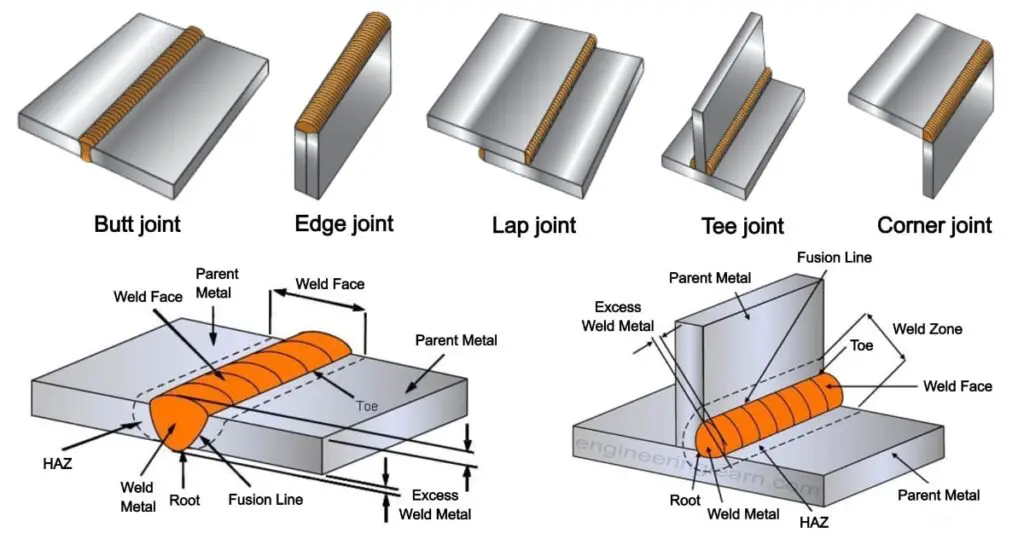

Fillet Joint Diagram . A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet weld types based on joint configuration. You’ll learn about selecting the right materials, precise. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. In total they probably account for around 80% of all joints made by arc welding. The aws defines a fillet weld as: It involves depositing a weld along the edge of the metal, creating a.

from engineeringexploration.com

Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. You’ll learn about selecting the right materials, precise. Fillet weld types based on joint configuration. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. It involves depositing a weld along the edge of the metal, creating a. The aws defines a fillet weld as: In total they probably account for around 80% of all joints made by arc welding. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle.

The 5 Types of Welding Joints, pros, cons, and their uses (In Details

Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. The aws defines a fillet weld as: You’ll learn about selecting the right materials, precise. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. In total they probably account for around 80% of all joints made by arc welding. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. Fillet weld types based on joint configuration. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. It involves depositing a weld along the edge of the metal, creating a. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle.

From www.weldingandndt.com

Welding Symbols explained (with photos and video) Welding and NDT Fillet Joint Diagram You’ll learn about selecting the right materials, precise. It involves depositing a weld along the edge of the metal, creating a. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. The aws defines a fillet weld as: Fillet weld types based on joint configuration. Fillet weld is a continuous weld joint. Fillet Joint Diagram.

From workforce.libretexts.org

1.6 Fillet Weld Symbols Workforce LibreTexts Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. In total they probably account for around 80% of all. Fillet Joint Diagram.

From www.youtube.com

Designing Fillet Welds for Skewed Single Plates Connections YouTube Fillet Joint Diagram Fillet weld types based on joint configuration. In total they probably account for around 80% of all joints made by arc welding. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. The aws defines a fillet weld as: Fillet welded joints such as 't', lap and corner joints are the. Fillet Joint Diagram.

From ar.inspiredpencil.com

Basic Weld Fillet Fillet Joint Diagram Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. In total they probably account for around 80% of all joints made by arc. Fillet Joint Diagram.

From punchlistzero.com

Butt Weld vs Fillet Weld Punchlist Zero Fillet Joint Diagram Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. In total they probably account for around 80% of all joints made by arc welding. You’ll learn about selecting the right materials, precise. A fillet weld can be between two members placed at a right angle to each other as a. Fillet Joint Diagram.

From www.researchgate.net

Loadcarrying cruciform fillet welded joint Download Scientific Diagram Fillet Joint Diagram Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. A fillet weld can be between two members placed at a right angle to each. Fillet Joint Diagram.

From www.researchgate.net

Schematic diagram of the fillet joint weld with numbered corner points Fillet Joint Diagram Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. The aws defines a fillet weld as: A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap. Fillet Joint Diagram.

From www.researchgate.net

Model of twosided fillet welded joint (color figure available online Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to. Fillet Joint Diagram.

From www.eng-tips.com

Max size fillet weld in T joint. Welding, Bonding & Fastener Fillet Joint Diagram Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. The. Fillet Joint Diagram.

From www.mdpi.com

Materials Free FullText A State of the Art Review of Fillet Welded Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. You’ll learn about selecting the right materials, precise. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. The aws. Fillet Joint Diagram.

From ecoursesonline.iasri.res.in

Design of Structures LESSON 7. Welded Connection Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet weld types based on joint configuration. A fillet weld can be between two members placed at a right angle. Fillet Joint Diagram.

From cedfzglx.blob.core.windows.net

Welding Fillet Joint at John Farrar blog Fillet Joint Diagram You’ll learn about selecting the right materials, precise. Fillet weld types based on joint configuration. In total they probably account for around 80% of all joints made by arc welding. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet welded joints. Fillet Joint Diagram.

From www.engineersgallery.com

Welding joints Engineers Gallery Fillet Joint Diagram You’ll learn about selecting the right materials, precise. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet weld types based on joint configuration. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel. Fillet Joint Diagram.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Fillet Joint Diagram Fillet weld types based on joint configuration. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. The aws defines a fillet weld as: Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. It. Fillet Joint Diagram.

From www.wcwelding.com

Arc Welding Rods Guide Fillet Joint Diagram In total they probably account for around 80% of all joints made by arc welding. Fillet weld types based on joint configuration. You’ll learn about selecting the right materials, precise. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. It involves depositing a weld along the edge of the metal,. Fillet Joint Diagram.

From engineersblog.net

What is Convex Fillet Joint? Explain in details step by step procedure Fillet Joint Diagram Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet weld types based on joint configuration. You’ll learn about selecting the right materials, precise. A fillet weld can be between two members placed at a right angle to each other as a. Fillet Joint Diagram.

From engineeringexploration.com

The 5 Types of Welding Joints, pros, cons, and their uses (In Details Fillet Joint Diagram You’ll learn about selecting the right materials, precise. In total they probably account for around 80% of all joints made by arc welding. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented. Fillet Joint Diagram.

From qualityinspectionforms.com

WELD JOINT TERMINOLOGY — QUALITY INSPECTION FORMS Fillet Joint Diagram Fillet weld types based on joint configuration. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap. Fillet Joint Diagram.

From thenavalarch.com

Designing Fillet Welds for Symmetrical Joint Sections TheNavalArch Fillet Joint Diagram A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. You’ll learn about selecting the right materials, precise. The aws defines a fillet weld as: Fillet weld is a. Fillet Joint Diagram.

From ar.inspiredpencil.com

Basic Weld Fillet Fillet Joint Diagram A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in. Fillet Joint Diagram.

From www.onestopndt.com

Fillet Weld Sizing Guidelines OnestopNDT Fillet Joint Diagram A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. Fillet weld types based on joint configuration. Fillet welding is a technique used to join two metal pieces together. Fillet Joint Diagram.

From www.researchgate.net

Schematic diagram of the fillet joint weld with numbered corner points Fillet Joint Diagram Fillet weld types based on joint configuration. In total they probably account for around 80% of all joints made by arc welding. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. A fillet weld can be between two members placed at a right angle to each other as a corner joint. Fillet Joint Diagram.

From www.youtube.com

Parts of A Weld Part 1 Toe and Leg of a fillet weld YouTube Fillet Joint Diagram Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. In total they probably account for around 80% of all joints made by arc welding. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed. Fillet Joint Diagram.

From diabloseason11start.blogspot.com

designing fillet welds for skewed t joints part 2 diabloseason11start Fillet Joint Diagram In total they probably account for around 80% of all joints made by arc welding. Fillet weld types based on joint configuration. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in. Fillet Joint Diagram.

From www.researchgate.net

Mesh details of the fillet welded Tjoint. Download Scientific Diagram Fillet Joint Diagram Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. In total they probably account for around 80% of all joints made by arc welding. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right. Fillet Joint Diagram.

From weldguru.com

Parts of A Weld Weld Components with Diagram Weld Guru Fillet Joint Diagram In total they probably account for around 80% of all joints made by arc welding. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. You’ll learn about selecting the right materials, precise. Fillet weld types based on joint configuration. Fillet welded joints. Fillet Joint Diagram.

From 108.168.129.178

Fillet weld in lap joint IDEA StatiCa Fillet Joint Diagram Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. It involves depositing a weld along the edge of the metal, creating a. The aws defines a fillet weld as: You’ll learn about selecting the right materials, precise. A fillet weld can be. Fillet Joint Diagram.

From www.youtube.com

Type of Joints butt welding Fillet welding YouTube Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet weld types based on joint configuration. In total they probably account for around 80% of all joints made by arc welding. Fillet welding is a technique used to join two metal pieces together by welding at an approximately right angle. You’ll learn about selecting the right. Fillet Joint Diagram.

From inchbyinch.de

INCH Technical English pictorial weld joints Fillet Joint Diagram The aws defines a fillet weld as: Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. It involves depositing a weld along the edge of the metal, creating a. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’. Fillet Joint Diagram.

From www.mig-welding.co.uk

Arc (MMA) Welding Fillet Joints Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. The aws. Fillet Joint Diagram.

From mewelding.com

Tee Joint Welding Fillet Joint Diagram Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. You’ll learn about selecting the right materials, precise. The aws defines a fillet weld as: A fillet weld can be between two members placed at a right angle to each other as a. Fillet Joint Diagram.

From mavink.com

Fillet Weld Procedure Fillet Joint Diagram The aws defines a fillet weld as: You’ll learn about selecting the right materials, precise. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. It involves depositing a weld along the edge of the metal, creating a. Fillet weld is a continuous weld joint used to connect two metal pieces which. Fillet Joint Diagram.

From telegra.ph

Filet weld cross section Telegraph Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. In total they probably account for around 80% of all joints made by arc welding. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the cases a 90 degree angle. Fillet welding is a technique. Fillet Joint Diagram.

From www.researchgate.net

FilletWelded Lap Joint Behavior. Download Scientific Diagram Fillet Joint Diagram In total they probably account for around 80% of all joints made by arc welding. A fillet weld can be between two members placed at a right angle to each other as a corner joint or ‘t’ shape configuration or placed parallel to each other to form a lap joint as represented in the below figure. The aws defines a. Fillet Joint Diagram.

From www.ideastatica.com

Fillet weld in angle plate joint IDEA StatiCa Fillet Joint Diagram It involves depositing a weld along the edge of the metal, creating a. Fillet weld types based on joint configuration. Fillet welded joints such as 't', lap and corner joints are the most common connection in welded fabrication. Fillet weld is a continuous weld joint used to connect two metal pieces which are making an angle, in most of the. Fillet Joint Diagram.