Industrial Control Networks . The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor.

from www.chemanager-online.com

Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants.

Cyber Security for Industrial Control Systems CHEManager

Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants.

From www.electricaltechnology.org

What are Industrial Communication Networks? An Overview Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Industrial control system (ics) networking. Industrial Control Networks.

From iebmedia.com

The Industrial Book Knowledge Technical Articles IT Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial. Industrial Control Networks.

From csiac.org

Practical Industrial Control System (ICS) Cybersecurity IT and OT Have Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant. Industrial Control Networks.

From www.researchgate.net

Industrial control system (ICS) network architecture. Download Industrial Control Networks The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network. Industrial Control Networks.

From www.semanticscholar.org

Industrial Communication Networks and the Future of Industrial Industrial Control Networks An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. The most essential difference is that industrial. Industrial Control Networks.

From press.siemens.com

Industrial 5G The Wireless Network of the Future Press Company Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. These control. Industrial Control Networks.

From www.chemanager-online.com

Cyber Security for Industrial Control Systems CHEManager Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing. Industrial Control Networks.

From www.researchgate.net

Simulated industrial control system (ICS) based on PLC Industrial Control Networks The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Industrial control. Industrial Control Networks.

From automationforum.co

Basics of industrial networking architecture Instrumentation and Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control. Industrial Control Networks.

From pondtechnical.com

Emerson SMART Wireless Industrial Control Networks An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial control system (ics). Industrial Control Networks.

From e2e.ti.com

How to select the right industrial standard Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and. Industrial Control Networks.

From forumautomation.com

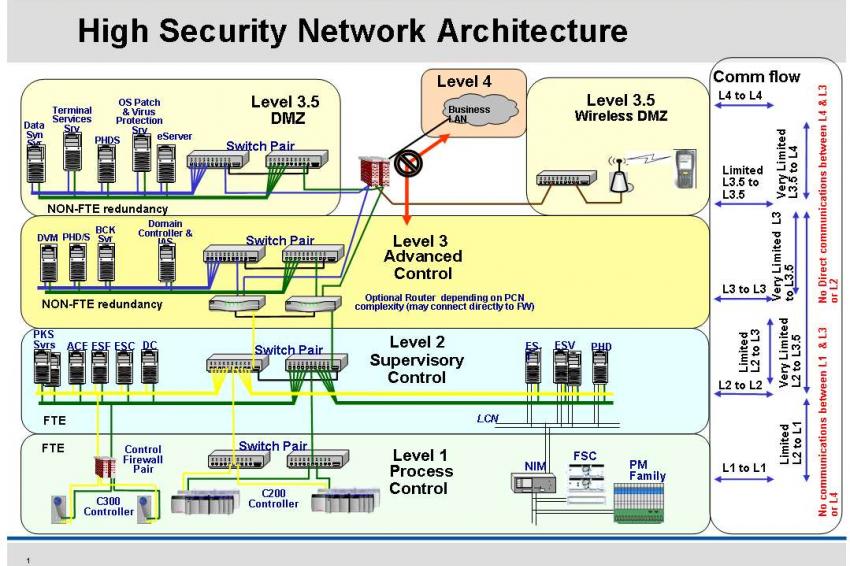

Process Control Network & Domain Controller in PCN Industrial Industrial Control Networks The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. Industrial control. Industrial Control Networks.

From verveindustrial.com

Protecting Industrial Control Systems (ICS) An Integrated Approach Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control. Industrial Control Networks.

From instrumentationtools.com

Basics of Industrial Communication Networks InstrumentationTools Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial. Industrial Control Networks.

From www.slideserve.com

PPT Introduction to Industrial Control Systems PowerPoint Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting. Industrial Control Networks.

From ebhorsman.com

Industrial Communication Networks E.B. Horsman & Son Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. In industrial settings, industrial control system (ics) is a term used to describe. Industrial Control Networks.

From www.cisco.com

Networking and Security in Industrial Automation Environments Design Industrial Control Networks The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Industrial control. Industrial Control Networks.

From www.electricalandcontrol.com

Advantages of Industrial Control Networks Industrial Control Networks In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. The most essential difference is that industrial networks are connected to physical equipment in some form and are. Industrial Control Networks.

From www.trendmicro.co.in

Industrial Control System Definition Industrial Control Networks In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Industrial control. Industrial Control Networks.

From www.researchgate.net

Example of industrial control network Download Scientific Diagram Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor.. Industrial Control Networks.

From www.moxa.com

Industrial Network Security Moxa Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting. Industrial Control Networks.

From dat.co.uk

Industrial Automation networks for Allen Bradley PLC's Digital Industrial Control Networks An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. The most essential difference is that industrial networks are connected to physical equipment in some form and are. Industrial Control Networks.

From loezufewp.blob.core.windows.net

Cisco Industrial Networking at Mandi Griffith blog Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control. Industrial Control Networks.

From blog.epcland.com

Industrial Control Networks A Comprehensive Guide 5 FAQs, Video Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. The most essential difference is that industrial. Industrial Control Networks.

From www.researchgate.net

Typical architecture of industrial control systems (ICS) over WideArea Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control. Industrial Control Networks.

From www.missionsecure.com

Industrial Control System (ICS)/OT Cybersecurity and Segmentation Industrial Control Networks The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. An industrial control network is a system of interconnected equipment used to monitor. Industrial Control Networks.

From plc247.com

Industrial Communication Networks Classify Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Based on the specialized functions, the industrial networks are composed of three major control components that. Industrial Control Networks.

From control.com

Designbased Fortifications Cybersecurity in Industrial Measurement Industrial Control Networks These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial. Industrial Control Networks.

From zinatullin.com

An Introduction to Industrial Control Systems Security Part II An Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. The most essential difference is that industrial networks are connected to physical equipment in some form and are used to control. In industrial. Industrial Control Networks.

From www.mdpi.com

Future Free FullText CKMI Comprehensive Key Management Industrial Control Networks An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on. Industrial Control Networks.

From forumautomation.com

What is Purdue model? Industrial Networking Industrial Automation Industrial Control Networks Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting and supporting industrial control systems on the plant floor. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable. Industrial Control Networks.

From dokumen.tips

(PDF) Introduction to Industrial Control Systems (ICS) DOKUMEN.TIPS Industrial Control Networks An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. The most. Industrial Control Networks.

From www.fairfields.co.uk

Industrial Networks Fairfield Control Systems Industrial Control Networks In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. An industrial control network is a system of interconnected equipment used to monitor and control physical equipment in. The most. Industrial Control Networks.

From subscription.packtpub.com

The Industrial control system architecture Industrial Cybersecurity Industrial Control Networks Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Industrial control system (ics) networking refers to the ethernet network infrastructure and protocols used specifically for connecting. Industrial Control Networks.

From www.dcinet.com.au

Control System Architecture DCI Networking Pty Ltd Industrial Control Networks In industrial settings, industrial control system (ics) is a term used to describe the integration of hardware and software with network connectivity to support. Based on the specialized functions, the industrial networks are composed of three major control components that include programmable logic. These control systems are responsible for controlling and monitoring various processes and equipment in manufacturing plants. The. Industrial Control Networks.