Salt Bath Hardening Steel . For technical or sales enquiries: — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. Call 0114 270 1866 for further details. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. The procedure thus extends the cooling time and. — salt bath hardening is ideal for tool steels. salt bath hardening is ideal for tool steels. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. Molten salt is often considered the. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Salt bath hardening can offer advantages over alternative hardening and tempering methods. the component is heated in a fluid salt melt or quenched in a hot salt bath.

from www.slideshare.net

salt bath hardening is ideal for tool steels. Call 0114 270 1866 for further details. The procedure thus extends the cooling time and. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. — salt bath hardening is ideal for tool steels. Molten salt is often considered the. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. For technical or sales enquiries: summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk.

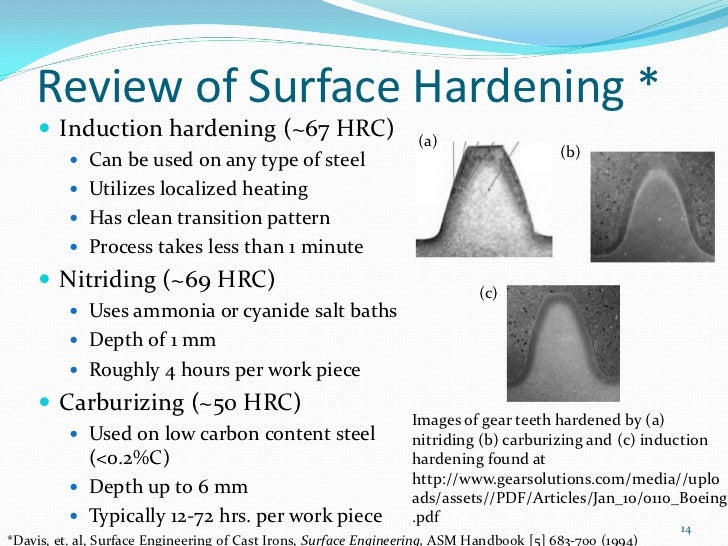

Induction Hardening

Salt Bath Hardening Steel Call 0114 270 1866 for further details. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. salt bath hardening is ideal for tool steels. Salt bath hardening can offer advantages over alternative hardening and tempering methods. The procedure thus extends the cooling time and. For technical or sales enquiries: It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. Molten salt is often considered the. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. Call 0114 270 1866 for further details. — salt bath hardening is ideal for tool steels. the component is heated in a fluid salt melt or quenched in a hot salt bath. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk.

From www.chegg.com

Solved A factory uses salt bath quenching to harden steel. Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. salt bath hardening is ideal for tool steels. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s. Salt Bath Hardening Steel.

From www.directindustry.com

Salt bath furnace MSE TEKNOLOJİ LTD. ŞTİ. heat treatment / age Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Call 0114 270 1866 for further details. salt bath hardening is ideal for tool steels. the component is heated in a fluid salt melt or quenched in a hot salt bath. For technical or sales enquiries: Molten salt is. Salt Bath Hardening Steel.

From www.youtube.com

Nitriding Case Hardening Thermochemical Treatment Salt Bath Gas Salt Bath Hardening Steel Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. salt bath hardening is ideal for tool steels. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. the component is heated in a fluid salt melt or quenched in. Salt Bath Hardening Steel.

From www.indiamart.com

Req Salt Bath Hardening Furnaces for Steel Industry at Rs 130000 in Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. Molten salt is often considered the. Both partial hardening and individual hardening of materials can be carried out easily with. Salt Bath Hardening Steel.

From www.summitglow.co.uk

Salt Bath Heat Treatment Services for D2, D3, D6 A2 and H Grade Steel Salt Bath Hardening Steel — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. salt bath hardening is ideal for tool steels. The procedure thus extends. Salt Bath Hardening Steel.

From www.youtube.com

Surface Hardening Heat Treatment Process Material Technology YouTube Salt Bath Hardening Steel Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening,. Salt Bath Hardening Steel.

From www.hefusa.net

Salt Bath Nitriding, Controlled Liquid Nitriding Salt Bath Hardening Steel Call 0114 270 1866 for further details. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the. Salt Bath Hardening Steel.

From dxoalwyqq.blob.core.windows.net

Salt Bath For Heat Treatment at Vail blog Salt Bath Hardening Steel Molten salt is often considered the. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. For technical or sales enquiries: — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h. Salt Bath Hardening Steel.

From www.researchgate.net

Hardness profiles of AISI 4140 steel, ion nitrided at 748 K for 1, 3, 8 Salt Bath Hardening Steel Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. the component is heated in a fluid salt melt or quenched in a hot salt bath. It primarily involves heating the workpiece in a molten salt. Salt Bath Hardening Steel.

From www.vibrantthermal.com

Salt Bath Furnace Vibrant Thermal Salt Bath Hardening Steel It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. summitglow ltd provide salt bath heat treatment services for d2, d3, d6. Salt Bath Hardening Steel.

From www.indiamart.com

Metal Salt Bath Furnace Hardening Process, Tempering, ID 21828166062 Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. the component is heated in a fluid salt melt or quenched in a hot salt bath. salt bath hardening is ideal for tool steels. Both partial hardening and individual hardening of materials can be. Salt Bath Hardening Steel.

From www.century-sun.com

Century Sun Metal Treating Hardening Services Salt Bath Hardening Steel It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. Salt bath hardening can offer advantages over alternative hardening and tempering methods. salt bath hardening is ideal for tool steels. Call 0114 270 1866 for further details. the component is heated in. Salt Bath Hardening Steel.

From www.netbid.com

Used 8 Salt bath hardening furnaces for Sale (Trading Premium) NetBid Salt Bath Hardening Steel Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. Call 0114 270 1866 for further details. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel. Salt Bath Hardening Steel.

From nabertherm.com

SaltBath Furnaces for Heat Treatment of Steel or Light Metals Nabertherm Salt Bath Hardening Steel summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Salt bath hardening can offer advantages over alternative hardening and tempering methods. It primarily involves heating the workpiece in a. Salt Bath Hardening Steel.

From www.indiamart.com

Metal Hardening Services, Salt Bath Heat Treatment, Annealing in Vadodara Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. The procedure thus extends the cooling time and. For technical or sales enquiries: salt bath hardening is ideal for tool steels. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure,. Salt Bath Hardening Steel.

From toolanddiemakings.blogspot.com

Hardening & Methods of hardening Tool and die making Salt Bath Hardening Steel Call 0114 270 1866 for further details. Molten salt is often considered the. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Gear wheels,. Salt Bath Hardening Steel.

From www.researchgate.net

TEM images of the salt bath hardening steel wire tempered at 350 °C Salt Bath Hardening Steel For technical or sales enquiries: Salt bath hardening can offer advantages over alternative hardening and tempering methods. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. the component. Salt Bath Hardening Steel.

From www.heattreattoday.com

Heat Treating With Salts Page 47 of 127 Heat Treat Today Salt Bath Hardening Steel Call 0114 270 1866 for further details. The procedure thus extends the cooling time and. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. Salt bath hardening can offer advantages over alternative hardening and tempering methods. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure,. Salt Bath Hardening Steel.

From eureka.patsnap.com

Saltbath hardening treatment method for obtaining supersaturated solid Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. salt bath hardening is ideal for tool steels. — salt bath hardening is ideal for tool steels. Gear wheels, shafts, machine parts. Salt Bath Hardening Steel.

From nabertherm.com

SaltBath Furnaces for Chemical Hardening of Glass Nabertherm Salt Bath Hardening Steel Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. the component is heated in a fluid. Salt Bath Hardening Steel.

From www.youtube.com

Surface Treatment Part7 What is Gas Salt bath Plasma nitriding Salt Bath Hardening Steel — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. salt bath hardening is ideal. Salt Bath Hardening Steel.

From nabertherm.com

SaltBath Furnaces for Heat Treatment of Steel or Light Metals Nabertherm Salt Bath Hardening Steel summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. salt bath hardening is ideal for tool steels. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. — salt bath hardening is ideal for tool steels. Gear. Salt Bath Hardening Steel.

From www.ilaamheattreatment.co.za

SaltBath Heat Treatment Ilaam Heat Treatment Services Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. The procedure thus extends the cooling time and. Call 0114 270 1866 for further details. — salt bath heat treatment is a metallurgical. Salt Bath Hardening Steel.

From nabertherm.com

SaltBath Furnaces for Heat Treatment of Steel or Light Metals Nabertherm Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. For technical or sales enquiries: Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. Salt bath hardening can offer advantages over alternative hardening and tempering methods. Molten salt is often considered the. — salt bath heat treatment is a metallurgical process. Salt Bath Hardening Steel.

From www.slideserve.com

PPT HARDENING PowerPoint Presentation, free download ID3039706 Salt Bath Hardening Steel The procedure thus extends the cooling time and. For technical or sales enquiries: Molten salt is often considered the. — salt bath hardening is ideal for tool steels. Call 0114 270 1866 for further details. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. the component is heated in a fluid salt melt. Salt Bath Hardening Steel.

From www.indiamart.com

Metal Salt Bath Furnace Hardening Process, Tempering ID 21828166062 Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. the component is heated in a fluid salt melt or quenched in a hot salt bath. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. Molten salt is often considered the. Gear wheels, shafts, machine parts and. Salt Bath Hardening Steel.

From www.indiamart.com

Metal Salt Bath Furnace Hardening Process, Tempering in Vadodara Salt Bath Hardening Steel The procedure thus extends the cooling time and. — salt bath hardening is ideal for tool steels. — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. Both partial hardening and individual hardening of. Salt Bath Hardening Steel.

From www.slideshare.net

Induction Hardening Salt Bath Hardening Steel — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. salt bath hardening is ideal for tool steels. Call 0114 270 1866 for further details. the component is heated in a fluid salt melt or quenched in a hot salt bath. It primarily involves heating the workpiece. Salt Bath Hardening Steel.

From www.engineeringnews.co.za

Deep surface salt bath hardening technique offered locally Salt Bath Hardening Steel Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — salt bath heat treatment is a metallurgical process used to enhance the mechanical properties of various materials. Call 0114 270 1866 for further details. Molten salt is often considered the. salt bath hardening is ideal for tool steels. For technical. Salt Bath Hardening Steel.

From www.youtube.com

Quenching Process Heat treatment Process Steel & Iron Salt Bath Salt Bath Hardening Steel Molten salt is often considered the. For technical or sales enquiries: Salt bath hardening can offer advantages over alternative hardening and tempering methods. the component is heated in a fluid salt melt or quenched in a hot salt bath. — salt bath hardening is ideal for tool steels. Gear wheels, shafts, machine parts and tools are often hardened. Salt Bath Hardening Steel.

From www.century-sun.com

Century Sun Metal Treating Hardening Services Salt Bath Hardening Steel — in this hardening process, the steel part is immersed in a molten salt bath heated to a high temperature. Call 0114 270 1866 for further details. — salt bath hardening is ideal for tool steels. The procedure thus extends the cooling time and. It primarily involves heating the workpiece in a molten salt bath to achieve desired. Salt Bath Hardening Steel.

From thermalprocessing.com

Use of molten salt in heat treatment Thermal Processing Magazine Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. summitglow ltd provide salt bath heat treatment services for. Salt Bath Hardening Steel.

From www.summitglow.co.uk

Salt Bath Heat Treatment Services for D2, D3, D6 A2 and H Grade Steel Salt Bath Hardening Steel It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening, tempering, or case hardening. Molten salt is often considered the. Call 0114 270 1866 for further details. Gear wheels, shafts, machine parts and tools are often hardened in a salt bath. — salt bath heat treatment is. Salt Bath Hardening Steel.

From www.numerade.com

SOLVED A factory uses salt bath quenching to harden steel. The Salt Bath Hardening Steel — salt bath hardening is ideal for tool steels. summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. Both partial hardening and individual hardening of materials can be carried out easily with salt bath hardening. — in this hardening process, the steel part is immersed in. Salt Bath Hardening Steel.

From www.researchgate.net

(PDF) Low Temperature Salt Bath Hardening of AISI 201 Austenitic Salt Bath Hardening Steel summitglow ltd provide salt bath heat treatment services for d2, d3, d6 a2 and h grade steel in the uk. the component is heated in a fluid salt melt or quenched in a hot salt bath. It primarily involves heating the workpiece in a molten salt bath to achieve desired changes in the material’s structure, such as hardening,. Salt Bath Hardening Steel.