Die Casting And Injection Moulding Similarities . Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? By looking at die casting vs. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Die casting requires a high injection pressure. There is a big difference in the compatible materials you can use. In this article, we will explore the similarities and differences. Here are some primary differences between die casting vs. Injection moulding primarily deals with plastic material. Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Injection molding, we can help you make informed decisions when making new products. So, let’s dig deeper into each process and look at die casting advantages and disadvantages.

from www.moulds.asia

In this article, we will explore the similarities and differences. Here are some primary differences between die casting vs. There is a big difference in the compatible materials you can use. Injection moulding primarily deals with plastic material. Injection molding, we can help you make informed decisions when making new products. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. By looking at die casting vs. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project?

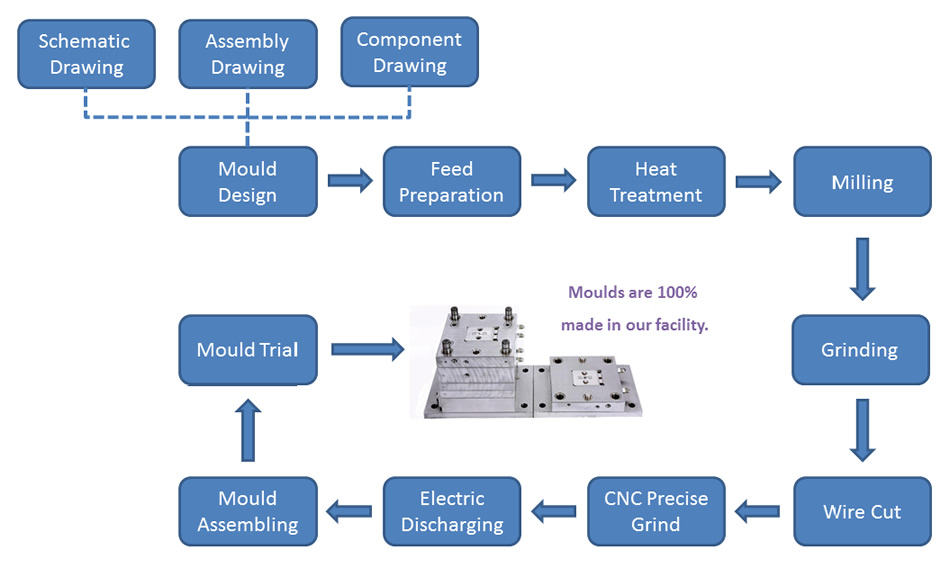

Plastic injection Molding Tooling & Die Manufacturer MINGLI

Die Casting And Injection Moulding Similarities Injection molding, we can help you make informed decisions when making new products. Die casting requires a high injection pressure. Injection molding, we can help you make informed decisions when making new products. Here are some primary differences between die casting vs. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Injection moulding primarily deals with plastic material. By looking at die casting vs. There is a big difference in the compatible materials you can use. In this article, we will explore the similarities and differences. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder.

From techsavvy.co.in

Sole Guide about PLASTIC INJECTION MOLDS TechSavvy Engineers Die Casting And Injection Moulding Similarities Injection moulding primarily deals with plastic material. By looking at die casting vs. Die casting requires a high injection pressure. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Injection. Die Casting And Injection Moulding Similarities.

From www.raymont-osman.com

What are Injection Moulding Tooling Loops? Die Casting And Injection Moulding Similarities Here are some primary differences between die casting vs. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. In this article, we will explore the similarities and differences. Die casting. Die Casting And Injection Moulding Similarities.

From www.teamrapidtooling.com

Die Casting vs. Injection Molding Differences and Benefits Die Casting And Injection Moulding Similarities By looking at die casting vs. Die casting requires a high injection pressure. Injection moulding primarily deals with plastic material. In this article, we will explore the similarities and differences. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Die casting uses molten metal to. Die Casting And Injection Moulding Similarities.

From www.zcmim.com

Metal Injection Molding vs Die Casting MIM vs Die Casting ZCMIM Die Casting And Injection Moulding Similarities Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Injection molding, we can help you make informed decisions when making new products. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. In this article, we will explore the. Die Casting And Injection Moulding Similarities.

From www.compass-anvil.com

Die Casting vs. Injection Molding Compass & Anvil Die Casting And Injection Moulding Similarities There is a big difference in the compatible materials you can use. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? In this article, we will explore the similarities and differences. Injection moulding primarily deals with plastic material. Die casting uses molten metal to create larger. Die Casting And Injection Moulding Similarities.

From www.teamrapidtooling.com

Differences Between Die Casting & Injection Moulding Die Casting And Injection Moulding Similarities Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Injection molding, we can help you make informed decisions when making new products. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. By looking at die casting vs. In this. Die Casting And Injection Moulding Similarities.

From www.sunrise-metal.com

Die Casting vs Injection Molding, What's the Difference? Die Casting And Injection Moulding Similarities Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Here are some primary differences between die casting vs. Injection moulding primarily deals with plastic material. By looking at die casting vs. Die casting requires a high injection pressure. So, let’s dig deeper into each process. Die Casting And Injection Moulding Similarities.

From exoyycojy.blob.core.windows.net

Injection Moulding And Die Casting Difference at Everett Gayle blog Die Casting And Injection Moulding Similarities Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. In this article, we will explore the similarities and differences. Injection moulding primarily deals with plastic material. Die casting requires a high injection pressure. By looking at die casting vs. So, let’s dig deeper into each process and look. Die Casting And Injection Moulding Similarities.

From integratedsol.co.in

What is the difference between die casting & injection molding Die Casting And Injection Moulding Similarities In this article, we will explore the similarities and differences. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Die casting requires a high injection pressure. Injection molding, we can help you. Die Casting And Injection Moulding Similarities.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Die Casting And Injection Moulding Similarities Injection moulding primarily deals with plastic material. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Although the end products of injection molding and die casting are similar, the two processes. Die Casting And Injection Moulding Similarities.

From www.zeal3dprinting.com.au

A Comparison Injection Moulding vs. Vacuum Casting Die Casting And Injection Moulding Similarities Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Injection molding, we can help you make informed decisions when making new products. Injection moulding. Die Casting And Injection Moulding Similarities.

From www.kemalmfg.com

Injection Molding vs. DieCasting Differences and Comparison Kemal Die Casting And Injection Moulding Similarities Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. There is a big difference in the compatible materials you can use. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Here are some. Die Casting And Injection Moulding Similarities.

From www.rapiddirect.com

Die Casting vs Injection Molding A Detailed Comparison rapiddirect Die Casting And Injection Moulding Similarities There is a big difference in the compatible materials you can use. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. Injection molding. Die Casting And Injection Moulding Similarities.

From www.zetwerk.com

What's the difference between Die Casting vs Injection Molding Zetwerk Die Casting And Injection Moulding Similarities In this article, we will explore the similarities and differences. Injection moulding primarily deals with plastic material. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. By looking at die casting vs. Here are some primary differences between die casting vs. Die casting requires a. Die Casting And Injection Moulding Similarities.

From www.kemalmfg.com

Injection Molding vs. DieCasting Differences and Comparison Kemal Die Casting And Injection Moulding Similarities By looking at die casting vs. There is a big difference in the compatible materials you can use. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Injection molding involves. Die Casting And Injection Moulding Similarities.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Die Casting And Injection Moulding Similarities So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Here are some primary differences between die casting vs. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. By looking at die casting vs. Both processes use molten metal or plastic. Die Casting And Injection Moulding Similarities.

From www.alpinemold.com

Injection Molding VS Die Casting, what is difference? Alpine Mold Die Casting And Injection Moulding Similarities Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? There is a big difference in the compatible materials you can use. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. Injection molding. Die Casting And Injection Moulding Similarities.

From best-diecasting.com

Plastic Injection Molding Custom Die Casting Die Casting And Injection Moulding Similarities In this article, we will explore the similarities and differences. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Injection molding involves injecting molten material into a mold under high pressure and. Die Casting And Injection Moulding Similarities.

From prototool.com

Die Casting Vs Injection Molding The Most Comprehensive Comparison Die Casting And Injection Moulding Similarities Die casting requires a high injection pressure. Here are some primary differences between die casting vs. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. There is a big difference in the compatible materials you can use. Injection moulding primarily deals with plastic material. Injection molding. Die Casting And Injection Moulding Similarities.

From hlhrapid.com

Die Casting vs Injection Moulding Mould Tooling Techniques Die Casting And Injection Moulding Similarities Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Die casting requires a high injection pressure. Injection molding, we can help you make informed decisions when making new products. By looking at die casting vs. Die casting involves forcing molten metal into a mold cavity. Die Casting And Injection Moulding Similarities.

From hlhrapid.com

Die Casting vs Injection Moulding Mould Tooling Techniques Die Casting And Injection Moulding Similarities Injection moulding primarily deals with plastic material. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. In this article, we will explore the similarities and differences. There is a big difference in the compatible materials you can use. Die casting requires a high injection pressure.. Die Casting And Injection Moulding Similarities.

From www.teamrapidtooling.com

Differences Between Die Casting & Injection Moulding Die Casting And Injection Moulding Similarities Injection moulding primarily deals with plastic material. Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. In this article, we will explore the similarities and differences. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from. Die Casting And Injection Moulding Similarities.

From richfieldsplastics.com

Plastic Injection Molding Or Die Casting? Richfields Blog Die Casting And Injection Moulding Similarities Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? In this article, we will explore the similarities and differences. Die casting involves forcing molten metal into a mold cavity under. Die Casting And Injection Moulding Similarities.

From www.kemalmfg.com

Injection Molding vs. DieCasting Differences and Comparison Kemal Die Casting And Injection Moulding Similarities Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Die casting requires a high injection pressure. There is a big difference in the compatible. Die Casting And Injection Moulding Similarities.

From assemblean.com

Injection Molding and Die Casting What is the difference? assemblean Die Casting And Injection Moulding Similarities Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number of critical ways. Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. There is a big difference in the compatible materials you can use. So,. Die Casting And Injection Moulding Similarities.

From www.acemold.ru

Difference Between Die Casting and Injection Moulding Explained Die Casting And Injection Moulding Similarities Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Die casting uses molten metal to. Die Casting And Injection Moulding Similarities.

From www.kemalmfg.com

Injection Molding vs. DieCasting Differences and Comparison Kemal Die Casting And Injection Moulding Similarities So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Here are some primary differences between die casting vs. Injection molding, we can help you make informed decisions when making new products. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project?. Die Casting And Injection Moulding Similarities.

From blog.thepipingmart.com

Die Casting vs Mold Casting What's the Difference Die Casting And Injection Moulding Similarities There is a big difference in the compatible materials you can use. Injection moulding primarily deals with plastic material. Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Although the end products of injection molding and die casting are similar, the two processes are vastly different in a. Die Casting And Injection Moulding Similarities.

From www.alpinemold.com

Injection Molding VS Die Casting, what is difference? Alpine Mold Die Casting And Injection Moulding Similarities Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part.. Die Casting And Injection Moulding Similarities.

From en.wikipedia.org

Injection moulding Wikipedia Die Casting And Injection Moulding Similarities Die casting involves forcing molten metal into a mold cavity under high pressure, while injection molding uses molten material injected into a mold. In this article, we will explore the similarities and differences. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Both processes use. Die Casting And Injection Moulding Similarities.

From www.dymold.com

China Professinal injection mold and die casting Die Casting And Injection Moulding Similarities Die casting uses molten metal to create larger parts, while metal injection molding (mim) forms small, detailed parts from metal powder. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. In this article, we will explore the similarities and differences. There is a big difference. Die Casting And Injection Moulding Similarities.

From www.moulds.asia

Plastic injection Molding Tooling & Die Manufacturer MINGLI Die Casting And Injection Moulding Similarities Die casting requires a high injection pressure. Injection moulding primarily deals with plastic material. Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Injection molding, we can help you make informed decisions when making new products. There is a big difference in the compatible materials. Die Casting And Injection Moulding Similarities.

From exoyycojy.blob.core.windows.net

Injection Moulding And Die Casting Difference at Everett Gayle blog Die Casting And Injection Moulding Similarities Injection molding, we can help you make informed decisions when making new products. Die casting requires a high injection pressure. Injection moulding primarily deals with plastic material. There is a big difference in the compatible materials you can use. Although the end products of injection molding and die casting are similar, the two processes are vastly different in a number. Die Casting And Injection Moulding Similarities.

From www.newayprecision.com

Metal Injection Molding vs. Die Casting A Comparative Analysis Die Casting And Injection Moulding Similarities Injection moulding primarily deals with plastic material. Both processes use molten metal or plastic to create complex shapes and designs, but which one is the better choice for your project? Injection molding involves injecting molten material into a mold under high pressure and then allowing it to cool and solidify before removing the part. Die casting uses molten metal to. Die Casting And Injection Moulding Similarities.

From www.researchgate.net

Die casting (left) and injection molding (right) inserts Download Die Casting And Injection Moulding Similarities So, let’s dig deeper into each process and look at die casting advantages and disadvantages. Thus the casting’s mould should be rather thick to prevent deformation and breakage during heat treatment. Injection molding, we can help you make informed decisions when making new products. Here are some primary differences between die casting vs. Although the end products of injection molding. Die Casting And Injection Moulding Similarities.