Casting Mould Foundry . Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The metal then cools and hardens into the form given to it by this shaped mold. Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. The mould is therefore essentially a die.

from www.alamy.com

Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The metal then cools and hardens into the form given to it by this shaped mold. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. The mould is therefore essentially a die. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. This series follows a cast iron or steel product through the metal casting process in a traditional foundry.

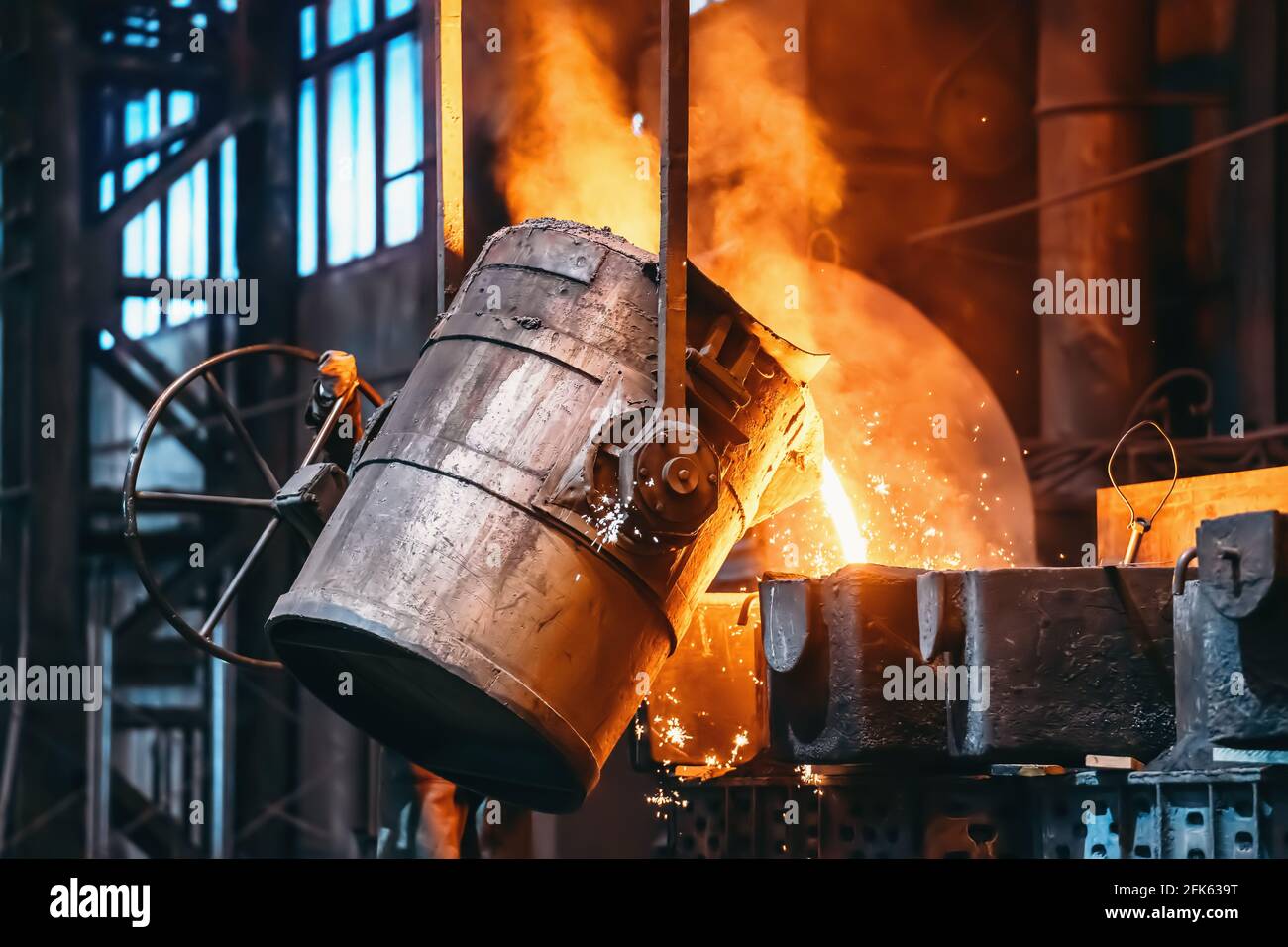

Metal casting process in foundry, liquid metal pouring from container

Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. The mould is therefore essentially a die. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. The metal then cools and hardens into the form given to it by this shaped mold. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. Iron melts at 2750°f and. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. This series follows a cast iron or steel product through the metal casting process in a traditional foundry.

From www.onallcylinders.com

Cast System An Inside Look at Edelbrock's Foundry and Casting Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The metal then cools and hardens into the form given to it by this shaped mold. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern,. Casting Mould Foundry.

From www.jamaicaplainnews.com

Mold Making and Metal CastingJamaica Plain News Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Casting is often a less expensive way to manufacture a piece compared with. Casting Mould Foundry.

From www.luenseng.com.my

Foundry Casting Sand Mould Foundry Casting Ipoh, Perak, Malaysia Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. Iron melts at 2750°f and. The mould is therefore essentially a die. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern. Casting Mould Foundry.

From www.dreamstime.com

Molten Metal Pour from Ladle into Sand Mold. Iron Casting Process in Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The mould is therefore essentially a die. Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a. Casting Mould Foundry.

From www.mfl.at

MFL The shell makes the differenc, Shell moulding process Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Iron melts at 2750°f and. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of. Casting Mould Foundry.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Casting Mould Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold. Casting Mould Foundry.

From www.reliance-foundry.com

The Metal Casting Process Take a Foundry Tour Reliance Foundry Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Iron melts at 2750°f and. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this. Casting Mould Foundry.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly. Casting Mould Foundry.

From www.weld2cast.com

Sand Casting Weld2Cast Casting Mould Foundry The mould is therefore essentially a die. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. Foundry pattern making is the process of designing and creating a. Casting Mould Foundry.

From www.reliance-foundry.com

Cast Steel Production Metal Casting Blog Casting Mould Foundry The mould is therefore essentially a die. Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. The metal then cools and hardens into the form given to it by this shaped mold. Whether the casting solidifies incorrectly, a misplaced or missing. Casting Mould Foundry.

From precisecast.com

Aluminum Casting Company American Foundry Rapid Prototyping Casting Mould Foundry The mould is therefore essentially a die. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Cast iron foundries essentially use silica sands to make the mould in which the. Casting Mould Foundry.

From www.steel-foundry.com

Grey Iron & Ductile Iron Shell Mold Casting Foundry Cast Iron Casting Casting Mould Foundry Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid. Casting Mould Foundry.

From www.1stdibs.com

1960’s Very Large Industrial Casting Foundry Mould 'Mould 1080' For Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. The mould is therefore essentially a die. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Cast iron foundries essentially use silica sands to make. Casting Mould Foundry.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Casting Mould Foundry The metal then cools and hardens into the form given to it by this shaped mold. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of. Casting Mould Foundry.

From www.patriotfoundry.com

Foundry Sand Casting Process Simple Step by Step Patriot Foundry Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. The metal then. Casting Mould Foundry.

From www.dla.mil

Casting Mold Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. Iron melts at 2750°f and. The mould is therefore essentially a die. The metal then cools and hardens into the form given to it by this shaped mold. This series follows. Casting Mould Foundry.

From www.1stdibs.com

1960’s Very Large Industrial Casting Foundry Mould 'Mould 1080' For Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. Cast iron foundries essentially use silica sands to make the mould in which the casting. Casting Mould Foundry.

From 5ab48851d99b177d.en.made-in-china.com

Cast Aluminum High Speed Rail Chassis Sand Mold Cope & Drag Casting Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this shaped mold. The mould is therefore essentially a die. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern. Casting Mould Foundry.

From dakotafoundry.com

Capabilities at Dakota Foundry Grey Iron & Ductile Iron Castings Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold. Casting Mould Foundry.

From stock.adobe.com

Molten metal casting in foundry. Filling mold with hot liquid iron and Casting Mould Foundry Iron melts at 2750°f and. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big. Casting Mould Foundry.

From studentlesson.com

Understanding foundry and casting process studentlesson Casting Mould Foundry The metal then cools and hardens into the form given to it by this shaped mold. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. This series follows a cast iron or steel product through the metal casting process in. Casting Mould Foundry.

From diecastor.com

Permanent Mold Casting Process; Material and Application. Casting Mould Foundry The metal then cools and hardens into the form given to it by this shaped mold. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. The mould. Casting Mould Foundry.

From www.onallcylinders.com

Cast System An Inside Look at Edelbrock's Foundry and Casting Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this shaped mold. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Cast iron foundries. Casting Mould Foundry.

From www.steel-foundry.com

Cast Iron and Steel Foundry by Investment Casting and Sand Casting Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting.. Casting Mould Foundry.

From www.xncasting.com

Foundry moulding machine manufacturers Fully automatic moulding Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The mould is therefore essentially a die. The. Casting Mould Foundry.

From www.leclairemfg.com

Permanent Mold Casting Photos LeClaire Manufacturing Co. Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. Iron melts at 2750°f and. The metal then cools and hardens into the form given to it by this shaped mold. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks,. Casting Mould Foundry.

From www.savimetal.com

Moulding shop Services cast products for industry foundry Casting Mould Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Iron melts at 2750°f and. This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this shaped mold.. Casting Mould Foundry.

From batesvilleproducts.com

Permanent Mold Casting Process Batesville Products (800) 7582372 Casting Mould Foundry Foundry pattern making is the process of designing and creating a mold pattern, casting pattern, or sand casting pattern if sand. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold. Casting Mould Foundry.

From www.dreamstime.com

Foundry, Sand Molded Casting Stock Photo Image of aluminium, cast Casting Mould Foundry The mould is therefore essentially a die. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. The metal then cools and hardens into the form given to it by this shaped mold. Iron melts at 2750°f and. Foundry pattern making. Casting Mould Foundry.

From www.patriotfoundry.com

Foundry Sand Casting Process Simple Step by Step Patriot Foundry Casting Mould Foundry Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Iron melts at 2750°f and. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. Foundry pattern making is the process of designing and. Casting Mould Foundry.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Casting Mould Foundry Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a small design change can have big repercussions on the accuracy of a mold and its casting. Casting is often a less expensive way to manufacture a piece compared with machining the part out of. Casting Mould Foundry.

From www.reliance-foundry.com

Metal Melting and Pouring Life of a Casting Reliance Foundry Casting Mould Foundry Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores to allow castings with complex geometries, with internal cavities. Iron melts at 2750°f and. Whether the casting solidifies incorrectly, a misplaced or missing riser causes a defect, or the mold cools too quickly and cracks, what may seem like a. Casting Mould Foundry.

From www.1stdibs.com

1960’s Very Large Industrial Casting Foundry Mould 'Mould 1080' For Casting Mould Foundry The metal then cools and hardens into the form given to it by this shaped mold. Iron melts at 2750°f and. The mould is therefore essentially a die. Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Metal casting is the process of making objects by. Casting Mould Foundry.

From reliance-foundry.com

Sand Casting Metal Casting Resources Casting Mould Foundry Casting is often a less expensive way to manufacture a piece compared with machining the part out of a piece of solid metal. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Cast iron foundries essentially use silica sands to make the mould in which the casting will be poured, and cores. Casting Mould Foundry.

From www.steel-foundry.com

Grey Iron & Ductile Iron Shell Mold Casting Foundry Cast Iron Casting Casting Mould Foundry This series follows a cast iron or steel product through the metal casting process in a traditional foundry. The metal then cools and hardens into the form given to it by this shaped mold. Metal casting is the process of making objects by pouring molten metal into an empty shaped space. Casting is often a less expensive way to manufacture. Casting Mould Foundry.