 5 online at Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. After you slide the tubing onto. Heat Shrink Tube After Solder.

From www.alibaba.com

Hscp Heat Shrink Tube Solder Sleeve Wire Shield Terminators For Shield Heat Shrink Tube After Solder Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Slide the heat shrink. Heat Shrink Tube After Solder.

From www.millsupply.com

250 Solder Heat Shrink Tube, 966745 Mill Supply, Inc. Heat Shrink Tube After Solder Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. After you slide the tubing onto the cable. Single or thin wall tubing is reliable and physically robust.. Heat Shrink Tube After Solder.

From www.amazon.co.uk

Ultimate Heat Shrink Tubing Kit 60 Pcs 200mm Long Heat Shrink Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Heat shrink tubing, also known as. Heat Shrink Tube After Solder.

From www.youtube.com

DIY soldering and heat shrink tubing YouTube Heat Shrink Tube After Solder Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Generally, when doing. Heat Shrink Tube After Solder.

From www.aliexpress.com

100/60/50 Pcs Mixed Heat Shrink Sordering Terminals Waterproof Solder Heat Shrink Tube After Solder Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. After you slide the tubing onto the cable. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder. Heat Shrink Tube After Solder.

From panbo.com

Heat shrink solder sleeve butt connectors, great for skinny boat wires Heat Shrink Tube After Solder Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Provides. Heat Shrink Tube After Solder.

From www.youtube.com

Heat Shrinkable Solder Sleeves YouTube Heat Shrink Tube After Solder Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Single or thin wall tubing is reliable and physically robust. Generally, when doing things by the book/ipc, then shrink tube should not. Heat Shrink Tube After Solder.

From yoibo.com

Solder Water Resistant Ring Heatshrinkable Tube 50PCS (MULTIA) Yoibo Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Slide the heat shrink tubing over the wire connection, ensuring it covers the area. Heat Shrink Tube After Solder.

From www.youtube.com

Heat Shrink Solder Ring Connectors Simple and Easy How To video YouTube Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. After you slide the tubing onto the cable. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Provides a tight seal and excellent. Heat Shrink Tube After Solder.

From www.aliexpress.com

Solder ring, solder heat shrinkable terminal/shrinkable sleeve,solder Heat Shrink Tube After Solder Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Generally, when doing. Heat Shrink Tube After Solder.

From www.youtube.com

Soldering tips & tricks how to put in a heat shrink tubing when you Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Single or thin wall tubing is reliable and physically robust. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9. Heat Shrink Tube After Solder.

From lessonluft.z19.web.core.windows.net

Heat Shrink Tubing Chart Heat Shrink Tube After Solder Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Single or thin wall tubing is reliable and physically robust. Heat shrink tubing, also known as heat shrink sleeving, is a specially. Heat Shrink Tube After Solder.

From www.aliexpress.com

Diameter 3mm 2mm 3.5mm 6mm Length 5M Heat Shrink Tubing Shrinkable Tube Heat Shrink Tube After Solder Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Provides a tight seal and excellent insulation after heating, enhancing the. Heat Shrink Tube After Solder.

From www.ourpcb.com

How to Solder Wires Tips on Soldering Techniques, Wire Tips Heat Shrink Tube After Solder Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Single or thin wall tubing is reliable. Heat Shrink Tube After Solder.

From jboards.ecwid.com

Solder Heat Shrink Connector 100pcs Heat Shrink Tube After Solder Single or thin wall tubing is reliable and physically robust. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. After you slide the tubing onto the cable.. Heat Shrink Tube After Solder.

From www.hampoolgroup.com

Heat Shrinkable Double Wall Tube Heat Shrink Tube After Solder Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. After you slide the tubing onto the cable. Heat shrink tubing, also known. Heat Shrink Tube After Solder.

From www.expresselectrical.co.uk

Express Electrical Heat Shrink Solder Sleeves Heat Shrink Tube After Solder Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection.. Heat Shrink Tube After Solder.

From www.alibaba.com

Qwt 120pcs Solder Sleeve Wire Splices Set Water Proof Butt Connector Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Provides a tight seal and excellent insulation after heating, enhancing the durability of the. Heat Shrink Tube After Solder.

From www.youtube.com

How to Use Heat Shrink Tubing YouTube Heat Shrink Tube After Solder After you slide the tubing onto the cable. Single or thin wall tubing is reliable and physically robust. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Heat shrink tubing is available in two basic. Heat Shrink Tube After Solder.

From www.aliexpress.com

40Pcs 4 Sizes Solder Sleeve Heat Shrink Tube Wire Terminal Connectors Heat Shrink Tube After Solder After you slide the tubing onto the cable. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing. Heat Shrink Tube After Solder.

From chileb.cl

New 300Pcs Assortment Heat Shrink Tube Wire Crimp Wire Connector Solder Heat Shrink Tube After Solder Single or thin wall tubing is reliable and physically robust. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as a shrink sleeve, can be used. Heat Shrink Tube After Solder.

From www.rabtron.co.za

Solder Seal Heat Shrink Tube Butt Wire Connector Heat Shrink Tube After Solder Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or. Heat Shrink Tube After Solder.

From www.aliexpress.com

Wholesale 25pcs Waterproof Solder Heat Shrink Tube Solder Sleeve Tubing Heat Shrink Tube After Solder Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing. Heat Shrink Tube After Solder.

From www.youtube.com

Heat Shrink SelfSolder Butt Splice Connectors YouTube Heat Shrink Tube After Solder Single or thin wall tubing is reliable and physically robust. Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. After you slide the tubing onto the cable. Slide the heat shrink tubing over the wire connection, ensuring it covers the area you want to insulate. Generally, when doing things. Heat Shrink Tube After Solder.

From www.mmnewman.com

105 C PVC Heat Shrink Tubing Heat Shrink Tubing Products Heat Shrink Tube After Solder Generally, when doing things by the book/ipc, then shrink tube should not be necessary on db9 solder cups, because the need for them implicitly means that the. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Single or thin wall tubing is reliable and physically robust. Heat shrink tubing,. Heat Shrink Tube After Solder.

From henrysautowarehouse.com

2To1 Heat Shrink Tube 1820Ga 50.Ft Roll Black Heat Shrink Tube After Solder Heat shrink tubing is available in two basic types, single or dual wall, also known as thin or double wall. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. After you slide the tubing onto the cable. Generally, when doing things by the book/ipc, then shrink tube. Heat Shrink Tube After Solder.

From yoibo.com

Solder Water Resistant Ring Heatshrinkable Tube 50PCS (MULTIA) Yoibo Heat Shrink Tube After Solder Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Heat shrink tubing, also known as heat shrink sleeving, is a specially designed casing that is widely used for the insulation and. Heat shrink tubing is. Heat Shrink Tube After Solder.

From guidelistcmmyocardium.z13.web.core.windows.net

How To Use Heat Shrink Wire Connectors Heat Shrink Tube After Solder Provides a tight seal and excellent insulation after heating, enhancing the durability of the connection. Use this guide to learn how to use heat shrink tubing to repair frayed sheathing on a wire or cable. Heat shrink tubing, also known as a shrink sleeve, can be used to repair and insulate wires and cables. Single or thin wall tubing is. Heat Shrink Tube After Solder.