Strain Gauge Not Working . The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). For a 120 ω gage, this is a change of. A strain gauge is a sensor whose resistance varies with applied force; It converts the change in resistance to the change in length. Most can be avoided by simply using only qualified supplies, and rigorously following the. Solder flux residue impacts resistance drift, while incorrect. strain gage bond failures are, in general, unnecessary. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. When external forces are applied to a stationary object, stress and strain are the result.

from electricalworkbook.com

critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). A strain gauge is a sensor whose resistance varies with applied force; Most can be avoided by simply using only qualified supplies, and rigorously following the. Solder flux residue impacts resistance drift, while incorrect. When external forces are applied to a stationary object, stress and strain are the result. It converts the change in resistance to the change in length. For a 120 ω gage, this is a change of.

What is Wire Strain Gauge? Working & Construction ElectricalWorkbook

Strain Gauge Not Working The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Solder flux residue impacts resistance drift, while incorrect. A strain gauge is a sensor whose resistance varies with applied force; When external forces are applied to a stationary object, stress and strain are the result. It converts the change in resistance to the change in length. Most can be avoided by simply using only qualified supplies, and rigorously following the. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. strain gage bond failures are, in general, unnecessary. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. For a 120 ω gage, this is a change of. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2).

From electricalgang.com

What Is a Strain Gauge? A Definitive Guide Strain Gauge Not Working For a 120 ω gage, this is a change of. Most can be avoided by simply using only qualified supplies, and rigorously following the. A strain gauge is a sensor whose resistance varies with applied force; It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. strain gauges work by measuring. Strain Gauge Not Working.

From www.youtube.com

Strain gauge Construction working Advantages Disadvantages Applications Strain Gauge Not Working Solder flux residue impacts resistance drift, while incorrect. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. strain gage bond failures are, in general, unnecessary. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually. Strain Gauge Not Working.

From www.allaboutcircuits.com

Strain Gauges Electrical Instrumentation Signals Electronics Textbook Strain Gauge Not Working It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. It converts the change in resistance to the change in length. strain gage bond failures are, in general, unnecessary. For a 120 ω gage, this is a change of. Most can be avoided by simply using only qualified supplies, and rigorously. Strain Gauge Not Working.

From electricalworkbook.com

What is Wire Strain Gauge? Working & Construction ElectricalWorkbook Strain Gauge Not Working When external forces are applied to a stationary object, stress and strain are the result. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). strain gauges work by measuring the change in electrical resistance across a thin conductive foil. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. . Strain Gauge Not Working.

From mg.michsci.com

What is a Strain Gauge and How Does it Work? • Michigan Scientific Strain Gauge Not Working strain gauges work by measuring the change in electrical resistance across a thin conductive foil. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. strain gage bond failures are, in general, unnecessary. critical. Strain Gauge Not Working.

From theinstrumentguru.com

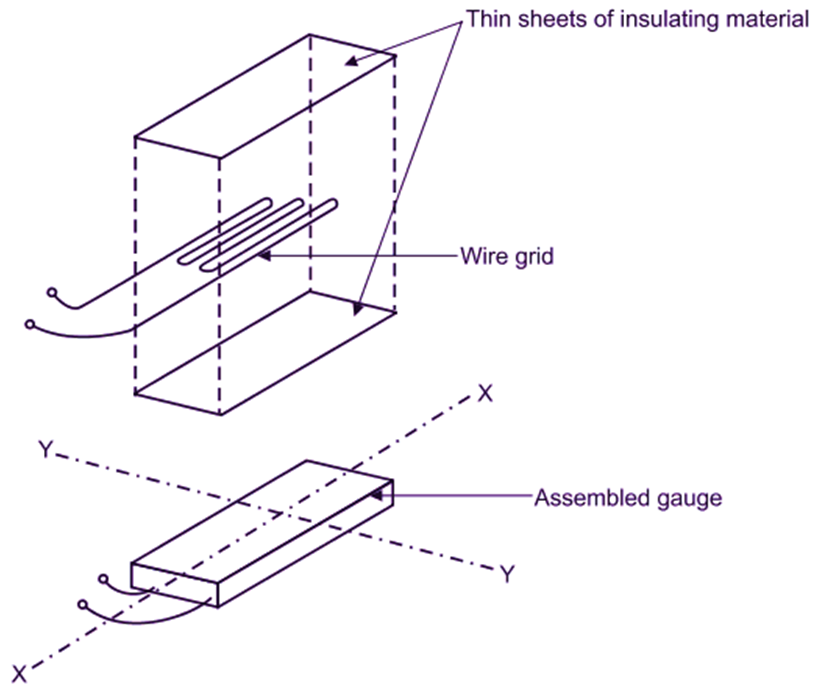

Unbonded strain gauge THE INSTRUMENT GURU Strain Gauge Not Working strain gauges work by measuring the change in electrical resistance across a thin conductive foil. When external forces are applied to a stationary object, stress and strain are the result. strain gage bond failures are, in general, unnecessary. A strain gauge is a sensor whose resistance varies with applied force; The gauge factor (or “gage factor”) is the. Strain Gauge Not Working.

From itestsystem.com

Strain Gauge Services Archives ITM Strain Gauge Not Working strain gauges work by measuring the change in electrical resistance across a thin conductive foil. A strain gauge is a sensor whose resistance varies with applied force; strain gage bond failures are, in general, unnecessary. Solder flux residue impacts resistance drift, while incorrect. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts. Strain Gauge Not Working.

From www.vrogue.co

Strain Gauge Diagram vrogue.co Strain Gauge Not Working strain gage bond failures are, in general, unnecessary. A strain gauge is a sensor whose resistance varies with applied force; When external forces are applied to a stationary object, stress and strain are the result. Solder flux residue impacts resistance drift, while incorrect. strain gauges work by measuring the change in electrical resistance across a thin conductive foil.. Strain Gauge Not Working.

From instrumentationtools.com

Strain Gauge Working Principle Inst Tools Strain Gauge Not Working strain gage bond failures are, in general, unnecessary. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). For a 120 ω gage, this is. Strain Gauge Not Working.

From www.iqsdirectory.com

Strain Gauge What Is It? How Is It Used? Types, Application Strain Gauge Not Working strain gauges work by measuring the change in electrical resistance across a thin conductive foil. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. strain gage bond failures are, in general, unnecessary. It converts the change. Strain Gauge Not Working.

From www.vrogue.co

Strain Gauge Definition Explanation Diagram Working P vrogue.co Strain Gauge Not Working Most can be avoided by simply using only qualified supplies, and rigorously following the. Solder flux residue impacts resistance drift, while incorrect. strain gage bond failures are, in general, unnecessary. For a 120 ω gage, this is a change of. When external forces are applied to a stationary object, stress and strain are the result. A strain gauge is. Strain Gauge Not Working.

From detoxicrecenze.com

Strain Gauge Wiring Diagram My Wiring DIagram Strain Gauge Not Working critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts the change in resistance to the change in length. For a 120 ω gage, this is a change of. Most can be avoided by simply using only qualified supplies, and rigorously following the. strain gauges work by measuring the change in electrical resistance across. Strain Gauge Not Working.

From edu.svet.gob.gt

What Is A Strain Gauge And How Does It Work? • Michigan Strain Gauge Not Working It converts the change in resistance to the change in length. A strain gauge is a sensor whose resistance varies with applied force; When external forces are applied to a stationary object, stress and strain are the result. For a 120 ω gage, this is a change of. It converts force, pressure, tension, weight, etc., into a change in electrical. Strain Gauge Not Working.

From www.ascend-tech.com

How Does A Strain GaugeBased Load Cell Work? Strain Gauge Not Working For a 120 ω gage, this is a change of. It converts the change in resistance to the change in length. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Solder flux residue impacts resistance drift, while incorrect. A strain gauge is a sensor whose resistance varies with applied force; When external forces are applied to. Strain Gauge Not Working.

From www.researchgate.net

The principle of the strain gauge. Download Scientific Diagram Strain Gauge Not Working Solder flux residue impacts resistance drift, while incorrect. It converts the change in resistance to the change in length. When external forces are applied to a stationary object, stress and strain are the result. For a 120 ω gage, this is a change of. strain gage bond failures are, in general, unnecessary. strain gauges work by measuring the. Strain Gauge Not Working.

From blog.endaq.com

Strain Gauges How they Work, Applications, and Types Strain Gauge Not Working strain gage bond failures are, in general, unnecessary. Most can be avoided by simply using only qualified supplies, and rigorously following the. For a 120 ω gage, this is a change of. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). A strain gauge is a sensor whose resistance varies with applied force;. Strain Gauge Not Working.

From www.researchgate.net

Strain gauge sensitivity (a) resistance variation (strain gauge Strain Gauge Not Working critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Solder flux residue impacts resistance drift, while incorrect. For a 120 ω gage, this is a change of. strain gage bond failures are, in general, unnecessary. When external forces are applied to a stationary object, stress and strain are the result. It converts force, pressure, tension,. Strain Gauge Not Working.

From engineerexcel.com

How Does a Strain Gauge Work Exploring the Fundamentals and Strain Gauge Not Working It converts the change in resistance to the change in length. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Most can be avoided by simply using only qualified supplies, and rigorously following the. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. When external forces are applied to. Strain Gauge Not Working.

From blog.endaq.com

Strain Gauges How they Work, Applications, and Types Strain Gauge Not Working Most can be avoided by simply using only qualified supplies, and rigorously following the. When external forces are applied to a stationary object, stress and strain are the result. It converts the change in resistance to the change in length. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. It converts force, pressure,. Strain Gauge Not Working.

From www.youtube.com

How to assemble and test Strain Gauges, a stepbystep guide YouTube Strain Gauge Not Working Solder flux residue impacts resistance drift, while incorrect. It converts the change in resistance to the change in length. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). A strain gauge is a sensor whose resistance varies with applied force; Most can be avoided by simply using only qualified supplies, and rigorously following the.. Strain Gauge Not Working.

From mavink.com

Strain Gauge Diagram Strain Gauge Not Working It converts the change in resistance to the change in length. strain gage bond failures are, in general, unnecessary. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. A strain gauge is a sensor whose resistance varies with applied force; Most can be avoided by simply using only qualified supplies,. Strain Gauge Not Working.

From www.iqsdirectory.com

Strain Gauge What Is It? How Is It Used? Types, Application Strain Gauge Not Working A strain gauge is a sensor whose resistance varies with applied force; It converts the change in resistance to the change in length. strain gage bond failures are, in general, unnecessary. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Solder flux residue impacts resistance drift, while incorrect. For a 120 ω gage, this is. Strain Gauge Not Working.

From www.allaboutcircuits.com

Strain Gauges Electrical Instrumentation Signals Electronics Textbook Strain Gauge Not Working critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts the change in resistance to the change in length. A strain gauge is a sensor whose resistance varies with applied force; Solder flux residue impacts resistance drift, while incorrect. When external forces are applied to a stationary object, stress and strain are the result. . Strain Gauge Not Working.

From www.dewetron.com

Strain gauges DEWETRON Strain Gauge Not Working critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts the change in resistance to the change in length. For a 120 ω gage, this is a change of. A strain gauge is a sensor whose resistance varies with applied force; The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually. Strain Gauge Not Working.

From www.yourelectricalguide.com

Strain Gauge Working Principle Your Electrical Guide Strain Gauge Not Working For a 120 ω gage, this is a change of. Most can be avoided by simply using only qualified supplies, and rigorously following the. strain gage bond failures are, in general, unnecessary. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts the change in resistance to the change in length. When external forces. Strain Gauge Not Working.

From cepvjzux.blob.core.windows.net

Strain Gauge Electrical Circuit at Julian Estabrook blog Strain Gauge Not Working strain gauges work by measuring the change in electrical resistance across a thin conductive foil. It converts the change in resistance to the change in length. strain gage bond failures are, in general, unnecessary. A strain gauge is a sensor whose resistance varies with applied force; Most can be avoided by simply using only qualified supplies, and rigorously. Strain Gauge Not Working.

From instrumentationtools.com

Unbonded Strain Gauge Principle Inst Tools Strain Gauge Not Working The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. A strain gauge is a sensor whose resistance varies with applied force; strain gauges work by measuring the change in electrical resistance across a thin conductive. Strain Gauge Not Working.

From mungfali.com

Strain Gauge Strain Gauge Not Working It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. strain gage bond failures are, in general, unnecessary. For a 120 ω gage, this is a change of. critical errors in strain gage application. Strain Gauge Not Working.

From instrumentationtools.com

Strain Gauge Working Principle Inst Tools Strain Gauge Not Working strain gage bond failures are, in general, unnecessary. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. Solder flux residue impacts resistance drift, while incorrect. Most can be avoided by simply using only qualified supplies, and rigorously following the. critical errors in strain gage application highlights 10 crucial factors affecting accuracy.. Strain Gauge Not Working.

From theinstrumentguru.com

Bonded strain gauge THE INSTRUMENT GURU Strain Gauge Not Working It converts the change in resistance to the change in length. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. strain gage. Strain Gauge Not Working.

From www.researchgate.net

Operation principle of strain gauges based on (a) Strainresistive Strain Gauge Not Working Most can be avoided by simply using only qualified supplies, and rigorously following the. strain gage bond failures are, in general, unnecessary. Solder flux residue impacts resistance drift, while incorrect. strain gauges work by measuring the change in electrical resistance across a thin conductive foil. It converts force, pressure, tension, weight, etc., into a change in electrical resistance. Strain Gauge Not Working.

From www.engineeringa2z.com

Strain Gauge Working EngineeringA2Z Strain Gauge Not Working critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts the change in resistance to the change in length. For a 120 ω gage, this is a change of. When external forces are applied to a stationary object, stress and strain are the result. A strain gauge is a sensor whose resistance varies with applied. Strain Gauge Not Working.

From electricalworkbook.com

What is Unbonded Strain Gauge? Working, Construction & Applications Strain Gauge Not Working Solder flux residue impacts resistance drift, while incorrect. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). critical errors in strain gage application highlights 10 crucial factors affecting accuracy. It converts force, pressure, tension, weight, etc., into a change in electrical resistance which can then be measured. It converts the change in resistance. Strain Gauge Not Working.

From www.allaboutcircuits.com

Strain Gauges Electrical Instrumentation Signals Electronics Textbook Strain Gauge Not Working When external forces are applied to a stationary object, stress and strain are the result. critical errors in strain gage application highlights 10 crucial factors affecting accuracy. Solder flux residue impacts resistance drift, while incorrect. For a 120 ω gage, this is a change of. It converts the change in resistance to the change in length. Most can be. Strain Gauge Not Working.

From electricalworkbook.com

What is Strain Gauge Load Cell? Working Principle, Construction Strain Gauge Not Working strain gage bond failures are, in general, unnecessary. For a 120 ω gage, this is a change of. Most can be avoided by simply using only qualified supplies, and rigorously following the. The gauge factor (or “gage factor”) is the sensitivity of the strain gauge (usually 2). Solder flux residue impacts resistance drift, while incorrect. A strain gauge is. Strain Gauge Not Working.