Eddy Current Testing For Hardness . The eddy current method can be divided into two basic areas of application: Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. This tutorial covers the basics of eddy current testing,. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line.

from www.semanticscholar.org

Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. This tutorial covers the basics of eddy current testing,. The eddy current method can be divided into two basic areas of application: In eddy current testing, a current is introduced to the material.

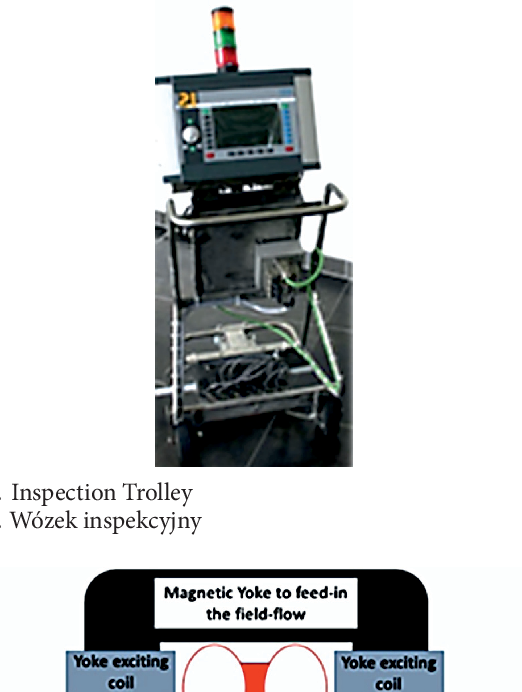

Figure 3 from Development and qualification of the EddyCurrent testing techniques “EC” and “EC+

Eddy Current Testing For Hardness Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. This tutorial covers the basics of eddy current testing,. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. The eddy current method can be divided into two basic areas of application: Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations.

From www.enggstudy.com

Eddy current testing Principle, Applications, Advantages, Limitations Eddy Current Testing For Hardness Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. This tutorial covers the basics of eddy current testing,. Eddy current for hardness testing calls for a solution that highlights irregularities on an. Eddy Current Testing For Hardness.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array) TWI Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. The eddy current method can be divided into two basic areas of application: Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy. Eddy Current Testing For Hardness.

From www.ndttester.com

Intelligent Eddy Current Testing Equipment HEC106 Metal Foil Resistivity Resistance Eddy Current Testing For Hardness Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Through the astute application of electromagnetic induction,. Eddy Current Testing For Hardness.

From blog.foerstergroup.com

Hardness testing The 7 largest challenges with eddy current systems Eddy Current Testing For Hardness Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how. Eddy Current Testing For Hardness.

From www.alibaba.com

Iso Portable Eddy Current Hardness Sorter For Testing Equipment Buy Eddy Current Hardness Eddy Current Testing For Hardness In eddy current testing, a current is introduced to the material. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Eddy current testing utilizes the principal of “electromagnetism” as the. Eddy Current Testing For Hardness.

From fyokaupvu.blob.core.windows.net

Eddy Current Hardness Testing at Francis Dupree blog Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. This tutorial covers the basics of eddy current testing,. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. The eddy current method can be divided into two basic areas of application: Learn. Eddy Current Testing For Hardness.

From www.tec-science.com

Eddy current testing (ECT) tecscience Eddy Current Testing For Hardness Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. In eddy current testing, a current is introduced to the material. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. This tutorial covers the basics of eddy current testing,. Through the astute. Eddy Current Testing For Hardness.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Eddy Current Testing For Hardness The eddy current method can be divided into two basic areas of application: In eddy current testing, a current is introduced to the material. This tutorial covers the basics of eddy current testing,. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how it can detect defects and measure. Eddy Current Testing For Hardness.

From www.hust.com.vn

Eddy Current Testing for Hardness, Case Depth & Material Verification Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. In eddy current testing, a current is introduced to the material. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. This tutorial covers the basics of eddy current testing,. The eddy current. Eddy Current Testing For Hardness.

From www.youtube.com

Eddy Current for hardness testing YouTube Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. The eddy current method can be divided into two basic areas of application: Learn how eddy current testing works, how it. Eddy Current Testing For Hardness.

From www.valencesurfacetech.com

Eddy Current Testing Methods Valence Surface Technologies Eddy Current Testing For Hardness The eddy current method can be divided into two basic areas of application: This tutorial covers the basics of eddy current testing,. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. In eddy current testing, a current is introduced to the material. Learn how eddy current testing works, how it can detect defects. Eddy Current Testing For Hardness.

From www.alibaba.com

Iso Portable Eddy Current Hardness Sorter For Testing Equipment Buy Eddy Current Hardness Eddy Current Testing For Hardness This tutorial covers the basics of eddy current testing,. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities on an. Eddy Current Testing For Hardness.

From www.youtube.com

CNC Eddy Current Testing Machine YouTube Eddy Current Testing For Hardness Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. In eddy current testing, a current is introduced to the material. Eddy current for hardness testing calls for a solution that highlights irregularities. Eddy Current Testing For Hardness.

From www.slideshare.net

Eddy current testing Eddy Current Testing For Hardness In eddy current testing, a current is introduced to the material. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Through the astute application of electromagnetic induction, eddy current testing empowers engineers. Eddy Current Testing For Hardness.

From www.hust.com.vn

Eddy Current Testing for Hardness, Case Depth & Material Verification Eddy Current Testing For Hardness Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers. Eddy Current Testing For Hardness.

From blog.foerstergroup.com

Hardness testing The 7 largest challenges with eddy current systems Eddy Current Testing For Hardness Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. The eddy current method can be divided into two basic areas of application: Through the astute application of electromagnetic induction, eddy. Eddy Current Testing For Hardness.

From 3anglesndt.com

How Eddy Current Testing Works 3angles Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. This tutorial covers the basics of eddy current testing,. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Eddy current testing utilizes the principal of “electromagnetism” as the basis for. Eddy Current Testing For Hardness.

From www.nde-solutions.com

Eddy Current Testing NDE Solutions Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. The eddy current method can be divided into two basic areas of application: In. Eddy Current Testing For Hardness.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. This tutorial covers the basics of eddy current testing,. The eddy current method can be divided into two basic areas of application: Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly. Eddy Current Testing For Hardness.

From ndtblog-us.fujifilm.com

Complete Guide to Eddy Current Testing Fujifilm NDT Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. Eddy current for hardness testing calls for a solution that highlights irregularities on an. Eddy Current Testing For Hardness.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Eddy Current Testing For Hardness This tutorial covers the basics of eddy current testing,. The eddy current method can be divided into two basic areas of application: In eddy current testing, a current is introduced to the material. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Learn how eddy current testing works, how it can detect defects. Eddy Current Testing For Hardness.

From www.onestopndt.com

Applications of Eddy Current Testing OnestopNDT Eddy Current Testing For Hardness Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current testing utilizes the principal of “electromagnetism” as the. Eddy Current Testing For Hardness.

From www.slideshare.net

Introduction_to_NDT Eddy Current Testing For Hardness This tutorial covers the basics of eddy current testing,. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes. Eddy Current Testing For Hardness.

From www.semanticscholar.org

Figure 3 from Development and qualification of the EddyCurrent testing techniques “EC” and “EC+ Eddy Current Testing For Hardness Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities. Eddy Current Testing For Hardness.

From engineersforum.com.ng

Eddy Current Testing Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. This tutorial covers the basics of eddy. Eddy Current Testing For Hardness.

From www.youtube.com

Eddy Current Solutions Hardness Testing YouTube Eddy Current Testing For Hardness The eddy current method can be divided into two basic areas of application: Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. In eddy current testing, a current is introduced to the material. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Learn how eddy current testing works,. Eddy Current Testing For Hardness.

From www.zetec.com

How to Use Eddy Current for Hardness Testing Zetec Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. In eddy current testing, a current is introduced to the material. The eddy current method can be divided into two basic areas of. Eddy Current Testing For Hardness.

From fyokaupvu.blob.core.windows.net

Eddy Current Hardness Testing at Francis Dupree blog Eddy Current Testing For Hardness Eddy current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. The eddy current method can be divided into two basic areas of application: Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic. Eddy Current Testing For Hardness.

From www.alibaba.com

Iso Portable Eddy Current Hardness Sorter For Testing Equipment Buy Eddy Current Hardness Eddy Current Testing For Hardness In eddy current testing, a current is introduced to the material. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. This tutorial covers the basics of eddy current testing,. Eddy. Eddy Current Testing For Hardness.

From www.engineersrail.com

Eddy Current Testing A Detailed Guide you are looking for Eddy Current Testing For Hardness Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. This tutorial covers the basics of eddy current testing,. Learn how eddy current testing works, how it can detect defects and. Eddy Current Testing For Hardness.

From www.alibaba.com

Iso Portable Eddy Current Hardness Sorter For Testing Equipment Buy Eddy Current Hardness Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. Learn how eddy current testing works, how it can detect defects and measure thickness in metals, and what types of probes are available. In eddy current testing, a current is introduced to the material. The eddy current. Eddy Current Testing For Hardness.

From www.youtube.com

NDT EDDY CURRENT CRACK & HARDNESS SORTING TEST SYSTEM YouTube Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. The eddy current method can be divided into two basic areas of application: This tutorial covers the basics of eddy current testing,. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly. Eddy Current Testing For Hardness.

From www.researchgate.net

(PDF) Eddy Current Testing Basics Eddy Current Testing For Hardness In eddy current testing, a current is introduced to the material. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. The eddy current method can be divided into two basic areas of application: This tutorial covers the basics of eddy current testing,. Eddy current testing utilizes the principal of “electromagnetism” as the basis. Eddy Current Testing For Hardness.

From www.ndttester.com

High Precision Eddy Current Testing Equipment Digital Eddy Current Conductivity Meter Eddy Current Testing For Hardness Through the astute application of electromagnetic induction, eddy current testing empowers engineers and inspectors to make critical determinations regarding the reliability of metal. In eddy current testing, a current is introduced to the material. The eddy current method can be divided into two basic areas of application: Eddy current for hardness testing calls for a solution that highlights irregularities on. Eddy Current Testing For Hardness.

From blog.foerstergroup.com

Hardness testing The 7 largest challenges with eddy current systems Eddy Current Testing For Hardness This tutorial covers the basics of eddy current testing,. In eddy current testing, a current is introduced to the material. Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. The eddy current method can be divided into two basic areas of application: Through the astute application of electromagnetic induction, eddy current testing empowers. Eddy Current Testing For Hardness.