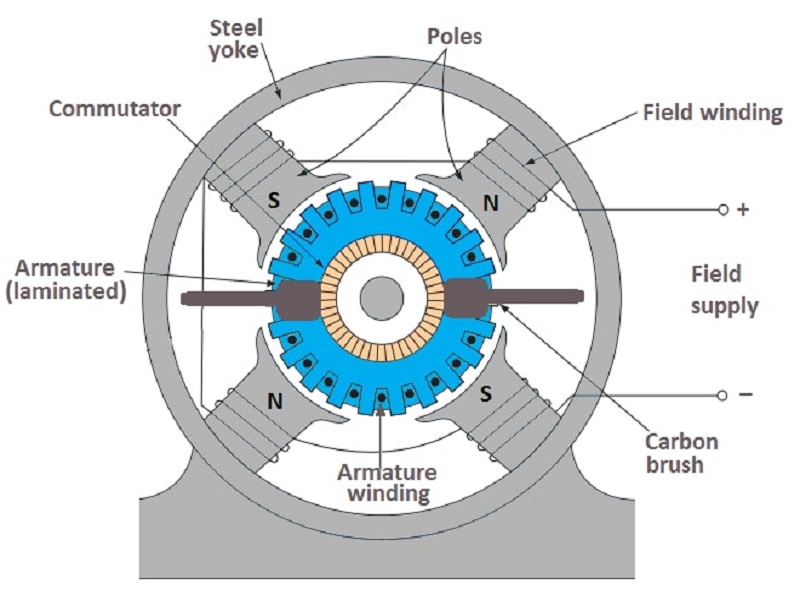

Brush Dc Motor Operation . Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. A typical brush dc motor contains six components: The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Like most electric motors, a brush dc motor comprises two essential parts: The smaller motors are sometimes called fractional horsepower motors. Brushed dc motors are available in several forms. The rotor typically features coils wound. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. The main features of dc motors are as follows. The stator surrounds the rotor, and generates a magnetic. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor).

from dxoomfrlv.blob.core.windows.net

The rotor typically features coils wound. This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. The smaller motors are sometimes called fractional horsepower motors. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The main features of dc motors are as follows. Like most electric motors, a brush dc motor comprises two essential parts: A typical brush dc motor contains six components: Brushed dc motors are available in several forms.

Function Of Brushes In A Dc Motor at Roger Gordon blog

Brush Dc Motor Operation The smaller motors are sometimes called fractional horsepower motors. This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. A typical brush dc motor contains six components: The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The stator surrounds the rotor, and generates a magnetic. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. The rotor typically features coils wound. Brushed dc motors are available in several forms. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Like most electric motors, a brush dc motor comprises two essential parts: The main features of dc motors are as follows. The smaller motors are sometimes called fractional horsepower motors. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers.

From www.slideserve.com

PPT DC Motor & DC Generator PowerPoint Presentation, free download Brush Dc Motor Operation Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a. Brush Dc Motor Operation.

From motorceowall.com

Brushed Dc Motor Principle Of Operation Brush Dc Motor Operation Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. A typical brush dc motor contains six components: This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. The stator surrounds the rotor,. Brush Dc Motor Operation.

From www.slideserve.com

PPT Direct current (DC)motors PowerPoint Presentation, free download Brush Dc Motor Operation The stator surrounds the rotor, and generates a magnetic. The smaller motors are sometimes called fractional horsepower motors. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. The main features of dc motors are as follows. This article explains the basics of brushed dc motors, the circuitry required to drive. Brush Dc Motor Operation.

From dxoomfrlv.blob.core.windows.net

Function Of Brushes In A Dc Motor at Roger Gordon blog Brush Dc Motor Operation Like most electric motors, a brush dc motor comprises two essential parts: Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational. Brush Dc Motor Operation.

From www.youtube.com

What are the Types of Brushes in a DC Motor? YouTube Brush Dc Motor Operation A typical brush dc motor contains six components: The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. Brushed dc motors are available in several forms. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets.. Brush Dc Motor Operation.

From www.youtube.com

Basics of Brushed DC Motors Another Teaching Moment DigiKey Brush Dc Motor Operation The rotor typically features coils wound. Brushed dc motors are available in several forms. A typical brush dc motor contains six components: The main features of dc motors are as follows. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. This. Brush Dc Motor Operation.

From www.medicaldesignandoutsourcing.com

What are the pros and cons of dc brush and brushless motors? Medical Brush Dc Motor Operation The main features of dc motors are as follows. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The rotor typically features coils wound. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. This article explains the basics of brushed dc motors,. Brush Dc Motor Operation.

From www.precisionmicrodrives.com

A Short Illustrated Primer On Brushed DC Motors Precision Microdrives Brush Dc Motor Operation The rotor typically features coils wound. Brushed dc motors are available in several forms. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. Stator, rotor/armature, commutator, brushes, an. Brush Dc Motor Operation.

From slideplayer.com

Introduction to Brush DC Motor Control ppt download Brush Dc Motor Operation The stator surrounds the rotor, and generates a magnetic. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The smaller motors are sometimes called fractional horsepower motors. Like most electric motors, a brush dc motor comprises two essential parts: Its simplicity and effectiveness have earned it a solid position in the array. Brush Dc Motor Operation.

From orbray.com

Brushless DC motors and brushed DC motors? Explaining the features of Brush Dc Motor Operation The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The smaller motors are sometimes called fractional horsepower motors. The stator surrounds the rotor, and generates a magnetic. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Like most electric motors, a brush dc motor. Brush Dc Motor Operation.

From www.linquip.com

Brushed DC Motor Working Principle, Parts, and Types Linquip Brush Dc Motor Operation The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Brushless dc motors, on the other hand, do not have a commutator and brushes, and. Brush Dc Motor Operation.

From www.alliedmotion.com

Choosing Between Brush and Brushless DC Motors Allied Motion Brush Dc Motor Operation Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. Brushed dc motors are available in several forms. A brushed direct current (dc) motor is a type of. Brush Dc Motor Operation.

From www.portescap.com

Brushed DC Motor Basics Portescap Brush Dc Motor Operation A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. The stator surrounds the rotor, and generates a magnetic. Like most electric motors, a brush dc motor comprises two essential parts: The rotor typically features coils wound. The smaller motors are sometimes called fractional. Brush Dc Motor Operation.

From www.iqsdirectory.com

DC Motor What Is It? How Does It Work? Types, Uses Brush Dc Motor Operation The smaller motors are sometimes called fractional horsepower motors. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The main features of dc motors are as follows. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are. Brush Dc Motor Operation.

From assunmotor.com

Brushed DC Motors How They Work and Their Advantages? Brush Dc Motor Operation The stator surrounds the rotor, and generates a magnetic. Brushed dc motors are available in several forms. The smaller motors are sometimes called fractional horsepower motors. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. The main features of dc motors are as follows. Like most electric motors, a brush. Brush Dc Motor Operation.

From collegedunia.com

DC Motor Types, Working Principle, Applications Brush Dc Motor Operation A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. The main features of dc motors are as follows. Its. Brush Dc Motor Operation.

From webmotor.org

What Is The Combined Function Of Brushes And Commutator In A Dc Motor Brush Dc Motor Operation Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The main features of dc motors are as follows. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). Like most electric. Brush Dc Motor Operation.

From dxoomfrlv.blob.core.windows.net

Function Of Brushes In A Dc Motor at Roger Gordon blog Brush Dc Motor Operation Like most electric motors, a brush dc motor comprises two essential parts: The stator surrounds the rotor, and generates a magnetic. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The article described the functions and components of brushed dc motors and brushless dc. Brush Dc Motor Operation.

From www.eeworldonline.com

The brushed DC motor Still a very viable option, Part 1 Operation Brush Dc Motor Operation The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. The smaller motors are sometimes called fractional horsepower motors. A typical brush dc motor contains six components: Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The rotor typically features coils wound. Brushless dc motors, on the other hand, do not have a commutator. Brush Dc Motor Operation.

From dxoomfrlv.blob.core.windows.net

Function Of Brushes In A Dc Motor at Roger Gordon blog Brush Dc Motor Operation A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. Brushed dc motors are available in. Brush Dc Motor Operation.

From electricalworkbook.com

Difference Between Brushed and Brushless DC Motor ElectricalWorkbook Brush Dc Motor Operation Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. The smaller motors are sometimes called fractional horsepower motors. A brushed direct current (dc) motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. Like most electric motors, a brush. Brush Dc Motor Operation.

From electricalbaba.com

Brushless DC Motor Construction, Working Principle and Advantages Brush Dc Motor Operation The smaller motors are sometimes called fractional horsepower motors. The stator surrounds the rotor, and generates a magnetic. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics. Brush Dc Motor Operation.

From www.globalspec.com

Brushed DC Motor Working Principle GlobalSpec Brush Dc Motor Operation Like most electric motors, a brush dc motor comprises two essential parts: Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics. Brush Dc Motor Operation.

From www.powerelectronictips.com

The brushed DC motor Still a very viable option, Part 1 Operation Brush Dc Motor Operation A typical brush dc motor contains six components: Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The rotor typically features coils wound. The operation of brushed dc motors is based on the. Brush Dc Motor Operation.

From klaxzeail.blob.core.windows.net

Brushed Dc Motor How It Works at Josh Bowers blog Brush Dc Motor Operation Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. This article explains the basics of brushed dc motors, the circuitry required to drive them, and the pros and cons of brushless dc motors. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Its simplicity and effectiveness have. Brush Dc Motor Operation.

From www.slideserve.com

PPT Chapter 3. DC Machines PowerPoint Presentation, free download Brush Dc Motor Operation The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. Like most electric motors, a brush dc motor comprises two essential parts: The stator surrounds the rotor, and generates a magnetic. A typical brush dc motor contains six components: A brushed direct. Brush Dc Motor Operation.

From slideplayer.com

Introduction to Brush DC Motor Control ppt download Brush Dc Motor Operation The rotor typically features coils wound. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Like most electric motors, a brush dc motor comprises two essential parts: The main features of dc motors are as follows. The smaller motors are sometimes called fractional horsepower motors. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead. Brush Dc Motor Operation.

From www.slideserve.com

PPT ELECTRIC DC MOTORS PowerPoint Presentation, free download ID Brush Dc Motor Operation The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to. Brush Dc Motor Operation.

From www.electricaleasy.com

Brushless DC (BLDC) Motor Construction and Working Brush Dc Motor Operation A typical brush dc motor contains six components: Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. Brushless dc motors, on the other hand, do not have a commutator and brushes, and instead are electronically controlled with a drive circuit. The smaller motors are sometimes called fractional horsepower motors. A. Brush Dc Motor Operation.

From www.slideserve.com

PPT ELECTRIC DC MOTORS PowerPoint Presentation, free download ID Brush Dc Motor Operation The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). A typical brush dc motor contains six components: The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing. Brush Dc Motor Operation.

From www.slideserve.com

PPT ELECTRIC DC MOTORS PowerPoint Presentation, free download ID Brush Dc Motor Operation The smaller motors are sometimes called fractional horsepower motors. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The rotor typically features. Brush Dc Motor Operation.

From www.slideserve.com

PPT DC Motor & DC Generator PowerPoint Presentation, free download Brush Dc Motor Operation Brushed dc motors are available in several forms. The smaller motors are sometimes called fractional horsepower motors. Stator, rotor/armature, commutator, brushes, an axle/shaft, and magnets. Like most electric motors, a brush dc motor comprises two essential parts: The main features of dc motors are as follows. A typical brush dc motor contains six components: Brushless dc motors, on the other. Brush Dc Motor Operation.

From slideplayer.com

Introduction to Brush DC Motor Control ppt download Brush Dc Motor Operation The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. The main features of dc motors are as follows. The rotor typically features coils wound.. Brush Dc Motor Operation.

From slideplayer.com

Introduction to Brush DC Motor Control ppt download Brush Dc Motor Operation The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). The operation of brushed dc motors is based on the mechanical linkage between their commutator and brushes. A typical brush dc motor contains six components: The stator surrounds the rotor, and generates a magnetic. A brushed direct current (dc) motor is a type. Brush Dc Motor Operation.

From www.researchgate.net

3 Model of a brush DC motor Download Scientific Diagram Brush Dc Motor Operation The main features of dc motors are as follows. The article described the functions and components of brushed dc motors and brushless dc (bldc) motors, while reviewing their important parameters and motor driver ics that can further. The stator (or stationary part of the motor) and the rotor (or rotating part of the motor). Stator, rotor/armature, commutator, brushes, an axle/shaft,. Brush Dc Motor Operation.