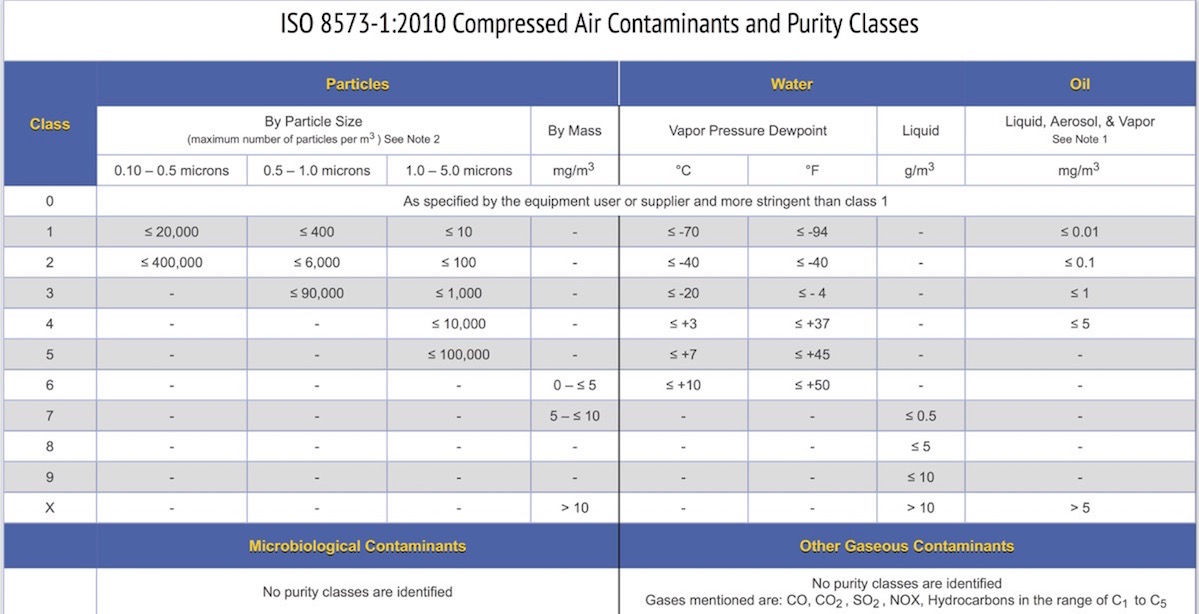

Class 4 Compressed Air . This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. So once you know which iso class your. To define the categories in more detail, i will separate the three to discuss the origins and solutions. To understand the international standards for compressed air quality, we must first of all understand sources of. Refrigerant or adsorption dryers are used to remove moisture from compressed air. Refrigerant dryers are used when the maximum air quality required. These class values will show the maximum value in each category. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). Solid particulates, water and oil (in both aerosol and vapor form) are recognized.

from www.airbestpractices.com

So once you know which iso class your. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. Refrigerant or adsorption dryers are used to remove moisture from compressed air. These class values will show the maximum value in each category. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. To define the categories in more detail, i will separate the three to discuss the origins and solutions. To understand the international standards for compressed air quality, we must first of all understand sources of. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3).

Using ISO 85731 to Test Compressed Air Clearing the Confusion

Class 4 Compressed Air Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). To define the categories in more detail, i will separate the three to discuss the origins and solutions. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. To understand the international standards for compressed air quality, we must first of all understand sources of. Refrigerant or adsorption dryers are used to remove moisture from compressed air. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). So once you know which iso class your. These class values will show the maximum value in each category. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. Refrigerant dryers are used when the maximum air quality required.

From www.accuform.com

Hazard Class 2 Compressed Air w/ ID Tab DOT Shipping Labels MSS229 Class 4 Compressed Air Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). To understand the international standards for compressed air quality, we must first of all understand sources of. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air. Class 4 Compressed Air.

From www.engineernewsnetwork.com

Selecting compressed air purification to ISO quality standards Class 4 Compressed Air As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. To define the categories in more detail, i will separate the three to discuss the origins and solutions. Refrigerant or adsorption dryers are used to remove moisture from compressed air. So once. Class 4 Compressed Air.

From sfs-fluidsysteme.com

Compressed air classes according to ISO 857312010 SFSFluidsysteme Class 4 Compressed Air So once you know which iso class your. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. To understand the international standards for compressed air quality, we must. Class 4 Compressed Air.

From www.discountsafetysigns.co.nz

Compressed Air Detailed Discount Safety Signs New Zealand Class 4 Compressed Air To define the categories in more detail, i will separate the three to discuss the origins and solutions. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. Refrigerant dryers are. Class 4 Compressed Air.

From www.youtube.com

Compressed Air Line In ShipMain air, service air,control air system in Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that. Class 4 Compressed Air.

From www.discountsafetysignsaustralia.com.au

COMPRESSED AIR HAZARD Buy Now Discount Safety Signs Australia Class 4 Compressed Air Solid particulates, water and oil (in both aerosol and vapor form) are recognized. These class values will show the maximum value in each category. Refrigerant dryers are used when the maximum air quality required. So once you know which iso class your. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates. Class 4 Compressed Air.

From www.britannica.com

Compressed air Energy Efficiency, Industrial Uses & Safety Britannica Class 4 Compressed Air As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). Iso 8573.1. Class 4 Compressed Air.

From www.sciencefacts.net

Is Gas Compressible Class 4 Compressed Air To define the categories in more detail, i will separate the three to discuss the origins and solutions. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). So once you know which iso class your. To understand the international. Class 4 Compressed Air.

From kennayouthparrish.blogspot.com

When a Volume of Air Is Compressed Its Temperature Class 4 Compressed Air This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. Iso 8573.1 identifies three primary contaminant types. Class 4 Compressed Air.

From www.airbestpractices.com

Using ISO 85731 to Test Compressed Air Clearing the Confusion Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. To define the categories in more detail, i will separate the three to discuss the origins and solutions. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. So once. Class 4 Compressed Air.

From www.historycentral.com

Compress Air Engine Class 4 Compressed Air These class values will show the maximum value in each category. To define the categories in more detail, i will separate the three to discuss the origins and solutions. To understand the international standards for compressed air quality, we must first of all understand sources of. Class 1 calls is required to contain no more than 0.01 mg of any. Class 4 Compressed Air.

From www.airchecklab.com

Compressed Air System Risk Assessment Do I Need to Test? Trace Class 4 Compressed Air To define the categories in more detail, i will separate the three to discuss the origins and solutions. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Refrigerant or adsorption dryers are used to remove moisture from compressed air. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102. Class 4 Compressed Air.

From newsigns.com.au

Danger Compressed Air Guidelines Sign New Signs Class 4 Compressed Air Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Refrigerant dryers are used when the maximum air quality required. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). To define the categories in more detail,. Class 4 Compressed Air.

From advancedct.com

Safety Tips for Working with Compressed Gas Advanced Consulting and Class 4 Compressed Air Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. Solid particulates, water and oil. Class 4 Compressed Air.

From www.sunrise-metal.com

Hospital Air CompressorsIntroduction of Hospital Compressed Air System Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. These class values will show the maximum value in each category. To understand the international standards for compressed air quality, we must first of all understand sources of. So once you know which iso class your. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed. Class 4 Compressed Air.

From www.youtube.com

Compressed air preparationEnglish class YouTube Class 4 Compressed Air As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. Refrigerant dryers are used when the maximum air quality required. To define the categories in more detail, i will separate the three to discuss the origins and solutions. These class values will. Class 4 Compressed Air.

From www.youtube.com

Part 1,Types of Compressed Gases, Labelling, Color coding, Safe Class 4 Compressed Air Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). To define the categories in more detail, i will separate the three to discuss the origins and solutions. These class values will show the maximum value in each category. As. Class 4 Compressed Air.

From www.airchecklab.com

How to Designate ISO 85731 Purity Classes Trace Analytics, the Class 4 Compressed Air Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. To define the categories in more detail, i will separate the three to discuss the origins and solutions.. Class 4 Compressed Air.

From www.mplusfiltration.com

Why is compressed air treatment necessary? Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. To define the categories in more detail, i will separate the three to discuss the origins and solutions. These class values will show the maximum value in each category. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent. Class 4 Compressed Air.

From www.processsensing.com

Moisture Measurement in Compressed Air ISO 85731 Class 4 Compressed Air Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). These class values will show the maximum value in each category. Refrigerant or adsorption dryers are used to remove moisture from compressed air. Solid particulates, water and oil (in both. Class 4 Compressed Air.

From www.ifsqn.com

Compressed Air How Clean is Yours? International Food Safety and Class 4 Compressed Air Refrigerant dryers are used when the maximum air quality required. Refrigerant or adsorption dryers are used to remove moisture from compressed air. So once you know which iso class your. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline. Class 4 Compressed Air.

From www.scribd.com

Requirements for Compressed Air in the Pharmaceutical Industry Gases Class 4 Compressed Air Refrigerant dryers are used when the maximum air quality required. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. To define the categories in more detail, i will separate the three. Class 4 Compressed Air.

From www.ency123.com

Composition of Air for Kids What is Air Made of? Ency123 Class 4 Compressed Air To understand the international standards for compressed air quality, we must first of all understand sources of. Refrigerant or adsorption dryers are used to remove moisture from compressed air. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. To define the categories in more. Class 4 Compressed Air.

From exyobnxjz.blob.core.windows.net

Compressed Air Can B And Q at Eric Wharton blog Class 4 Compressed Air Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. So once you know which iso class your. Refrigerant or adsorption dryers are used to remove moisture from compressed air. These class values will show the maximum value in each category. As a voluntary code of practice, bcas food and beverage grade compressed air best practice. Class 4 Compressed Air.

From jhfoster.com

Ensure Compressed Air Purity Levels Using ISO JHFOSTER Class 4 Compressed Air This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). To understand the international standards. Class 4 Compressed Air.

From www.beko-technologies.com

Compressed Air Quality BEKO TECHNOLOGIES Class 4 Compressed Air To understand the international standards for compressed air quality, we must first of all understand sources of. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. These class values will show the maximum value in each category. Refrigerant or adsorption dryers are used to remove moisture from compressed air. Refrigerant dryers are used when the maximum. Class 4 Compressed Air.

From www.industrialair.co.nz

Compressed air quality standards Class 4 Compressed Air To define the categories in more detail, i will separate the three to discuss the origins and solutions. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system. So once you know which iso class your. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. This part of iso 8573 specifies purity. Class 4 Compressed Air.

From mavink.com

Iso 8573 Chart Class 4 Compressed Air So once you know which iso class your. To understand the international standards for compressed air quality, we must first of all understand sources of. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Refrigerant dryers are used when the maximum air quality required. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed. Class 4 Compressed Air.

From www.ipesearch.co.uk

IPE Purification to ISO standards Class 4 Compressed Air Solid particulates, water and oil (in both aerosol and vapor form) are recognized. Class 1 calls is required to contain no more than 0.01 mg of any type of oil, while class 4 air can have 500 times that amount (5 mg/m 3). As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102. Class 4 Compressed Air.

From www.youtube.com

Safety Series 4 Compressed Gas Cylinder Labels and DOT Hazard Classes Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. So once you know which iso class your. These class values will show the maximum value in each category. To define the categories. Class 4 Compressed Air.

From www.safewellsolutions.co.uk

Compressed Air Quality Testing & Validation in accordance with ISO 8573 Class 4 Compressed Air To understand the international standards for compressed air quality, we must first of all understand sources of. Refrigerant or adsorption dryers are used to remove moisture from compressed air. To define the categories in more detail, i will separate the three to discuss the origins and solutions. Solid particulates, water and oil (in both aerosol and vapor form) are recognized.. Class 4 Compressed Air.

From tuongotchinsu.net

Can Air Be Compressed Into A Solid? Exploring The Possibilities Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. So once you know which iso class your. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. This part of iso 8573 specifies purity classes of compressed air with respect to particles, water and oil, independent of the location in the compressed. To define. Class 4 Compressed Air.

From www.hafner-pneumatik.com

The basics of air preparation Class 4 Compressed Air Refrigerant dryers are used when the maximum air quality required. To understand the international standards for compressed air quality, we must first of all understand sources of. These class values will show the maximum value in each category. To define the categories in more detail, i will separate the three to discuss the origins and solutions. So once you know. Class 4 Compressed Air.

From instrumentationtools.com

Process Design of Instrument Air System InstrumentationTools Class 4 Compressed Air Refrigerant or adsorption dryers are used to remove moisture from compressed air. So once you know which iso class your. To define the categories in more detail, i will separate the three to discuss the origins and solutions. Solid particulates, water and oil (in both aerosol and vapor form) are recognized. This part of iso 8573 specifies purity classes of. Class 4 Compressed Air.

From www.inkace.com

Class 2 Compressed Air Placard Class 4 Compressed Air As a voluntary code of practice, bcas food and beverage grade compressed air best practice guideline 102 stipulates compressed air that is in direct contact with the product. To define the categories in more detail, i will separate the three to discuss the origins and solutions. Iso 8573.1 identifies three primary contaminant types as prevalent in a compressed air system.. Class 4 Compressed Air.