Shear Cutting Force Formula . Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: Cutting force = l x s x t max. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Progressive wear of flank and/or rake face of tool. Formula for calculating the cutting force: = sheet thickness in ‘mm’. Max = shear strength in n/mm2. Adhesion, abrasion, diffusion (at high. The cut off ‘blank’ becomes the workpiece. To find the shear force for a cut we can go back to the basic mechanics of materials (with. A shear force is applied that will cut off part of a sheet. = length of periphery to be cut in ‘mm’. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. Catastrophic failure whichever occurs first. The shear cutting force depends on several factors:

from www.minaprem.com

Catastrophic failure whichever occurs first. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. The shear cutting force depends on several factors: Cutting force = l x s x t max. A shear force is applied that will cut off part of a sheet. Formula for calculating the cutting force: = length of periphery to be cut in ‘mm’. Progressive wear of flank and/or rake face of tool. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. Adhesion, abrasion, diffusion (at high.

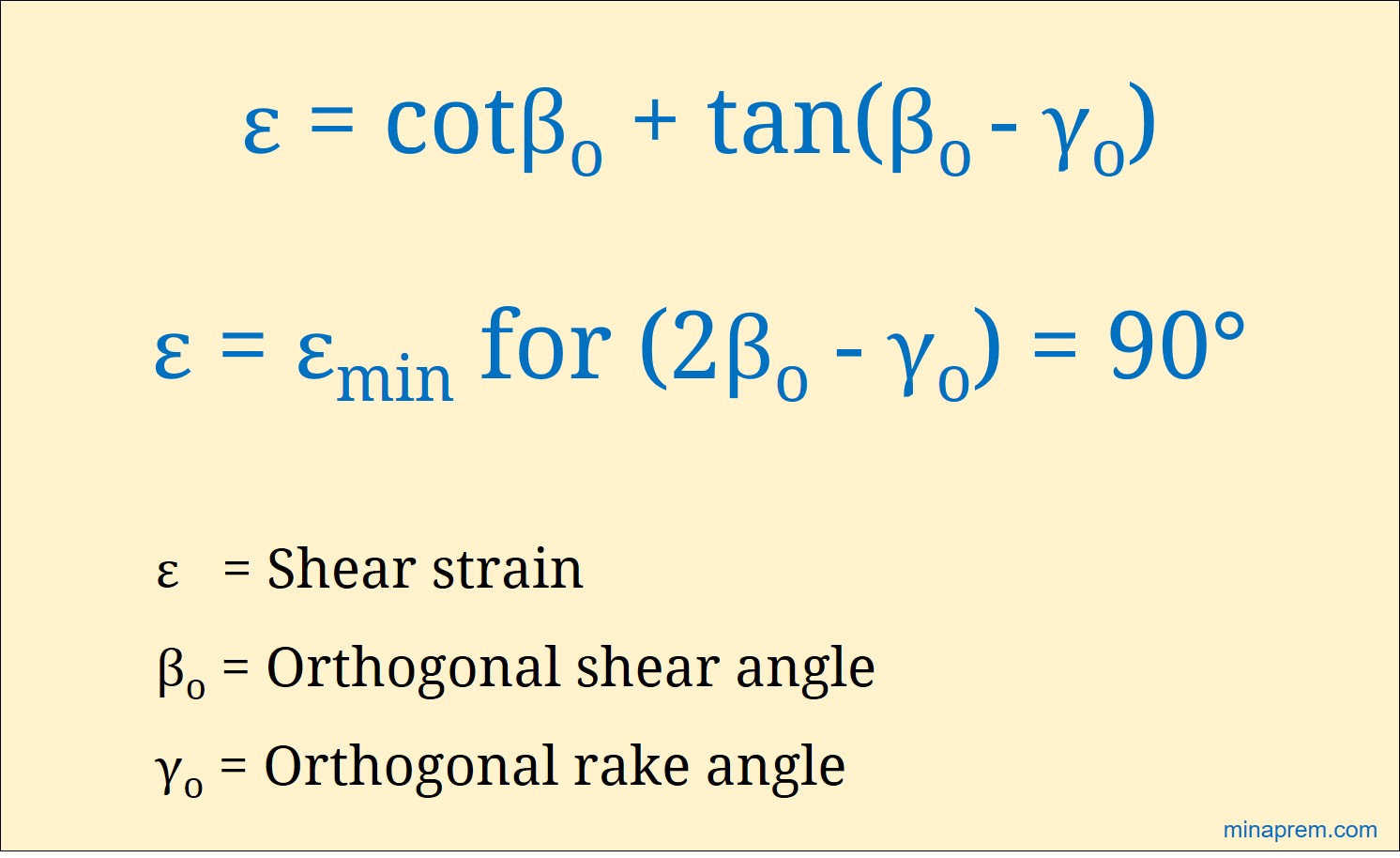

Calculate shear angle for minimum shear strain with positive rake angle

Shear Cutting Force Formula • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. A shear force is applied that will cut off part of a sheet. = sheet thickness in ‘mm’. Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. To find the shear force for a cut we can go back to the basic mechanics of materials (with. The cut off ‘blank’ becomes the workpiece. Catastrophic failure whichever occurs first. Cutting force = l x s x t max. Progressive wear of flank and/or rake face of tool. Formula for calculating the cutting force: Adhesion, abrasion, diffusion (at high. F = shearing force (in kilonewtons,. Max = shear strength in n/mm2. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied.

From www.youtube.com

Engineering Statics Theory Shear and Bending Moment Diagrams Shear Cutting Force Formula The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. = sheet thickness in ‘mm’. The shear cutting force depends on several factors: Adhesion, abrasion, diffusion (at high. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’. Shear Cutting Force Formula.

From www.minaprem.com

Calculate shear plane angle and shear strain in orthogonal cutting Shear Cutting Force Formula Adhesion, abrasion, diffusion (at high. Formula for calculating the cutting force: The cut off ‘blank’ becomes the workpiece. = sheet thickness in ‘mm’. A shear force is applied that will cut off part of a sheet. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. = length of periphery to. Shear Cutting Force Formula.

From ecoursesonline.iasri.res.in

D&S_1 LESSON 22. Shear Stress in Beams Shear Cutting Force Formula The cut off ‘blank’ becomes the workpiece. To find the shear force for a cut we can go back to the basic mechanics of materials (with. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. = sheet thickness in ‘mm’. Max = shear strength in. Shear Cutting Force Formula.

From mavink.com

Shear And Moment Diagram Cheat Sheet Shear Cutting Force Formula • stress on shear plane is uniformly distributed. Adhesion, abrasion, diffusion (at high. To find the shear force for a cut we can go back to the basic mechanics of materials (with. Max = shear strength in n/mm2. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Formula for calculating. Shear Cutting Force Formula.

From www.researchgate.net

Plane shear force and chip impact model during cutting. a Shear plane Shear Cutting Force Formula Cutting force = l x s x t max. To find the shear force for a cut we can go back to the basic mechanics of materials (with. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: • stress on shear plane is uniformly distributed. Adhesion, abrasion, diffusion. Shear Cutting Force Formula.

From slidetodoc.com

Shear Force and Bending Moment Diagrams SFD BMD Shear Cutting Force Formula The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. = sheet thickness in ‘mm’. A shear force is applied that will cut off part of a sheet. Max = shear strength in n/mm2. Formula for calculating the cutting force: Cutting force = l x s. Shear Cutting Force Formula.

From www.pinterest.com

Shear Force & Bending Moments engineering Pinterest Bending Shear Cutting Force Formula The shear cutting force depends on several factors: • stress on shear plane is uniformly distributed. A shear force is applied that will cut off part of a sheet. Catastrophic failure whichever occurs first. Formula for calculating the cutting force: To find the shear force for a cut we can go back to the basic mechanics of materials (with. F. Shear Cutting Force Formula.

From www.structuralbasics.com

Understand Shear Forces [An Engineering Explanation] Structural Basics Shear Cutting Force Formula Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: Cutting force = l x s x t max. = sheet thickness in ‘mm’. Progressive wear of flank and/or rake face of tool. Shear force on metal sheets refers to the cutting force acting on the metal sheet during. Shear Cutting Force Formula.

From www.youtube.com

SA09U Drawing Shear & Moment Diagrams without the use of Equations Shear Cutting Force Formula The shear cutting force depends on several factors: Max = shear strength in n/mm2. A shear force is applied that will cut off part of a sheet. = length of periphery to be cut in ‘mm’. The cut off ‘blank’ becomes the workpiece. • stress on shear plane is uniformly distributed. Calculating shearing force the shearing force (f) required to. Shear Cutting Force Formula.

From www.reddit.com

Design of Shear Reinforcement using Staad r/StructuralEngineering Shear Cutting Force Formula = sheet thickness in ‘mm’. The shear cutting force depends on several factors: Catastrophic failure whichever occurs first. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Cutting force = l x s x t max. Max = shear strength in n/mm2. A shear force is applied that will cut. Shear Cutting Force Formula.

From engineeringinfohub.com

Bending Moment And Shear Force Formula's Engineering Information Hub Shear Cutting Force Formula The cut off ‘blank’ becomes the workpiece. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: To find the shear force for a cut we can go back to the basic mechanics of materials (with. = length of periphery to be cut in ‘mm’. = sheet thickness in. Shear Cutting Force Formula.

From www.minaprem.com

Calculate shear velocity in terms of rake angle, shear angle, cutting Shear Cutting Force Formula Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: Max = shear strength in n/mm2. The cut off ‘blank’ becomes the workpiece. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. = length. Shear Cutting Force Formula.

From www.eigenplus.com

How to draw shear force and bending moment? eigenplus Shear Cutting Force Formula A shear force is applied that will cut off part of a sheet. Formula for calculating the cutting force: = length of periphery to be cut in ‘mm’. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Max = shear strength in n/mm2. Catastrophic failure whichever occurs first. Shear force. Shear Cutting Force Formula.

From br.pinterest.com

What Is Punching Shear Failure And How To Prevent Engineering Shear Cutting Force Formula The shear cutting force depends on several factors: = sheet thickness in ‘mm’. • stress on shear plane is uniformly distributed. = length of periphery to be cut in ‘mm’. Max = shear strength in n/mm2. A shear force is applied that will cut off part of a sheet. The two cutting faces, the pressure face ad and the flank. Shear Cutting Force Formula.

From www.chegg.com

Solved Part II Shear Force and Moment Formulas 1. Find the Shear Cutting Force Formula Catastrophic failure whichever occurs first. = sheet thickness in ‘mm’. • stress on shear plane is uniformly distributed. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. To find the shear force for a cut we can go back to the basic mechanics of materials (with. A shear force is. Shear Cutting Force Formula.

From www.minaprem.com

Calculate shear angle for minimum shear strain with positive rake angle Shear Cutting Force Formula The cut off ‘blank’ becomes the workpiece. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: = length of periphery to be cut in ‘mm’. = sheet thickness in ‘mm’. • stress on shear plane is uniformly distributed. Progressive wear of flank and/or rake face of tool. The. Shear Cutting Force Formula.

From www.minaprem.com

Calculate chip shear force from cutting and thrust forces and shear angle Shear Cutting Force Formula Formula for calculating the cutting force: To find the shear force for a cut we can go back to the basic mechanics of materials (with. The shear cutting force depends on several factors: F = shearing force (in kilonewtons,. • stress on shear plane is uniformly distributed. • resultant force r on chip applied at shear plane is equal, opposite. Shear Cutting Force Formula.

From engineeringdiscoveries.com

Brief Information About Shear Force And Bending Moment Diagrams Shear Cutting Force Formula F = shearing force (in kilonewtons,. To find the shear force for a cut we can go back to the basic mechanics of materials (with. The cut off ‘blank’ becomes the workpiece. = sheet thickness in ‘mm’. Max = shear strength in n/mm2. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated. Shear Cutting Force Formula.

From proper-cooking.info

Shear Force Diagram Distributed Load Shear Cutting Force Formula Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. The shear cutting force depends on several factors: Max = shear strength in n/mm2. To find the shear force for a cut we can go back to the basic mechanics of materials (with. Progressive wear of flank and/or rake face of. Shear Cutting Force Formula.

From www.youtube.com

03_02_P6 Calculating Cutting Forces in Sheet Metal Cutting Operations Shear Cutting Force Formula To find the shear force for a cut we can go back to the basic mechanics of materials (with. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as. Shear Cutting Force Formula.

From pulseplots.com

Understanding Shear Force Diagrams An Essential Guide Shear Cutting Force Formula Max = shear strength in n/mm2. To find the shear force for a cut we can go back to the basic mechanics of materials (with. The shear cutting force depends on several factors: • stress on shear plane is uniformly distributed. = sheet thickness in ‘mm’. The cut off ‘blank’ becomes the workpiece. Shear force on metal sheets refers to. Shear Cutting Force Formula.

From www.difference.minaprem.com

Difference Between Rake Angle and Clearance Angle Shear Cutting Force Formula The shear cutting force depends on several factors: Cutting force = l x s x t max. Adhesion, abrasion, diffusion (at high. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. Shear force on metal sheets refers to the cutting force acting on the metal. Shear Cutting Force Formula.

From www.chegg.com

Solved This experiment examines how shear force varies with Shear Cutting Force Formula Cutting force = l x s x t max. Catastrophic failure whichever occurs first. Max = shear strength in n/mm2. To find the shear force for a cut we can go back to the basic mechanics of materials (with. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known. Shear Cutting Force Formula.

From www.pinterest.com.au

Learn How To Draw Shear Force And Bending Moment Diagrams Civil Shear Cutting Force Formula Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. A shear force is applied that will cut off part of a sheet. = sheet thickness in ‘mm’. = length of periphery to be cut in ‘mm’. Calculating shearing force the shearing force (f) required to cut a sheet of metal. Shear Cutting Force Formula.

From www.researchgate.net

Summary of procedures for shear strength calculation Download Table Shear Cutting Force Formula A shear force is applied that will cut off part of a sheet. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Adhesion, abrasion, diffusion (at high. Progressive wear of flank and/or rake face of tool. To find the shear force for a cut we can go back to the. Shear Cutting Force Formula.

From www.minaprem.com

Calculate shear strain from chip thickness ratio and rake angle Shear Cutting Force Formula F = shearing force (in kilonewtons,. To find the shear force for a cut we can go back to the basic mechanics of materials (with. Progressive wear of flank and/or rake face of tool. • stress on shear plane is uniformly distributed. Adhesion, abrasion, diffusion (at high. • resultant force r on chip applied at shear plane is equal, opposite. Shear Cutting Force Formula.

From proper-cooking.info

Shear Force Diagram Distributed Load Shear Cutting Force Formula The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk, known as cutters (fig. Progressive wear of flank and/or rake face of tool. Max = shear strength in n/mm2. • stress on shear plane is uniformly distributed. Adhesion, abrasion, diffusion (at high. Catastrophic failure whichever occurs first. Calculating shearing force. Shear Cutting Force Formula.

From www.sandvik.coromant.com

Specific cutting force What is it and how to use it Shear Cutting Force Formula Adhesion, abrasion, diffusion (at high. = length of periphery to be cut in ‘mm’. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: A shear force is applied that will cut off part of a sheet. Catastrophic failure whichever occurs first. Formula for calculating the cutting force: The. Shear Cutting Force Formula.

From skyciv.com

How to Calculate Shear Force Diagrams SkyCiv Shear Cutting Force Formula = sheet thickness in ‘mm’. To find the shear force for a cut we can go back to the basic mechanics of materials (with. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated. Shear Cutting Force Formula.

From www.youtube.com

Shear strain YouTube Shear Cutting Force Formula Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: Adhesion, abrasion, diffusion (at high. The shear cutting force depends on several factors: Shear force on metal sheets refers to the cutting force acting on the metal sheet during the shearing process. Catastrophic failure whichever occurs first. To find. Shear Cutting Force Formula.

From www.mdpi.com

JMMP Free FullText Determination of the Shear Angle in the Shear Cutting Force Formula Progressive wear of flank and/or rake face of tool. = sheet thickness in ‘mm’. Max = shear strength in n/mm2. Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: F = shearing force (in kilonewtons,. Shear force on metal sheets refers to the cutting force acting on the. Shear Cutting Force Formula.

From www.youtube.com

Shear force and bending moment diagrams example 2 multiple point Shear Cutting Force Formula = sheet thickness in ‘mm’. = length of periphery to be cut in ‘mm’. F = shearing force (in kilonewtons,. Catastrophic failure whichever occurs first. Adhesion, abrasion, diffusion (at high. The cut off ‘blank’ becomes the workpiece. Progressive wear of flank and/or rake face of tool. The two cutting faces, the pressure face ad and the flank af form the. Shear Cutting Force Formula.

From michaelbadillokup4.web.app

Cutting Force Formula For Sheet Metal Shear Cutting Force Formula Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: Progressive wear of flank and/or rake face of tool. Catastrophic failure whichever occurs first. Cutting force = l x s x t max. The cut off ‘blank’ becomes the workpiece. • stress on shear plane is uniformly distributed. A. Shear Cutting Force Formula.

From www.youtube.com

Shear Force and Bending Moment diagram of Beam with Triangular Load Shear Cutting Force Formula Formula for calculating the cutting force: Calculating shearing force the shearing force (f) required to cut a sheet of metal can be calculated using the following formula: The cut off ‘blank’ becomes the workpiece. Max = shear strength in n/mm2. The two cutting faces, the pressure face ad and the flank af form the cutting edges on these components sk,. Shear Cutting Force Formula.

From www.numerade.com

SOLVED Text cc uousan In an orthogonal cutting test with a tool of Shear Cutting Force Formula Cutting force = l x s x t max. To find the shear force for a cut we can go back to the basic mechanics of materials (with. • resultant force r on chip applied at shear plane is equal, opposite and collinear to force r’ applied. A shear force is applied that will cut off part of a sheet.. Shear Cutting Force Formula.