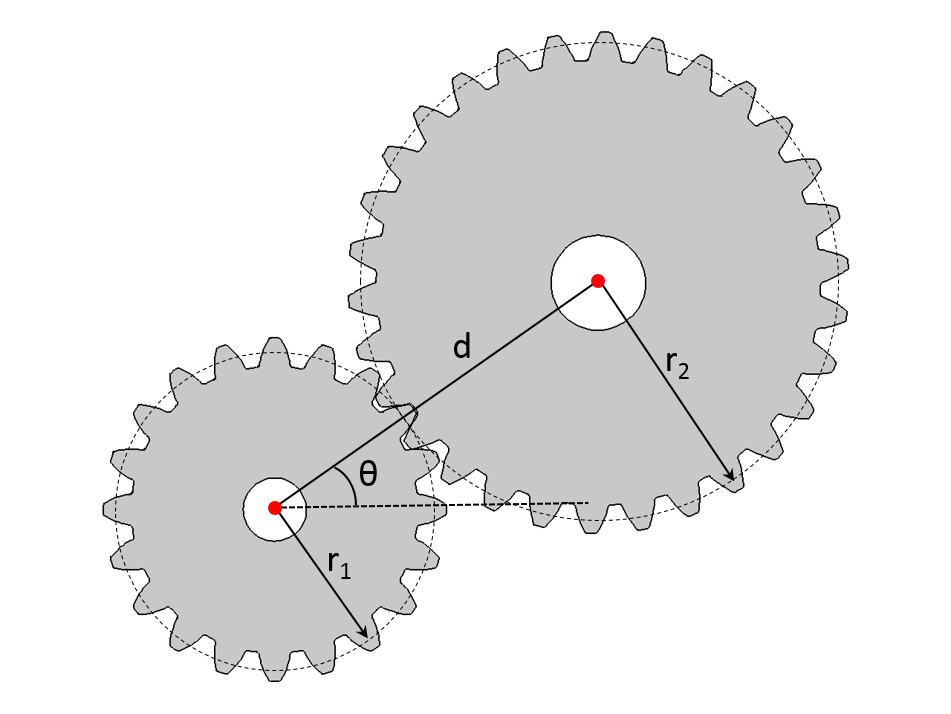

Gear Center Distance Tolerance . This is useful when mounting gears to. Finally, be careful of indiscriminately specifying a low center distance Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. This calculator provides the ideal distance between two the centers of two external spur gears. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Gearboxes is to vary the center distance tolerance by size. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. How do you find the distance between two gears?

from www.comsol.fr

Gearboxes is to vary the center distance tolerance by size. This is useful when mounting gears to. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. Finally, be careful of indiscriminately specifying a low center distance How do you find the distance between two gears? Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. This calculator provides the ideal distance between two the centers of two external spur gears. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters.

How to Build Gear Geometries in the Multibody Dynamics Module COMSOL Blog

Gear Center Distance Tolerance This is useful when mounting gears to. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Gearboxes is to vary the center distance tolerance by size. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Finally, be careful of indiscriminately specifying a low center distance This calculator provides the ideal distance between two the centers of two external spur gears. This is useful when mounting gears to. How do you find the distance between two gears? A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a.

From gioaoadkj.blob.core.windows.net

Spur Gear Center Distance Tolerance at Stephanie Newton blog Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Finally, be careful of indiscriminately specifying a low center distance Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half. Gear Center Distance Tolerance.

From www.eng-tips.com

Gear center distance question Drafting Standards, GD&T & Tolerance Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. How do you find the distance between two gears? Gearboxes is to vary the center distance tolerance by size. Center. Gear Center Distance Tolerance.

From www.eng-tips.com

Gear center distance question Drafting Standards, GD&T & Tolerance Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. How do you find the distance between two gears? A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. This is useful when mounting gears to. Gearboxes is to vary the center distance tolerance by size. Center distance = (pitch. Gear Center Distance Tolerance.

From khkgears.net

Gear Nomenclature KHK Gears Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. Finally, be careful of indiscriminately specifying a low center distance Total radial composite. Gear Center Distance Tolerance.

From www.researchgate.net

1 Ranges of typical center distance allowance and tolerance [1 Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. This calculator provides the ideal distance between two the centers of two external spur gears. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the. Gear Center Distance Tolerance.

From www.researchgate.net

Schematic diagram of gear center displacement Download Scientific Diagram Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Gearboxes is to vary the center distance tolerance by size. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center.. Gear Center Distance Tolerance.

From www.bearing-manufacturers.com

tolerance between shaft and bearing Gear Center Distance Tolerance This is useful when mounting gears to. This calculator provides the ideal distance between two the centers of two external spur gears. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a). Gear Center Distance Tolerance.

From www.school-mechademic.com

Composite Position tolerance in GD&T What is it? Gear Center Distance Tolerance How do you find the distance between two gears? Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. This. Gear Center Distance Tolerance.

From engineering.stackexchange.com

mechanical engineering Fixing center distance of worm gear Gear Center Distance Tolerance Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with. Gear Center Distance Tolerance.

From technofaq.org

Specifying Tolerance in Engineering Drawings Techno FAQ Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. This is useful when mounting gears to. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches,. Gear Center Distance Tolerance.

From www.piping-designer.com

Centertocenter Distance Gear Center Distance Tolerance How do you find the distance between two gears? Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. Gearboxes is to vary the center distance tolerance by size. This is useful when mounting gears to. A plus/minus. Gear Center Distance Tolerance.

From www.comsol.fr

How to Build Gear Geometries in the Multibody Dynamics Module COMSOL Blog Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with. Gear Center Distance Tolerance.

From paulbupejr.com

Wood Clock Gears with Motor Drive Part 1 of 3 Paul Bupe, Jr Gear Center Distance Tolerance Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. This is useful when mounting gears to. How do you find the distance between two gears? A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. This calculator provides the ideal distance between two. Gear Center Distance Tolerance.

From www.chegg.com

Solved Problem 2 (a) Determine the center distance of gears Gear Center Distance Tolerance A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. Finally, be careful of indiscriminately specifying a low center distance This is useful when mounting gears to. Gearboxes is to vary the center distance tolerance by size. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula. Gear Center Distance Tolerance.

From www.dimensionalconsulting.com

Tolerance Of Position Dimensional Consulting Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. This is useful when mounting gears to. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. How do you find the distance. Gear Center Distance Tolerance.

From mechanicalsphere.blogspot.com

Mechanical Minds GEAR TERMINOLOGY EXPLAINED Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. This calculator provides the ideal distance between two the centers of two external spur gears. Finally, be careful of indiscriminately specifying a low center distance Center distance and backlash when a pair of gears are. Gear Center Distance Tolerance.

From us.misumi-ec.com

Center to Center Spacing for Shafts with Spur Gears MISUMI Mech Lab Blog Gear Center Distance Tolerance Finally, be careful of indiscriminately specifying a low center distance Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. Gearboxes is to vary the center distance tolerance by size. Center distance = (pitch diameter of gear a. Gear Center Distance Tolerance.

From gioaoadkj.blob.core.windows.net

Spur Gear Center Distance Tolerance at Stephanie Newton blog Gear Center Distance Tolerance Finally, be careful of indiscriminately specifying a low center distance How do you find the distance between two gears? For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. This calculator provides the ideal distance between two the centers of two external spur gears. Center. Gear Center Distance Tolerance.

From www.researchgate.net

The tolerance specification results of the cycloidal gear on the Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. This calculator provides the ideal distance between two the centers of two external spur gears. How do you find the distance between two gears? This is useful when mounting gears to. Center distance = (pitch. Gear Center Distance Tolerance.

From www.smlease.com

GD&T Basics Introduction to Geometric Dimension and Tolerance Gear Center Distance Tolerance This is useful when mounting gears to. This calculator provides the ideal distance between two the centers of two external spur gears. Gearboxes is to vary the center distance tolerance by size. How do you find the distance between two gears? Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh. Gear Center Distance Tolerance.

From www.chegg.com

Solved 3. A Vbelt drive operates on two sheaves having Gear Center Distance Tolerance How do you find the distance between two gears? Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Gearboxes is to vary the center distance tolerance by size. This is useful when mounting gears to. This calculator provides the ideal distance between two the. Gear Center Distance Tolerance.

From www.geartechnology.com

The Basics of Gear Theory Gear Technology Magazine Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. How do you. Gear Center Distance Tolerance.

From www.youtube.com

How to measure Gear Backlash and Center Distance YouTube Gear Center Distance Tolerance Gearboxes is to vary the center distance tolerance by size. Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Center distance and backlash. Gear Center Distance Tolerance.

From www.youtube.com

Gear How to calculate center distance Center distance between Gear Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. How do you find the distance between two gears? This calculator provides the ideal distance between two the centers of two external spur gears. Total radial composite deviation represents variation in center distance when product. Gear Center Distance Tolerance.

From www.gdandtbasics.com

True Position Position Tolerance GD&T Basics Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Gearboxes is to vary the center distance tolerance by size.. Gear Center Distance Tolerance.

From www.mechanicdrive.com

Spur gear calculation Gear Center Distance Tolerance This calculator provides the ideal distance between two the centers of two external spur gears. How do you find the distance between two gears? Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. This is useful when. Gear Center Distance Tolerance.

From www.researchgate.net

Ring gear with tolerance specifications [12]. Download Scientific Diagram Gear Center Distance Tolerance Gearboxes is to vary the center distance tolerance by size. Finally, be careful of indiscriminately specifying a low center distance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Total radial composite deviation represents variation in center distance when product gear is rotated one. Gear Center Distance Tolerance.

From cr4.globalspec.com

Gear Confusion CR4 Discussion Thread Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Finally, be careful of indiscriminately specifying a low center distance Gearboxes is to vary the center distance tolerance by size. How do you find the distance between two gears? Center distance = (pitch diameter of. Gear Center Distance Tolerance.

From www.mdpi.com

Sensors Free FullText Gear Shape Measurement Potential of Laser Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. Center distance and backlash when a pair of gears are meshed so that their reference circles are in contact, the center distance (a) is half the sum total of their reference diameters. Finally, be careful. Gear Center Distance Tolerance.

From ar.inspiredpencil.com

Simple Gear Sketch Gear Center Distance Tolerance Total radial composite deviation represents variation in center distance when product gear is rotated one revolution in tight mesh with a. How do you find the distance between two gears? For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Center distance and backlash when. Gear Center Distance Tolerance.

From gioaoadkj.blob.core.windows.net

Spur Gear Center Distance Tolerance at Stephanie Newton blog Gear Center Distance Tolerance This is useful when mounting gears to. How do you find the distance between two gears? This calculator provides the ideal distance between two the centers of two external spur gears. Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. A plus/minus tolerance of.0010. Gear Center Distance Tolerance.

From www.researchgate.net

Analysis of gear profile tolerance measuring protocol Download Gear Center Distance Tolerance How do you find the distance between two gears? This calculator provides the ideal distance between two the centers of two external spur gears. This is useful when mounting gears to. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. A plus/minus tolerance of.0010. Gear Center Distance Tolerance.

From www.tec-science.com

Engaging of involute gears (meshing) tecscience Gear Center Distance Tolerance A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Finally, be careful of indiscriminately specifying a low center distance Center distance = (pitch diameter of gear a + pitch. Gear Center Distance Tolerance.

From americanbobcat.blog

MECHANICAL DESIGN ENGINEERING Geometrical Dimensioning and Gear Center Distance Tolerance For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. This is useful when mounting gears to. A plus/minus tolerance of.0010 is used for centers from 1.5 to 4.0 inches, with an. Gearboxes is to vary the center distance tolerance by size. This calculator provides. Gear Center Distance Tolerance.

From www.spiroidgearing.com

Design High Torque Gearbox FAQ Gear Center Distance Tolerance Center distance = (pitch diameter of gear a + pitch diameter of gear b) / 2 this formula calculates the nominal value of the center. For an average application, fine pitched gears could have a +0.002 inch center distance tolerance and coarse pitched gears could go up to +.005 inches. Center distance and backlash when a pair of gears are. Gear Center Distance Tolerance.