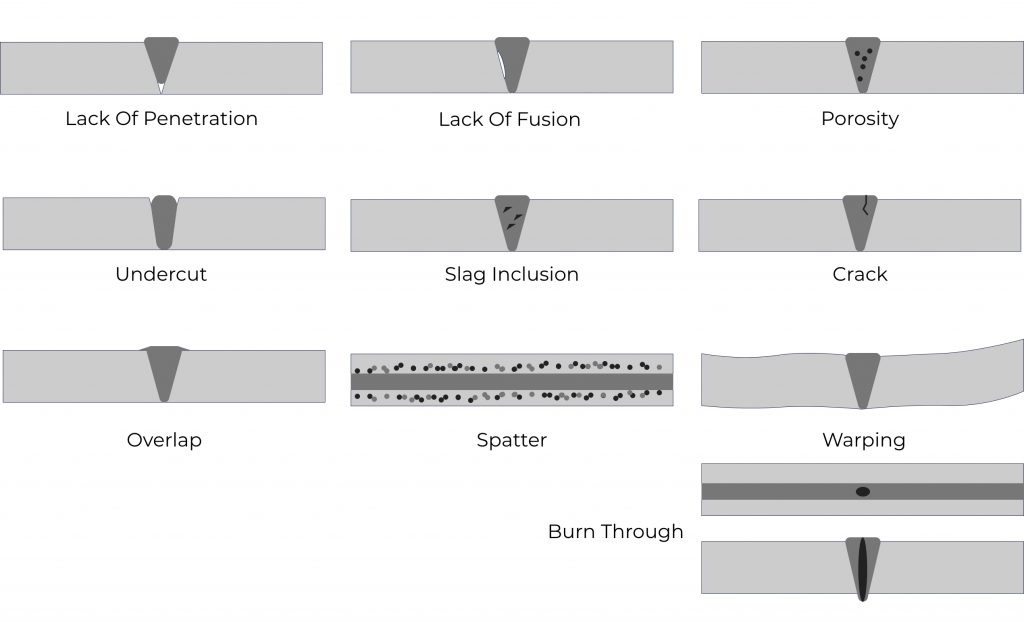

Laser Welding Issues . the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding machines and provides practical solutions. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). laser welding is a powerful technique, but improper handling can lead to issues.

from sentin.ai

the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding machines and provides practical solutions. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality.

The 10 Common Weld Defects You Should Know. sentin

Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. this article explores common problems associated with laser welding machines and provides practical solutions. the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). laser welding is a powerful technique, but improper handling can lead to issues.

From www.laserfocusworld.com

Dissimilar metal welding with advanced laser beam control Laser Focus Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding machines and provides practical solutions. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios.. Laser Welding Issues.

From sentin.ai

The 10 Common Weld Defects You Should Know. sentin Laser Welding Issues this article explores common problems associated with laser welding machines and provides practical solutions. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding. Laser Welding Issues.

From makemoneywelding.com

8 Ways To Avoid Weld Porosity Laser Welding Issues laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found from the surface of the workpiece. Laser Welding Issues.

From inbound.cammmetals.com

9 Common Welding Problems and How to Fix Them Laser Welding Issues adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). the main defects in laser welds in both steel and aluminium are. Laser Welding Issues.

From knoxfr.com

Welding Defects And What They Are? How To Avoid Them! Knox Incorporated Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. For example, external defects can be found from the surface of the workpiece without the. Laser Welding Issues.

From www.twi-global.com

What is Laser Welding and How Does it Work? TWI Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. by. Laser Welding Issues.

From www.victoriana.com

Anfänger Sich entwickeln Stich laser welding aluminium problems tragbar Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. this article explores common problems associated with laser welding machines and provides practical solutions. the main. Laser Welding Issues.

From superiorlasermarking.com

Laser Welding A Comprehensive Guide Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding. Laser Welding Issues.

From www.theengineerspost.com

16 Common Types of Welding Defects [Causes, Remedies] PDF Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. the. Laser Welding Issues.

From weldingpros.net

Pulsed MIG Welding Clad Weld Issues Laser Welding Issues this article explores common problems associated with laser welding machines and provides practical solutions. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. adjusting laser power, focal position, and. Laser Welding Issues.

From www.mdpi.com

Investigation of Weld Root Defects in HighPower Laser Laser Welding Issues laser welding is a powerful technique, but improper handling can lead to issues. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). the main defects in laser welds in both steel and aluminium are solidification cracking (also called. Laser Welding Issues.

From www.shutterstock.com

2,389 Weld defect Images, Stock Photos & Vectors Shutterstock Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. laser welding is a powerful technique, but improper handling can lead to issues. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found. Laser Welding Issues.

From www.hgtech-laser.com

Common problems and solutions in laser welding Knowledge Wuhan Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. this article explores common problems associated with laser welding machines and provides practical solutions. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks,. Laser Welding Issues.

From tft-pneumatic.com

How to Identify the 7 Most Dangerous Welding Defects TFT Pneumatic Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. by controlling the relative motion of the laser beam. Laser Welding Issues.

From www.victoriana.com

Komponente selbst Krise laser welding defects Abstrich Rachen zuordnen Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot. Laser Welding Issues.

From www.theweldingmaster.com

types of welding defects Laser Welding Issues adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. by controlling the relative motion of the laser beam and the welding. Laser Welding Issues.

From aavishkargroup.com

7 Laser Welding Quality Problems & Solutions Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding. Laser Welding Issues.

From www.youtube.com

Welding defects, their visual appearance, and identification for CSWIP Laser Welding Issues For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. the main defects in laser welds in both steel and aluminium are. Laser Welding Issues.

From www.findlight.net

Laser Welding A Brief Introductory Guide Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. adjusting laser power, focal position, and. Laser Welding Issues.

From cnctlaser.com

Eight Problems in Welding of Dissimilar Materials Laser Cleaning Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores,. Laser Welding Issues.

From blog.thepipingmart.com

Spot Welding vs Laser Welding What's the Difference Laser Welding Issues laser welding is a powerful technique, but improper handling can lead to issues. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). this article explores common problems associated with laser welding machines and provides practical solutions. adjusting. Laser Welding Issues.

From www.researchgate.net

The schematic diagram of laser welding. Download Scientific Diagram Laser Welding Issues adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. this article explores common problems associated with laser welding machines and provides practical solutions. laser welding is a powerful technique, but improper handling can lead to issues. the main defects in laser welds in both steel and aluminium are. Laser Welding Issues.

From www.intechopen.com

Laser Welding of Magnesium Alloys Issues and Remedies IntechOpen Laser Welding Issues laser welding is a powerful technique, but improper handling can lead to issues. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. For example, external defects. Laser Welding Issues.

From docslib.org

Problems and Issues in LaserArc Hybrid Welding DocsLib Laser Welding Issues adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. laser welding is a powerful technique, but improper handling can lead to issues. by controlling the relative motion of. Laser Welding Issues.

From normaltancn.com

The Solution to Common Problems Laser Welding Machine N.C. Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks,. Laser Welding Issues.

From www.youtube.com

Laser Welding vs. TIG Welding ! Most Satisfactory Factory Machines Laser Welding Issues this article explores common problems associated with laser welding machines and provides practical solutions. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve. Laser Welding Issues.

From www.omsmeasure.com

Most common welding defects — OMS Optical Metrology Services Ltd Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). this article explores common problems associated. Laser Welding Issues.

From hantencnc.com

Common Problems And Solutions For Handheld Laser Welding Machines Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. For example, external defects can be found. Laser Welding Issues.

From www.circuitdiagram.co

Laser Welding Schematic Diagram Circuit Diagram Laser Welding Issues laser welding is a powerful technique, but improper handling can lead to issues. this article explores common problems associated with laser welding machines and provides practical solutions. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. adjusting laser power, focal position, and. Laser Welding Issues.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. laser welding is a powerful technique, but improper handling can lead to issues. . Laser Welding Issues.

From www.heatsign.com

Complete Guide to Laser Welding Machines HeatSign Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. laser welding is a powerful technique, but improper handling can lead to issues. by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. . Laser Welding Issues.

From blog.thepipingmart.com

What are Welding Defects? ThePipingMart Blog Laser Welding Issues adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges, welding bumps, flying measurements, etc.). by controlling the relative motion of the laser beam and the welding. Laser Welding Issues.

From weldguru.com

13 Common Types of Welding Defects & How to Prevent Them Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. adjusting laser power, focal position, and welding speed can help reduce smoke generation and improve welding quality. the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot. Laser Welding Issues.

From hantencnc.com

Common Problems And Solutions For Handheld Laser Welding Machines Laser Welding Issues by controlling the relative motion of the laser beam and the welding position, the welding will have welding defects in some application scenarios. this article explores common problems associated with laser welding machines and provides practical solutions. laser welding is a powerful technique, but improper handling can lead to issues. adjusting laser power, focal position, and. Laser Welding Issues.

From www.thefabricator.com

The evolution of laser welding technology Laser Welding Issues the main defects in laser welds in both steel and aluminium are solidification cracking (also called hot cracking or centreline. this article explores common problems associated with laser welding machines and provides practical solutions. For example, external defects can be found from the surface of the workpiece without the aid of instruments (such as cracks, pores, biting edges,. Laser Welding Issues.