Tungsten Electrode For Tig Welding . You will hear three names for tungsten electrodes when it comes to welding processes. One of the reasons tig welding is favored for sensitive welding applications is because it gives the. 1m+ visitors in the past month Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Tig, gtaw and argon welding are suitable tungsten processes. This would be referred to as tungsten inclusion and may result in weld failure. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. 1m+ visitors in the past month

from hogaki.com

One of the reasons tig welding is favored for sensitive welding applications is because it gives the. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig, gtaw and argon welding are suitable tungsten processes. 1m+ visitors in the past month 1m+ visitors in the past month You will hear three names for tungsten electrodes when it comes to welding processes. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination.

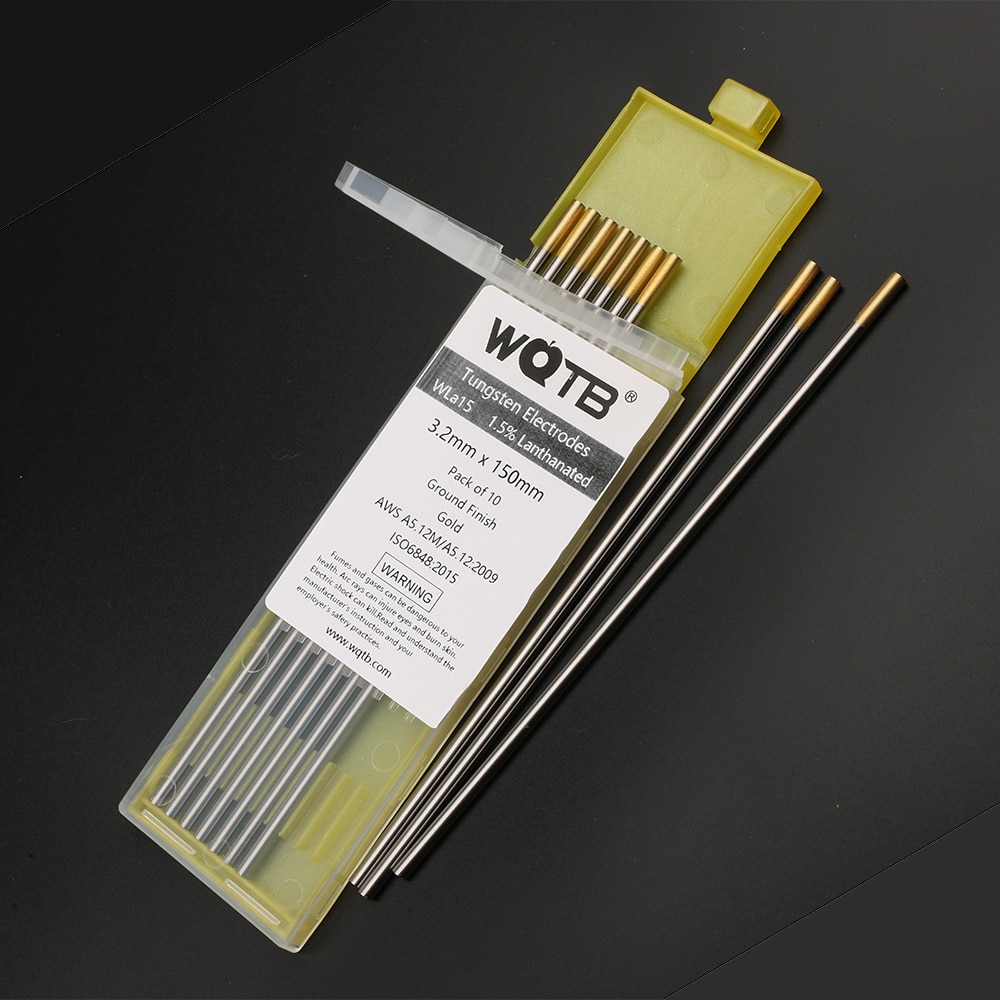

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP

Tungsten Electrode For Tig Welding One of the reasons tig welding is favored for sensitive welding applications is because it gives the. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination. 1m+ visitors in the past month Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. You will hear three names for tungsten electrodes when it comes to welding processes. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. One of the reasons tig welding is favored for sensitive welding applications is because it gives the. Tig, gtaw and argon welding are suitable tungsten processes. 1m+ visitors in the past month This would be referred to as tungsten inclusion and may result in weld failure.

From www.amazon.com

TIG Welding Tungsten Electrodes 2 Thoriated Welding Rods 3/32” x 7” 10 Tungsten Electrode For Tig Welding One of the reasons tig welding is favored for sensitive welding applications is because it gives the. You will hear three names for tungsten electrodes when it comes to welding processes. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create. Tungsten Electrode For Tig Welding.

From www.weldingcity.com

TIG Welding 10pk 2 Thoriated (Red) Tungsten Electrode 3/32" (2.4mm) Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. 1m+ visitors in the past month 1m+ visitors in the past month. Tungsten Electrode For Tig Welding.

From www.intibangunan.com

Tig Welding Tungsten Electrodes PT. INTI BANGUNAN PERKASA Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. You will hear three names for tungsten electrodes when it comes to welding processes. 1m+ visitors in the past month What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption.. Tungsten Electrode For Tig Welding.

From shop.tungsten.com

Sharpened Tungsten TIG Welding Electrodes Midwest Tungsten Service Tungsten Electrode For Tig Welding Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. 1m+ visitors. Tungsten Electrode For Tig Welding.

From johnstoolshed.com

Professional Tungsten Electrodes TIG Welding Rods Tungsten Electrode For Tig Welding Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the. Tungsten Electrode For Tig Welding.

From midwesttungsten.com

Sharpened Tungsten TIG Welding Electrodes Midwest Tungsten Service Tungsten Electrode For Tig Welding One of the reasons tig welding is favored for sensitive welding applications is because it gives the. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed. Tungsten Electrode For Tig Welding.

From johnstoolshed.com

Professional Tungsten Electrodes TIG Welding Rods Tungsten Electrode For Tig Welding You will hear three names for tungsten electrodes when it comes to welding processes. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination. This would be referred to as tungsten inclusion and may result. Tungsten Electrode For Tig Welding.

From johnstoolshed.com

Professional Tungsten Electrodes TIG Welding Rods Tungsten Electrode For Tig Welding Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig, gtaw and argon welding are suitable tungsten processes. From providing excellent thermal conductivity to. Tungsten Electrode For Tig Welding.

From www.weldingcity.com

10pcs WeldingCity® TIG Welding Tungsten Electrode 1/16" and 3/32" x 7 Tungsten Electrode For Tig Welding Tig, gtaw and argon welding are suitable tungsten processes. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. From providing excellent thermal conductivity to ensuring precision arc control,. Tungsten Electrode For Tig Welding.

From johnstoolshed.com

Professional Tungsten Electrodes TIG Welding Rods Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig, gtaw and argon welding are suitable tungsten processes. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a. Tungsten Electrode For Tig Welding.

From www.aliexpress.com

10Pcs TIG Welding Tungsten Electrodes Rod Mayitr 2 Thoriated Tungsten Tungsten Electrode For Tig Welding You will hear three names for tungsten electrodes when it comes to welding processes. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Thus, it is important that the tig tungsten size be selected carefully to add to. Tungsten Electrode For Tig Welding.

From www.ebay.com

TIG Welding Tungsten Electrodes 2 Thoriated 3/32” x 7” (Red, WT20) 10 Tungsten Electrode For Tig Welding 1m+ visitors in the past month 1m+ visitors in the past month One of the reasons tig welding is favored for sensitive welding applications is because it gives the. This would be referred to as tungsten inclusion and may result in weld failure. What makes tungsten an excellent choice for this purpose is its high melting point and low rate. Tungsten Electrode For Tig Welding.

From akita-mitsubishi.co.jp

x1 Piece TIG WELDING TUNGSTEN ELECTRODES GREEN PURE 1.6/2.4mm PARWELD Tungsten Electrode For Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig, gtaw and argon welding are suitable tungsten processes. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to. Tungsten Electrode For Tig Welding.

From kowelding.com.au

2 Thoriated [WT20] Tungsten Electrodes 1.6mm/2.4mm/3.2mm RED KO Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig, gtaw and argon welding are suitable tungsten processes. You will hear three names for tungsten electrodes when it comes to welding processes. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black,. Tungsten Electrode For Tig Welding.

From uk.gcegroup.com

TIG Welding (GTAW) Tungsten Electrode For Tig Welding This would be referred to as tungsten inclusion and may result in weld failure. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination. You will hear three names for tungsten electrodes when it comes. Tungsten Electrode For Tig Welding.

From weldingpros.net

Tips For Selecting Tungsten Electrodes [TIG Welding] Tungsten Electrode For Tig Welding Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Tig welding electrodes are a ‘non consumable’ as it is not melted into. Tungsten Electrode For Tig Welding.

From www.weldingcity.com

TIG Welding 5pk 2 Thoriated (Red) Tungsten Electrode 1/8" (3.2mm) Tungsten Electrode For Tig Welding Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. This would be referred to as tungsten inclusion and may result in weld failure. 1m+ visitors in the past month Tig welding electrodes are a ‘non consumable’ as it is not melted into. Tungsten Electrode For Tig Welding.

From www.dhgate.com

2020 TIG Welding Tungsten Electrode Pure Tungsten 1/16 X 7 Green, EWP Tungsten Electrode For Tig Welding You will hear three names for tungsten electrodes when it comes to welding processes. Tig, gtaw and argon welding are suitable tungsten processes. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. 1m+ visitors in the past month From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various. Tungsten Electrode For Tig Welding.

From intejweld.en.made-in-china.com

Intej Weld Pure Tungsten Electrode for TIG Welding Wc/Wt/Wp20 China Tungsten Electrode For Tig Welding This would be referred to as tungsten inclusion and may result in weld failure. Tig, gtaw and argon welding are suitable tungsten processes. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig stands for tungsten inert gas. Tungsten Electrode For Tig Welding.

From www.ebay.com

10Pcs 1mm x 175mm Green Tip Pure Tungsten Electrode For TIG Welding Tungsten Electrode For Tig Welding 1m+ visitors in the past month Tig, gtaw and argon welding are suitable tungsten processes. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. This would be referred to as tungsten inclusion and may result in weld failure. Tig welding electrodes are a ‘non consumable’ as it is not. Tungsten Electrode For Tig Welding.

From blog.thepipingmart.com

3 Types of Tungsten Electrodes for TIG Welding Tungsten Electrode For Tig Welding Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc. Tungsten Electrode For Tig Welding.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Tig welding electrodes are a ‘non consumable’ as it is not melted into the weld pool and great care should be taken not to let the electrode contact the welding pool to avoid weld contamination. 1m+ visitors in the past. Tungsten Electrode For Tig Welding.

From weldguru.com

TIG Tungsten Electrodes Explained (with Color Chart) Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig welding electrodes are a ‘non consumable’ as. Tungsten Electrode For Tig Welding.

From www.aliexpress.com

Wqtb Tungsten Electrodes Tig Tungsten Rods Wt20 Wl15 Wl20 Wc20 Wzr8 Wp Tungsten Electrode For Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. You will hear three names for tungsten electrodes when it comes to welding processes. From providing excellent thermal conductivity to ensuring. Tungsten Electrode For Tig Welding.

From shop.tungsten.com

Tungsten TIG Welding Electrodes (10 Pack) Midwest Tungsten Service Tungsten Electrode For Tig Welding 1m+ visitors in the past month What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. You will hear three names for tungsten electrodes. Tungsten Electrode For Tig Welding.

From www.weldfabworld.com

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. 1m+ visitors in the past month What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding electrodes are a ‘non consumable’ as it is not melted into the. Tungsten Electrode For Tig Welding.

From www.topwellwelders.com

TIG Welding Tungsten Electrode 2 Thoriated (Red, WT20/ EWTh2) 10pk Tungsten Electrode For Tig Welding This would be referred to as tungsten inclusion and may result in weld failure. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. One of the reasons tig welding is favored for sensitive welding applications is because it. Tungsten Electrode For Tig Welding.

From brunei.desertcart.com

Buy SPARC TIG Tungsten Welding Electrodes Set Of 10 Purple Tungsten Tungsten Electrode For Tig Welding Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the new universal standard binzel e3 purple tip. You will hear three names for tungsten electrodes when it comes to welding processes. Tig, gtaw and argon welding are suitable tungsten processes. One of the reasons tig welding is favored for sensitive. Tungsten Electrode For Tig Welding.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding This would be referred to as tungsten inclusion and may result in weld failure. You will hear three names for tungsten electrodes when it comes to welding processes. One of the reasons tig welding is favored for sensitive welding applications is because it gives the. What makes tungsten an excellent choice for this purpose is its high melting point and. Tungsten Electrode For Tig Welding.

From www.lazada.com.my

Professional Tungsten Electrodes TIG Welding Rods 150mm 6" 1.0 1.6 2.4 Tungsten Electrode For Tig Welding 1m+ visitors in the past month Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. You will hear three names for tungsten electrodes when it comes to welding processes. Tig stands for tungsten inert gas and gtaw stands. Tungsten Electrode For Tig Welding.

From www.ebay.com

TIG Welding Tungsten Rod Electrodes 2 Lanthanated 3/32” x 7”(Blue Tungsten Electrode For Tig Welding From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the. Tungsten Electrode For Tig Welding.

From tbws.co.uk

TIG Welding Tungsten Electrode Selection Pack TIG Tungsten Mix Tungsten Electrode For Tig Welding 1m+ visitors in the past month 1m+ visitors in the past month One of the reasons tig welding is favored for sensitive welding applications is because it gives the. This would be referred to as tungsten inclusion and may result in weld failure. Tig stands for tungsten inert gas and gtaw stands for gas tungsten arc welding. You will hear. Tungsten Electrode For Tig Welding.

From yeswelder.com

How To Shape Tungsten Electrode For TIG Welding YesWelder Tungsten Electrode For Tig Welding Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and. Tungsten Electrode For Tig Welding.

From www.amazon.com

TIG Welding Tungsten Electrode 2 Thoriated 1/16" x 7" (Red, EWTh2) 10 Tungsten Electrode For Tig Welding Tig, gtaw and argon welding are suitable tungsten processes. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig tungsten electrodes for all material types and sizes from 0.8mm to 6,35mm dia red, black, gold, white and the. Tungsten Electrode For Tig Welding.

From www.weldequip.com

TIG Tungsten Electrodes Weldequip Tungsten Electrode For Tig Welding This would be referred to as tungsten inclusion and may result in weld failure. One of the reasons tig welding is favored for sensitive welding applications is because it gives the. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. 1m+ visitors in the past month Tig, gtaw and argon. Tungsten Electrode For Tig Welding.